Troubleshooting a networked Room Controller...........................................................................25

Formatting the Room Controller .................................................................................. 25

LED's......................................................................................................................... 25

Serial number ............................................................................................................ 27

Replacing the battery in a networked Room Controller................................................. 27

To take the Room Controller out of service................................................................... 27

METHOD B: Installing a stand-alone Room Controller ................................................................28

To mount the Room Controller..................................................................................................28

Wiring for power......................................................................................................................28

To wire for power ........................................................................................................ 28

Wiring inputs and outputs........................................................................................................29

Wiring specifications .................................................................................................. 29

To wire inputs and outputs.......................................................................................... 30

Selecting or downloading a control program..............................................................................31

To select a built-in control program............................................................................. 31

To download a custom control program....................................................................... 35

To set up a stand-alone RC642D Room Controller......................................................................36

To set display options ................................................................................................. 36

To set the time and date ............................................................................................. 37

To change the time or date format............................................................................... 37

To set up schedules .................................................................................................... 37

Troubleshooting a stand-alone Room Controller.........................................................................38

LED's......................................................................................................................... 38

Serial number ............................................................................................................ 39

Replacing the battery in a stand-alone Room Controller .............................................. 39

Compliance............................................................................................................................40

FCC Compliance......................................................................................................... 40

CE Compliance........................................................................................................... 40

BACnet Compliance ................................................................................................... 40

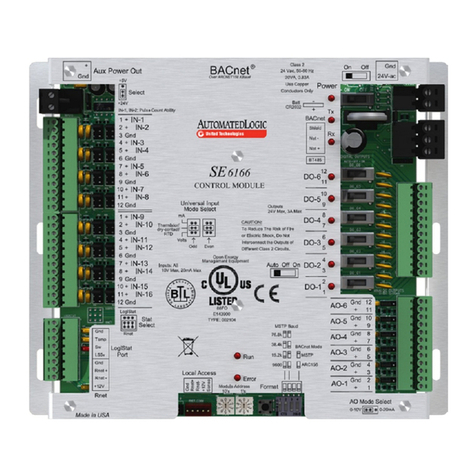

Appendix A - Room Controller diagram......................................................................................41

Appendix B - Built-in control programs in a stand-alone Room Controller .....................................42

#1: 100% outside air unit .......................................................................................................43

Control schematics .................................................................................................... 43

Point list .................................................................................................................... 44

Sequence of operation ............................................................................................... 44

#2: Air source heat pump - reverse to heat................................................................................47

Control schematic ...................................................................................................... 47

Point list .................................................................................................................... 47

Sequence of operation ............................................................................................... 48

#3: Air source heat pump - reverse to cool ................................................................................51

Control schematic ...................................................................................................... 51

Point list .................................................................................................................... 51

Sequence of operation ............................................................................................... 52

#4: Air source heat pump - intermittent fan - reverse to heat.......................................................55

Control schematic ...................................................................................................... 55

Point list .................................................................................................................... 55

Sequence of operation ............................................................................................... 56

#5: Air source heat pump - intermittent fan - reverse to cool .......................................................58

Control schematic ...................................................................................................... 58

Point list .................................................................................................................... 58

Sequence of operation ............................................................................................... 59