Revised 3/29/00 •M4106nx 3 © 2000 Automated Logic Corporation

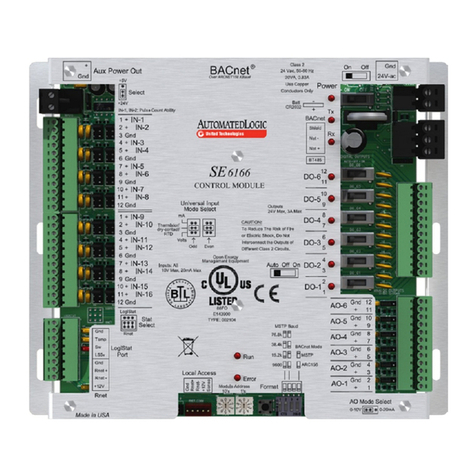

Specifications

Power 24VAC ± 10%, 50-60Hz (24VAC

±10%, 60Hz for UUKL Smoke Control

Systems), 20VA power consumption

single Class 2 source only, 100VA or less.

Inputs ten universal inputs, configurable

for0-5VDC,0-20mA,orthermistor.

Input Resolution 12 bit A/D.

Digital Outputs four digital outputs, relay

contacts rated at 3A resistive @ 24VAC.

Configurable as normally open or

normally closed.

Analog Outputs six analog outputs, 0-

10VDC.

Output Resolution 8bitD/A.

Communication 156 kbps ARCNET, 9600

bps or 38.4 kbps CMnet.

Environmental Operating Range 0°to

130°F(-17.8°to 54.4°C); 10 to 90%

relative humidity, non-condensing. (For

UUKL Smoke Control Systems, 32 to

120.2 °F[0to49°C]; 10 to 85% relative

humidity, non-condensing.)

Status Indication Visual (LED) status of

CMnet communication, running, errors,

and power.

Memory 1MB Flash memory and 1MB non-

volatile battery-backed RAM.

Protection Voltage, current, and ESD

protection on incoming power and

CMnet.

Bat t e ry Seven-year lithium BR2325 battery

provides a minimum of 10,000 hours of

data retention during power outages.

Listed by UL 916 (PAZX), cUL C22.2 No.

205-M1983 (PAZX7), FCC Part 15 -

Subpart B - Class A.

Mounting

Screw the M4106nx into an enclosed panel

using the mounting holes provided on the

cover plate. Be sure to leave about 2 inches (5

centimeters) on each side for wiring.

Addressing

Before setting or changing the address, make

sure the M4106nx’s power is off. The

M4106nx only reads the address when the

module is turned on. After changing the

address, you must transfer memory to the

module. Refer to “Transferring Memory”on

page 9.

The M4106nx has two rotary switches for

assigning the module’s CMnet address. One

switch corresponds to the tens digit and the

other corresponds to the ones digit. For

example, if the module’saddressisthree,set

the tens switch to zero and the ones switch to

three, as shown in Figure 2.

Power Wiring

Whenever possible, make sure the module’s

power and communications connections are

working properly before connecting any input

or output points.

CAUTION The M4106nx module is a Class

2 device (less than 30VAC, 100VA maximum).

Take appropriate isolation measures when

mounting the M4106nx module in a control

panel where non-Class 2 devices (for

example, 120VAC) or wiring are present.

You can power several modules from the

same transformer if you maintain the same

polarity.

The M4106nx’s operating range is 21.6VAC to

26.4VAC. If voltage measured at the module’s

Figure 2. Setting the module’s address

10's 1's