Hi-Force JCS Series Instruction Manual

Operating Instruction Manual:

OM-JCS-01

Serial Number:

ALL

1

OPERATING INSTRUCTION MANUAL

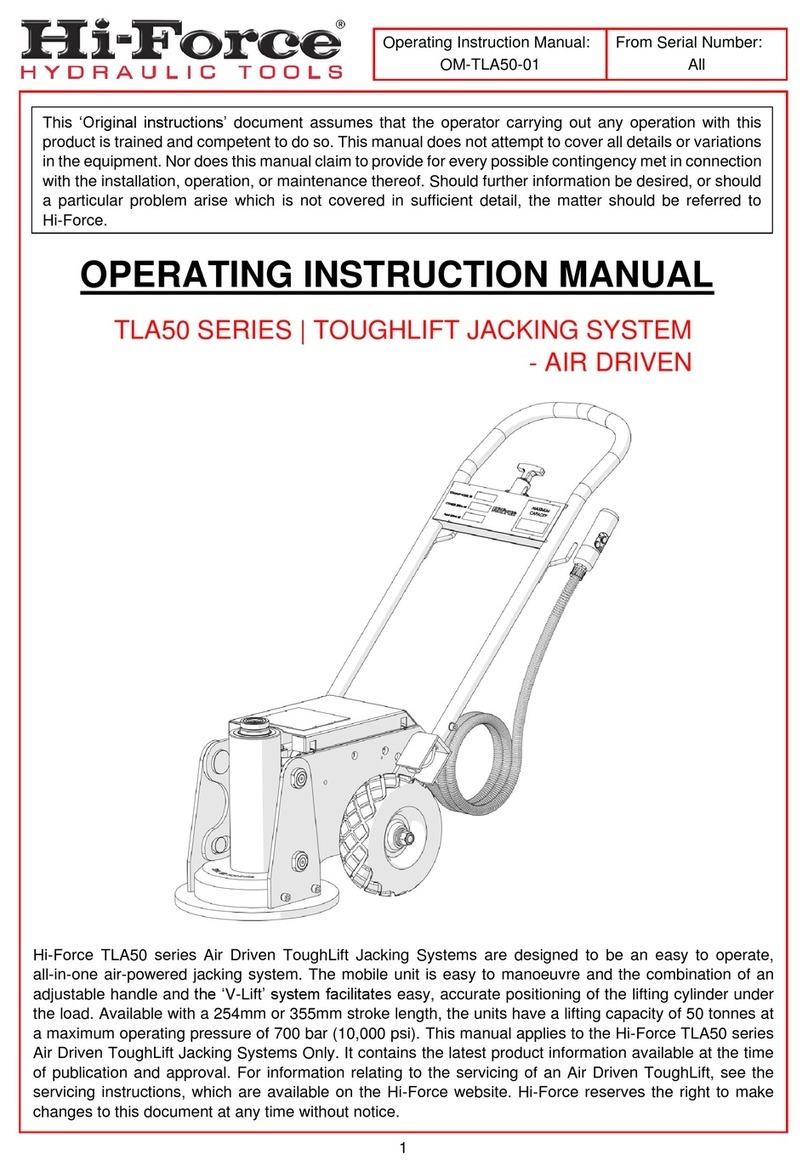

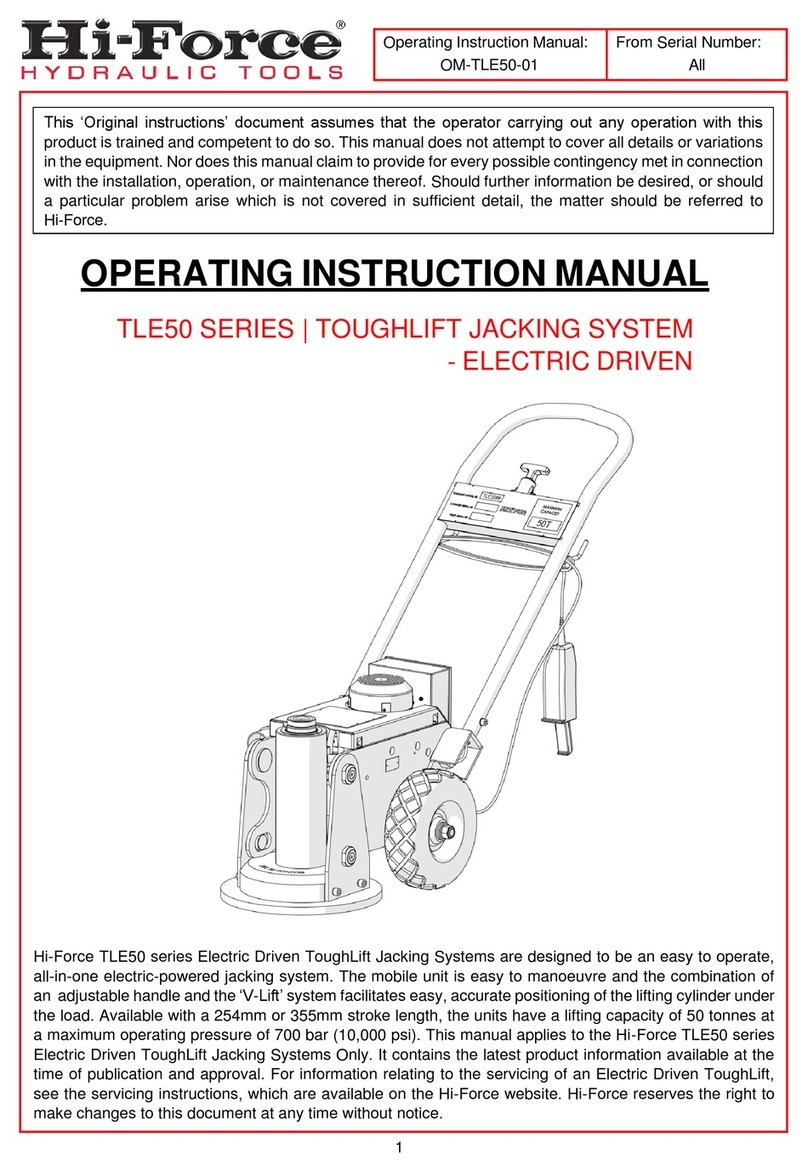

JCS SERIES | COMPACT JACKS - SOLID PISTON

This manual applies to the Hi-Force JCS series of Compact Jacks. It contains the latest product information

available at the time of publication and approval. For information relating to the servicing of a hydraulic jack,

see the servicing instructions, which are available on the Hi-Force website. Hi-Force reserves the right to

make changes to this document at any time without notice.

This document assumes that the operator carrying out any operation with this product is trained and

competent to do so. This manual does not attempt to cover all details or variations in the equipment. Nor

does this manual claim to provide for every possible contingency met in connection with the installation,

operation, or maintenance thereof. Should further information be desired, or should a particular problem

arise which is not covered in sufficient detail, the matter should be referred to Hi-Force.

Operating Instruction Manual:

OM-JCS-01

Serial Number:

ALL

2

Table of Contents

1.0 Inspection upon Receipt ................................................................. 3

2.0 Safety Precautions ........................................................................... 3

3.0 Declaration of Conformity ............................................................... 5

4.0 Component Identification ................................................................ 5

5.0 Installation/Setup ............................................................................. 6

6.0 Operation .......................................................................................... 8

7.0 Maintenance and Storage ................................................................ 9

8.0 Specifications ................................................................................... 9

9.0 Trouble Shooting ........................................................................... 10

10.0 Contact Details ............................................................................ 11

Operating Instruction Manual:

OM-JCS-01

Serial Number:

ALL

3

1.0 Inspection upon Receipt

Upon receipt of the product, visually inspect the item for any evidence of shipping damage. Please note:

the warranty does not cover shipping damage. Notify the courier immediately if shipping damage is found

and refrain from putting the product into service. The carrier is responsible for repair and replacement costs

resulting from damage that occurred in transit.

2.0 Safety Precautions

2.1 Introduction

Read and follow all the instructions and safety warnings carefully before handling, installation or

use of any hydraulic equipment. Failure to do so could lead to equipment damage, equipment

failure, personal injury or even death. Hi-Force will not be held responsible for any damage to the

equipment, injury or death resulting from the unsafe use of, lack of maintenance to, or incorrect operation

of the product. If in doubt on the correct use of any Hi-Force equipment, contact your nearest Hi-Force office

or distributor. Only qualified personnel should be allowed to operate hydraulic equipment. If an operator has

not been trained on high-pressure hydraulic equipment and its safe usage, consult your local Hi-Force sales

office who can offer training courses for operators.

2.2 General Hydraulic System Safety Precautions

Failure to observe and obey the following safety precautions could result

in property damage, significant personal injury or death;

When operating any hydraulic equipment, all operators should ensure that all necessary personal

protective equipment (PPE) is worn, as specified by their employer. Steel toe-cap safety shoes,

safety glasses/visor, and protective gloves should be worn at all times. All relevant risk assessments

should be completed before the use of the equipment.

Keep hydraulic equipment away from open flames and direct heat.

Immediately replace any worn or damaged parts using genuine Hi-Force parts only.

Failure to observe and obey the following safety precautions could result

in property damage, equipment damage or minor/moderate personal

injury;

Servicing of hydraulic equipment must only be undertaken by a qualified technician.

Operating Instruction Manual:

OM-JCS-01

Serial Number:

ALL

4

2.3 Hydraulic Jack Specific Safety Precautions

Failure to observe and obey the following safety precautions could result

in property damage, serious personal injury or death;

DO NOT work under or near a load supported only by hydraulic means. A hydraulic jack, when used

as a lifting device, should not be used as a load-holding device. Once lifted, all loads should be

supported using rigid mechanical structures.

ALWAYS raise the piston to the load. DO NOT drop loads onto the jack.

NEVER exceed the maximum rated capacity of any hydraulic jack and DO NOT attempt to lift a load

greater than the jack’s stated maximum capacity.

Overloading hydraulic jacks can result in component failure and possible serious personal injury.

ALWAYS place hydraulic jacks on a flat, even surface that supports the entire base plug (6) and

can support the load to be applied.

Where applicable, use an additional support base to assist in supporting the load to be lifted.

Avoid lifting loads that are not central to the lifting piston. Avoid offset loading as this can damage

the cylinder bores and piston rods, and also lead to unstable load lifting.

DO NOT weld any items to the jack or modify it in any way from its delivered condition. Your warranty

may be invalidated, and it could lead to serious personal injury.

Failure to observe and obey the following safety precautions could result

in property damage, equipment damage or minor/moderate personal

injury;

To protect your warranty, only use hydraulic oil grades as specified in the oil table in Section 8.1.

Make sure there is sufficient spare lifting capacity and stroke when selecting Jack/s for any

application.

Ensure hydraulic jacks are used only under environmental conditions that are suitable for their use.

The jacks proper functioning cannot be guaranteed under adverse conditions, and a shortened

product lifespan can result.

Operating Instruction Manual:

OM-JCS-01

Serial Number:

ALL

5

3.0 Declaration of Conformity

Hi-Force declares that this product has been tested and complies with the standards and

declarations as set out in the Declaration of Incorporation/Conformity (DoI/DoC). The DoI/DoC is

included as Annex A to this instruction document and is supplied with all shipments of this

product.

4.0 Component Identification

1. Operating Lever

3. Release valve

5. Oil Filler screw

2. Piston

4. Jack body

Operating Instruction Manual:

OM-JCS-01

Serial Number:

ALL

6

5.0 Installation/Setup

5.1 Before Each Use

Check the selected jacks load rating before use.

Ensure the jack is in good condition.

Check the external surfaces for signs of mechanical damage and/or oil leaks. If either is present,

DO NOT use the equipment until it has been serviced and returned to its proper operating condition.

Ensure the external surfaces are dirt free.

5.2 Filling with Oil

Hi-Force JCS Jacks are despatched from the factory pre-filled with oil, and ready for use. If at some stage

the jack requires to be topped up with oil, proceed as follows;

Place the jack on its back edge with the oil filler port facing upwards.

Remove the oil filler port plug (5)

Top up with high grade ISO15 hydraulic oil.

Replace the oil filler plug (5)

Wipe away any excess oil that may have spilt on the jack exterior.

6. Base plug

Operating Instruction Manual:

OM-JCS-01

Serial Number:

ALL

7

5.3 Operating Orientation

JCS jacks are designed so that the base plug (6) protrudes the jack body (5). This

is to ensure that any load is borne by the steel base plate and not the aluminium

jack body. If full support of the base plug can be achieved, the JCS jack can be used in any orientation. The

jack must not be used with the base plug partially supported to prevent damage and/or injury.

The load bearing area is shown above, highlighted yellow.

5.4 Placing the Jack

Carefully determine the jacking/loading point of the item to be lifted/moved, taking the following into

consideration:

1. Make sure the jacking/loading point is strong enough to withstand the load that will be applied

to it, without damaging the object being lifted/moved. If necessary place suitable material

between the load point and the jack ram to avoid damaging the structure to be lifted/moved.

2. Ensure the chosen loading point will not cause the structure to topple or shift unexpectedly

when the piston is extended. If necessary put additional safety measures in place (eg.

Rigging, blocking) to limit any unexpected movement of the load.

Place the jack on a firm, level foundation capable of supporting the load to be lifted/moved, whilst

fully supporting the jack base plug (6). Where necessary, use an additional support base of suitable

material to support the jack and distribute the load evenly across its base.

DO NOT position the jack by using the operating lever in the release valve. If the jack is to be placed

some distance under the load, use the operating lever in the operating lever/quadrant socket to

position the jack.

ALWAYS ensure the jack’s piston contacts the load to be lifted as squarely as possible.

Operating Instruction Manual:

OM-JCS-01

Serial Number:

ALL

8

6.0 Operation

Hi-Force JCS Jacks feature 2 built in safety devices to ensure safe operation and to protect the jack from

damage. They are as follows:

An internal (factory set) pressure relief valve to prevent over-loading. This limits the load that may

be lifted to a maximum equal to the equipment rated load + 10%.

An integral stop ring to limit maximum stroke and prevent over-stroking of the piston. Note: Never

operate the pump without an external load present, to prevent damage/injury.

6.1 To Lift or Push a Load

Using the key on the end of the operating lever, turn the release valve screw clockwise to close it.

NOTE: Excessive tightening is not necessary and will lead to component wear.

Put the operating lever into the socket on the pump mechanism and operate the pump. The piston

will rise and lift/push the load. When the piston reaches full stroke the stop ring prevents the piston

from rising further.

If you need to raise the load further than the rated stroke of the jack. Mechanically support the load

in its raised position, then retract and remove the jack. Using a suitable support material (eg steel

plate) raise the level of the jack and continue with the lift.

ALWAYS remove the operating lever from the jack when not in use.

6.2 To Lower the Load

Whenever possible, wipe the piston clean before lowering.

Use the key on the end of the operating lever to turn the release valve screw anti-clockwise and

open it. Opening the release valve SLOWLY will control the rate of lowering.

WARNING: NEVER turn the release valve quickly when there is a load on the jack. The load will fall

uncontrolled and may lead to personal injury or property damage.

DO NOT overload the jack during lowering.

JCS jacks are fitted with a return spring, so the piston will retract even under no-load.

Operating Instruction Manual:

OM-JCS-01

Serial Number:

ALL

9

7.0 Maintenance and Storage

ALWAYS use Hi-Force specified hydraulic oil grades with the jacks. The use of other fluids may invalidate

your warranty.

After use, always wipe the piston clean and retract it fully.

Keep the jack exterior clean in order to prolong the products lifespan.

Routinely perform a visual inspection of the jack for signs of general damage.

When not in use, store the hydraulic jack upright in clean and dry conditions. If storage is to be for a

prolonged period, it is advisable to apply grease to exposed metal surfaces.

Lubricate the pump rocker periodically.

NEVER store, transport or lift a jack with its piston in the extended position.

8.0 Specifications

8.1 Oil Specifications

Hi-Force Jack’s use high quality ISO15 grade hydraulic oil. They are designed to operate at temperatures

between -20°C and 50°C.

Hi-Force

Model Number ISO Hydraulic Oil Grade Temperature Range: Degrees Celcius (°C)

From: To:

HFO15 ISO15 -23 44

HFO46 ISO46 -2 73

8.2 JCS Specifications

Refer to the markings on the jack body for identification.

Model Number Jack Capacity

(tonnes)

Body

Construction

Stroke

(mm)

Weight

(kg)

JCS10 10 Steel 35 4.5

JCS20 20 Aluminium 41 5.5

JCS30 30 Aluminium 45 8.0

Operating Instruction Manual:

OM-JCS-01

Serial Number:

ALL

10

9.0 Trouble Shooting

Hi-Force JCS Jack’s should be serviced and repaired only by authorised Hi-Force repair centres. The

following table gives possible causes and solutions for common problems.

TROUBLESHOOTING GUIDE

Problem Possible Cause Solution

1. Piston will not

advance, advances

part way or erratically.

a. Release valve open. Close release valve.

b. Load is too heavy for jack. Use suitably rated jack.

c. Oil level is low. Add oil to the reservoir. (See Section 5.2 )

d. Piston binding. Repair or replace jack.

e. Jack seals leaking. Repair or replace jack.

2. Piston advances, but

will not hold.

a. Load is too heavy for jack. Use suitably rated jack.

b. Piston seals leaking. Repair or replace jack.

3. Jack leaks oil. a. Worn or damaged seals. Repair or replace cylinder.

b. Jack damaged internally. Repair or replace cylinder.

c. Jack over-stroked. Stop operation and wipe away excess oil.

4. Piston will not retract

or retracts slower than

normal.

a. Release valve is closed. Open release valve. (See section 6.2)

b. Oil reservoir over-filled. Drain excess oil from reservoir.

c. Weak or damaged retraction spring. Repair or replace jack.

d. Damaged or worn seals. Repair or replace jack.

e. Jack damaged internally. Repair or replace jack.

Operating Instruction Manual:

OM-JCS-01

Serial Number:

ALL

11

UK Head Office:

Hi-Force Limited

Prospect Way, Daventry, Northamptonshire

NN11 8PL

United Kingdom

Tel: + 44 1327 301000

Fax: + 44 1327 706555

Email: daventr[email protected]

Operating Instruction Manual:

OM-JCS-01

Serial Number:

ALL

12

Hi-Force Regional Offices:

Hi-Force Caspian

Baku

Azerbaijan

Tel: +994 12 447 4100

Email: [email protected]

Hi-Force Hydraulics (Asia) S.B

Selangor

Malaysia

Tel: +603 5525 4203

Email: [email protected]

Hi-Force Nederland BV

Numansdorp

Netherlands

Tel: +31 85 902 8111

Email: [email protected]

Hi-Force Hydraulics (Pty) Ltd

Midrand

South Africa

Tel: +27 11 314 0555

Email: [email protected]

Hi-Force Saudi

Dammam

Saudi Arabia

Tel: +966 13 802 1338

Email: [email protected]

Hi-Force Hydraulics

Abu Dhabi

United Arab Emirates

Tel: +971 2 551 3100

Email: [email protected]

Hi-Force FZCO

Dubai

United Arab Emirates

Tel: +971 4 815 0600

Email: [email protected]

GLOBAL BRAND. LOCAL SERVICE.

www.hi-force.com

Other manuals for JCS Series

1

This manual suits for next models

3

Table of contents

Other Hi-Force Jack manuals

Popular Jack manuals by other brands

Cattini

Cattini YAK 215/L Operating and maintenance manual

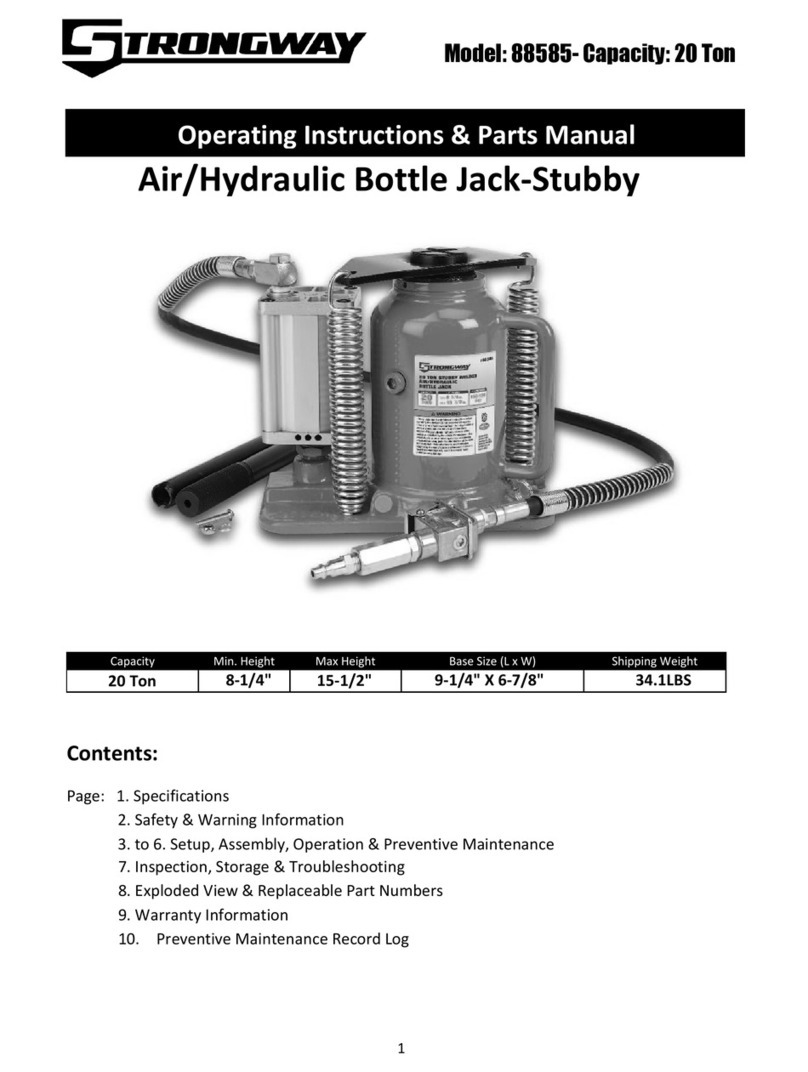

Strongway

Strongway 88585 Operating instructions & parts manual

Tractel

Tractel hydrofor H 5 Operation and maintenance manual

HOLZMANN MASCHINEN

HOLZMANN MASCHINEN RWH125ALU user manual

Daytona

Daytona DA-15PR Owner's manual & safety instructions

Sealey

Sealey TSJ12 instructions