RB-473-C02G

Contents

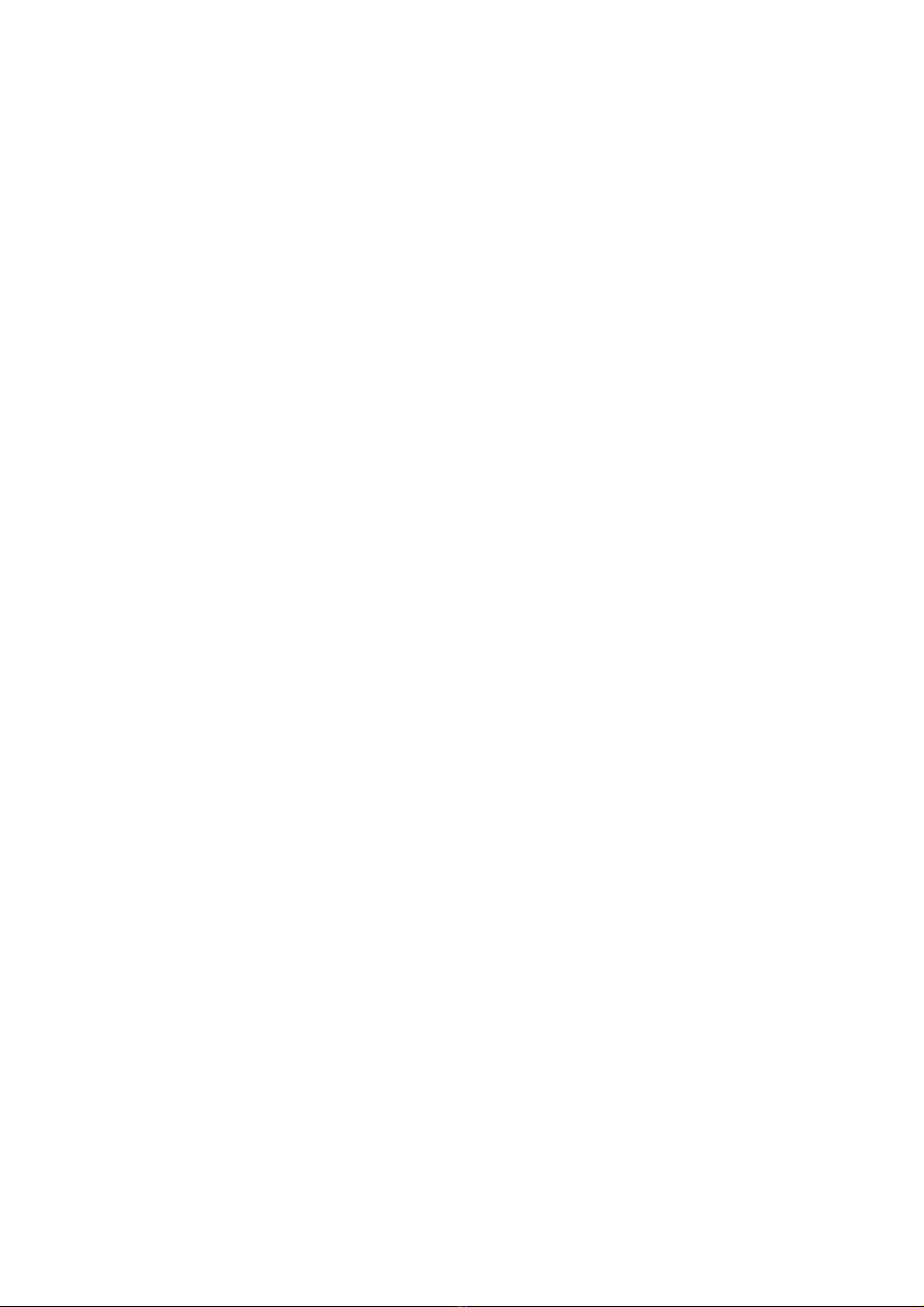

1. External View .....................................................................................................................................................0

2. Exploded View....................................................................................................................................................3

3. Wiring Diagram..................................................................................................................................................4

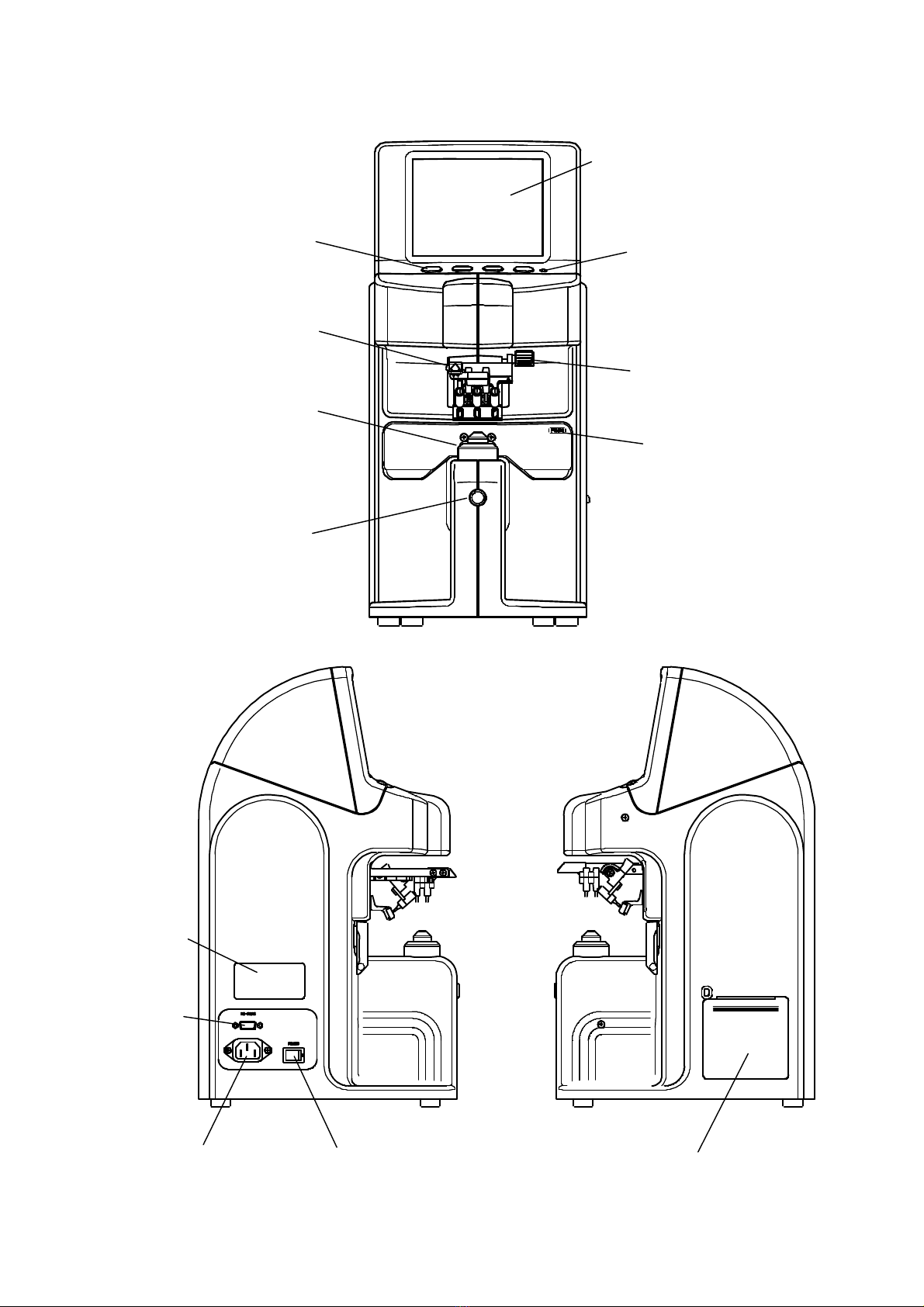

4. Assembly/disassembly of exterior features ........................................................................................................6

4.1. Ink tank holder(※Inkwell specification only)......................................................................................6

4.2. Lens plate....................................................................................................................................................6

4.3. Cases...........................................................................................................................................................6

5. Part replacement .................................................................................................................................................8

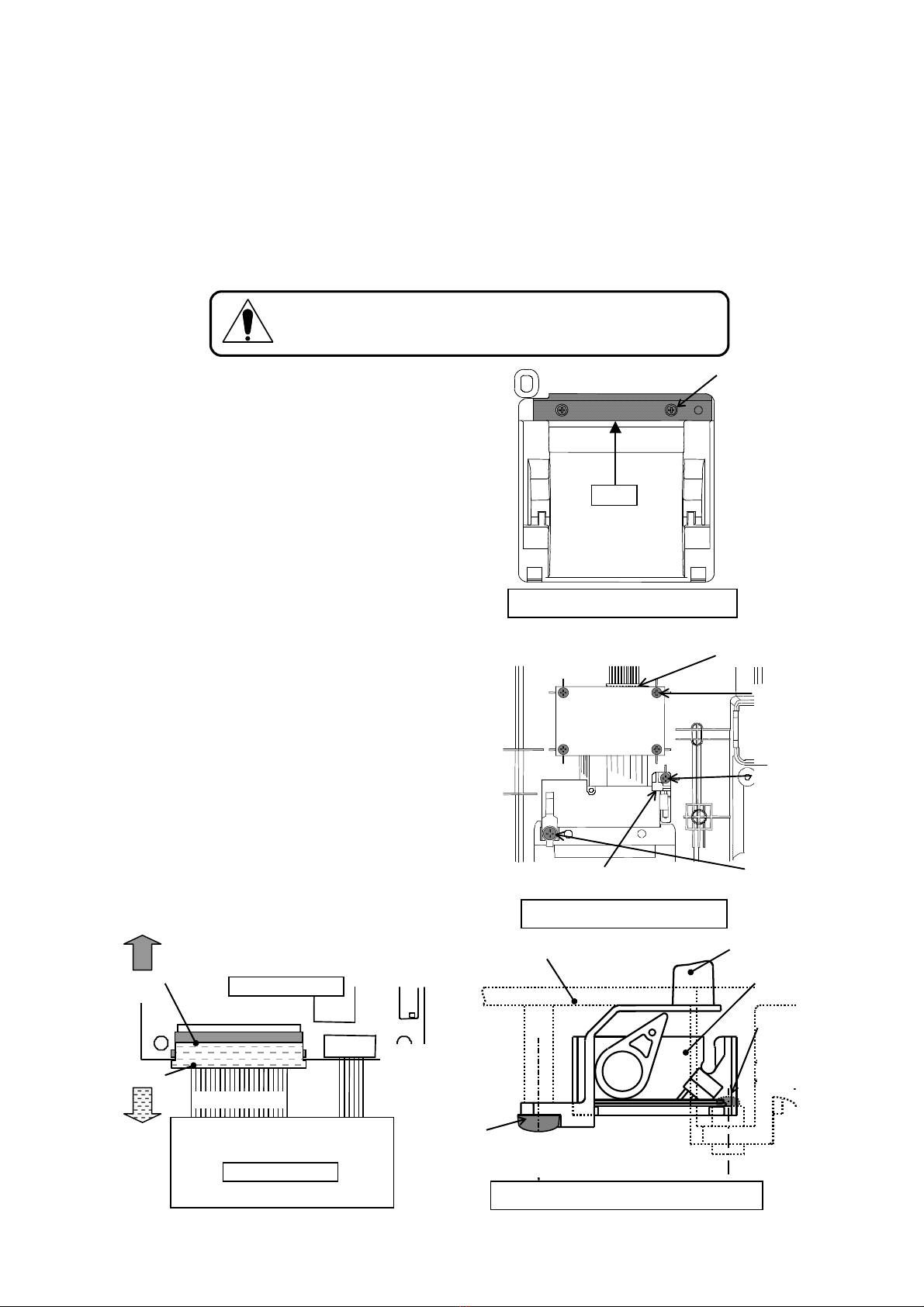

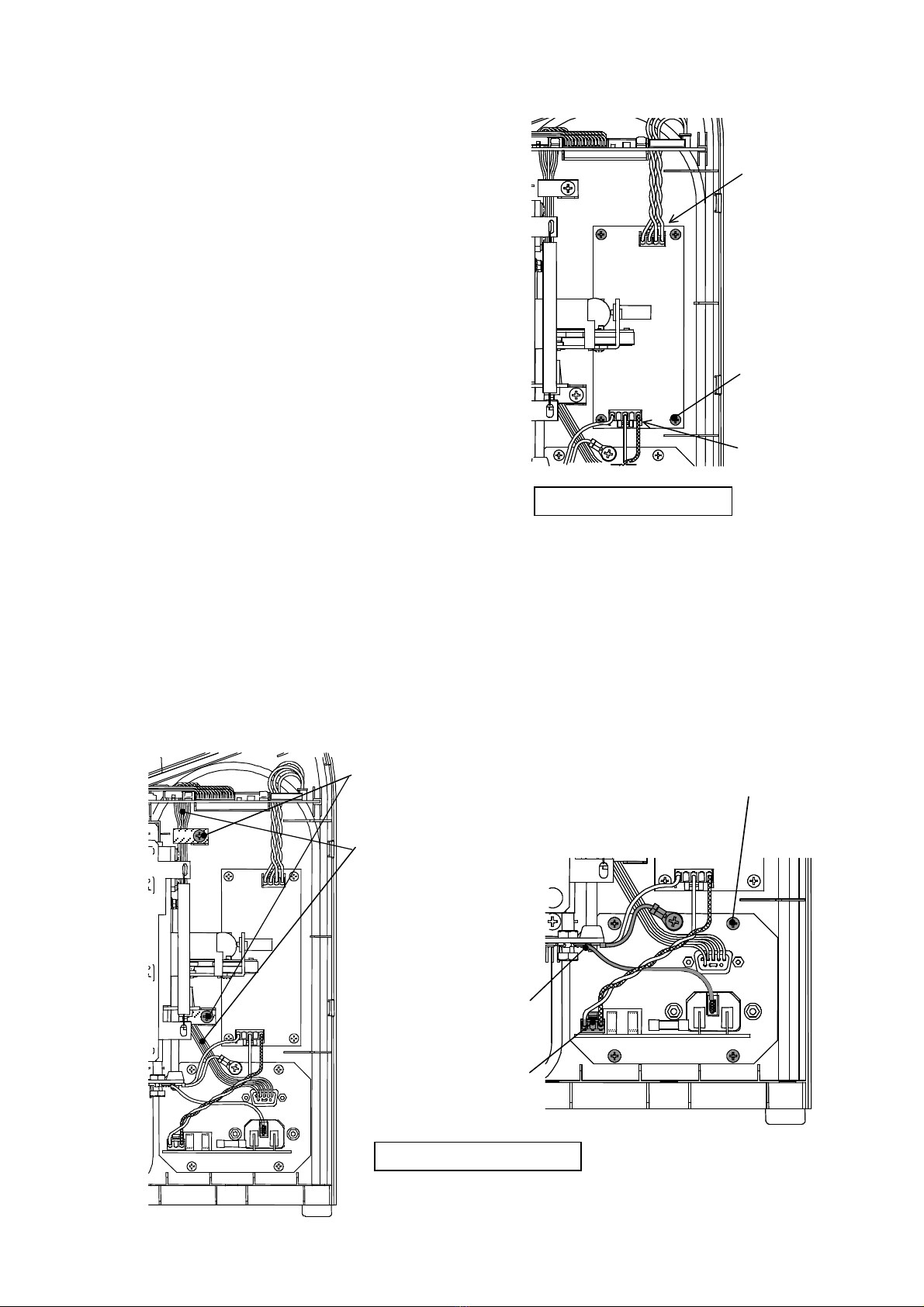

5.1. Control board..............................................................................................................................................8

5.2. Printer and printer I/F board .......................................................................................................................8

5.3. LCD monitor...............................................................................................................................................9

5.4. Inverter board............................................................................................................................................11

5.5. Operation switch board.............................................................................................................................11

5.6. Switching power supply ...........................................................................................................................12

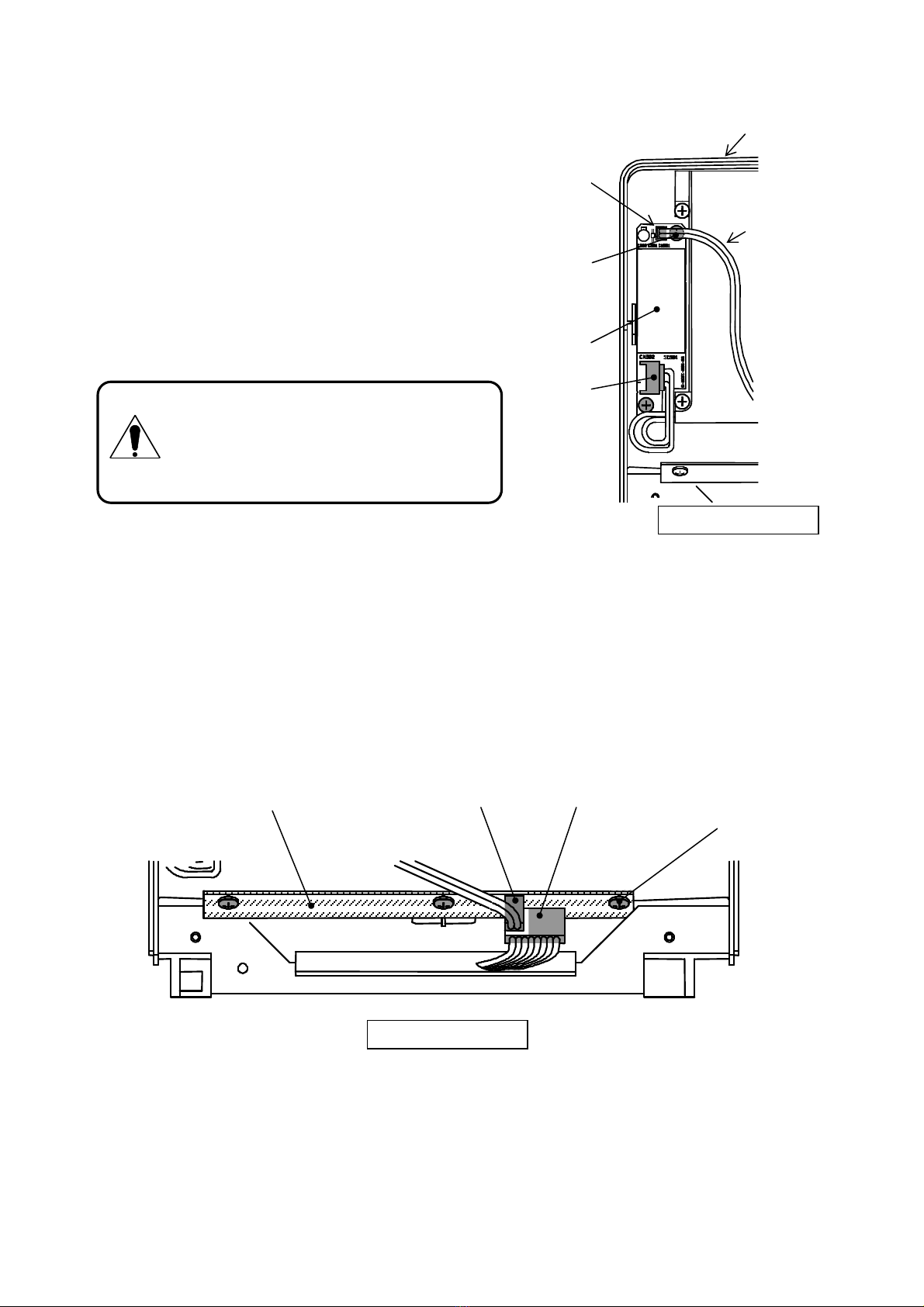

5.7. Terminal ASSY.........................................................................................................................................12

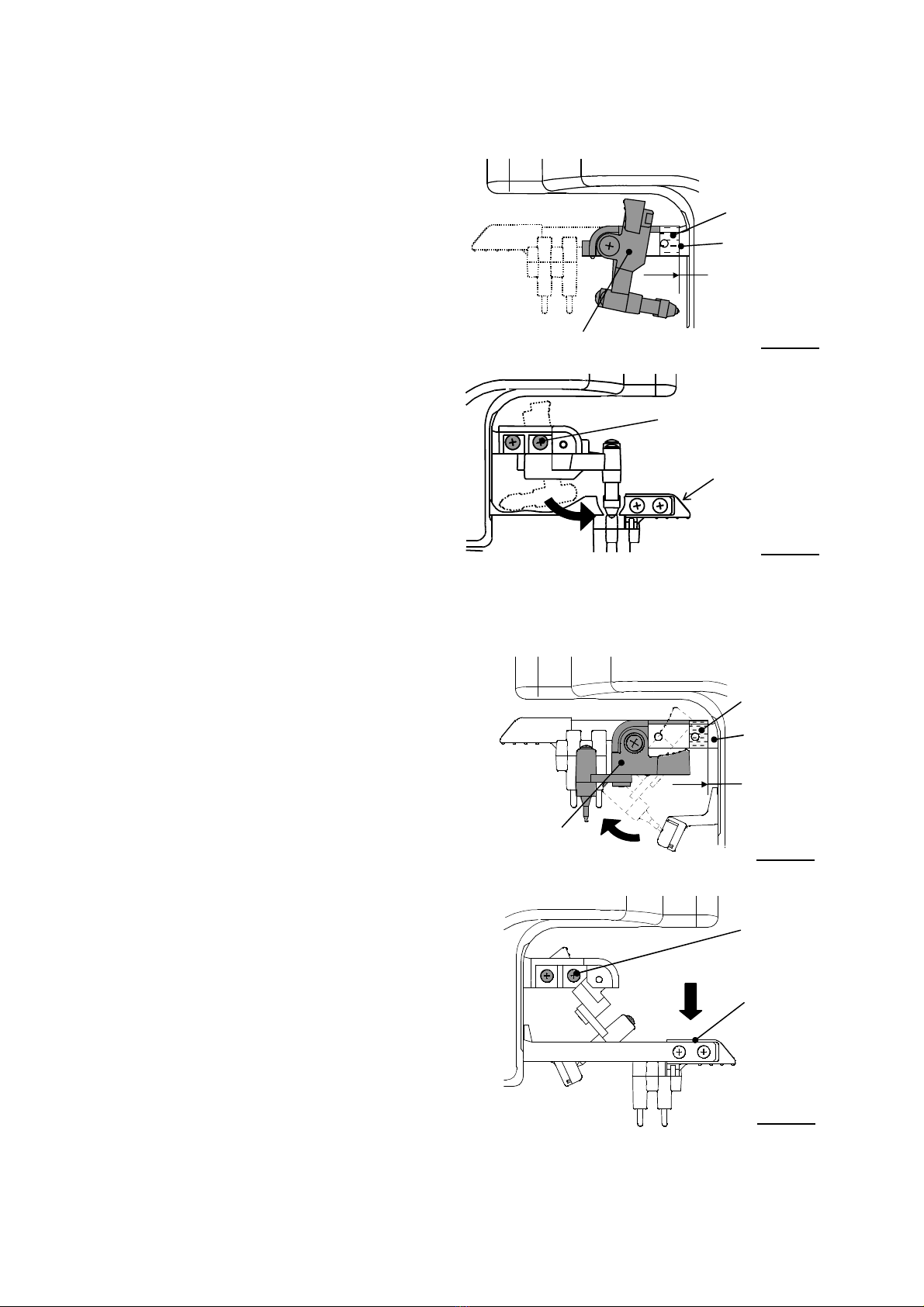

5.8. Marking ASSY..........................................................................................................................................13

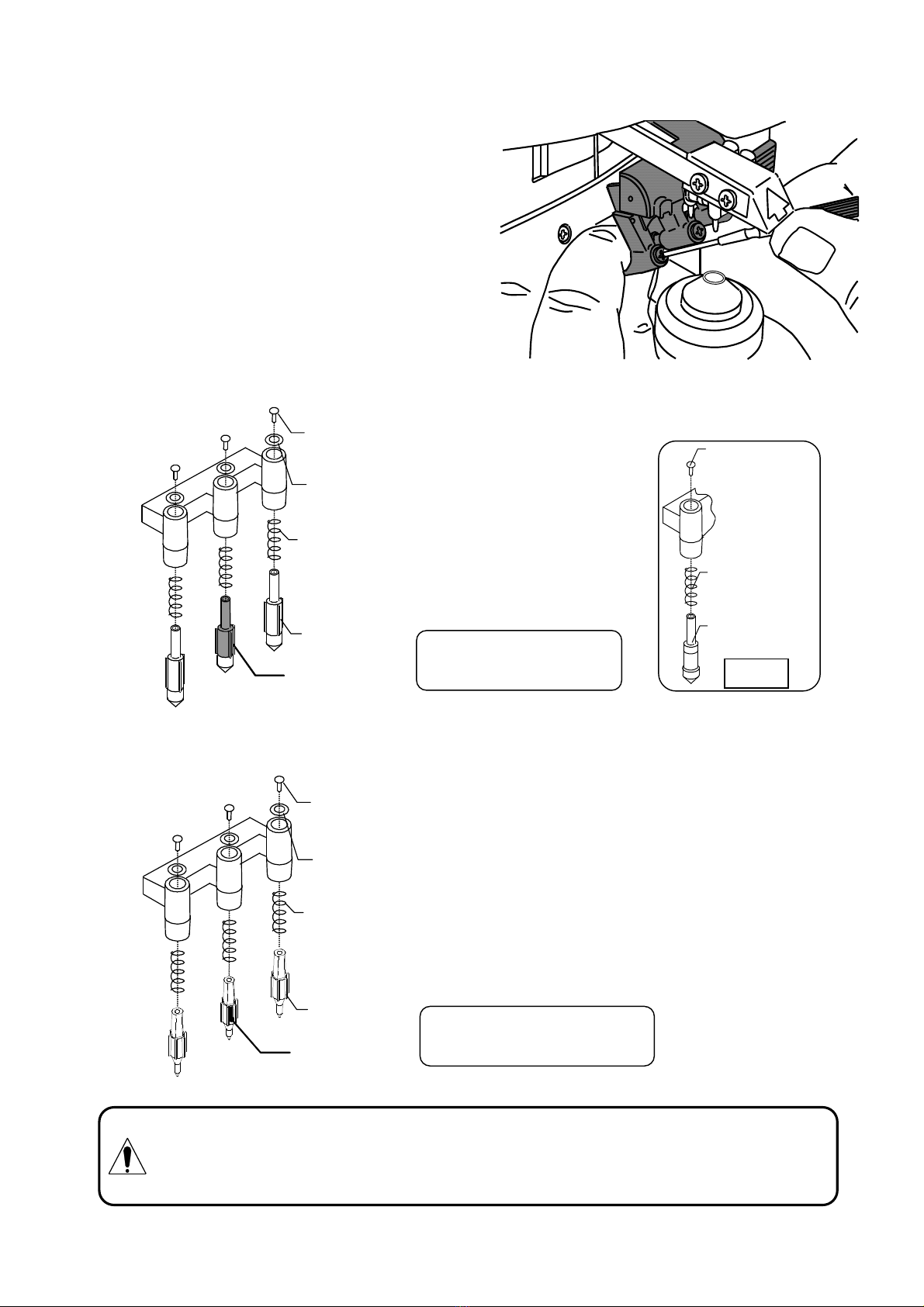

5.9. Marking pen(pin).................................................................................................................................14

5.10. Inkwell(※Inkwell specification only).................................................................................................15

5.11. Lens holder ASSY ....................................................................................................................................15

5.12. Illmination circuit board ASSY ................................................................................................................16

5.13. Heavy motion damper/Light motion damper............................................................................................17

6. Troubleshooting................................................................................................................................................18

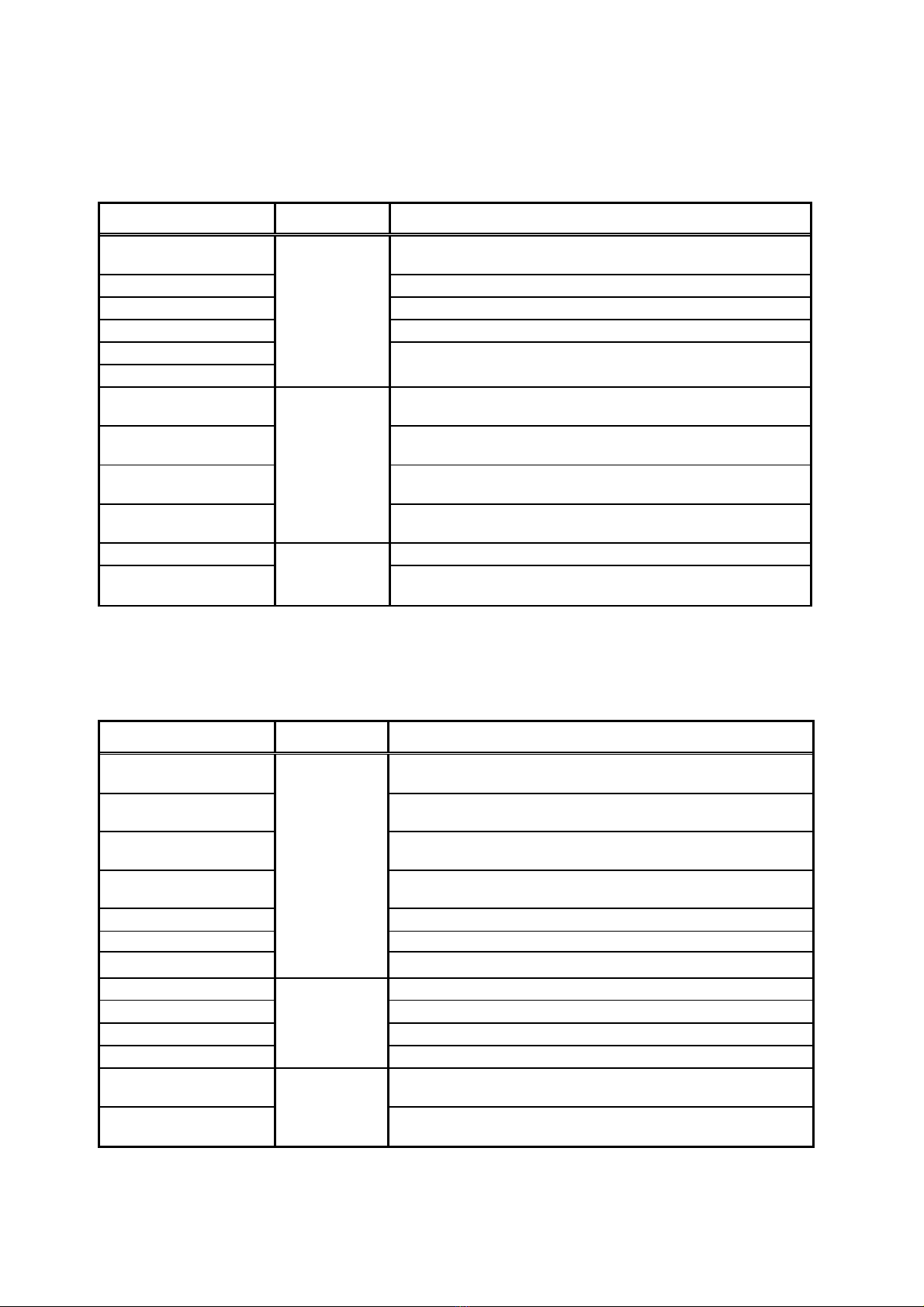

6.1. Measures against errors ............................................................................................................................19

6.1.1. Measure Error.................................................................................................................................. 19

6.1.2. Paper Empty..................................................................................................................................... 20

6.1.3. Printer Cover Open.......................................................................................................................... 20

6.1.4. SPH/CYL/Prism/ADD Over............................................................................................................ 21

6.1.5. Printer Heat Over............................................................................................................................. 21

6.1.6. EEPROM Fault, Sensor Error.......................................................................................................... 21

6.1.7. DRAM Error.................................................................................................................................... 22

6.1.8. Retry Error, Notarget Error.............................................................................................................. 22

7. Image assessment..............................................................................................................................................23

7.1 How to engage in Dealer Mode................................................................................................................23

7.2. How to check images................................................................................................................................23

7.3. Image samples ..........................................................................................................................................24

8. Calibration........................................................................................................................................................27

8.1 How to engage in Dealer Mode................................................................................................................27

8.2. Device setting ...........................................................................................................................................28

8.3. How to engage in Calibration screen........................................................................................................29

8.4. Calibration procedure ...............................................................................................................................29

9. Cleaning............................................................................................................................................................33

9.1. Main unit...................................................................................................................................................33

9.2. Optical unit ...............................................................................................................................................33

10. Software change - upgrading............................................................................................................................34

10.1. Preparation................................................................................................................................................34

10.2. Procedure..................................................................................................................................................34

11. Input/output of adjustment data........................................................................................................................36

11.1. Input/output of adjustment data................................................................................................................36

11.2. General-purpose equipment used..............................................................................................................36

11.3. Preparation................................................................................................................................................37

11.4. Output of adjustment data.........................................................................................................................41

11.5. Input of adjustment data ...........................................................................................................................43