Automatic LPE 500 User manual

Page 1 of 26 7/9/19

LPE 500 & LPE 700

LOW PROFILE ELECTRIC

STATIONARY ROLLER MILL

Operator, Parts &

Installation Manual

Page 2 of 26 7/9/19

Exchange & Resharpening Roll Service

If your rolls ever become dull or require resharpening, you can order an exchange set of rolls. For further

details on our special roll replacement program, contact your nearest dealer or distributor. If you do not

have a dealer or distributor in your area, contact the factory. Credit allowance on used rolls is subject to roll

inspection upon return to factory via prepaid freight.

Introduction

Congratulations! You are now the owner/operator of America’s finest roller mill. Please take a few minutes to

be sure that you understand the maintenance and operation of this roller mill. Read this operator’s manual

carefully: you’ll get better results and have fewer problems.

After your roller mill has been in operation for a few hours, check for loose bolts, setscrews, belts, etc.

All are tight when the roller mill leaves the factory; however, after a break-in period, some items may

require additional tightening. Like any other machine, your Automatic roller mill requires proper care and

intelligence in operation. Misuse and neglect will only cause unnecessary expense and dissatisfaction.

This manual is written as a guide for owners and operators of the Automatic LPE500 & LPE700 model roller

mill. Read it carefully and follow the suggestions made. Keep this manual in a convenient place for quick,

easy reference, and use it whenever questions arise.

Fill in the following information now for future reference and convenience. Always give this information

to your dealer when ordering new parts. If at any time it becomes necessary for you to write directly to

Automatic Equipment Manufacturing Company for additional information, give the model and serial number

of your machine, and as much descriptive information as possible. It will enable us to more thoroughly and

quickly expedite your order.

Model No. _____________________ Serial No. _____________________ Date of Purchase ______________

Name and Address of Dealer _________________________________________________________________

_________________________________________________________________

DEALER/OPERATOR PRE-USE INSPECTION CHECKLIST

Although everything is in working order when the roller mill leaves the factory, some components may

get out of adjustment in transit. The following inspection must be made prior to operation. Check each item

listed and make adjustments if necessary. Refer to the corresponding sections of the manual to determine

the correct settings for individual items.

• Check all belts for proper tension and alignment.

• Check to make sure the set screws in all pulleys and bearings are tight.

• Check all grease line connections and lines for damage during shipment.

• Make a general check for bolts that may have vibrated loose during shipment.

• Check greased bearings for proper lubrication.

• Check to make sure all shields and guards are in place.

• After operating the roller mill for the first few times, go through this checklist again. Some

bolts, setscrews and belts may require additional adjustment during this break-in period.

Page 3 of 26 7/9/19

SAFETY

DO NOT OPERATE OR USE THIS EQUIPMENT UNTIL THE FOLLOWING

OPERATING AND SAFETY INSTRUCTIONS HAVE BEEN READ AND UNDERSTOOD.

SAFETY

This symbol is used to bring attention to safety precautions and instructions.

When you see this symbol, be alert and pay attention to all instructions. YOUR

PERSONAL SAFETY IS INVOLVED.

The words CAUTION, WARNING, and DANGER following a symbol indicate three degrees of

hazard. CAUTION indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury. It may also be used to alert against unsafe practices. WARNING indicates

a potentially hazardous situation which, if not avoided, could result in death or serious injury.

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

SAFETY PRECAUTIONS

FAILURE TO UNDERSTAND AND PRACTICE GOOD SAFETY PROCEDURES COULD RESULT IN

PERSONAL INJURY OR DEATH.

All farm machinery is inherently dangerous to children and to persons unfamiliar with its general

operation. Children should not be permitted in areas where machinery of this nature is operating.

Since mills contain numerous moving parts, some of which may not always be visible to the

operator, they can be extremely dangerous. Steps should be taken to assure the safety of the

operator, and any other people in the area. Automatic Equipment strongly recommends that no

person be permitted to operate this mill without a thorough understanding of how the machine

works and the precautions to be observed.

If the mill discharges into an auger, be sure the auger is covered and shields are

provided between the mill discharge and the auger.

Because of the dry, highly flammable material associated with this machine,

FIRE FIGHTING EQUIPMENT SHOULD BE READILY AVAILABLE DURING THE

OPERATION OF THIS MACHINE.

The operator of this machine should be a responsible adult who is familiar with

farm machinery, and trained in its operation. REMEMBER! Your best insurance

against accidents is a careful and responsible operator. A careless operator is a

liability to himself and those who work with him.

Before operating this equipment, be sure to read and understand this operator’s manual. If there is any

portion of the manual, or any phase of the hammer mill’s operation you do not understand, be sure to

contact your local Automatic dealer or Automatic Equipment, Pender, Nebraska. 402-385-3051.

SAFETY PRECAUTIONS - BEFORE OPERATION

1 Keep the mill in good repair. Good maintenance is your responsibility. A poorly

maintained machine is an invitation for trouble. Always use proper tools when servicing your

mill.

2 DO NOT start, operate, or attempt repair work on the mill until you carefully read and

thoroughly understand this operator’s manual.

3 Be sure all shields are in place and all bolts are tight throughout the mill.

4 Be sure the rolls and drive belts are properly adjusted and in good condition. (See Operation

Section)

5 Be sure there are no tools or other foreign objects lying on or in the machine.

Page 4 of 26 7/9/19

SAFETY PRECAUTIONS - DURING OPERATION

1 DO NOT wear loose-fitting clothing that may catch in moving parts.

2 Children should not be permitted in areas where machinery of this nature is operating.

3 DO NOT operate this machine until you are sure everyone is clear of the area.

4 NEVER leave the mill running unattended.

5 Always keep hands, feet, and clothing away from moving parts.

6 DANGER Keep hands and feet out of the hopper when machine is in

operation. Never remove safety grates, or use your hands or feet to dislodge

any obstruction from the mill. Never try to push or force feed grain or snow

that may be bridged or laying in the hopper.

7 NEVER sit or stand on the mill while it is in operation.

8 NEVER adjust or service the unit while it is in operation.

9 NEVER open shields, mill access doors or clean out doors while the

mill is in operation.

10 DANGER Avoid contact between the discharge auger and overhead electrical lines. Failure

to heed warning will result in serious personal injury or death.

11 Hydraulic fluid can cause serious burns. Hydraulic fluid escaping under pressure can have

enough force to penetrate the skin and may also infect a minor cut or opening in

the skin. If injured by escaping fluid, see a doctor at once. Make sure all connections are tight

and that hoses are in good condition.

SAFETY PRECAUTIONS - SERVICE AND REPAIR

1 SAFETY SHUTDOWN PROCEDURE: Working on the mill when it is operating is

expressly prohibited. Never clean, adjust, lubricate, or otherwise service this machine until the

following steps have been taken.

A. Disengage the power source.

B. Lock all switches.

C. Wait until all mechanical motion has stopped on the mill.

Only when these precautions have been taken, should you proceed in the adjustment or

servicing of the mill. Failure to follow the above procedure could lead to death or

serious personal injury.

2 Keep the mill in good repair. Good maintenance is your responsibility. A poorly maintained

machine is an invitation for trouble. Always use proper tools when servicing machine, making

certain that they are removed from the unit when services or repairs have been completed.

3 All mills are equipped with shielding to protect the operator from injury. For purposes of

clarity only, some illustrations in this manual may show the mill with the shields removed or

missing. Although shields may be opened or removed for servicing and repair of the

mill, they MUST always be closed or replaced before operation resumes.

SAFETY

Page 5 of 26 7/9/19

SETUP / OPERATION

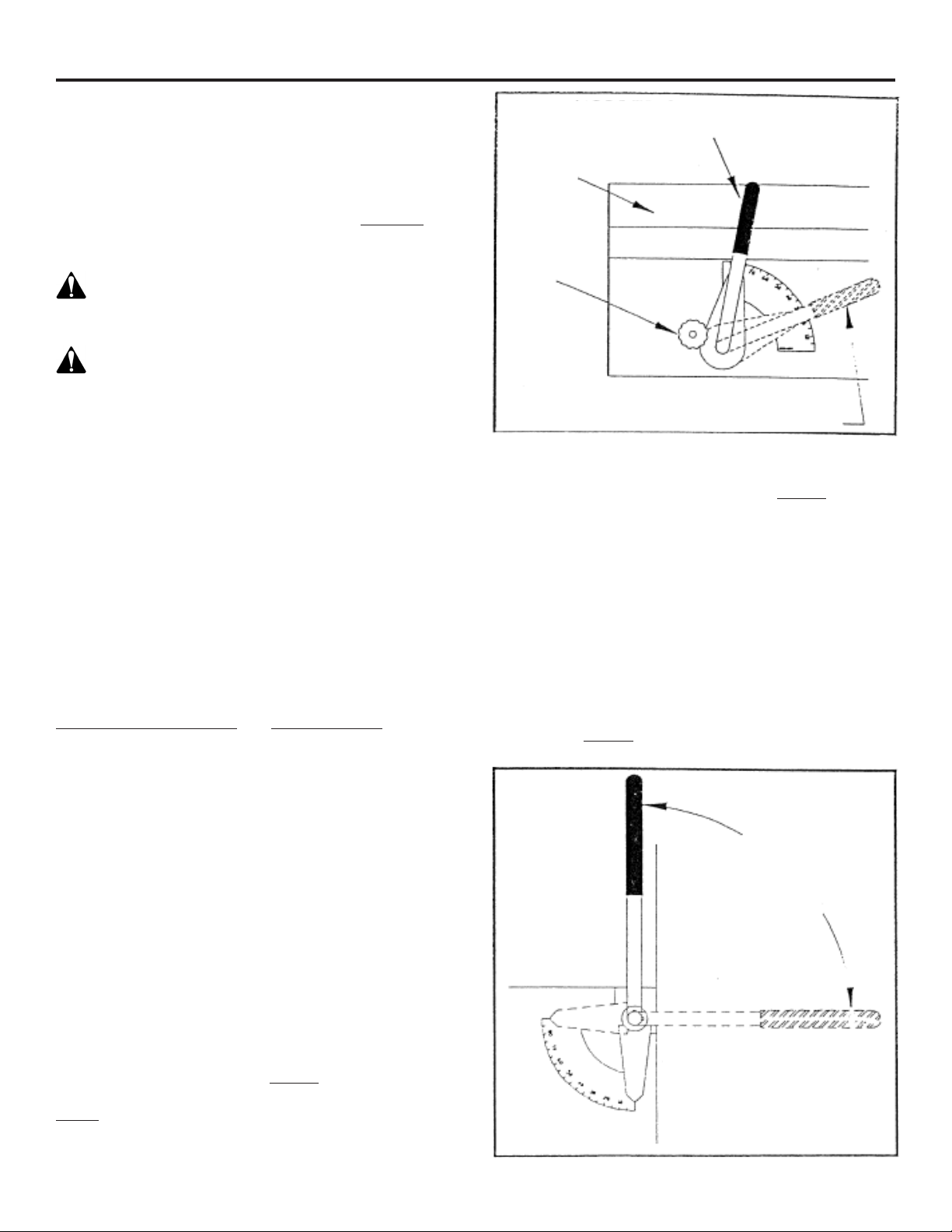

SET UP - Be sure the roller mill is mounted on a firm

base with adequate room for proper servicing. The roller

mill should be level while operating to allow the grain to

flow evenly across the rolls. An even flow of grain will

produce a more consistent product and helps to eliminate

unnecessary strain on roll bearings and shafts. Electric

powered units should be operated at about 780 RPM

(drive roll). Use a pulley ratio of 2.3 to 1 on 1800 RPM

motors.

CAUTION: Before attempting to operate this roller

mill, review and comply with all Safety Precautions listed

in the SAFETY portion of this manual.

CAUTION: Always check to make sure everyone is

clear of the roller mill before engaging power.

STARTING MILL - Your roller mill will not start properly

if grain is present between the rolls. Always start the

roller mill with the hopper gate in the hopper completely

closed. (See Figure 2) After bringing the rolls up to full

operating speed (780 RPM), open the hopper gate to

allow grain to the rolls. If grain is released to the rolls

before they are turning, it may bridge up and cause the

mill to stop. If this happens, shut the hopper gate, shut

down the roller mill and spread apart the rolls to allow

the excess grain to pass through before restarting the

mill. (See safety shut down procedure (Page 2) and roll

adjustment (Below).

YOUR ROLLER MILL IS DESIGNED TO ELIMINATE

COMPLICATED ADJUSTMENTS. Only two major points

of adjustment exist for any small grain or shelled corn.

HOPPER GATE CONTROL and ROLL SPACING.

HOPPER GATE CONTROL - Open the hopper gate

gradually until you reach the maximum flow of grain

that power will handle. If it becomes necessary to stop

the machine at any time before the hopper is empty, be

sure to close the hopper gate before disengaging power.

DON’T OVERCROWD ROLLS. Keep a ribbon of grain

feeding between the rolls and you’ll do a more consistent

job of rolling. This is especially true of oats and barley. It is

not necessary to completely flatten the kernel of any grain

being rolled. Grain is easier to digest when the hard coat

or hull is broken open or cracked, exposing their nutrients

to the digestive juices of livestock.

ROLL SPACING depend upon the type of grain to be

rolled and roll corrugation. Grain varies in size, shape,

toughness and moisture content. This is also true of the

same type of grain from dierent localities. For these

reasons, it is impossible to say exactly where to set the

rolls. The roll spacing is factory set at approximately

0.015”, placing the rolls as close together as possible. Do

not over-roll hard or dry grains, as this will cause dusting.

Remember, proper adjustment keeps dust at a minimum,

even when rolling the driest grain.

ADJUSTING ROLLS - (See Figure 3) When the roll adjust

handle is straight up, the rolls are at their closest setting,

producing the finest, or smallest, particle size possible

with the current roll corrugation. To increase the roll

spacing and particle size, loosen the locking handle on

the motor side of the mill (See Figure 1) and rotate the roll

adjust handle clockwise. A wider roll spacing is achieved

with the roll adjust handle in the horizontal position. The

curved decal by the indicator pointer of the roll adjust

handle should be used by the operator as a reference

to note frequently used roll spacing for dierent rolling

applications. It is not intended for specific roll spacings.

IMPORTANT: Remember to tighten the locking handle

before resuming any rolling operations.

IMPORTANT: NEVER OPERATE THE MILL WITH THE

ROLLS TOUCHING!

Figure 2

HOPPER GATE CONTROL

MAXIMUM OPENING

HOPPER

HOPPER GATE CLOSED

LOCKING

KNOB

ROLL SPACING

ADJUSTMENT

ROLL SPACING

APPROX. 0.015”

(FACTORY SETTING)

HOPPER

BASIC

ROLL SPACING

APPROX. 1/4”

(MAX. OPENING IS 1/2”

WITH HANDLE

STRAIGHT DOWN)

Page 6 of 26 7/9/19

SETUP / OPERATION

BELT TENSIONING AND ALIGNMENT

To properly tighten the drive belt you should first open the rolls to a gap of approximately 1/4 inch. This is

done by rotating the roll spacing adjustment handle clockwise until it is 90 from vertical.

Tighten the drive belt. The tension should be measured between the motor and flat pulley. The belt should

deflect 3/16” using approximately 60 pounds of force.

Reset the roll gap spacing as instructed on page 6 of the LPE manual.

Periodic checks of all belts should be made to ensure proper alignment, correct tension levels, and detect

worn or deteriorating belts.

To check belt alignment, lay a long straight edge along the cog belt sprockets. The outside edge of all three

should line up, including the motor sprocket.

SHUT DOWN PROCEDURE

During normal operation of this mill, the following shut down procedure should always be followed to ensure

that the rolls are free from excess grain build up that may prevent the mill from starting up properly.

1 When shutting down your mill, always stop the flow of grain into the hopper first.

2 When all grain has passed through the rolls and the hopper is empty, the hopper gate control should be

closed. (rotated clockwise)

3 Finally, disengage the electrical power to the roller mill.

FUSED

SERVICE

DISCONNECT

MOTOR

STARTER

BOX

POWER

DISCONNECT

ON MILL

CONNECT MOTOR

PER MOTOR MFG.

WIRE DIAGRAM

5, 7.5 OR 10 HP MOTOR

METERED POWER SOURCE - 1 PHASE POWER

240 VOLT MAX.

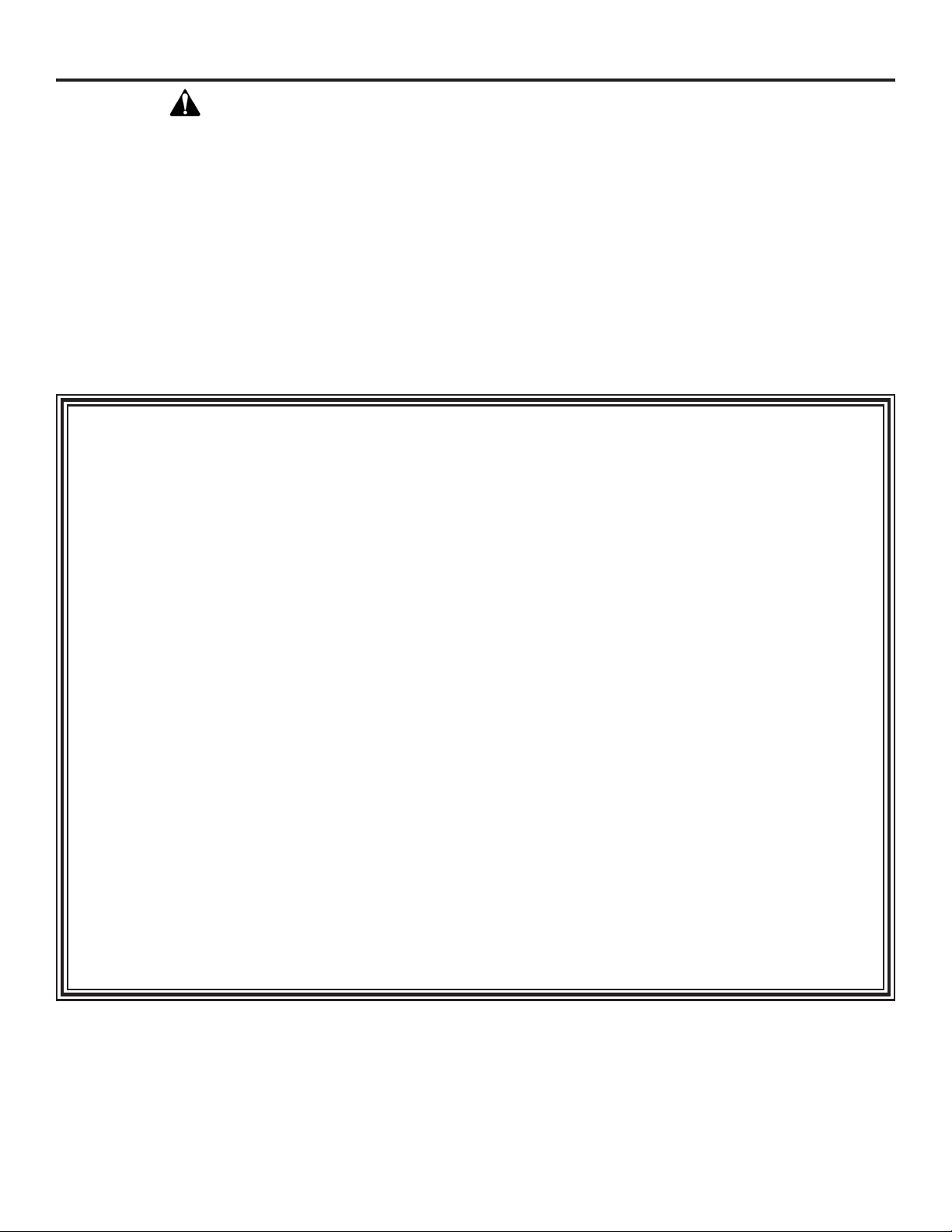

The following are instructional diagram on how to wire the power disconnect box which is located on the roller mill

hopper, just above the electric motor. Below is a diagram covering single phase electricity. The maximum power which a

particular box can handle will be displayed on the box, but should be 60 amps and 220-240 volts, single or 3 phase.

If you have any questions on these instructions or how to wire up the disconnect box, please contact your local

dealership which sold you the mill.

Page 7 of 26 7/9/19

LUBRICATION / SPECIFICATIONS

SPECIFICATIONS

Model LPE 500 LPE 700

Roll Corrugation (Teeth Per Inch)............................ 4, 6 1/2, 8, 10, or 14.................... 4, 6 1/2, 8, 10, or 14

Roll Size .............................................................................. 9” Dia. x 10” Long.......................9” Dia. x 14” Long

Power Requirements

Minimum Horsepower.......................................................... 5.......................................................7.5

Maximum Horsepower....................................................... 7.5 ..................................................... 10

Overall Height (With Legs*).......................................................39” ................................................... 39”

Overall Height (Without Legs*)................................................24” ...................................................24”

Overall Height (Without Legs*) (With Auger Base*)....31 1/2” .............................................31 1/2”

Overall Length............................................................................. 43 1/2”............................................ 43 1/2”

Overall Width...................................................................................28” ................................................... 32”

*Discharge Auger (Diameter).....................................................8”...................................................... 8”

Length................................................................................. 5’ or 10’ ...........................................5’ or 10’

Drive ........................................................................................ Belt.................................................. Belt

*OPTIONS:

Auger Base

Leg Pack

Discharge Auger

LUBRICATION - DANGER: Do not attempt to lubricate, adjust or service the roller mill while it is in operation.

BEARINGS - All pillow block bearings are sealed and as a general rule, REQUIRE NO LUBRICATION. However, the

bearing manufacturer does furnish grease zerks and recommends that the bearings be greased before 1/3 of the

bearing’s calculated life elapses. Usually a pump or two of grease every 100 hours of operation will be sucient.

IMPORTANT: DO NOT OVERGREASE! Overgreasing can cause damage to the bearing seal. Each time the bearings are

greased, be sure to check the condition of the grease lines on the drive side of the mill.

GEARBOX (Discharge Auger Option) - The gearbox is filled at the factory, but the oil level should be checked initially,

and periodically thereafter. It is very important to keep the gearbox from running dry. There will be a slight leakage

around the seals so expect to add grease from time to time. Automatic recommends SAE 80 W-90 multipurpose gear

lubricant.

Page 8 of 26 7/9/19

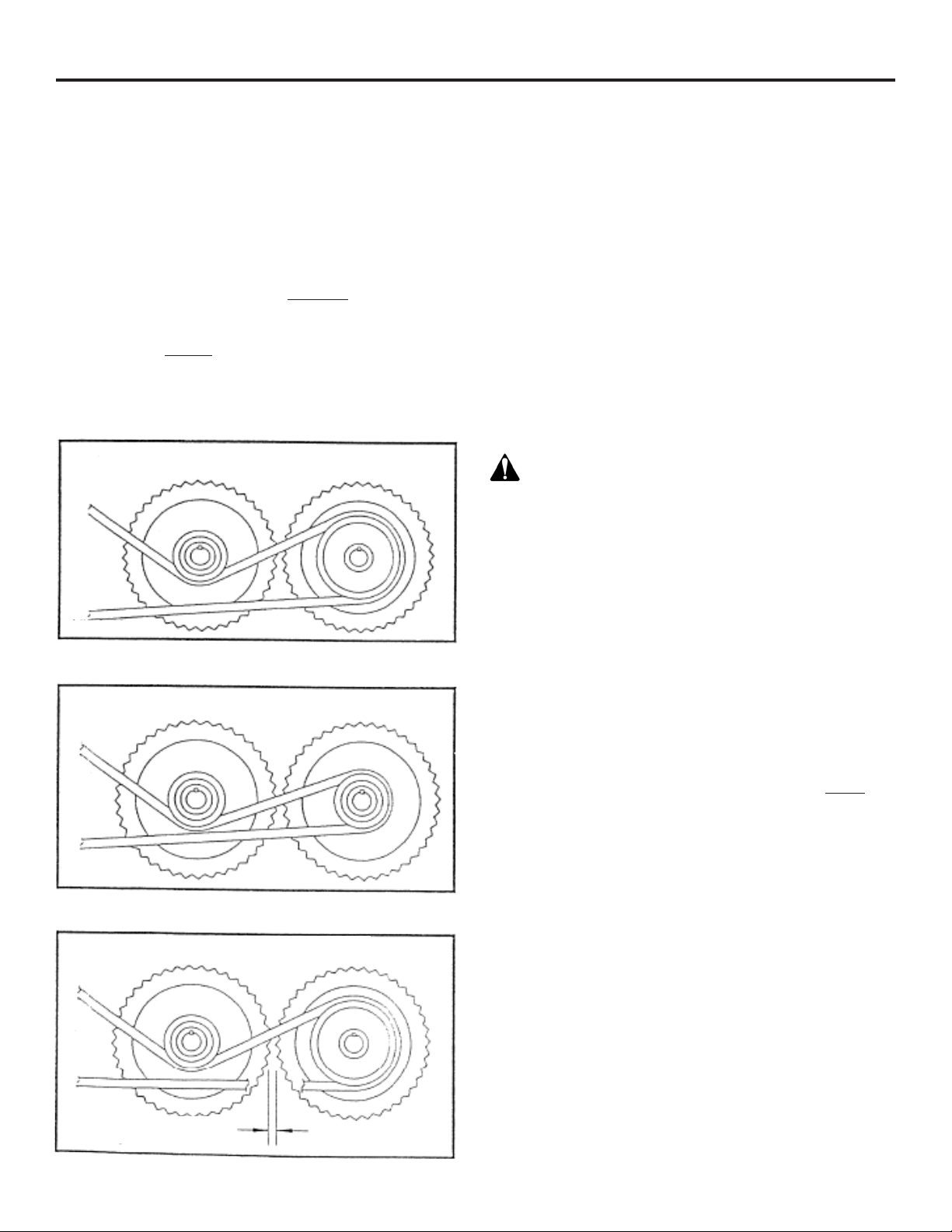

Figure 4

Figure 5

Figure 6

OPERATION / MAINTENANCE

OPTIONAL ROLL CONFIGURATION - This roller mill

is available with five dierent roll configurations and

comes standard with a dierential drive (See Figure 4).

Corrugation numbers refer to the number of corrugations

or “teeth” per inch. The larger the corrugation number,

the smaller the particle size produced. Changing the roll

gap is the next preferred method for adjusting particle

size. (See Adjusting Rolls section, page 6) In addition,

feed consistency, or particle size, may be adjusted by

changing the relative drive roll and idler speeds. This

is accomplished by replacing the drive roll pulley with

a pulley the same size as that of the idler roll. (See

Figure 5). However, when the drive method is changed,

it will generally reduce the capacity of the mill and

not allow as fine a particle size. Consult your dealer, or

Automatic Equipment for recommendations regarding roll

configuration by any other method than those approved

by Automatic Equipment will void the warranty.

MAINTENANCE - Automatic roller mills are manufactured

from the best materials and workmanship available.

Simple adjustments and minimum maintenance have been

emphasized in their engineering. Although all components

of your roller mill are tested and properly adjusted

before it leaves the factory, some may require additional

adjustment after a break in period.

After your roller mill has been in operation for a few hours,

examine the entire machine for loose bolts, set screws,

lock collars, belts, etc. This initial check is an important

first step in an ongoing program for keeping your roller

mill in top running condition and should be performed

periodically as part of the general maintenance of your

roller mill. Like any other implement, your roller mill

requires proper care and intelligence in operation. Misuse

and/or neglect will only cause unnecessary expense and

dissatisfaction.

WARNING: SHIELDS AND GUARDS ARE PROVIDED

FOR YOUR PROTECTION. Although some shields and

guards may need to be removed or opened for servicing

and adjustments, they should always be replaced or

closed before operation resumes.

BELTS - All belts should be inspected for proper

alignment and tension after a few hours of operation.

Tension should be measured between the motor and flat

pulley. The belt should deflect 3/16” using approximately

60 pounds of force. Periodic checks of all belts should be

made to ensure proper alignment, correct tension levels

and to detect worn or deteriorating belts.

PULLEY SET SCREW ADJUSTMENT - The belt drive

system on your roller mill includes several pulleys which

use a setscrew to hold them in place on the key. ONLY

“Cup Point” set screws with knurled tips should be used.

To correctly seat the set screw, turn it “IN” and “OUT”

several times before tightening in place. This will wear a

groove in the key for the setscrew to seat in.

ROLLER TENSION SPRINGS - The roller tension springs

on the idler roll are set at the factory to maintain the

correct amount of pressure. They should be 4 1/2” long

±1/8”. The springs allow the rolls to separate so foreign

objects such as nails, bolts, stones, gravel, etc. may

pass between the rolls. A magnetic grate is standard

on the roller mill and should remove most of the metal

items, but in the event that something gets through, the

spring action will help prevent the roll teeth from being

damaged. If the rolls become out of alignment and require

readjustment, the springs may require similar adjustments.

(See Realigning Rolls, Page 8)

DIFFERENTIAL DRIVE

Idler (left)

SAME SPEED DRIVE

Idler (left)

ROLL SPACING

.015”

Idler (left)

Page 9 of 26 7/9/19

6 Once the roll teeth

touch, turn the

nuts (9) IN about

1/4 to 1/2 flat on

the nut. (See

Figure 7).

NOTE: There are

six flat sides on

each nut. Turning

one full flat means

turning the nut so

that the flats

advance one

position.

7 Hold the nuts (9) in

place and tighten the jam nuts (10) on both sides of

the mill. Recheck that the rolls do not touch by

repeating step 5.

8 Move the roll spacing adjustment handle 5 each way

from center and check to assure the rolls are not

touching. Readjust if necessary. Be sure to tighten jam

nuts (10) when finished.

9 If adjustments were made, measure the length of the

springs (5). They should be 4 1/2” long ±1/8”. If

spring adjustment is needed, loosen the jam nut

(2) on the spring side and move spring nut (3) until

the correct spring length is established. Once

adjusted, tighten the jam nut (2) to hold setting.

10 Make a final check of the rolls for parallel and roll

gap. You may need to use a feeler gauge for 8 cut and

finer rolls. Reinstall the drive belt and shields. Be sure

to remove any tools from the machine before

restarting.

Figure 7

Figure 8

REALIGNING ROLLS

REALIGNING ROLLS - If the rolls ever become out of

alignment (more gap on one end of the roll pair than

the other) they must be realigned to maintain feed

consistency and prolong the life of the rolls. To accomplish

this, follow the instructions below.

DANGER: Before attempting to service your

roller mill be sure to follow the SAFETY SHUTDOWN

PROCEDURE on page 2.

1 Remove the drive belt from all the pulleys and lay it

aside. Loosen the jam nut (item 10) on one of the

sides of the mill. It may be necessary to loosen and

adjust both sides to acquire the correct settings. This

will be determined by how far out of parallel the rolls

are.

2 Adjust the other nut (9) on the same side, until the

rolls are parallel. To check for roll spacing, a strip

of metal banding works well but any strip of metal

approximately 1/32” thick will also work. Slide the

strip between the rolls and verify the roll spacing is

the same along their entire length. Check the spacing

3 or 4 times with the rolls at various rotated positions

to assure the rolls are as close to parallel as possible.

NOTE: Rolls will vary a few thousandths of an inch

in diameter along their length, be sure to check for

the tightest gap.

3 With the rolls parallel you can now set the roll

spacing. Place the roll spacing adjustment handle

straight up with the indicator straight down. This will

place the rolls at their closest possible setting.

4 WARNING: Be careful not to get your hands

between the rolls or between the rolls and the basic

channel.

WARNING: Do not power the mill with the

motor. This creates a personal danger to you and

may cause damage to the rolls if they are touching.

5 By hand, spin the rolls in the same direction

(clockwise) at dierent speeds. Strike the idler roll

shaft at the bearing, towards the drive roll, with a

rubber mallet to ensure that the idler bearing

mount (6) is free to allow the rolls to be at their

closest position. With the rolls spinning freely at

dierent speeds, turn the nuts (9) on both sides of

the mill out evenly until you hear the roll teeth

touch. They will make a ticking sound that should

be easily heard. This is to ensure that the rolls do

not move closer together with the vibration of the

mill. Some additional adjustment may be needed

at this time.

292-1329 5/94

ROLL SPACING

ADJUSTMENT

ORIGINAL

1/2 FLAT

1/4 FLAT

1 FLAT

1

1

1

1

2

2

2

2

3

3

3

3

4

4

4

4

5

5

5

5

6

6

6

6

Page 10 of 26 7/9/19

REPLACEMENT PARTS

DRIVE ASSEMBLY....................................................................................... 11

BASIC ........................................................................................................12-13

HOPPER ASSEMBLY............................................................................14-15

PRIMARY ASSEMBLY ..........................................................................16-17

BELT DRIVE SHIELDS .............................................................................. 18

AUGER BASE (option)............................................................................. 19

DISCHARGE AUGER (option)........................................................ 20-21

REPLACEMENT PARTS

When ordering parts for your roller mill, please state your needs with the following information:

COMPLETE COMPLETE

MODEL NO. SERIAL NO. PART NO. DESCRIPTION

LPE500X8 000000 61-3967 Weldment, Idler Bearing Mount

When you order in this way, you can be certain the correct part will be delivered in the shortest time

possible.

IMPORTANT: Use only genuine factory replacement parts on your roller mill. Do not substitute homemade

or non-typical parts. If a bolt is lost or in need of replacement, for your safety and the preservation of your

roller mill, be sure to use a replacement bolt of the same grade (Usually Grade 5).

Repair parts may be ordered through your nearest Automatic dealer. If there is no dealer in your area, write

or call Automatic Equipment Mfg. Co., Pender, Nebraska 68047, phone (402) 385- 3051.

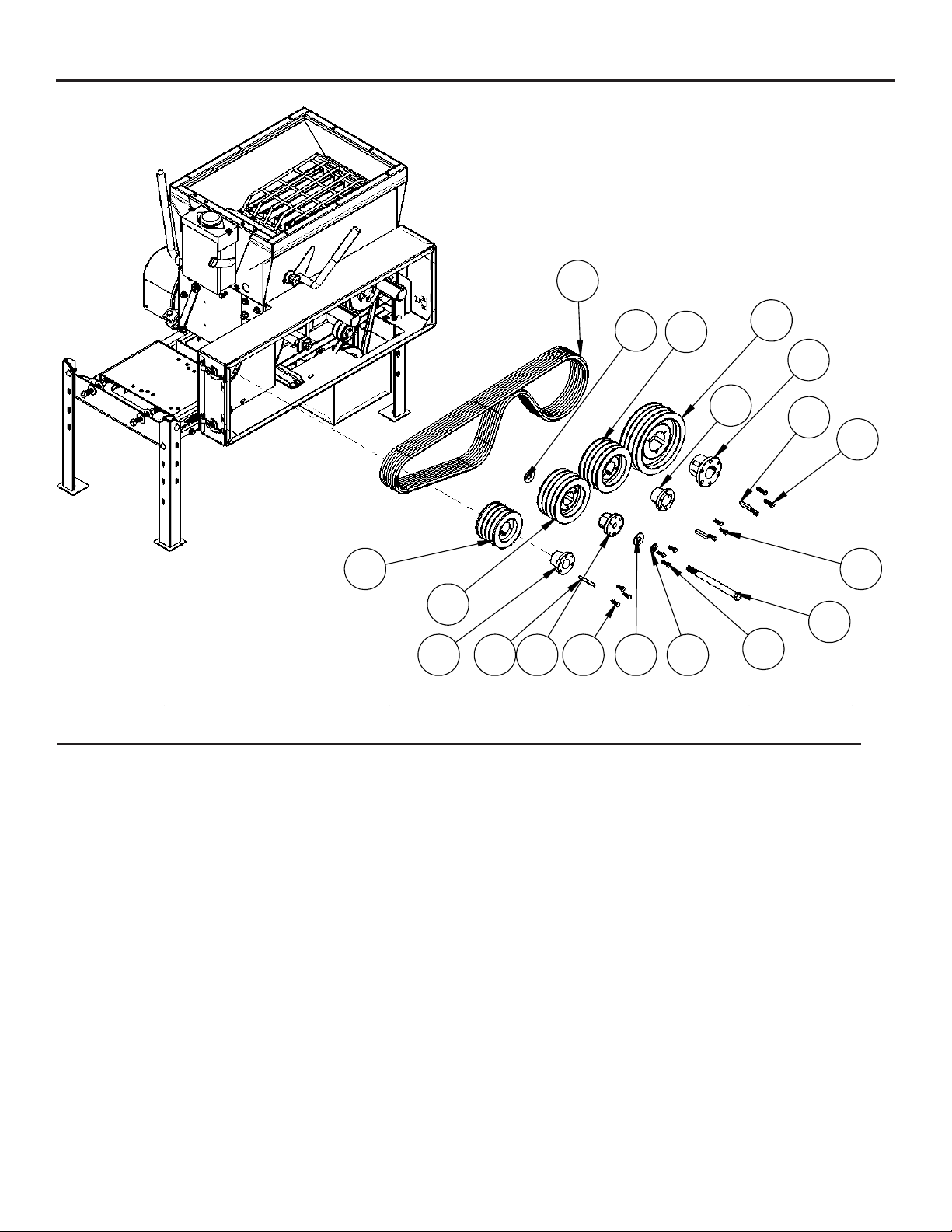

Page 11 of 26 7/9/19

16

711

13

9 3

4

5

3

87

14

LPE500 & 700 DRIVE ASSEMBLY

2

1

12

10

6

14

15

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

100-0224

KEY, 3/8 X 3/8 X 2

2

2

100-0304

KEY, 5/16 X 5/16 X 2 3/4

1

3

201-0120

5/16-18 X 1 BOLT, HH GRD5, ZP

6

4

201-0368

3/8-16 X 1-1/4, BOLT HH GRD5, ZP

3

5

201-0469

5/16-18 X 1 HEX BOLT, GRD 5, ZP

3

6

201-1107

5/8-11 X 9" HH BOLT, ZP

1

7

203-0006

5/8" FLAT WASHER, ZP

2

8

203-0013

WASHER, 5/8 LOCK, ZP

1

9

205-0052

BUSHING, P1-1 3/8

1

10

205-0054

BUSHING, P1-1 3/4

1

11

205-0209

SHEAVE, 4TB86 BROWNING

1

12

205-0221

BUSHING, Q1-1 3/4, BROWNING

1

13

205-0292

SHEAVE, 4TB48, BROWNING

1

14

205-0307

SHEAVE, 4TB62 BROWNING

2

15

205-0414

BUSHING, P1-BB X 5/8'

1

16

251-0083

BELT-V, BB85

4

DRIVE ASSEMBLY

Item No. Part No. Description Qty.

1.................................100-0224 ...........................3/8” x 3/8” x 2” Key ..........................................................2

2.................................100-0304 ...........................5/16” x 5/16” x 2-3/4” Key................................................1

3.................................201-0120 ...........................5/16”-18 x 1” Hex Head Bolt, Grade 5, ZP ......................6

4.................................201-0368 ...........................3/8”-16 x 1-1/4” Hex Head Bolt, Grade 5, ZP ..................3

5.................................201-0469 ...........................5/16” -18 x 1” Hex Head Bolt, Grade 5, ZP .....................3

6.................................201-1107 ...........................5/8”-11 x 9” Hex Head Bolt, ZP........................................1

7.................................203-0006 ...........................5/8” Flat Washer, ZP........................................................2

8.................................203-0013 ...........................5/8” Lock Washer, ZP ......................................................1

9.................................203-0052 ...........................P1 - 1-3/8” Bushing .........................................................1

10...............................203-0054 ...........................P1 - 1-3/4” Bushing .........................................................1

11 ...............................205-0209 ...........................4TB86 Browning Sheave.................................................1

12...............................205-0221 ...........................Q1 - 1-3/4” Browning Bushing .........................................1

13...............................205-0292 ...........................4TB48 Browning Bushing................................................1

14...............................205-0307 ...........................4TB62 Browning Bushing................................................2

15...............................205-0414 ...........................P1-BB x 5/8” Bushing ......................................................1

16...............................251-0083 ...........................BB85 Belt-V.....................................................................4

Page 12 of 26 7/9/19

BASIC

1

3

11

13

7

10

2

4

8 1422

35

40

3

30

16

15

21

20

3233

11

36

39

41

43

38

34

5

6

LPE500 & 700 BASIC ASSEMBLY

18

26

23

24

27

2935

37

42

12

17

9

28

19

31

14

25

Page 13 of 26 7/9/19

BASIC

Item No. Part No. Description Qty.

1...................................... 53-0005 ...................................1-3/4” Pillow Block Bearing ............................................................4

2...................................... 61-1968 ...................................Spring Center .................................................................................2

3...................................... 61-3966 ...................................Take Up Rod, LPE..........................................................................2

4...................................... 61-3967 ...................................Idler Bearing Mount, LPE...............................................................2

5...................................... 61-3968 ...................................Drive Bearing Stop, LPE ................................................................1

6...................................... 61-3969 ...................................Idler Bearing Stop, LPE..................................................................1

7...................................... 61-3984 ...................................LPE500 Basic.................................................................................1

........................................ 61-4009 ...................................LPE700 Basic.................................................................................1

8...................................... 61-4018 ...................................Cam Locking Handle, LPE.............................................................1

9...................................... 61-4025 ...................................LPE500 Cam Adjustment Rod .......................................................1

........................................ 61-4004 ...................................LPE700 Cam Adjustment Rod .......................................................1

10.................................... 71-0450 ...................................LPE500 Roll, 4 Cut.........................................................................2

........................................ 71-0451 ...................................LPE500 Roll, 6.5 Cut......................................................................2

........................................ 71-0452 ...................................LPE500 Roll, 8 Cut.........................................................................2

........................................ 71-0453 ...................................LPE500 Roll, 10 Cut.......................................................................2

........................................ 71-0454 ...................................LPE500 Roll, 12 Cut.......................................................................2

........................................ 71-0455 ...................................LPE500 Roll, 14 Cut.......................................................................2

........................................ 71-0457 ...................................LPE700 Roll, 4 Cut.........................................................................2

........................................ 71-0458 ...................................LPE700 Roll, 6.5 Cut......................................................................2

........................................ 71-0459 ...................................LPE700 Roll, 8 Cut.........................................................................2

........................................ 71-0460 ...................................LPE700 Roll, 10 Cut.......................................................................2

........................................ 71-0461 ...................................LPE700 Roll, 12 Cut.......................................................................2

........................................ 71-0462 ...................................LPE700 Roll, 14 Cut.......................................................................2

11 .................................... 100-1268 .................................Cam Adjustment Rocker, LPE........................................................2

12.................................... 101-4962 .................................10 GA Roll Wear Plate, LPE ..........................................................1

13.................................... 101-4963 .................................14 GA Roll Wear Plate, LPE ..........................................................1

14.................................... 101-4982 .................................LPE500 Cam Side End Plate.........................................................1

........................................ 101-5044 .................................LPE700 Cam Side End Plate.........................................................1

15.................................... 101-4993 .................................Drive Roll Cover, LPE ....................................................................2

16.................................... 101-4994 .................................LPE500 Drive Roll Side End Plate.................................................1

........................................ 101-5049 .................................LPE700 Drive Roll Side End Plate.................................................1

17.................................... 102-4003 .................................Cam Adjustment Pivot, LPE ...........................................................2

18.................................... 102-4006 .................................Flat Bearing Stop, Bolt On, LPE.....................................................2

19.................................... 150-0028 .................................LPE500 Rubber Baes..................................................................2

........................................ 150-0037 .................................LPE700 Rubber Baes..................................................................2

20.................................... 201-0024 .................................1/2”-13 x 1” Carriage Bolt, Grade 5................................................4

21.................................... 201-0034 .................................3/8”-16 x 1” Carriage Bolt, Grade 5, ZP .......................................14

22.................................... 201-0081 .................................3/8”-16 x 3/4” Hex Head Bolt, Grade 2, ZP....................................2

23.................................... 201-0111..................................1/4”-20 x 3/4” Slot Truss Head Screw ............................................6

24.................................... 201-0346 .................................3/4”-10 x 4” Hex Head Bolt, Grade 8, ZP.......................................2

25.................................... 201-0351 .................................5/8”-11 x 2” Hex Head Bolt, Grade 5, ZP .......................................6

26.................................... 201-0368 .................................3/8”-16 x 1-1/4” Hex Head Bolt, Grade 5, ZP.................................2

27.................................... 201-0490 .................................1/2”-13 x 3” Hex Head Bolt, Grade 5, ZP.......................................2

28.................................... 201-0553 .................................1/4”-20 x 1/2” Hex Washed Type F TCS, ZP..................................6

29.................................... 202-0003 .................................3/8”-16 Hex Nut, ZP .......................................................................2

30.................................... 202-0006 .................................5/8”-11 Hex nut.............................................................................14

31.................................... 202-0069 .................................1/4”-20 Hex Flange Whiz Lock Nut, ZP..........................................6

32.................................... 202-0071 .................................3/8”-16 Whiz Flange Lock Nut, ZP...............................................14

33.................................... 202-0072 .................................1/2”-13 Hex Flange Whiz Lock Nut, ZP..........................................4

34.................................... 202-0094 .................................1/2”-13 Hex Nylon Insert Lock Nut, ZP ..........................................1

35.................................... 203-0010 .................................3/8” Lock Washer, ZP.....................................................................4

36.................................... 203-0013 .................................5/8” Lock Washer, ZP.....................................................................6

37.................................... 203-0066 .................................18 GA x 1-1/4” x 3/4” Machine Bushing .........................................8

38.................................... 220-0032 .................................3/16” x 1-1/4” Sping Pin, ZP...........................................................2

39.................................... 222-0078 .................................Comp Spring ..................................................................................2

40.................................... 224-0327 .................................1/4”-28 Grease Zerk.......................................................................2

41.................................... 224-0375 .................................1/8” NPT x 45 Degree Grease Zerk ...............................................2

42.................................... 224-0425 .................................1/4”-28 Self-Tap Straight Zerk ........................................................2

43.................................... 224-0469 .................................1/4”-28 Male to NPT Female Set-Up..............................................2

Page 14 of 26 7/9/19

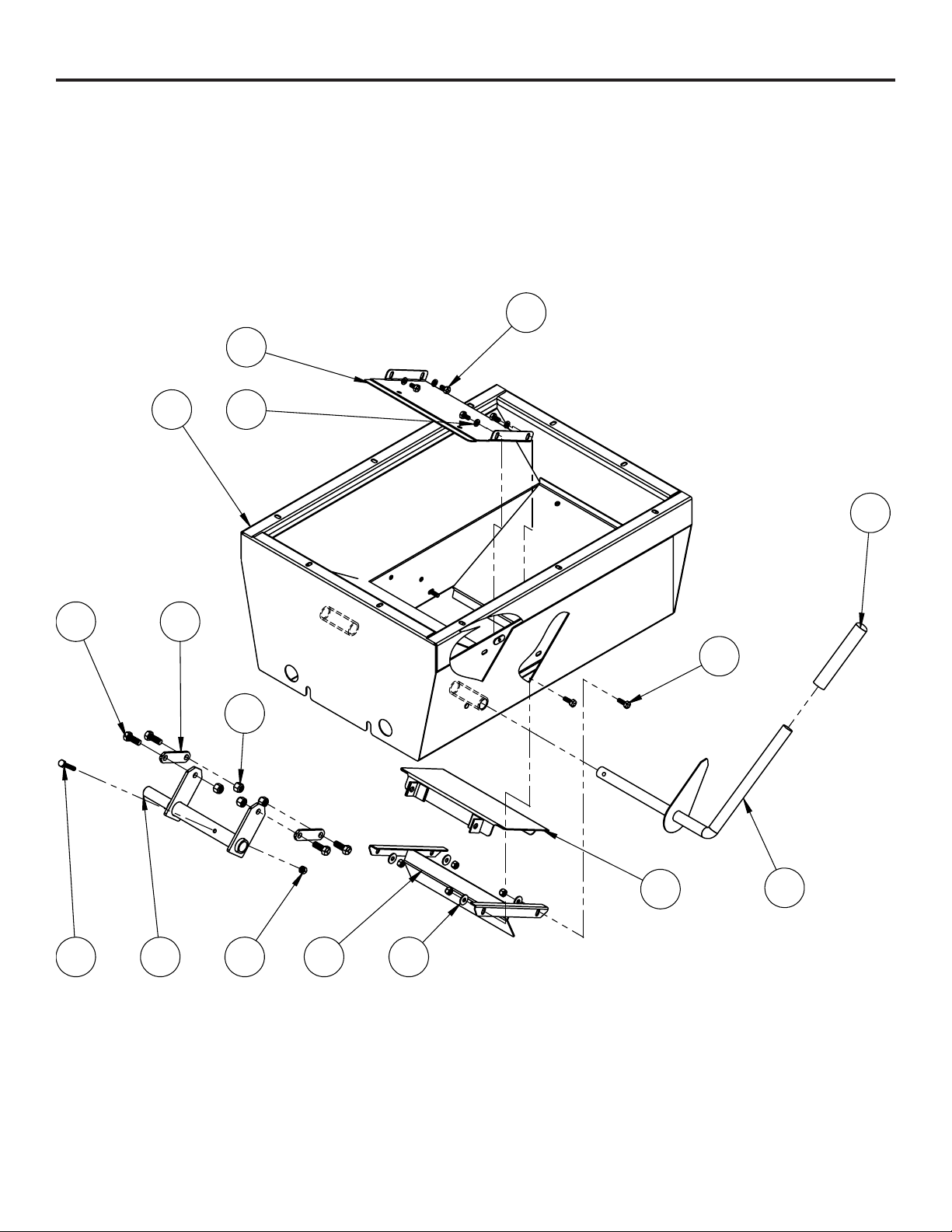

HOPPER ASSEMBLY

LPE500 & 700 HOPPER ASSEMBLY

5

6

14

2 3

710

8

9

11 13

12

14

15

16

Page 15 of 26 7/9/19

HOPPER ASSEMBLY

Item No. Part No. Description Qty.

1.................................61-3951 .............................LPE500 Slide Gate..........................................................1

...................................61-4000 .............................LPE700 Slide Gate..........................................................1

2.................................61-3952 .............................LPE500 Gate Rod ...........................................................1

...................................61-4001 .............................LPE700 Gate Rod ...........................................................1

3.................................61-3953 .............................LPE500 Gate Holder .......................................................1

...................................61-4013 .............................LPE700 Gate Holder .......................................................1

4.................................61-3954 .............................Gate Handle ....................................................................1

5.................................61-3955 .............................LPE500 Hopper...............................................................1

...................................61-4002 .............................LPE700 Hopper...............................................................1

6.................................61-3956 .............................LPE500 Gate Slope.........................................................1

...................................61-4003 .............................LPE700 Gate Slope.........................................................1

7.................................102-3996 ...........................Bolted Link Arm ...............................................................2

8.................................201-0050 ...........................1/4”-20 x 3/4” Hex Head Bolt, Grade 5, ZP .....................4

9.................................201-0193 ...........................1/4”-20 x 1/2” Hex Head Bolt, Grade 5, ZP .....................4

10...............................201-0443 ...........................3/8”-16 x 1” Hex Head Bolt, Grade 5, ZP ........................4

11 ...............................201-0448 ...........................1/4”-20 x 1-1/2” Hex Head Bolt, Grade 5, ZP ..................1

12...............................202-0090 ...........................3/8”-16 Hex Nylon Insert Lock Nut, ZP............................4

13...............................202-0102 ...........................1/4”-20 Hex Nylon Nut, ZP ..............................................5

14...............................203-0001 ...........................1/4” Flat Washer, ZP........................................................4

15...............................203-0008 ...........................1/4” Lock Washer, ZP ......................................................4

16...............................290-0300 ........................... .75 Round x 5” Vinyl Handle...........................................1

Page 16 of 26 7/9/19

PRIMARY ASSEMBLY

LPE500 & 700 PRIMARY ASSEMBLY

1

2

3

5

6

7

8

9

10

11

1314

15

16

17

18

20

22

23

24

25

26

31

32

28 27

29

30

33

4

12

21

19

Page 17 of 26 7/9/19

PRIMARY ASSEMBLY

Item No. Part No. Description Qty.

1.................................61-3961 .............................LPE500 Magnetic Grate ..................................................1

...................................61-4005 .............................LPE700 Magnetic Grate ..................................................1

2.................................61-3964 .............................LPE500 Frame ................................................................1

...................................61-4010 .............................LPE700 Frame ................................................................1

3.................................61-3970 .............................Cam Handle ....................................................................1

4.................................61-3971 .............................Leg ..................................................................................4

5.................................61-3972 .............................LPE500 Motor Mounting Plate ........................................1

...................................61-4011 .............................LPE700 Motor Mounting Plate ........................................1

6.................................62-3066 .............................LPE500 hopper Assembly ...............................................1

...................................62-3089 .............................LPE700 hopper Assembly ...............................................1

7.................................62-3207 .............................LPE Disconnect Box Assembly .......................................1

8.................................93-0527 .............................LPE500 x 4 Basic Assembly............................................1

...................................93-0528 .............................LPE500 x 6.5 Basic Assembly.........................................1

...................................93-0529 .............................LPE500 x 8 Basic Assembly............................................1

...................................93-0530 .............................LPE500 x 10 Basic Assembly..........................................1

...................................93-0531 .............................LPE500 x 12 Basic Assembly..........................................1

...................................93-0532 .............................LPE500 x 14 Basic Assembly..........................................1

...................................93-0534 .............................LPE700 x 4 Basic Assembly............................................1

...................................93-0535 .............................LPE700 x 6.5 Basic Assembly.........................................1

...................................93-0536 .............................LPE700 x 8 Basic Assembly............................................1

...................................93-0537 .............................LPE700 x 10 Basic Assembly..........................................1

...................................93-0538 .............................LPE700 x 12 Basic Assembly..........................................1

...................................93-0539 .............................LPE700 x 14 Basic Assembly..........................................1

9.................................100-0544 ...........................3/16” x 3/16” x 1” Key ......................................................1

10...............................101-3323 ...........................Idler Support, Third Rod Washer.....................................1

11 ...............................200-1419 ...........................3/4” Hole Plug..................................................................1

12...............................201-0008 ...........................3/8”-16 x 1-1/4” Carriage Bolt, Grade 5...........................8

13...............................201-0024 ...........................1/2”-13 x 1” Carriage Bolt, Grade 5 .................................4

14...............................201-0120 ...........................5/16”-18 x 1” Hex Head Bolt, Grade 5, ZP ......................8

15...............................201-0193 ...........................1/4”-20 x 1/2’ Hex Head Bolt, Grade 5, ZP......................6

16...............................201-0368 ...........................3/8”-16 x 1-1/4” Hex Head Bolt, Grade 5.........................2

17...............................201-0377 ...........................1/2”-13 x 5-1/2” Hex Head, Grade 5, FT..........................2

18...............................201-0527 ...........................1/4”-28 x 5/16” Set Screw................................................2

19...............................201-0537 ...........................5/16”-18 x x1-1/2” Bolt Flsckt Head, FT...........................1

20...............................202-0012 ...........................1/2-13 Square Nut Plate (Not Plated)..............................2

21...............................202-0071 ...........................3/8”-16 Whiz Flange Lock Nut, ZP ..................................8

22...............................202-0072 ...........................1/2”-13 Hex Flange Whiz Lock Nut, ZP...........................4

23...............................202-0090 ...........................3/8”-16 Hex Nylon Insert Lock Nut, ZP............................2

24...............................202-0094 ...........................1/2”-13Hex Nylon Insert Lock Nut, ZP.............................2

25...............................202-0102 ...........................1/4”-20 Hex Nylon Nut, ZP ..............................................2

26...............................203-0001 ...........................1/4” Flat Washer, ZP........................................................6

27...............................203-0002 ...........................5/16” Flat Washer, ZP......................................................7

28...............................203-0003 ...........................3/8” Flat Washer, ZP........................................................4

29...............................203-0005 ...........................1/2” Flat Washer ..............................................................4

30...............................203-0008 ...........................1/4” Lock Washer, ZP ......................................................4

31...............................203-0009 ...........................5/16 Lock Washer............................................................8

32...............................290-0023 ...........................5/16”-18 Plastic Knob ......................................................1

33...............................290-0300 ............................75 Round x 5” Vinyl Handle............................................2

Page 18 of 26 7/9/19

5

1

15 14

7

10 6

3

8

7

4

10

16

17

12

11

LPE500 & 700 BELT DRIVE SHIELDS

9

13 2

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

61-3977

WLDM'T, SHROUD, LPE

1

2

100-0899

CABLE, SHIELD TETHER, LPE

1

3

101-2532

FILLER, BELT SHIELD

1

4

101-4986

SHIELD, MOTOR HOLE, LPE

1

5

101-5011

SHIELD, DRIVE PULLEYS, LPE

1

6

201-0112

1/4-20 X 1/2 SLOT TRUSS HEAD SCREW

2

7

201-0120

5/16-18 X 1 BOLT, HH GRD5, ZP

9

8

202-0069

1/4-20 HEX FLANGE WHIZ LOCK NUT, ZP

2

9

202-0070

5/16-18 HEX FLANGE WHIZ LOCK NUT ZP

2

10

203-0002

WASHER, 5/16 FLAT, ZP

9

11

203-0009

5/16 LOCK WASHER

8

12

224-0468

1/8" FEMALE NPT GREASE ZERK

2

13

225-0049

SWAGING SLEEVE, 3/32 CABLE

1

14

229-0132

LATCH, TENSION

4

15

229-0988

POP RIVET, 3/16 X 1/16-1/8 SB6-2

8

16

253-0184

GREASE LINE, 1/8 X 16

1

17

253-0261

GREASE LINE, 1/8 X 22

1

BELT DRIVE SHIELDS

Item No. Part No. Description Qty.

1.................................61-3977 .............................Shroud.............................................................................1

2.................................100-0899 ...........................Shield Tether Cable .........................................................1

3.................................101-2532 ...........................Belt Shield Filler ..............................................................1

4.................................101-4986 ...........................Motor Hole Shield............................................................1

5.................................101-5011 ...........................Drive Pulleys Shield ........................................................1

6.................................201-0112 ...........................1/4”-20 x 1/2” Slot Truss Head Screw .............................2

7.................................201-0120 ...........................5/16”-18 x 1” Hex Head Bolt, Grade 5, ZP ......................9

8.................................202-0069 ...........................1/4”-20 Hex Flange Whiz Lock Nut, ZP...........................2

9.................................202-0070 ...........................5/16”-18 Hex Flange Whiz Lock Nut, ZP.........................2

10...............................203-0002 ...........................5/16” Flat Washer, ZP......................................................9

11 ...............................203-0009 ...........................5/16” Lock Washer ..........................................................8

12...............................224-0468 ...........................1/8” Female NPT Grease Zerk ........................................2

13...............................225-0049 ...........................3/32” Cable Swaging Sleeve ...........................................1

14...............................229-0132 ...........................Tension Latch ..................................................................4

15...............................229-0988 ...........................3/16” x 1/16”-1/8 SB6-2 Pop Rivet ..................................8

16...............................253-0184 ...........................1/8” x 16” Grease Line.....................................................1

17...............................253-0261 ...........................1/2” x 22” Grease Line.....................................................1

Page 19 of 26 7/9/19

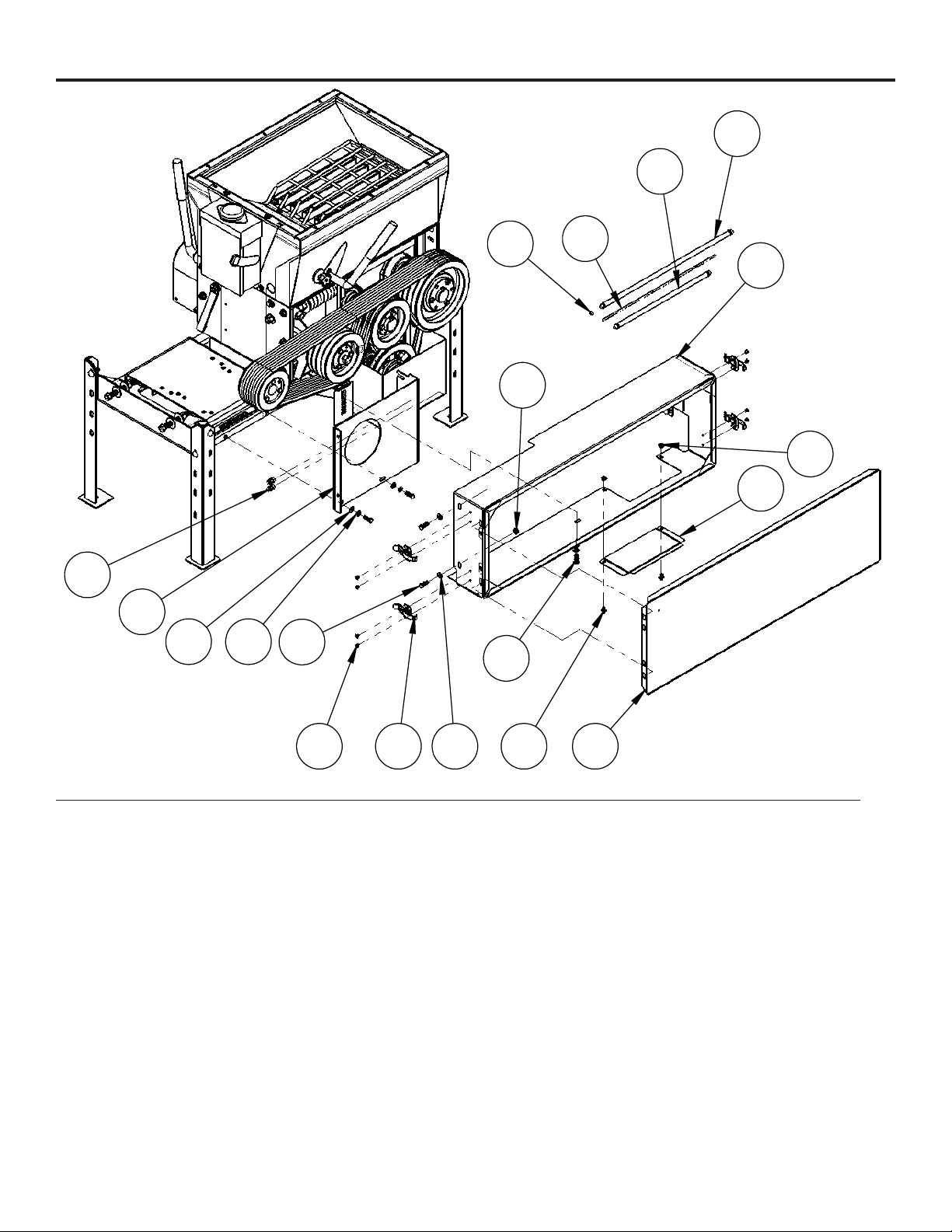

AUGER BASE (Option)

1

2

3

4

5

6

78

9

10

11

12

1315

14

LPE500 & 700 AUGER BASE (OPTIONAL)

11

Item No. Part No. Description Qty.

1.................................61-3975 .............................Auger Base Leg...............................................................2

2.................................61-3976 .............................Auger Base Shield...........................................................1

3.................................62-3067 .............................LPE500 Auger Base Pack ...............................................1

4.................................63-1314 .............................Auger Base B & P Pack...................................................1

5.................................100-0545 ...........................1/4” X 1/4” x 2” Key .........................................................1

6.................................101-2306 ...........................Clean Out Door Cover.....................................................2

7.................................101-5010 ...........................Auger Base Leg Clamp ...................................................2

8.................................201-0007 ...........................3/8”-16 x 1” Hex Head Bolt, Grade 2, ZP ........................8

9.................................201-0120 ...........................5/16”-18 x 1” Hex Head Bolt, Grade 5, ZP ......................6

10...............................201-0351 ...........................5/8”-11 x 2” Hex Head Bolt, Grade 5, ZP.........................1

11 ...............................202-0070 ...........................5/16”-18 Hex Flange Whiz Lock Nut, ZP.......................10

12...............................202-0073 ...........................5/8”-11 Whiz Flange Lock Nut, ZP...................................1

13...............................203-0003 ...........................3/8” Flat Washer, ZP........................................................8

14...............................203-0006 ...........................5/8” Flat Washer, ZP........................................................4

15...............................203-0010 ...........................3/8” Lock Washer, ZP ......................................................8

Page 20 of 26 7/9/19

DISCHARGE AUGER (Option)

LPE500 & 700 DISCHARGE AUGER (OPTIONAL)

1

2

3

4

5

7

8

9

10

11

13

14 15 12

16

17

18

19

20

21

22

25

26

23 24

6

This manual suits for next models

1

Table of contents

Other Automatic Industrial Equipment manuals