Automatic Solutions KING 24V User manual

KING 24V

Operatore

Operateur

Operator

Torantrieb

Operador

Alimentazione

Alimentation

Power Supply

Stromspannung

Alimentacion

Forza max di spinta

Force maxi de poussée

Thrust force

Max. Schubkraft

Fuerza max de empuje

codice

code

code

code

codigo

KING 24V 24Vdc N 1800 AA14028

Peso max cancello

Poids maxi portail

Max gate weight

Max Torgewicht

Peso máx verja

400 kg / 880 lbs

KING 24V L 24Vdc N 1800 AA14029500 kg / 1100 lbs

ITALIANO pag. 05 / FRANÇAIS pag. 16 / ENGLISH page 27 / DEUTSCH pag. 38 / ESPAÑOL pag. 49

OPERATORE IRREVERSIBILE PER CANCELLI A BATTENTE

OPERATEUR IRREVERSIBLE POUR PORTAILS À BATTANT

IRREVERSIBLE OPERATOR FOR LEAF GATES

TORANTRIEBE FÜR FLÜGELTORE

OPERADOR IRREVERSIBLE PARA CANCELAS DE BATIENTE

T2 24V

con / avec / with / mit

27

27

TECHNICAL FEATURES

KING 24V is a irreversible operator suitable for opening gates

with a leaf length of up to 4,5 metres (Fig. 1).

The KING 24V operator use mechanical stoppers, thus avoiding

the need for electrical limit switches.

G

B

SYSTEM LAY-OUT

** With incorporated mechanical stop that cuts in during opening. - If

the mechanical stop is used during closing (optional), the maximum

travel is reduced by 50 mm.

21

2

1

2

Connection

Motor

TECHNICAL DATA

Max. leaf length

Max. leaf weight

Max. travel

Average opening time

Operating speed

Thrust force

EEC Power supply

Motor capacity

Power absorbed

Daily operations suggested

Service

Guaranteed consecutive cycles

Grease

Weight of electroreducer

Noise

Volume

Operating Temperature

Protection

m 3,5* 4,5*

kg 400 500

mm 345** 475**

s. 14÷27 29÷38

m/s. 0,0125

N 1800

24V

W 118

A 5,4

n° 150

90%

n° 200/14s

Bechem - RHUS 550

kg 10 14

db <70

m3 0,0184 0,0211

°C -10 ÷ +55°C

IP 44

KING 24V KING 24V L

Measurements in mm

KING L L=1020 L1=945 L2=470

KING L=888 L1=815 L2=340

1 - KING 24V operator

2 - Tuned aerial

3 - Flashing lamp

4 - Key selector

5 - Photoelectric cells (external)

1

❺

❹

❶❶❺❹

❷❸

28

28

G

BINSTALLATION KING 24V

PRE-INSTALLATION CHECKS

The leaf must be fixed firmily on the hinges to the pillars, must not be

flexible during the movement and must move without frictions.

Before the installation of KING 24V, verify all dimensions etc.

There’s no need for any modification, if the gate is like that shown

in Fig. 1.

Gate features must be uniformed with the standards and laws in

force. The gate can be automated only if it is in a good condition and

its conditions comply with the EN 12604 norm.

- The gate leaf does not have to have a pedestrian opening. In the

opposite case it is necessary to take the appropriate steps, in

accordance with EN 12453 norm (for instance; by preventing the

operation of the motor when the pedestrian opening is opened, by

installing a safety microswitch connected with the control panel).

- No mechanical stop shall be on top of the gate, since mechanical

stops are not safe enough.

FIXING THE ACTUATOR ATTACHMENT TO THE COLUMN

To obtain a correct movement of the leaf gate it is necessary to respect

the measures (to see the TABLES of the measures).

COLUMN ATTACHMENT FOR KING 24V OPERATOR

(code CCA1293 - CCA1294)

If the column is in iron, the attack can be screwed directly using four

metric screws M8.

If the column is in concrete, the attack can be fixed with four expansion

screws Ø 8 mm (Fig. 3).

In the case you have a wall parallel with the open gate, you must

provide a niche in which to place the operator.

COLUMN ATTACHMENT FOR KING 24V L OPERATOR

(code CCA1370 - CCA1319)

To obtain a correct movement of the leaf gate it is necessary to respect

the measures.

If there is an iron pillar you can weld the attachment directly.

If there is a cement pillar, you can use the fixing plate as in Fig. 5 which

is fastened with 4 Fischer-screws of Ø 8 mm.

There is also the possibility to cement the attachment welding an

anchor at its base Fig. 6.

Naturally you have to respect predetermined fixing measures.

Afterwards you must weld the other actuator’s attachment to the gate

(Fig. 8).

In the case you have a wall parallel with the open gate, you must

provide a niche in which to place the operator.

FIXING THE OPERATOR ATTACHMENT TO THE GATE

(to see the TABLES of the measures).

Before inserting the pin into the gate attachment, grease

thoroughly.

Weld the base at the right height (Fig. 8).

Fix the KING 24V and try several times to open and to close the gate,

controlling that the operator does not touch the moving gate.

76

4 5

3

8

COMMAND TYPE USE OF THE SHUTTER

Skilledpersons Skilledpersons Unrestricteduse

(outofpublicarea*) (publicarea)

withmannedoperation A B nonpossibile

withvisibleimpulses CorE CorE CandD,orE

(e.g.sensor)

withnotvisibleimpulses CorE CandD,orE CandD,orE

(e.g.remotecontroldevice)

automatic CandD,orE CandD,orE CandD,orE

*atypicalexamplearethoseshutterswhichdonothaveaccesstoanypublicway

A:Commandbuttonwithmannedoperation(thatis,operatingaslongasactivated),

likecodeACG2013

B:Keyselectorwithmannedoperation,likecodeACG1010

C:Adjustablepowerofthemotor

D:Safetyedges,likecodeACG3010and/orothersafetydevicestokeepthrustforce

withinthelimitsofEN12453regulation-AppendixA.

E:Photocells,likecodeACG8026(Toapplyevery60÷70cmforalltheheightofthe

columnofthegateuptoamaximumof2,5m-EN12445point7.3.2.1)

Parts to install meeting the EN 12453 standard

29

29

G

B

MECHANICAL STOPPER ADJUSTMENT

To adjust the stoppers you have to follow the scheme (Fig. 9).

To set the opening limit it’s enough to fix the stopper (A) in the needed

position by tightening the 8mA screw with a n. 13 key.

To obtain the desired closing limit you must adjust the stopper (B)

(OPTIONAL) ) in the needed position and tighten it as for stopper (A).

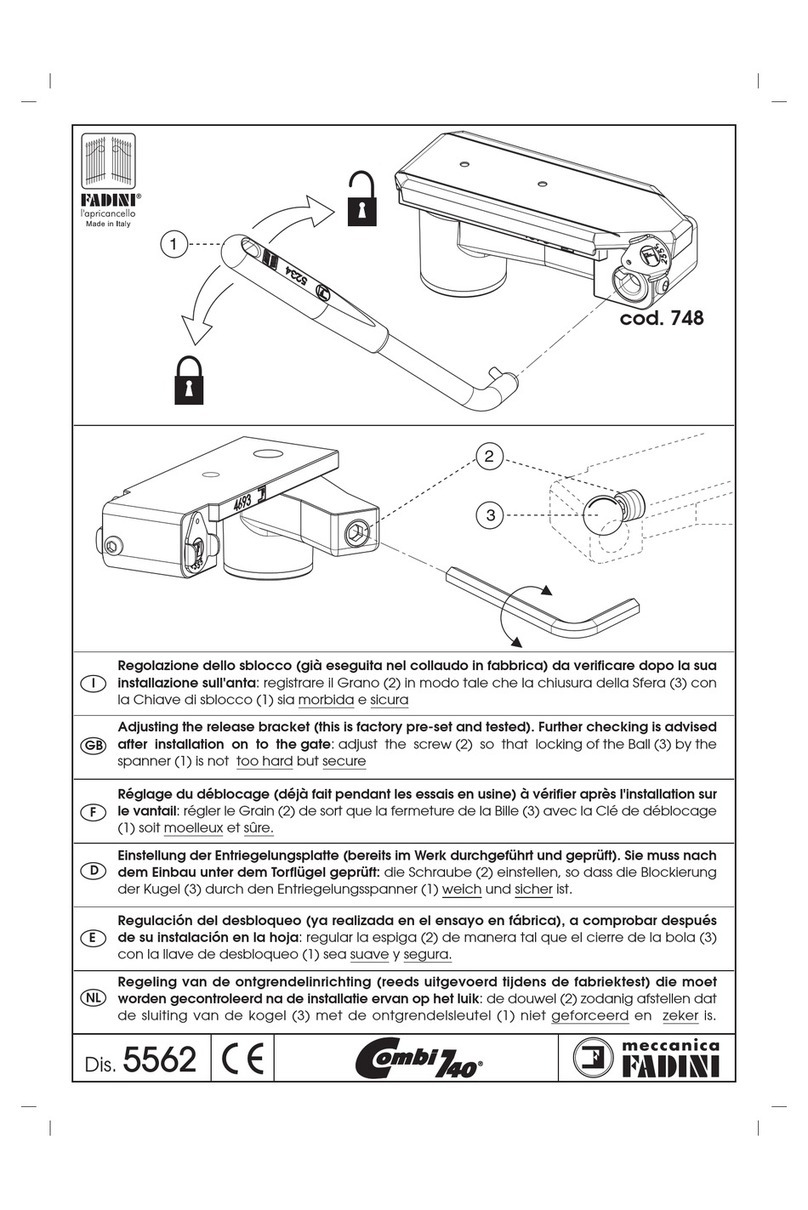

EMERGENCY RELEASE

To move the gate manually it is necessary to release the operator

inserting the special key and turning it 2 times in the anti-clockwise

sense (Fig. 11).

In order to carry out the manual operation of the gate leaf the followings

must be checked:

- That the gate is endowed with appropriate handles;

- That these appropriate handles are placed so to avoid safety risks for

the operator;

- That the physical effort necessary to move the gate leaf should not be

higher than 225 N, for doors/gates for private dwellings, and, 390N for

doors/gates for commercial and industrial sites ( values indicated in

5.3.5 of the EN 12453 norm).

MAINTENANCE

To be undertaken only by specialized staff after disconnecting power

supply.

Lubricate the hinges and check the oil level and thrust force generated

by the operator on the gate once a year.

Lubricate the nut screw with silicon grease every two years.

10

9

11

ANT

Leafattachment

KING24V

S1

Z

Y

X

S2

Z Y X

S3

Z Y X

COL

Columnattachment

KING24V

ANTKING24VL

Leafattachment

KING24VL

B

ACD

45

12

30

30

G

B

13

* In the case of leaf longer than 2,5 metres, an electric lock must be fitted to ensure

efficient closing.

If the pillar is too large, and it is not possible to adjust the actuator respecting the measure

(B), you must make a niche in the pillar or you have to move the gate to the edge of the pillar.

ANT

Leafattachment

S1

Z

Y

X

COL

Columnattachment

KING24V

RESPECT THE MEASURES FOR A CORRECT INSTALLATION

MECHANICAL STOP - OPTIONAL

Code ACG8089

Optional mechanical stop to stop closing, if the gate is not fitted with a floor stop (Fig. 14).

RESPECT THE MEASURES WITH 2 MECHANICAL STOPPERS

14

B

A

CD

ANTKING24VL

LeafattachmentKING24VL

S3-Y

S3-X

S1-Z

S2-Y

S2-Y

-

-

S1-Z

S2-Y

S1-Y

-

-

-

COL

1÷1,80

1,81÷2,20

2,21÷2,50

2,51*÷3,00*

3,01*÷3,50*

3,51*÷4,00*

4,01*÷4,50*

90°

45 100 100 815 90 14 A

45 110 110 815 90 18 A

70 140 110 815 90 20 A

90 170 140 815 115 25 B

115 200 140 815 115 27 B

105 190 190 945 150 26 D

160 214 120 945 150 20 D

L

Min.÷Max aA

max

T

sec

B C D E

1÷1,80

1,81÷2,20

2,21÷2,50*

2,51*÷3,00*

3,01*÷3,50*

3,51*÷4,00*

110° 20

90 140 815 90 20 A

100 130 815 90 21 A

110 140 815 115 24 B

130 140 945 120 29 C

160 150 945 120 19 C

160 230 945 150 22 D

L

Min.÷Max aA

max

T

sec

B C D E

ANT

ANT

KING24V

KING24V

KING24V

KING24V

KING24V

KING24VL

KING24VL

KING24V

KING24V

KING24V

KING24VL

KING24VL

KING24VL

COL

S3-Y

S3-X

S1-Z

S1-Y

-

-

COL

COL

S1-Z

S2-Y

S1-Y

-

-

1÷1,80

1,81÷2,20

2,21÷2,50

2,51*÷3,00*

3,01*÷3,50*

3,51*÷4,00*

90°

45 100 100 775 90 14 A

45 110 110 775 90 18 A

70 140 110 775 115 20 B

70 160 140 775 115 25 B

60 170 170 905 120 23 C

100 190 180 905 120 25 C

L

Min.÷Max aA

max

T

sec

B C D E ANT

ANT

1÷1,80

1,81÷2,20

2,21÷2,50*

2,51*÷3,00*

3,01*÷3,50*

110° 20

90 140 775 90 20 A

100 130 775 90 21 A

110 140 775 115 24 B

130 140 905 120 18 C

130 150 905 120 19 C

L

Min.÷Max aA

max

T

sec

B C D E

KING24V

KING24V

KING24V

KING24V

KING24VL

KING24VL

KING24V

KING24V

KING24V

KING24VL

KING24VL

31

31

G

B

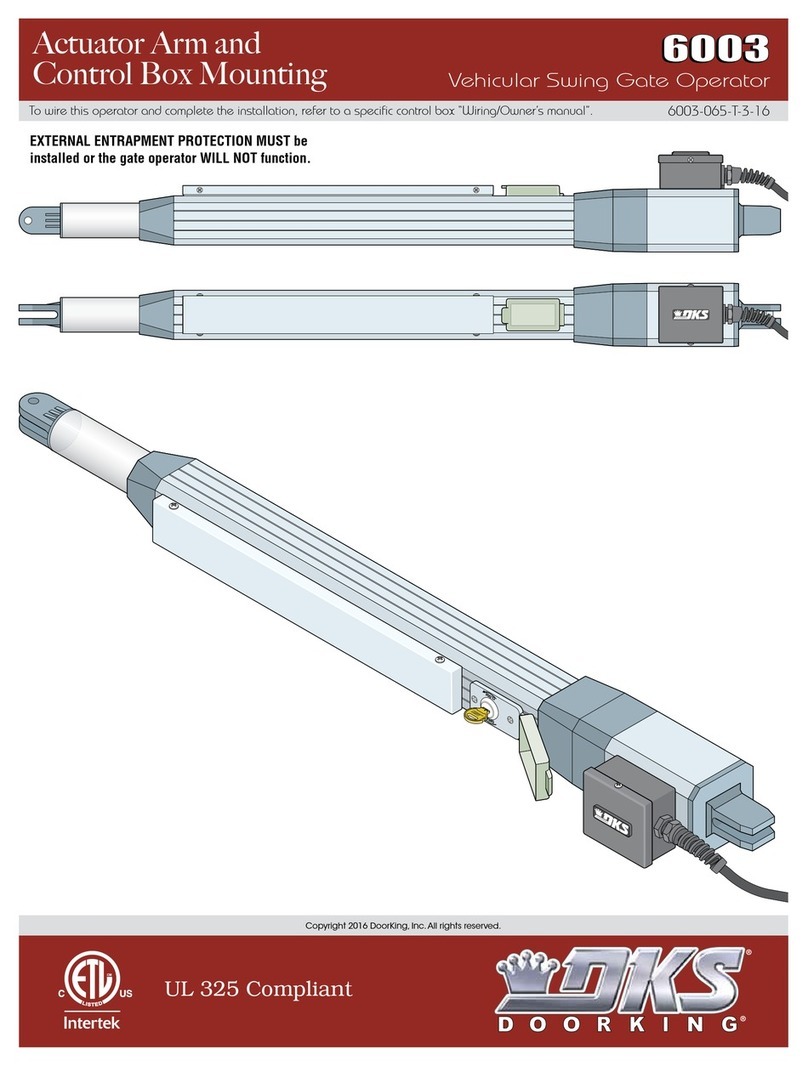

ELECTRIC CONNECTIONS T2 24V code BC07088

T2 24V CRX code BC07089

ANTENNA

ANTENNA

BRAIDING

CLOSE

OPEN

STOP

FUSE

T 2 A

PHOTOCELLS

STEP BY STEP

COMMON

COMMON

24Vdc 0,8A ± 15% for ACCESSORY SUPPLY

24Vdc 0,8A ± 15% for AUTOTEST SAFETY STRIPS BLINKER

24Vdc 20W

LED R=2,2K 1/4W

ELECTRIC

LOCK

PEDESTRIAN

SAFETY STRIPS

POWER SUPPLY

230Vac 50 Hz

TRANSFORMER

M1

M2

32

32

G

B

Power supply 230 Vac 50/60 Hz - external to

the control panel - (120V/60Hz upon request)

Common contact

Closing impulse contact (NA)

Opening impulse contact (NA)

STOP impulse contact (NC)

Radio Antenna

Gate open state and battery state output

indicator (24Vdc 3W max)

+ 24Vdc safety strip self-test power supply

Safety strip contact (NC)

Common contact

Photocells contact (NC)

Single pulse contact (NO)

Pedestrian opening contact (NA)

+ 24Vdc accessories power supply

- 24Vdc accessories power supply

Electric lock connection (MAX 15W 12V)

- 24Vdc blinker (code ACG7061) power

supply. Pay attention to the polarity.

Connection to secondary coil of transformer

18 Vac

MOTOR 1 CONNECTION (without polarity)

MOTOR 2 CONNECTION (without polarity)

Connector dedicated to the factory

programming.

DO NOT REMOVE ANY JUMPER!

OTHERWISE THE OPERATOR WILL NOT

WORK!

Connector dedicated to the factory

programming (only CRX control board)

DO NOT REMOVE ANY JUMPER!

OTHERWISE THE OPERATOR WILL NOT

WORK!

Built-in radio module (model CRX), or

connector for radio receiver RIB, 24 Vdc

supply

Connector for charge card of 24Vdc battery

(code ACG4648)

Trimmer for high speed adjustment operations

Trimmer for low speed adjustment operations

Trimmer for automatic closing time adjustment

(DISABLED DEFAULT AND DL6 LED OFF)

Programming button

Motor protection fuse

Transformer protection fuse

J1

J2

J3

J4

J5

J6

J7

J8

J9

J10

TR1

TR2

TR3

S3

FUSE 1

F1

N F

COM.

CLOSE

OPEN

STOP

AERIAL

SIGNAL

A+TEST

EDGE N.C.

COM.

PHOTO N.C.

K BUTT.

PED. BUTT.

A+

A -

LOCK

SECONDARY

TRANSFORMER

MOTOR 1

MOTOR 2

SW T2 24V

SW RADIO

RADIO

BATTERY

CHARGER

TRIMMER RUN

TRIMMER

LOW SPEED

TRIMMER TCA

PROG

T 8 A

T 2 A

J3

TR2TR1

J2

J4

F1

FUSE 1

J5

J6

TR3

J10

J8

J9

J1

J7

S3

A - CONTROL PANEL FEATURES

TRANSFORMER

33

33

G

B

B - SETTINGS

DIP 1 (ON) - MOTOR ROTATION DIRECTION CONTROL (POINT C)

DIP 2 (ON) - TIMER (POINT D)

DIP 3 (ON) - ACTIVATES DOOR RELEASE DURING PHASES OF

SLOWDOWN AND TOTAL OPENING AND CLOSING (AS PER THE

IMPACT TESTS OF EN12453)

DIP 1-2 MEMORIZATION/CANCELLATION OF RADIO CONTROL CODES FOR

TOTAL OPENING (ONLY MODEL CRX) (POINT E)

DIP 1-3 MEMORIZATION/CANCELLATION OF RADIO CONTROL CODES FOR

PEDESTRIAN OPENING (ONLY MODEL CRX) (POINT F)

DIP 2-1 MICRO-SWITCH CONTROLLER FOR PEDESTRIAN OPENING TIMER

DIP 4 Photocells always active (OFF) - Photocells active only during closing

(ON)

DIP 5 Pre-blinking (ON) - Normal blinking (OFF)

DIP 6 Single pulse command (K BUTT) and step-by-step radio receiver (OFF) -

automatic (ON)

DIP 7 Power sensor operation (ON-activated) time operation (OFF-activated).

DIP 8 Electric lock activation (ON-activated)

DIP 9 Electric lock pulse release (ON-activated)

DIP 10 Electric lock pulse engagement (ON-activated)

DIP 11 Easy release activation (ON-activated)

DIP 12 Sensor TEST activation (ON-activated).

DIP 13 Selection of 1 or 2 motor operation (default OFF 2 motors)

DIP 14 KING 24 - ON

DIP 15 KING 24 - OFF

DIP 16 IMMEDIATE CLOSING AFTER PASSING IN FRONT OF PHOTOCELLS

ON ACTIVATED

OFF DEACTIVATED

JP1 => Check that the jumper is inserted!

JP2 => Check that the jumper is inserted!

JP3 => Check that the jumper is inserted!

PROG => S3 Programming button

ADJUSTMENTS

ATTENTION: PUT DIP 3 IN THE ON MODE ONLY AFTER HAVING CARRIED

OUT ALL THE PROGRAMMING PROCEDURES.

NOTE: WITH DIP 3 (ON) BRIEF GATE REVERSAL AFTER IMPACT IS

ACTIVATED.

THIS BRIEF GATE REVERSAL PERMITS STATIC FORCE TO BE REDUCED

TO ZERO WITHIN 5 SECONDS AS PER STANDARD EN12453 POINT A.2.2

(ACCEPTABLE STATIC FORCE), THEREBY COMPLYING WITH THE IMPACT

TESTS ALSO OUTLINED BY EN12453).

IF COMPLIANCE WITH THE AFOREMENTIONED STANDARD IS

UNNECESSARY, SIMPLY POSITION DIP 3 TO OFF. IN THIS CASE THE GATES

STOP WITHOUT REVERSING.

RUN TRIMMER (TR1) high-speed electronic regulator

This trimmer permits motor speed adjustment (the default setting is maximum

speed). Adjustment of the automation is useful for compliance with European impact

standards.

LOW-SPEED TRIMMER (TR2) Electronic slow speed approach control

The slow speed control is performed by adjusting the LOW- SPEED TRIMMER

which changes the voltage output across the motor(s) (turning it clockwise increases

the speed). Adjustment is performed to determine the correct speed at the end of

opening and closing according to the gate or when there is friction that might cause

the system to function poorly.

AUTOMATIC CLOSING TRIMMER - TCA (TR3) TOTAL OR PEDESTRIAN

default NOT ACTIVATED and LED DL6 OFF (TRIMMER FULLY ROTATED

COUNTERCLOCKWISE)

This trimmer makes it possible to adjust the time for total or pedestrian automatic

closing. Only with gate completely (total) or partially (pedestrian) open and LED DL6

on (trimmer rotated clockwise).

The pause time can be adjusted from a minimum of two seconds up to a maximum

of two minutes.

LED SIGNALS

DL1 program activated (red)

DL2 gate opening M2 (green)

DL3 gate closing M2 (red)

DL4 gate opening M1 (green)

DL5 gate closing M1 (red)

DL6 automatic closing indicator (red)

DL7 photocell contact (NC) (red)

DL8 sensor contact (NC) (red)

DL9 STOP button (NC) (red)

DL10 radio code program (green)

FUSES

Fuse 1 T 8A MOTOR PROTECTION FUSE

F1 T 2A TRANSFORMER PROTECTION FUSE (on the outside of the T2 24V

board)

C - MOTOR ROTATIONAL DIRECTION CONTROL

1 - Set DIP 1 to ON => LED DL1 starts flashing.

2 - Press and hold the PROG button. (movement is now manually controlled - open-

stop-close-stop-open - etc.) => GREEN LEDS DL2 and DL4 are lit and the gate

panels open with a fixed lag of 2 sec. If they close instead of open, release the

button and reverse the two wires on the motor used.

3 - After opening release the PROG button and calibrate the mechanical opening

stops (on the operator).

4 - Press and hold the PROG button => RED LEDs DL3 and DL5 turn on and the

gate panels close with a time lag of 2 sec.

5 - Continue to hold the PROG button until the gate is completely closed.

6 - Leave the two doors completely closed to set the timer.

7 - Reset DIP1 to OFF => LED DL1 turns off, signaling exit from control.

N.B.: During this check the stop, the photocells and the sensors are not active.

D - SETTING THE TIMER FOR 2 MOTORS (#) WITH POWER

SENSOR ACTIVATED (DIP 7 ON)

WHILE SETTING THE TIMER THE POWER SENSOR IS CONTINUOUSLY

ACTIVATED.

1 - The gate must be completely closed.

2 - Set DIP 2 to ON => LED DL1 will blink rapidly.

3 - Press the PROG button. => M1 opens.

4 - When the mechanical opening stop is reached, the AUTOMATIC POWER

SENSOR stops M1 (memorizing the time and the power) => At the same time

M2 is triggered to open.

5 - When the mechanical opening stop is reached, the AUTOMATIC POWER

SENSOR stops M2 (memorizing the time and the power).

6 - Press the PROG button. => M2 closes.

7 - Press the PROG button. => M1 closes and sets the lag time between M2 and M1.

At the same time LED DL1 stops flashing indicating exit from the programming

procedure.

Safety and other gate commands now operate normally (inversions, stop,

alarms, etc.).

8 - The gate panels will close in high-speed mode (depending on how you set the

RUN trimmer) and near total closure in the slow mode (depending on how you

set the LOW-SPEED trimmer).

9 - Upon closing the power sensors stop the gate.

10 - AFTER PROGRAMMING RESET DIP 2 TO OFF.

D - SETTING THE TIME FOR ONE MOTOR (M1) (#) WITH POWER

SENSOR ACTIVATED (DIP 7 ON)

CAUTION: FOR ONE MOTOR CONTROL DIP 13 MUST BE POSITIONED TO ON;

DURING PROGRAMMING THE POWER SENSOR IS CONTINUOUSLY ACTIVE.

The gate must be completely closed.

1 - Set DIP 2 to ON => LED DL1 will blink rapidly.

2 - Press the PROG button. => M1 opens.

When the mechanical opening stop is reached, the AUTOMATIC POWER

SENSOR stops M1 (memorizing the time and the power).

3 - Press the PROG button. => M1 closes.

At the same time LED DL1 stops flashing indicating exit from programming.

Safety and other gate commands now operate normally (inversions, stop,

alarms, etc.).

Upon closing the power sensor stops the gate.

4 - AFTER PROGRAMMING RESET DIP 2 TO OFF.

(#) DURING PROGRAMMING THE SAFETY DEVICES ARE ACTIVE AND STOP

THE PROGRAMMING PROCEDURE (LED DL1 FROM FLASHING BECOMES

CONSTANT). TO REPEAT PROGRAMMING SET DIP 2 TO OFF, CLOSE

THE GATE USING THE PROCEDURE “MOTOR ROTATIONAL DIRECTION

CONTROL” AND REPEAT THE DESIRED PROGRAMMING PROCEDURE.

34

34

G

B

D - SETTING THE TIME FOR 2 MOTORS (#) WITH TIME OPERATION

(DIP 7 OFF)

1 - The gate must be completely closed.

2 - Set DIP 2 to ON => LED DL1 will blink rapidly.

3 - Press the PROG button. => M1 opens.

4 - When the mechanical opening stop is reached, wait a second then press the

PROG button => M1 stops and M2 opens.

5 - When the mechanical opening stop is reached => wait 1 second and press the

PROG button => M2 stops.

6 - Press the PROG button => M2 closes.

7 - Press the PROG button => M1 closes setting the time lag between M2 and M1.

At the same time LED DL1 stops flashing indicating exit from the programming

procedure.

Safety and other gate commands now operate normally (inversions, stop,

alarms, etc.).

8 - After the set amount of time, the gate will stop.

9 - AT THE END OF PROGRAMMING RESET DIP 2 TO OFF.

NOTE: The slowdown is automatically determined by the control board during

the time setting phase and is activated at about 50 to 60 cm before reaching the

mechanical opening or closing limit.

D - SETTING THE TIME FOR 1 MOTOR (#) WITH TIME OPERATION

(DIP 7 OFF)

CAUTION: FOR ONE MOTOR CONTROL DIP 13 MUST SET TO ON

1 - The gate must be completely closed.

2 - Set micro-switch DIP 2 to ON => LED DL1 will blink rapidly.

3 - Press the PROG button => M1 opens.

4 - When the mechanical opening stop is reached, wait a second then press the

PROG button => M1 stops.

5 - Press the PROG button => M1 closes.

At the same time LED DL1 stops flashing indicating exit from the programming

procedure.

Safety and other gate commands now operate normally (inversions, stop,

alarms, etc.).

6 - After the set amount of time, the gate will stop.

7 - AT THE END OF PROGRAMMING RESET DIP 2 TO OFF.

D - SETTING PEDESTRIAN OPENING TIMES (#) BOTH FOR TIME AND

POWER SENSOR OPERATION

With gate closed:

1 - First set DIP2 to ON (LED DL1 flashes quickly) and then DIP1 to ON ( LED DL1

flashes slowly).

2 - Push the pedestrian button (COM-PED.BUTT) => M1 opens.

3 - Push the pedestrian button to stop movement (thereby setting M1 opening).

4 - Push the pedestrian button to start closing.

5 - Upon closing reset DIP 1 and 2 to OFF.

(#) DURING PROGRAMMING THE SAFETY DEVICES ARE ACTIVE AND STOP

THE PROGRAMMING PROCEDURE (LED DL1 FROM FLASHING BECOMES

CONSTANT).

TO REPEAT PROGRAMMING SET DIP 2 TO OFF, CLOSE THE GATE USING

THE PROCEDURE “MOTOR ROTATIONAL DIRECTION CONTROL” AND

REPEAT THE DESIRED PROGRAMMING PROCEDURE.

E - RADIO CODE PROGRAMMING FOR TOTAL OPENING

(UP TO 62 CODES - CRX MODELS ONLY)

Programming can be done only when the gate is stationary.

1 - First set DIP 1 to ON and then DIP 2 to ON.

2 - The red LED DL1 flashes ON every 1 sec. and OFF for 10 seconds.

3 - Press the remote control button (usually channel A) within the allotted 10

seconds. If the remote is memorized properly LED DL10 (green) blinks.

4 - The programming time for codes is automatically renewed in order to memorize

the next remote control.

5 - To finish programming, wait 10 seconds, or press the PROG button briefly. The

red LED DL1 stops flashing.

6 - Reset DIP 1 to OFF and DIP 2 to OFF.

7 - End of procedure.

CANCELLATION OF ALL RADIO CODES FOR TOTAL OPENING

Cancellations can only be performed when gate is stationary.

1 - Set DIP 1 to ON and then DIP 2 to ON.

2 - The red LED DL1 flashes ON every 1 second and OFF for 10 seconds.

3 - Press and hold the PROG button for 5 seconds. Memory cancellation is indicated

by two flashes of green LED DL10.

4 - The red LED DL1 remains active and you can add new codes as shown above.

5 - Reset DIP 1 to OFF and DIP 2 to OFF.

6 - End of procedure.

INDICATOR MEMORY FULL OF RADIO CODES FOR TOTAL OPENING

Indication only when gate is stationary.

1 - Set DIP 1 to ON and then DIP 2 to ON.

2 - The green LED DL10 flashes 6 times when the memory is full (62 codes).

3 - LED DL1 will then remain active for 10 seconds enabling possible cancellation

of codes.

4 - Reset DIP 1 to OFF and DIP 2 to OFF.

5 - End of procedure.

F - PROGRAMMING PEDESTRIAN OPENING RADIO CODES

(UP TO 62 CODES - CRX MODELS ONLY)

Programming can be done only when the gate is stationary.

1 - Set DIP 1 to ON and then DIP 3 to ON.

2 - The red led DL1 flashes ON for 1 second and OFF for 1 second for 10 seconds.

3 - Press the remote control button (usually channel B) within the allotted 10

seconds. If the remote is properly memorized LED DL10 (green) blinks.

4 - The programming time for codes is automatically renewed in order to memorize

the next remote control.

5 - To finish programming wait 10 seconds, or press the PROG button briefly. The

red LED DL1 stops flashing.

6 - Reset DIP 1 to OFF and DIP 3 to OFF.

NOTE: If LED DL1 CONTINUES BLINKING QUICKLY IT MEANS THAT DIP 1

IS STILL SET TO ON AND THAT ANY OPERATION IS REFUSED.

7 - End of procedure.

CANCELLATION PROCEDURE FOR ALL PEDESTRIAN OPENING RADIO

CODES

Cancellation can only be performed when the gate is stationary.

1 - Set DIP 1 to ON and then DIP 3 to ON.

2 - The red LED DL1 flashes ON for 1 second and OFF for 1 second for 10 seconds.

3 - Press and hold the PROG button for 5 seconds. Memory cancellation is indicated

by two flashes of green LED DL10.

4 - The red LED DL1 remains active and you can add new codes as shown above.

5 - Reset DIP 1 to OFF and DIP 3 to OFF.

6 - End of procedure.

INDICATION MEMORY FULL OF PEDESTRIAN OPENING RADIO CODES

Indication only when the gate is stationary.

1 - Set DIP 1 to ON and then DIP 3 to ON.

2 - The green LED DL10 flashes 6 times when the memory is full (62 codes).

3 - The LED DL1 will then remain active for 10 seconds enabling possible

cancellation of codes.

4 - Set DIP 1 to OFF and DIP 3 to OFF.

5 - End of procedure.

CONTROL ACCESSORIES OPERATION

ATTENTION: ONLY IMPULSIVE COMMANDS HAVE TO BE CONNECTED.

Make sure that any other type of command accessories (e.g. mass detectors)

used on the installation are set in the IMPULSIVE mode, otherwise, the gate

will be operated even without the protection of the safety devices.

STEP-BY-STEP BUTTON (COM-K BUTTON)

If DIP6 ON => It cyclically performs the commands open-stop-close-stop-open

etc.

If DIP6 OFF => Opens the gate when closed. There is no effect if activated

while opening. If activated when gate is open, the gate closes. If

activated while closing, the gate reopens.

OPEN BUTTON (COM-OPEN)

The button controls the opening movement when the gate is stationary. If activated

while closing, it reopens the gate.

CLOCK FUNCTION OF OPEN BUTTON

If you want the Clock Function must request T2 24V with firmware 02.

ATTENTION: A CLOCK CONNECTED TO T2 24V with fw 03 or more

ACTIVATES THE OPENING MOVEMENT OF THE GATE WITHOUT HAVING

THE PROTECTION OF THE SAFETY DEVICES!

This function is useful during peak hours, when vehicle traffic is slow (e.g. entry/

exit of workers, emergencies in parking or residential areas and, temporarily, for

moving operations).

35

35

G

B

CLOCK FUNCTION APPLICATION

It is necessary to request a T2 24V control panel with firmware 02.

By connecting a switch and/or a daily/weekly clock (instead of or in parallel to the

open button N.O. “COM-OPEN”), you can open and keep the automation open for

as long as the switch is pressed or the clock remains active. Command functions

are inoperative with open automation.

Releasing the switch or at the preset time, the automation closes immediately.

CLOSE BUTTON (COM-CLOSE)

Controls the closing movement when the gate is stationary.

REMOTE CONTROL

If DIP6 ON => It cyclically performs the commands open-stop-close-stop-open

etc.

If DIP6 OFF => Opens the gate when closed. There is no effect if activated

while opening. If activated when gate is open, the gate closes. If

activated while closing, the gate reopens.

PEDESTRIAN OPEN BUTTON (COM-PED.BUTT.)

Partial opening and closing control.

During pedestrian opening, pausing or closing, you can control the opening of any

command linked to the T2 24V board.

With DIP 6 you can choose the operation mode of the pedestrian push button.

If DIP6 ON => It cyclically performs the commands open-stop-close-stop-open

etc.

If DIP6 OFF => Opens the gate when closed. There is no effect if activated

while opening. If activated when gate is open, the gate closes. If

activated while closing, the gate reopens.

ELECTRIC LOCK (LOCK)

Set DIP 8 to ON to enable control of the electric lock when opening.

ELECTRIC LOCK PULSE RELEASE IN OPENING

Set DIP 9 to ON to enable the electric lock pulse release when opening (provided

DIP 8 is ON).

If a command to open the gate is given when the gate is closed, the closing

movement is performed for 0.5 seconds and the electric lock is simultaneously

activated (followed by a 0.5 second pause and then the opening of the gate).

ELECTRIC LOCK PULSE ENGAGEMENT

Set DIP 10 to ON to enable the pulse engagement of the electric lock when closing.

Upon closing, motors are activated for 0.5 seconds at full voltage to ensure lock

engagement.

EASY MOTOR RELEASE

Set DIP 11 to ON to enable easy manual release (provided that DIP 10 is ON),

upon closing a reverse motion with a fixed time of 0.2 seconds occurs to facilitate

manual release.

OPERATION OF SAFETY ACCESSORIES

PHOTOCELL (COM-PHOT)

DIP 4 OFF => if an obstacle is placed in range of the photocells when the gate is

closed, the gate does not open. During operation, photocells work

when opening (by starting the opening movement only after the

obstacle is removed) and closing (by starting the reverse movement

only after the obstacle is removed).

DIP 4 ON => if an obstacle is placed in range of the photocells when the gate

is closed and the command to open is given, the gate opens (the

photocells do not work while opening). Photocells work only during

closing (with reverse motion restored after a second, even if they are

still engaged).

CONTROL OF IMMEDIATE CLOSING AFTER MOVEMENT IN FRONT OF

PHOTOCELLS

DIP 16 ON and DIP 4 OFF => if photocells are engaged during opening, the gate

stops and the gate only closes one second after the

photocells are disengaged.

DIP 16 ON and DIP 4 ON => if photocells are engaged during opening, the gate

continues to open. Upon disengagement of the

photocells, the gate stops and reverses closing

motion after a one second pause.

If total opening is reached (end of opening time),

immediate closing is deactivated and automatic

time closing is activated (if TCA trimmer is

activated and LED DL6 is on). If during closing

there is a rapid movement (e.g. pedestrian) the

gate will open again for two seconds and then

close once again.

DIP 12 OFF => immediate closing after movement in front of the

photocells is deactivated.

N.B.: Please check photocell operation at least every six months.

EDGE (SAFETY STRIP) (COM-EDGE)

If engaged during opening, reverses the motion when closing.

If engaged when closing, reverses the motion when opening.

If it remains engaged again, it performs a further reversal after 2 seconds, then

performs an additional short reversal and then gives the sensor failure or engaged

alarm (N.O. contact).

If the sensor remains engaged (N.O. contact) no movement is allowed.

If not used, jump the terminals COM-EDGE.

MONITORING OF SAFETY SENSORS (A+ TEST A-)

Sensors can be monitored through the A+ TEST input and DIP 12 ON.

The monitoring consists of a functional test of the sensor run after every full gate

opening.

Closing the gate is therefore permitted only if the sensors have passed the functional

test after each opening.

CAUTION: MONITORING OF THE SENSOR INPUT CAN BE ACTIVATED WITH

DIP 12 ON OR DEACTIVATED WITH DIP 12 OFF. IN FACT, THE FUNCTIONAL

TESTING OF SENSORS IS ‘POSSIBLE ONLY IF THESE DEVICES HAVE THEIR

OWN POWER SUPPLY.

A MECHANICAL SENSOR CAN NOT BE MONITORED, SO DIP 12 SHOULD BE

SET TO OFF.

SENSOR AUTOTEST ALARM (DIP 12 ON)

If the sensor fails the monitoring test after opening, an alarm is displayed by the

blinker lighting up. Gate closure is not allowed in this condition. Normal operation

can be restored only by repairing the sensor and pressing one of the activated

controls.

STOP BUTTON (COM-STOP)

The STOP button stops the gate during any operation.

If held when the gate is fully open (or partially when using the pedestrian control)

automatic closing is temporarily deactivated (if activated by the TCA trimmer and

LED DL6 on). It is therefore necessary to use a new command to make it close.

The automatic closing function is reactivated on the next cycle (if activated by the

TCA trimmer and LED DL6 on).

POWER SENSOR ALARM

The T2 24V control panel has automatic sensors that make the movement of the

gate reverse in case of impact against objects or persons in accordance with the

current EN standards (always use the right tool to ensure compliance with the values

imposed by the standard), without special adjustments on the control panel, as it

operates using special internal software.

If the power sensor is used in opening or closing (only in high-speed) and then

again, in the opposite direction, the gate stops and then reverses for 1 second.

The alarm status will be displayed by the blinker which will remain active for one

minute, during which time you can restore gate operation by pressing any command

button.

FUNCTIONING IN DEAD MAN MODE WHEN THE SAFETY DEVICES ARE

FAILING

If the safety edge fails or remains engaged for more than 5 seconds, or if photocell

fails or remain engaded for more than 60 seconds, the open, close, k button and

pedestrian commands will work only in dead man mode.

The signal that this mode has been activated is given by the blinking of the

programming led.

With the blinking of the programming led, the opening and closing operation are

allowed only with the command button pressed and held. The radio commands

and that of automatic closing, will be excluded, since their use in this mode, is not

allowed by the norms.

Once the failing safety device is repaired, in automatic after 1 second, all standard

commands that were selected, such as step by step, automatic mode, radio

commands and automatic closing start functioning again.

Note 1: during this functioning in dead man mode, in case of damage to the safety

strips (or photocells) the photocells (or safety strips) still work by interrupting

the operation in progress.

Note 2: the stop command is not to be considered a safety command that can be

bypassed in this mode. Therefore, when pressed or damaged, it will not

allow any movement of the gate.

36

36

G

B

The dead-man operation is only an emergency operation which must be

activated for a very short period and with the complete installation at sight so

to have a secure and safe control of the system. As soon as possible however,

the failing safety devices must be repaired and activated.

BLINKER

N.B.: This control panel can power ONLY BLINKERS ON A (ACG7061) CIRCUIT

with lamps up to 24V and 20W.

PRE-BLINKING

DIP 5 - OFF => the motor and blinker begin simultaneously.

DIP 5 - ON => the blinker begins 3 seconds before the motor.

GATE OPEN WARNING LIGHT (COM-SIGNAL)

Signals when the gate is open, partially open or not closed completely. Turns off only

when the gate is completely closed.

This signal is active during programming.

N.B.: Max 3 W. If push buttons or lamps are in excess, the control panel processes

will be endangered and possibly halt operation.

OPERATION AFTER A BLACK-OUT (WITHOUT BATTERIES)

When the power supply comes back the DL1 led turns on and remains on for all

the time the gate stays open. The led will turn off only once the gate is completely

closed.

It is recommended to fully open the gate. Let the gate close by itself or with automatic

closing, or wait until the blinker stops flashing before commanding it to close.

This will allow the gate to realign. If, motors were released and moved from the

normal position when closed during the blackout, the first movement after power

returns must be complete.

If the black out occurs when the gate is still moving or when the gate is open and the

first command sent after the black out is a closing command, the closing of the gate

will be carried out with a total delay between the two gate leaves. Therefore, first

the leaf M2 will close completely; once it is off, M1 will start closing. This separate

movement of the two gate leaves is done to avoid their incorrect overlapping.

TECHNICAL SPECIFICATIONS

- Temperature range 0 ÷ 55°C

- Humidity <95% without condensation

- Voltage 230V~ ± 10%

(120V/60Hz upon request)

- Frequency 50/60 Hz

- Battery power 20-24Vdc

- Transformer Power 130VA -

primary 230Vac

secondary 18Vac

- Maximum absorption 50 mA

- Network Micro-switches 100ms

- Maximum power gate open indicator 24Vdc 3W (equivalent to one

3W or 5 LED light bulb with

resistor in series at 2.2 K ohm)

- Maximum blinker power 24Vdc 20W

- Power available for photocells and accessories 1A ± 15%

- Power available for radio connector 200Ma

RADIO SPECIFICATIONS (model T2 24V CRX)

- Receiving Frequency 433,92 MHz

- Impedance 52 OHM

- Sensitivity >2,24µV

- Pick-up time 300ms

- Drop time 300ms

- All inputs must be used as clean contacts because the power is generated

internally (secure power) to the board and is set up to ensure compliance with

double or reinforced insulation with regard to dangerous voltage.

- Any external circuits connected to the outputs of the control panel must be made

in such a manner as to ensure compliance with double or reinforced insulation with

regard to dangerous voltage.

- All inputs are controlled by a programmed integrated circuit that performs a self

check every time it starts operating.

After having carried out the various connections and having supplied voltage, all the LEDS

are switched off.

The motor opens and closes, but it has no strength and moves slowly.

The gate opens but does not close after the time set.

The gate does not open or close by activating the various K, Radio, Open and Close

buttons.

The electric lock does not work.

LED DL1 blinks rapidly and no movement is activated.

Check fuses F1, FUSE 1.

If the fuse is blown, use only a suitable replacement.

F1 T 2A TRANSFORMER PROTECTION FUSE (on the outside of the T2 24V

board)

FUSE 1 8A MOTOR PROTECTION FUSE

Check trimmers RUN and LOW-SPEED adjustment.

Make sure that the TCA trimmer is activated with LED DL6 on.

OPEN button always on, replace the OPEN control button or switch.

Sensor Auto test failed, check the connections between the control panel and the sensor power

supply.

Warning: If you are not using a power supply for the sensors, DIP 12 should be OFF.

Faulty safety edge contact. Faulty photocells contact with DIP 4 OFF.

Fix or replace the relative contact.

Ensure to have enabled DIP 8 at ON.

Place dip switches 1, 2 or 3 in the OFF position.

FAULT SOLUTION

TROUBLE SHOOTING

After having carried out all connections, by carefully following the layout and having positioned the gate in intermediate position, check the correct ignition

of red LEDS DL7, DL8 and DL9

In case of no ignition of the LEDS, always with gate in intermediate position, check the following and replace any faulty components.

DL7 switched off Faulty photocells

DL8 switched off Faulty safety edge (In case the edge is not connected, carry out jumper between COM and EDGE)

DL9 switched off Stop button malfunction (if Stop is not connected, perform the jump between COM and STOP).

During functioning with personnel present, with DIP 1 at ON, check that during opening of M1 and M2 the green DL2 and DL4 LEDS switch on and that

during closing of M1 and M2 the red DL3 and DL5 LEDS switch on.

Or else, reverse the wires of the motor.

G

B

ACCESSORIES - For the connections and the technical data of the optional equipments follow the relevant

handbooks.

BATTERY

Battery 2,2Ah 12V code ACG9515

BATTERY CHARGE CARD

code ACG4648

Wi-Fi DEVICES

MASTER Wi-Fi

RECEIVER CARD TO MANAGE WIRELESS SYSTEM

with connector - 12÷30V ac/dc code ACG6094

with terminal block - 12÷30V ac/dc code ACG6099

NOVA Wi-Fi

PHOTOCELLS WITHOUT WIRES code ACG8037

PAIR OF COLUMS NOVA code ACG8039

TOUCH Wi-Fi

STRIP WITHOUT WIRES code ACG3016

SPARK Wi-Fi

BLINKER WITHOUT WIRES code ACG7064

LATERAL SUPPORT code ACG7042

BLOCK Wi-Fi

KEY SELECTOR WITHOUT WIRES code ACG6098

Discover the only

wireless automation devices

at www.ribind.it.

SET SOLAR AMPLIFIER

Interface for 50W solar panels. code AD00319

SUN 2CH code ACG6052 SUN 4CH code ACG6054

SUN CLONE 2CH code ACG6056 SUN CLONE 4CH code ACG6058

RADIO TRANSMITTER SUN

Cod.CVA2031-20032013-Rev.08

KING 24V

SeegerE25

Spinaelettrica520

Spinacilindrica8x32

MollapersbloccoserieKING

MollatrazionecoperchioserieKING

AnelloditenutaOR158

AnelloditenutaOR2037

Boccola12x16x12BronzoF7/R7

CilindrettoperserraturaserieKING

DadoAutob.M10AltoInox

RondellaPiana10X20Inox

RondellaPiana10X30Inox

RondellaPiana12X24

ViteTCEIM6x35zinc.

ViteTCCroce5,5x50

ViteTCEI6X30InoxUNI5931

ViteTE8X30InoxUNI5739

ViteTE10X40InoxUNI5737

CTC1123

CTC1158

CTC1214

CTC1258

CTC1259

CTC1303

CTC1307

CVA1176

CVA1325

DDD10MAI

DRL10X20I

DRL10X30I

DRL12X24Z

DTB6X35

DTC55X50Z

DTE10X20I

DTE8X30I

DTM10X40I

ACG8089

BA01019

BA10052

BA10065

BA10066

BA10102

CAL1160

CAL1162

CME6082

CCA1294

CCA1319

CCA1328

CCA1351

CCA1355

CCA1370

CCM6005ZZ

CEL1425

GruppoFermomeccanicodichiusura

OPZIONALE

SerieaccessoripercilindroKING

GruppoChiocciolaserieKING

Grupposemig.sup.KINGcompleto

Grupposemig.sup.KINGLcompleto

Conf.accessoriconnettore,pressacavo,

cap.coprirondella,rondellacap.

SemiguscioinferioreKING

SemiguscioinferioreKINGL

ForcellaPosterioreserieKING

Piattocolonnaregolabile

PiattofissaggiocolonnaKINGL

PiattoattaccocancelloKINGL

AttaccocancelloserieKING

Angolareattaccoacolonna(2pezzi)KING

PiastraattaccocolonnaKINGL

Cuscinettomotore6005ZZ

Condensatore10µF450Vxserie230V/50

Codice DenominazioneParticolare

CEL1426

CME1166

CME1299

CME2042

CME2041

CME8996

CME9129

CME9130

CME9785

CME9868

CMO2515C

CPL1087

CPL1157

CPL1161

CRS62042R

CTC1004

CTC1008

CTC1119

CTC1120

Condensatore35µF450Vxserie120V/60

Adattat.motoreKING24V

PernoperingranaggioserieKING

Coronaelicoidalesbloccosx

CoronaelicoidaledxserieKING

Vites/fineKING12/24V

VitemadreKINGL

VitemadreKING

PernoSbloccoserieKING

PernoditrainoserieKING

MotoreKING24V

Ingranaggioconico

TappoperfermomeccanicoserieKING

IngranaggioconicoserieKING

Cuscinetto6204/2RS

Chiavetta6612

Chiavetta6630

SeegerE17

SeegerE20

Codice DenominazioneParticolare Codice DenominazioneParticolare

Questo prodotto è stato completamente progettato e costruito in Italia · Ce produit a été complètement développé et fabriqué en Italie · This product has been

completely developed and built in Italy · Dieses Produkt wurde komplett in Italien entwickelt und hergestellt · Artìculo totalmente proyectado y producido en Italia

25014CASTENEDOLO(BS)-ITALY

ViaMatteotti,162

Tel.+39.030.2135811

Fax+39.030.21358279

www.ribind.it-[email protected]

SELF INSTALL - NEED TECHNICAL

ASSISTANCE?

OPTION 1: DIRECT WITH THE SERVICE DESK – QUICKEST AND MOST EFFECTIVE METHOD

Submit your enquiry direct with the service desk at – service@automaticsolutions.com.au

The service desk has the most experienced staff in Australia to help with your problem but they need your help.

Describe your problem in detail and as clearly as possible. Don’t forget to include a telephone number.

Be certain to detail which model or models of you are working with.

Send photos of the installation – they love photos. The people at the service desk are good but they are

even better when they can see the installation. Send photos of the overall scene so they can see the

entire installation. Also send photos of the wiring to the control board and any other part of the

installation you think is relevant.

Send video if appropriate. Smartphone’s these days take remarkably good video in small file sizes which

can be emailed in a moment. If your problem needs a video to show the issue please feel free to send it.

NOTE: THIS IS BY FAR THE FASTEST AND MOST SUCCESFUL WAY TO SOLVE YOUR PROBLEM

PHOTOS AND VIDEOS ARE THE NEXT BEST THING TO BEING THERE

OPTION 2: LODGE YOUR ENQUIRY LOCALLY - SLOWER BUT CAN STILL BE EFFECTIVE

Make contact with the store of purchase. Branch staffs are typically not technicians and dependent on their length

of service will have varying degrees of technical knowledge. If they cannot help however they will certainly either

source help locally from their technicians or make contact with the service technicians on your behalf.

OPTION 3: SERVICE CALL WITH AUTOMATIC SOLUTIONS TECHNICIAN – SLOWEST METHOD

If you fall within the local branch service area it may be possible to book a local technician to look at your

installation. Wait times will vary dependent on local workloads. The cost is a service fee which includes the first

half hour and the hourly rate thereafter. If any Automatic Solutions provided parts are found to be defective and

within warranty these will be provided free of charge.

(NOTE: If you suspect that any parts are defective and within warranty you may wish to consider option 4)

A note on this option: If you decide on this option you will be asked to sign an “authorisation to proceed” which

will provide legal authority and payment security. This form has three options available of which only the first two

are available to you. The third option is for warranty repairs only for full install customers. Self install customers

requiring warranty only service need to refer to option four below.

IMPORTANT: IN SHORT THIS OPTION WILL INCUR CHARGES

OPTION 4: RETURN THE PRODUCT IF BELIEVED TO BE FAULTY

As a self install customer who has purchased product if you believe the product to be faulty rather than an

installation or site problem you have the option of returning the product for evaluation and to exercise your right

to a replacement, repair or refund as applicable. All returned product is forwarded immediately to the service

technicians for evaluation and response. There are two main methods available to return product –

Direct to the service centre – this is the quickest method as it cuts out the branch delay

Via the branch of purchase – slower because of the delay at the branch

When choosing this option you need to complete a product return form. This form gives you all the information

on procedure involved and where to send to. These are available at the branch of purchase, can be emailed to

you (contact your branch), or available here - http://automaticsolutions.com.au/page/warranty.php

Table of contents

Other Automatic Solutions Gate Opener manuals

Popular Gate Opener manuals by other brands

Allstar

Allstar GS1000 Installation and owner's manual

Mighty Mule

Mighty Mule MM362-D installation manual

Chamberlain

Chamberlain Swing GATE Installation and operation instructions

GTO

GTO PRO SL-1000B brochure

Allstar

Allstar HDSLG 1000 Installation and owner's manual

Chamberlain

Chamberlain WGO200 instructions