Instruction Manual

RG Series SA CT Cylinder - V1.4 www.durapac.com Page 2 of 26

This is a safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid injury or death

1.0 Product Information

DURAPAC –Hydraulic Cylinders are engineered to meet ANSI/ASME B30.1 Standards for

Performance and Safety. The RG-Series is a general purpose spring return cylinder designed for use

in production, maintenance and fabrication applications.

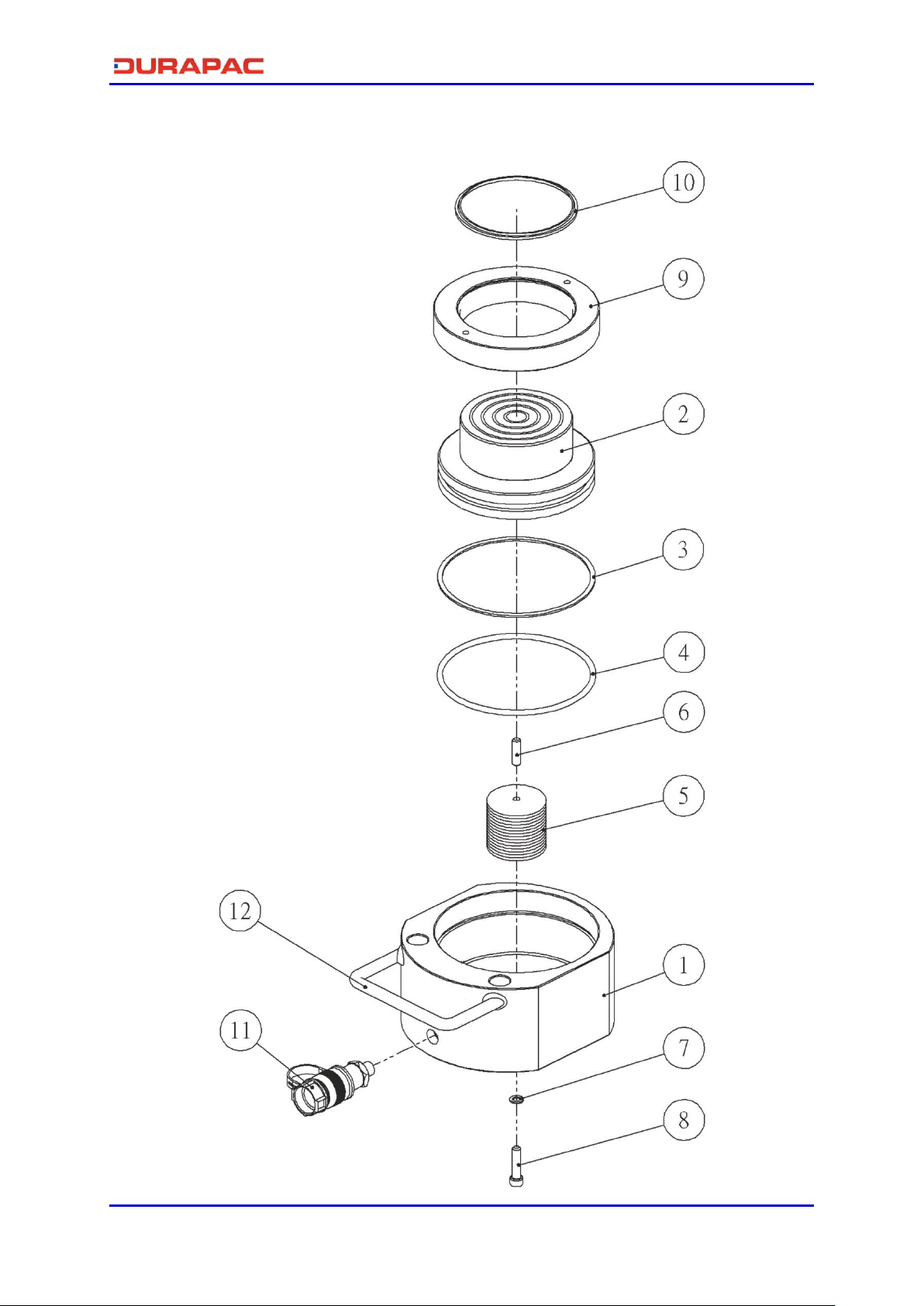

All RG Series cylinders feature a hard chrome cylinder bore and piston rod for maximum corrosion-

resistance. When combined with the bronze overlay on the piston bearing area and low-friction

surface treatment on the gland nut, this cylinder is suitable for demanding applications. Cylinder

body mounting threads and base mounting holes are included on most models. Optional TSX tilt

saddles are available for all models from RG-102 to RG-10010.

Hardened grooved saddle to prevent piston rod damage (except RG-101)

Optional tilt saddles available

Gland nut with low friction coating withstands full dead end loading

Hard chrome plated piston rod for maximum corrosion-resistance and cylinder life

Bronze overlay on piston bearing area reduces side load induced damage and extends

cylinder life

Piston rod threads and base mounting holes permit easy fixture

Hard chrome plated bore for maximum corrosion-resistance and cylinder life

Piston rod wiper reduces contaminants

Return springs are sized to ensure efficient piston rod return and maximum spring life

Powder coated finish enhances appearance and reduces corrosion

Parker industry standard high flow coupling for compatibility

Note –Durapac offers a range of piston and base attachments to suit the RG Series cylinders.

Special skill, knowledge and training may be required for a specific task and the product may not be

suitable for all jobs. The user must ultimately make the decision regarding suitability of the product

for any given task and assume the responsibility of safety for all in the work area. Contact a Durapac

representative if you are unsure of your cylinder’s suitability for a particular application.

2.0 Receiving Instructions

It is recommended prior to use that an inspection be done by qualified personnel and that any

missing or damaged parts, decals, warning/safety labels or signs are replaced with Durapac

authorised replacement parts only. Any cylinder that appears to be damaged in any way, is worn,

leaking or operates abnormally should be removed from service immediately until such time as

repairs can be made. Any cylinder that has been or suspected to have been subject to a shock load

should be removed from service immediately until inspected by a Durapac authorised service centre.

Owners and operators of this equipment should be aware that the use and subsequent repair of this

equipment may require specialised training and knowledge.