Contents

Contents ........................................................................................................................................ I

Chapter 1 Instrument Introduction............................................................................................. 1

1.1 Components inspection ................................................................................................... 1

1.2 UV/Vis spectrophotometer and method........................................................................... 1

1.2.1 UV/Vis spectrophotometer method......................................................................... 1

1.2.2 UV/Vis spectrophotometer...................................................................................... 1

1.2.3 Condition of measure method ................................................................................ 2

1.3 Components description.................................................................................................. 3

1.3.1 Front view............................................................................................................... 3

1.3.2 Rear view ............................................................................................................... 4

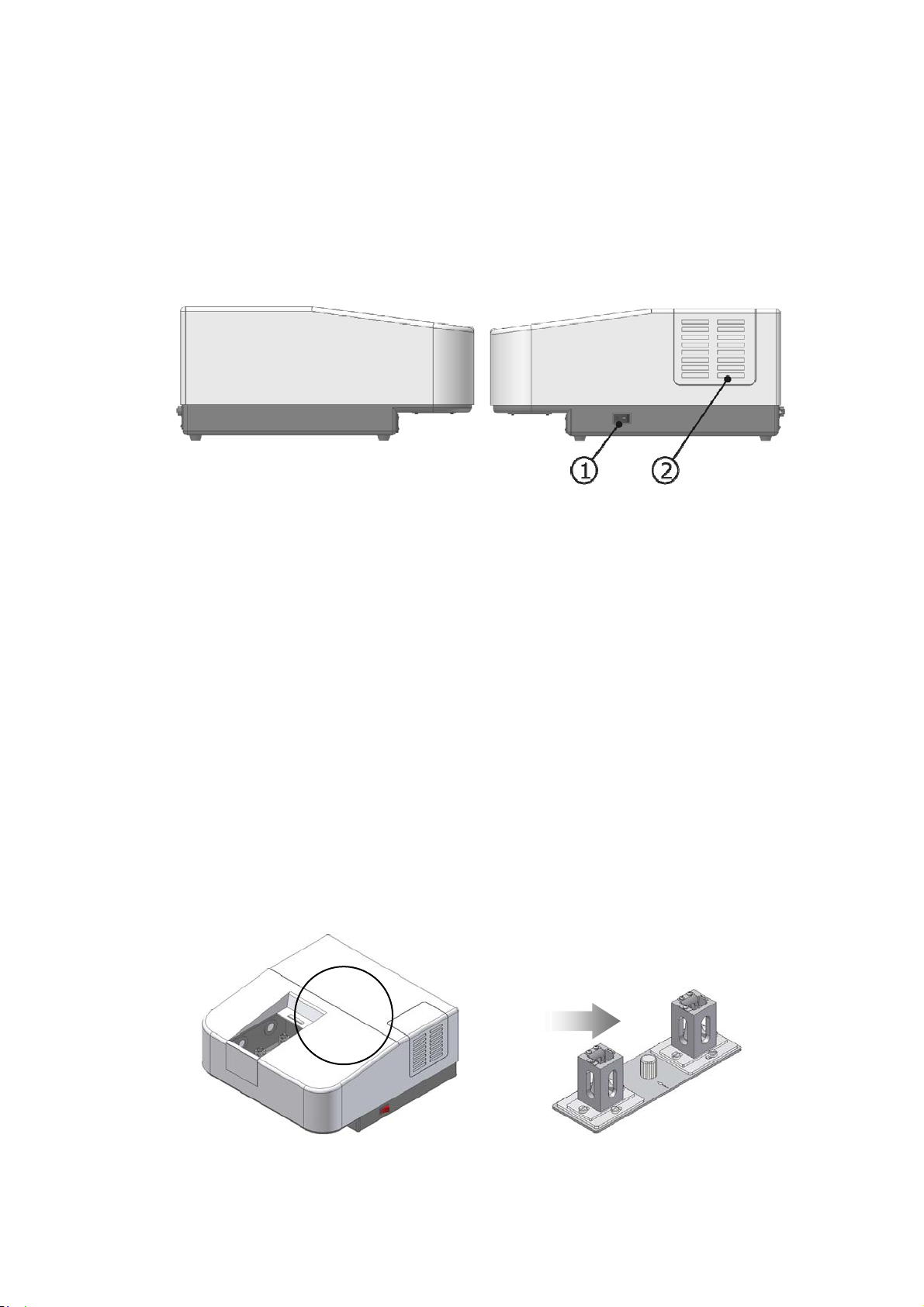

1.3.3 Side view ................................................................................................................ 5

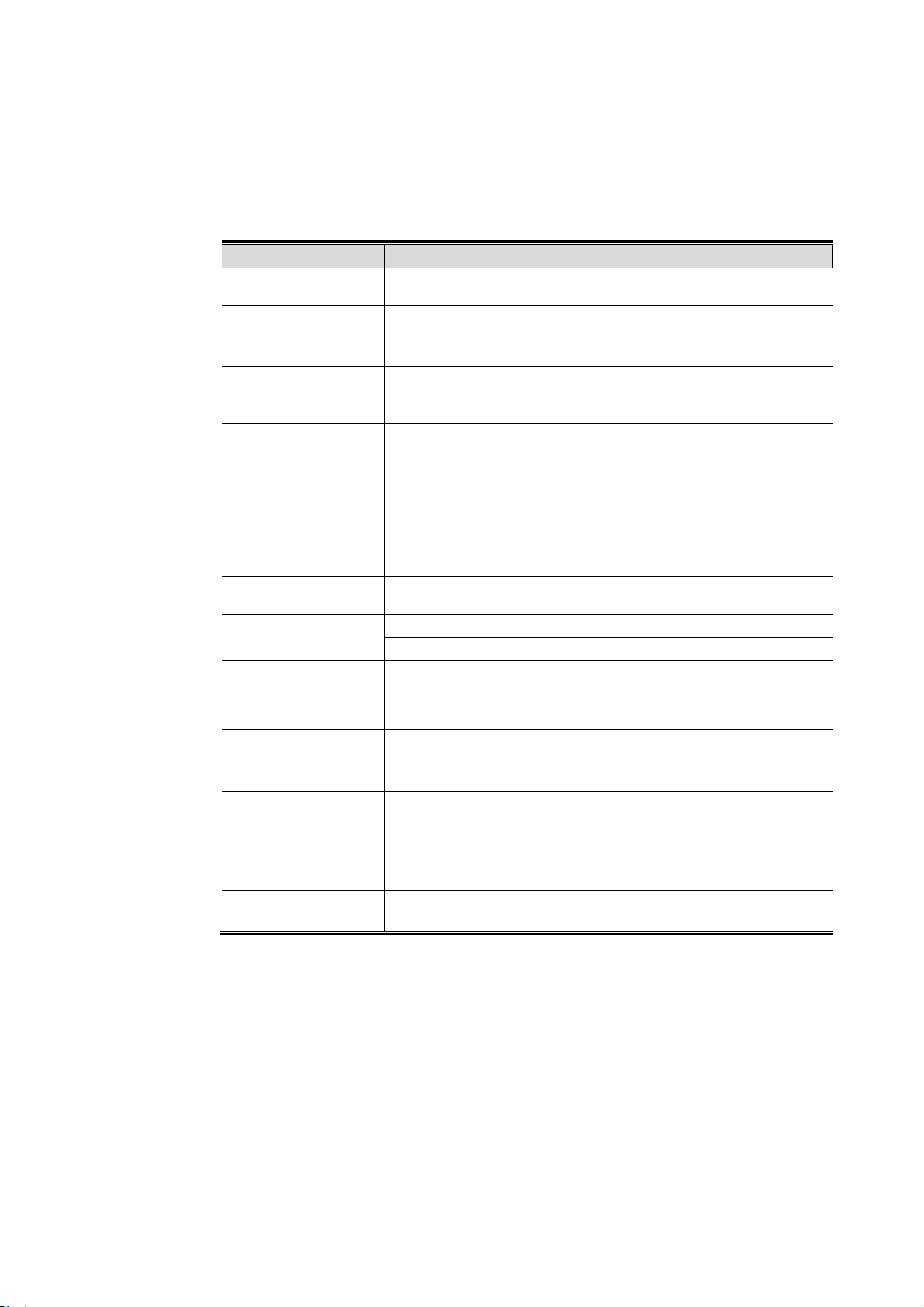

1.3.4 Sample cell holder .................................................................................................. 5

1.4 Specifications .................................................................................................................. 6

Chapter 2 Installation .................................................................................................................. 7

2.1 Installation location ........................................................................................................ 7

2.2 Installation ..................................................................................................................... 7

2.3 Start ............................................................................................................................... 9

2.4 Installation performance .............................................................................................. 10

2.4.1 The accuracy and reproducibility of wavelength................................................... 10

2.4.2 Flatness of the baseline........................................................................................ 12

Chapter 3 Instrument operation ............................................................................................... 13

3.1 About double beam measurement............................................................................... 13

3.1.1 What is double beam............................................................................................ 13

3.1.2 How to use a double beam instrument ................................................................. 14

3.2 Application examples................................................................................................... 15

3.2.1 Photometric measurement example ..................................................................... 15

3.2.2 Spectrum measurement example......................................................................... 16

3.2.3 Quantitative measurement example ..................................................................... 18

Chapter 4 Optional accessories ............................................................................................... 22

4.1 CH19-1 Thermostatic cell holder ................................................................................... 22

4.2 DS19-1 Angle-changeable solid sample holder............................................................. 23

4.3 IS19-1 Integrating sphere .............................................................................................. 24

4.4 LS19-1 Long pathlength cell holder............................................................................... 25

4.5 MH19-1 Micro cell holder............................................................................................... 26

4.6 MH19-2 Ultra-micro cell holder...................................................................................... 27

4.7 MR19ˉ1 Specular reflection accessory........................................................................ 28

4.8 MS19-1 Manual 8-cell holder......................................................................................... 29

4.9 PS19-2 Sipper pump ..................................................................................................... 30

4.10S19-1 Solid sample holder ............................................................................................ 32

4.11SS19-1 Short pathlength cell holder .............................................................................. 33