4. PREPARATION

4.1. Connect air supply

4.1.1. Anin-linelterisrecommended,draindaily.Draincompressortankdaily.

4.1.2. Before connecting air supply hose ensure trigger is not pressed down.

4.1.3. Ensureconstantairpressureismaintainedduringoperation:7-10kg/cm²andaminimumairowof28ltr/min.

4.2. Bleed system

4.2.1. Prior to using the jack, eliminate any air that may have accumulated in the system.

4.2.2. Position the lever in the release valve and turn once in an anti-clockwise direction.

4.2.3. Place the lever into the lever support and pump the jack several times to ensure internal lubrication and the elimination of accumulated

air.Alternatively,presstriggerAofthevalvebriey.

4.2.4. Place the lever in release valve again and close it in a clockwise direction.

4.2.5. Jack is now ready for operation.

5. OPERATION

IMPORTANT! Prior to lifting the load ensure that all of the above safety instructions are followed.

5.1. The feed screw of the jack, compliments its stroke, DO NOT fully extend it.

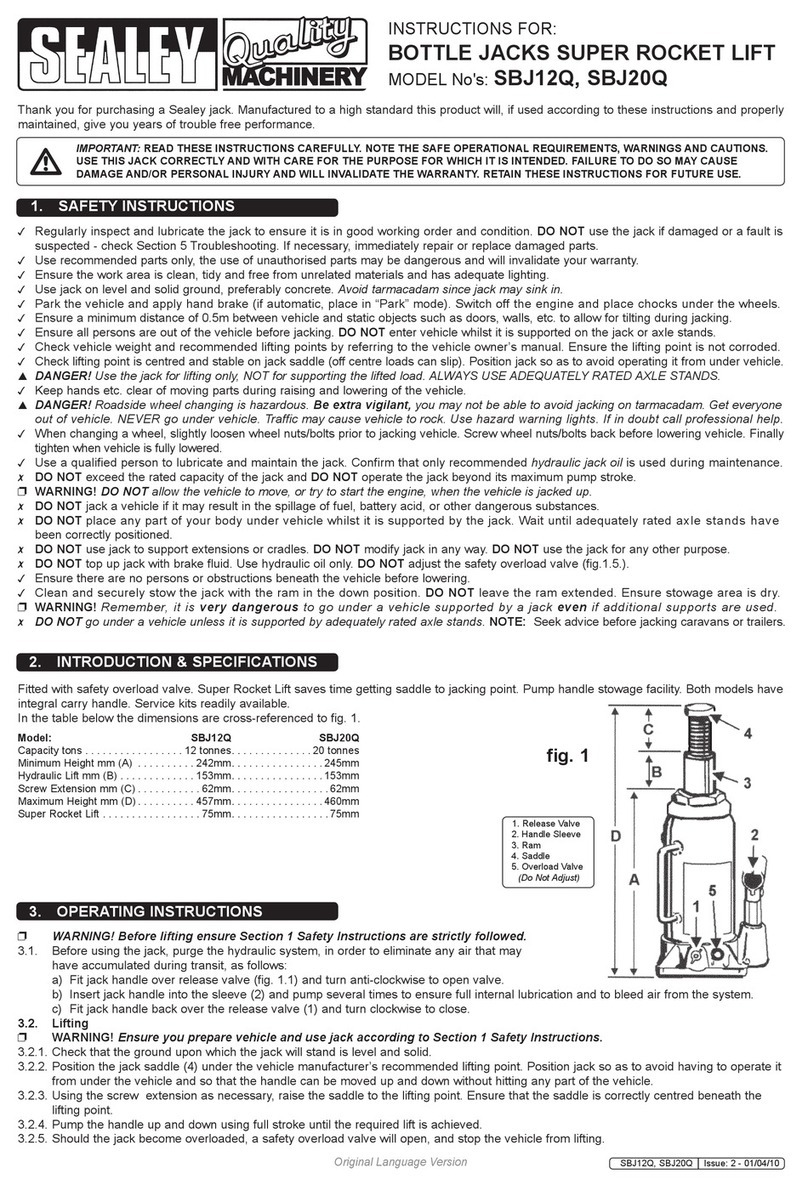

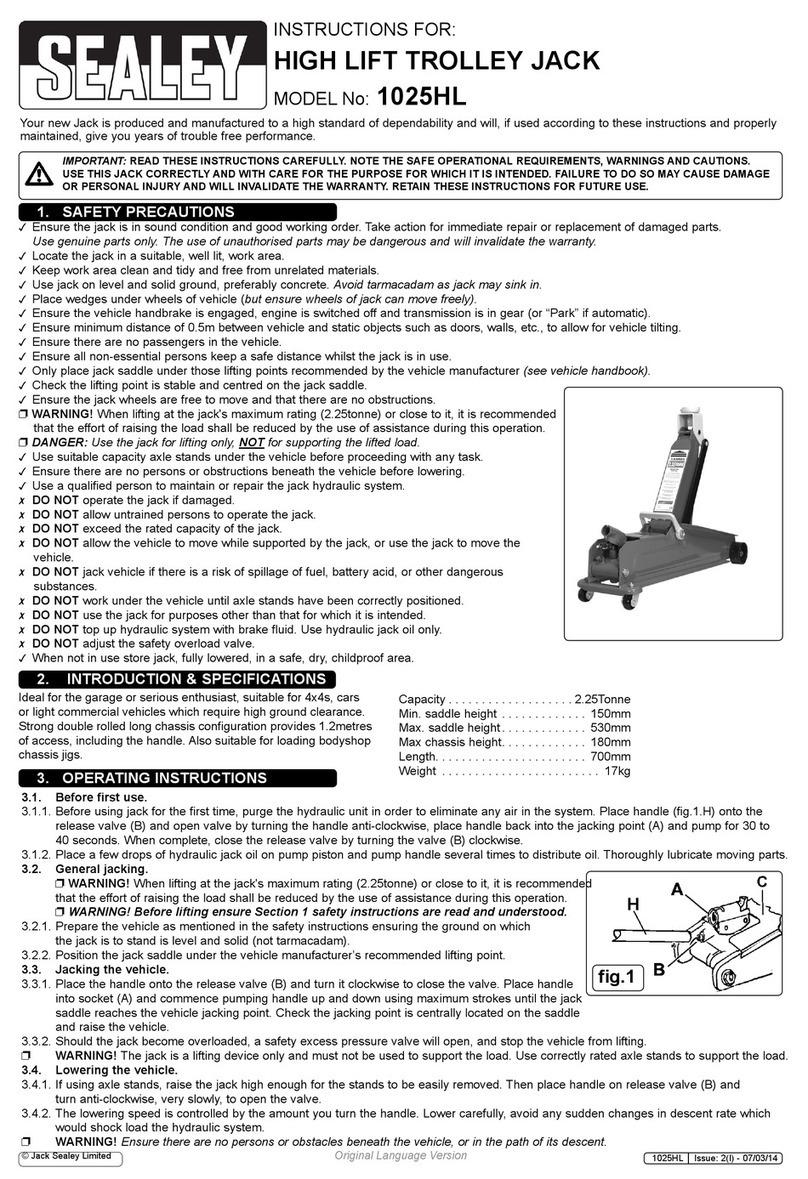

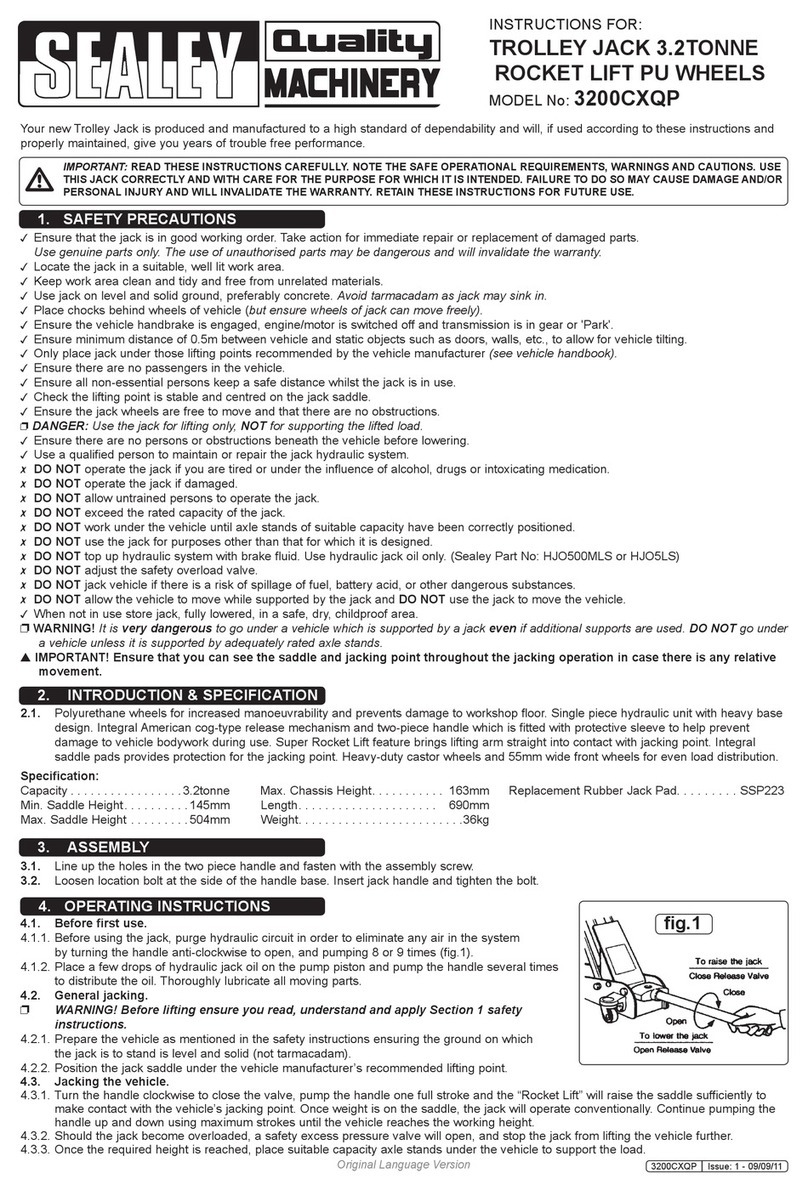

5.2. LIFTING

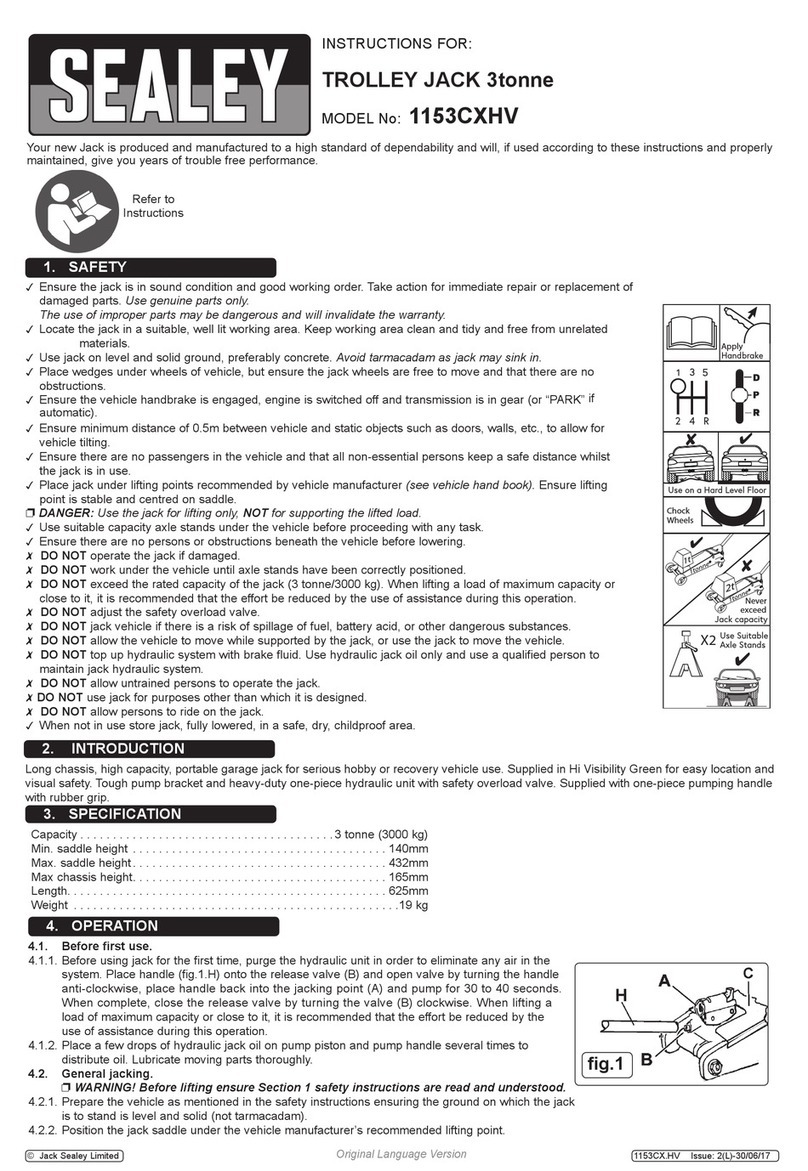

5.2.1. Close the release valve fully and press trigger of the air hose. Lifting may also be performed by fully moving the lever downwards to

obtain greater speed by using the full stroke range of the piston.

5.3. LOWERING

5.3.1. Slowly turn the release valve in an anticlockwise direction using the lever. Ensure that there are no persons or obstacles under the

vehicle to be lowered.

5.3.2. The lowering speed is controlled by the amount of the valve is opened.

5.3.3. During lowering air is eliminated through a small hole in connector C, this is normal.

5.4. Shouldthejackbeoverloaded,itisttedwithanoverloadvalvewhichwillpreventthe

vehicle from being lifted.

5.5. Never move the jack with the lever in the release valve as this will cause damage.

5.6. DO NOT attempt to move the jack by pulling on the plastic air supply tube.

6. MAINTENANCE

IMPORTANT! Both the maintenance and repair of the jack may only be performed by

qualiedpersons,whohavesufcientknowledgeofthehydraulicsystemsusedinthese

devices as a result of their training and experience.

6.1. Keep the jack clean and lubricate all moving parts at regular intervals, which must be clean and protected from aggressive conditions

at all times.

6.2. Only original spare parts should be used.

6.3. Prior to each use, check for bent, broken, cracked or loose parts and solve the problem. If it is suspected that the jack has been

subjectedtoabnormalloadsorhassufferedanyknocks,withdrawitfromserviceuntiltheproblemhasbeenrectied.

6.4. Iftheoillevelneedstobecheckedorrelled,withthepistonfullyretracted,removethellerpluganddrainitscontentsintoa

container.

6.5. Rellwithoil.UseagoodqualityoilsuchasSealeyhydraulicjackoil.DO NOTusebrakeuid.Bleedsystemasinsection

4.2.Replaceoilllerplug.Ensurenodirtentersthehydraulicsystemwhendraining,llingremovingorreplacingcomponents.

Annual oil replacement is recommended for jacks in daily use.

IMPORTANT Too much oil may render the jack inoperative.

6.6. When the jack is not in use, the screw, main piston and the pump piston should be retracted to avoid corrosion.

6.7. Remove the handle from its position.

IMPORTANT: NO RESPONSIBILITY IS ACCEPTED FOR INCORRECT USE OF THIS PRODUCT.

Hydraulic products are only repaired by local service agents. We have service/repair agents in all parts of the UK.

DO NOT reTurN prODucT TO us. Please telephone us on 01284 757500 to obtain the address and phone number of your local

agent.

If product is under guarantee please contact your dealer.

De-commissioning Product

Should the product become completely unserviceable and require disposal, draw off the oil into an approved container and dispose of the

product and the oil according to local regulations.

6.8. Preventative maintenance

6.8.1. When the jack is not in use, keep piston and rod fully retracted. Store the jack on its base in an upright position, in a well protected area,

where it will not be exposed to corrosion, abrasive dust, or other harmful elements.

6.8.2. Visually inspect jack before each use. Take corrective action if any of the following are found:

a. Cracked or damaged housing

b. Excessive wear, bending or other damage

c. Leaking hydraulic fluid

d. Scored or damaged piston or rod

e. Incorrectly functioning swivel head or adjustment screw

f. Loose hardware

g. Modified or altered equipment

AM20.V3, AM30.V3| Issue 1 20/09/16

Original Language Version

© Jack Sealey Limited