AutoMeter Spek Pro Installation manual

Programming Instructions for : Pressure 2 1/16”

Spek Pro Fuel Rail Pressure Gauge

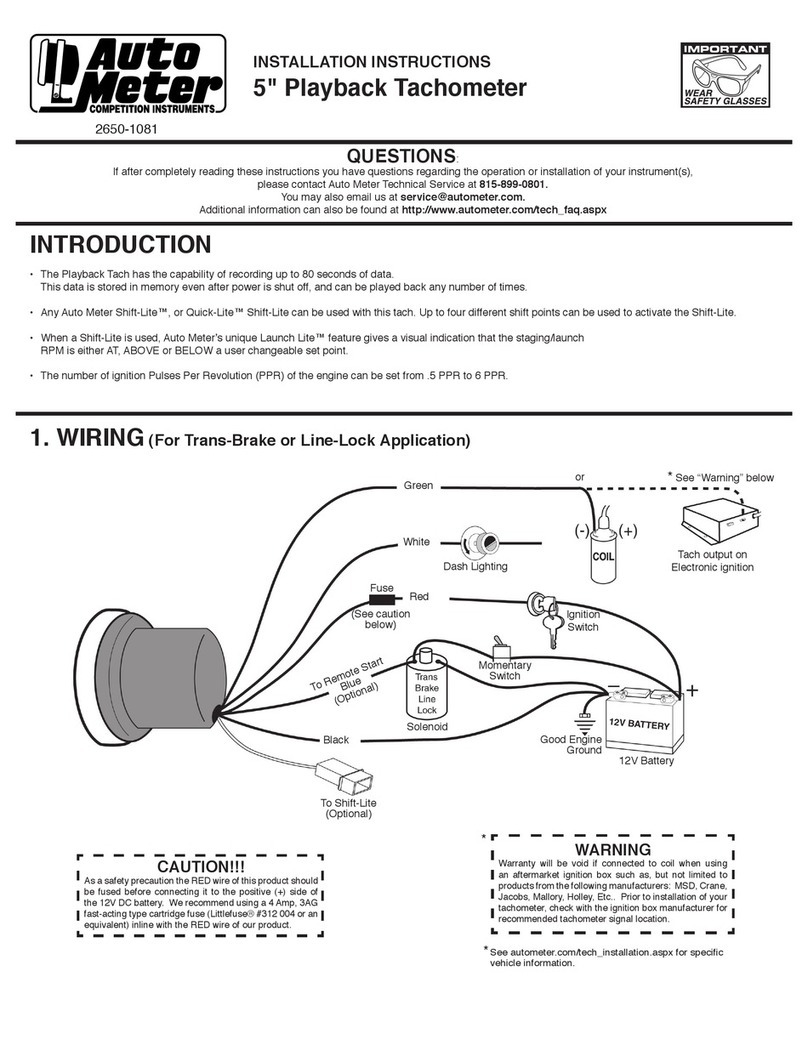

Refer to the “Flow Chart Programming Instructions” while reviewing this guide.

Gauge is field programmable by the operator while installed in the vehicle. This programming is

accessed by pressing the control buttons located on the face or the meter dial, ONE AT A TIME. The

“Down” and “Up” buttons move the pointer to a desired setting or controls the faceplate illumination.

NORMAL/DIAL BRIGHTNESS

PEAK PLAYBACK

HIGH RED-LINE SETTING

LOW THRESHOLD SETTING

COLORSCHEME

DIAL BRIGHTNESS

OPTION:RESTORE FACTORY DEFAULT

OPTION:DEMO MODE

OPTION:ADJUST POINTER BRIGHTNESS

MAIN MENU SUBMENU

PRESS “MODE” BUTTON TO PROGRAM LEVEL. THEN PRESS BOTH CENTER AND

LEFT OR CENTER AND RIGHT BUTTONS FOR FIVE SECONDS TO ENTER SUBMENU

DOWN MODE UP

+

–

OPTION: CALIBRATE GAUGE TO ENVIROMENT

PROGRAMMING STARTS IN

MAIN MENU

PRESS PROGRAM BUTTON ONE (1) AT A TIME IN THE MAIN MENU MODE.

1NORMAL/DIAL BRIGHTNESS:

On power up, the meter usually starts operation in NORMAL/DIAL BRIGHTNESS. Gauge reads the

sensor value as temperature, pressure, etc. The “Down” and “Up” buttons will control the

brightness of the dial lighting. Press the center “Mode” button to save the setting and advance you

to PEAK PLAYBACK

2PEAK PLAYBACK:

Reads the highest value displayed on the gauge since the last time the “PEAK” value was displayed.

“PEAK” value will be held in memory until erased by pressing the RIGHT or LEFT button while in the

“PEAK” level. Press the center “Mode” button to advance to HIGH RED-LINE SETTING

3HIGH RED-LINE SETTING:

Sets the point at which “HIGH” warning threshold is reached for that specific gauge. The “Down and

“Up” buttons will move the dial pointer to select HIGH RED-LINE SETTING. During normal

operation the gauge constantly monitors the sensor value and compares it to the “HIGH” threshold.

If the threshold is exceeded, the red “HI” indicator is turned on. Press the center “Mode” button to

save the setting and advance to LOW THRESHOLD SETTING

4LOW THRESHOLD SETTING:

Set the Minimum Threshold: Sets the point at which “LOW” warning threshold is reached for that

specific gauge. The “Down” and “Up” buttons will move the dial pointer to select the LOW

THRESHOLD SETTING. During normal operation the gauge constantly monitors the sensor value

and compares it to the “LOW” threshold. If the sensor value drops below the threshold, the yellow

“LOW” indicator is turned on. Press the center “Mode” button save the setting and advance to

5 COLORSCHEME

5COLORSCHEME:

Set Faceplate Color Scheme: Operator can select the color of the gauge dial illumination. Each

time you press the “Down” control button you scroll through dial color selection until the dial

light goes off. Then press the “Up” button to reverse the scroll. Select your dial color illumina-

tion by pressing the center “Mode” button to save the setting and advance to DIAL BRIGHT-

NESS

6DIAL BRIGHTNESS:

Adjust dial brightness for day or evening driving conditions. The RIGHT or LEFT command but-

tons will dim or brighten faceplate illumination. Press the Center mode button to save the setting

and return to NORMAL OPERATION.

Programming Instructions for : Pressure

2 1/16” Spek Pro Fuel Rail Pressure Gauge

2

SUBMENU

SUBMENU IS ACCESSED THROUGH THE MAIN MENU. FIRST GO TO THE APPROPRIATE LEVEL OF

THE MAIN MENU AND THEN FOLLOW THE INSTRUCTIONS IN THE PROGRAMMING FLOW DIAGRAM TO

ENTER THE SUBMENU. PRESS THE “MODE” AND “UP” OR “MODE” AND “DOWN” BUTTONS

SIMULTANEOUSLY FOR 5 SECONDS TO ENTER THE SUBMENU AND ONE BUTTON AT A TIME WHILE IN

THAT SUBMENU.

OPTION:CALIBRATE GAUGE TO ENVIORNMENT: Turn the ignition ON with the engine

OFF. While in the Normal Mode, Press and hold the CENTER and LEFT buttons for five (5) seconds. The

dial face plate will flash GREEN rapidly. Press the CENTER Mode button to save the setting and return

to NORMAL OPERATION.

OPTION:RESTORE FACTORY DEFAULT: While in Peak Playback. Main Menu, press and

hold both the CENTER and RIGHT buttons for 5 seconds. The dial pointer will step 5 times and return

to zero (0). All user programmed setting will be erased and the gauge will return to NORMAL OPERA-

TION

OPTION:DEMO MODE: Displays the features of the meter. The pointer goes up and down the

scale, the dial colors change and the HI, LOW and PEAK warning indicators light. The DEMO MODE

does not time out. If the gauge is turned off in the DEMO MODE, it will start up in the DEMO MODE.

Press the “Mode” button to return the gauge to NORMAL operation.

OPTION:POINTER BRIGHTNESS MODE : The DOWN and UP buttons adjust the dial pointer

brightness to blend in with original manufacturer’s gauges and the owner’s requirements. Press the

MODE button to return to NORMAL OPERATION.

Factory default programming settings:

High Fuel Rail Pressure.............29,500 PSI

Low Fuel Rail Pressure..............12,000 PSI

Programming Instructions for : Pressure

2 1/16” Spek Pro Fuel Rail Pressure Gauge

3

PROGRAMMING INFORMATION:

• TO RESET THE PROGRAM TO NORMAL OPERATION FROM ANY MODE PRESS THE “UP” AND

“DOWN” BUTTONS SIMULTANEOUSLY. THIS SOFT RESET CANCELS THE INFORMATION YOU

PROGRAMMED IN THAT MODE ONLY AND RETURN YOU TO NORMAL OPERATION.

• THE FACEPLATE WILL “FLASH” WHEN BUTTONS ARE DEPRESSED TO ACKNOWLEDGE COMMANDS.

• PROGRAMMING ERRORS WILL BE SIGNALLED BY FLASHING THE FACEPLATE LIGHTING “PURPLE”,

“BLUE”, “GREEN” THEN “ORANGE”.

• IF PROGRAMMING IS INACTIVE FOR 60 SECONDS THE MODE WILL TIME OUT AND THE GAUGE WILL

RETURN TO NORMAL OPERATION, EXCEPT FOR IN THE DEMONSTRATION MODE. THE DEMO MODE

WILL NOT TIME OUT UNTIL THE CENTER “MODE” BUTTON IS PRESSED. IF THE GAUGE IS TURNED

OFF IN THE DEMO MODE, IT WILL START-UP IN THE DEMO MODE.

• TO RESTORE FACTORY DEFAULTS, PRESS THE “MODE” BUTTON ONCE TO ENTER THE PEAK

PLAYBACK. THEN PRESS AND HOLD THE “MODE” AND “UP” BUTTONS FOR FIVE SECONDS. YOUR

PROGRAMMING WILL BE ERASED BUT FACTORY PROGRAM WILL NOT BE AFFECTED.

THE GAUGE FACEPLATE WILL FLASH ALTERNATELY “RED” THEN “GREEN” IF THE SENSOR PROBE IS

NOT CONNECTED TO THE WIRING HARNESS.

Programming Instructions for : Pressure

2 1/16” Spek Pro Fuel Rail Pressure Gauge

4

GAUGE TYPE

TEMPERATURE

PRESSURE

TACHOMETER

PYROMETER

NITROUS OXIDE PRESSURE

BOOST PRESSURE

AIR/FUEL

VOLTMETER

ALERT FLASHES “RED”

HIGH

LOW

HIGH

HIGH

LOW

HIGH

LOW

LOW

U.S. Patent# 7,278,749 and # 7,612,660

Additional Patents Pending

PEAK

LIGHT LIT

PEAK LOW HI

PRESS

LOW

LIGHT LIT

PEAK LOW HI

PRESS

PEAK,LOW,HI

LIGHT LIT

PEAK LOW HI

PRESS

PEAK,LOW,HI

LIGHT LIT

PEAK LOW HI

PRESS ONE

AT A TIME

DOWN

-

UP

+

LOW

LIGHT LIT

PEAK LOW HI

PRESS ONE

AT A TIME

DOWN

-

UP

+

PEAK

LIGHT LIT

PEAK LOW HI

PRESS

LOW THRESHOLD SETTING:

Press the center button to advance to

COLORSCHEME.

Flow Chart Programming Instructions for : Fuel Rail Pressure Gauge 2 1/16”

5

Program main menu

START HERE

Main Menu

(Press one

button at a time)

NORMAL/DIAL BRIGHTNESS:

Press the down or up button to adjust dial

brightness. Press the center button to save and

advance to PEAK PLAYBACK.

NORMAL

LIGHTING

PEAK LOW HI

PRESS ONE

AT A TIME

DOWN

-

UP

+

PEAK PLAYBACK:

Reads the highest value displayed on the Gauge

since the last time the PEAK value was dis-

played. PEAK value will be held in memory until

erased by pressing the RIGHT or LEFT button

while in the PEAK level Press the center button

to advance to HIGH RED-LINE SETTING.

HIGH RED-LINE SETTING:

Press the down or up button to move dial

pointer to the high threshold. Press the center

button to save and advance to LOW

THRESHOLD SETTING.

HI

LIGHT LIT

PEAK LOW HI

PRESS ONE

AT A TIME

DOWN

-

UP

+

LOW PRESSURE SETTING:

Sets the value at which the Low Pressure Warn-

ing is reached. The dial faceplate will flash

RED for 60 seconds and then stay lit. Press the

LEFT or RIGHT buttons to select the Low Pres-

sure Setting. Press the center button to save

and advance to COLORSCHEME.

COLORSCHEME:

Press down and up buttons to select a color

scheme. (OFF-VIOLET-BLUE-GREEN-YELLOW-

ORANGE-RED-WHITE). Press the center but-

ton to save and return to NORMAL/DIAL

BRIGHTNESS.

NORMAL/DIAL BRIGHTNESS:

ON POWER UP THE GAUGE READS THE PRESSURE.

OPTION: CALIBRATE GAUGE

Press the center button to

advance to PEAK PLAYBACK.

NORMAL

LIGHTING

PEAK LOW HI

PRESS

PEAK PLAYBACK:

Press the center button to advance to

HIGH RED-LINE SETTING.OR

OPTION:RESTORE FACTORY DEFAULT

HIGH RED-LINE SETTING:

Press the center button to advance to

LOW THRESHOLD SETTING.

HI

LIGHT LIT

PEAK LOW HI

PRESS

COLORSCHEME:

Press the center button to advance to

NORMAL/DIAL BRIGHTNESS.OR

OPTION A:DEMO MODE

Down

Button

PEAK

LOW

HI

Up

Button

Mode

Button

PEAK,LOW,HI

LIGHT LIT

PEAK LOW HI

PRESS ONE

AT A TIME

DOWN

-

UP

+

DIAL BRIGHTNESS:

Press the RIGHT or LEFT command buttons to

Control the brightness of the faceplate illumina-

tion. Press the center button to save and ad-

vance to NORMAL OPERATION. PEAK,LOW,HI

LIGHT LIT

PEAK LOW HI

PRESS DIAL BRIGHTNESS:

Press the center button to

advance to NORMAL OPERATION

OPTION A:POINTER BRIGHTNESS

PRESS

BOTH

6

Flow Chart Programming Instructions for : Fuel Rail Pressure Gauge 2 1/16”

Submenu

(enter from main menu)

(Press two(2) buttons simultaneously for 5 seconds)

OPTION:RESTORE FACTORY DEFAULT:

While in PEAK PLAYBACK, press and hold the

center and right buttons for five seconds. Dial

pointer will step five times and return to zero.

This will erase all user-programmed calibrations

and settings, and return to NORMAL/DIAL

BRIGHTNESS.

OPTION:DEMO MODE:

WHILE IN COLORSCHEME, press and hold the center and

right buttons for five seconds. Dial will scroll through the

seven color schemes. The HI,LOW and PEAK will light,

and the dial pointer will move. Press the center button to

return to NORMAL/DIAL BRIGHTNESS.

PRESS

BOTH

PRESS

BOTH

Calibrate Gauge to Environment: Turn the ignition ON with the engine

OFF. While in the Normal Mode, press and hold the CENTER and LEFT but-

tons for five (5) seconds. The dial face plate will flash GREEN rapidly. Press

the CENTER mode button to save the setting and return to NORMAL OPERA-

TION.

Default Pressure Settings:

High Fuel Rail Pressure.....29,500 PSI

Low Fuel Rail Pressure......12,000 PSI

PRESS

BOTH

OPTION A:POINTER BRIGHTNESS:

Press CENTER and LEFT buttons for five (5) seconds to

enter pointer brightness mode. The dial pointer will start to

flash and point to the upper right.

PRESS ONE

AT A TIME

DOWN

-

UP

+

OPTION:POINTER BRIGHTNESS:

Press LEFT or RIGHT buttons to adjust pointer

brightness. Press the CENTER burron to save and

return to NORMAL/DIAL BRIGHTNESS.

Wiring Installation Instructions for : Pressure Gauge

2 1/16” Spek Pro Fuel Rail Pressure Gauge

SPEK PRO™ FUEL RAIL PRESSURE GAUGE

FEATURES:

SPEK PERFORMANCE GAUGE FEATURES:

• INTELLIGENT ELECTRICAL GAUGES.

• GAUGES ARE PROGRAMMED THROUGH COMMAND KEYS ON FACEPLATE.

• STEPPER MOTOR DRIVES THE GAUGE POINTER OVER A 280 DEGREE SWEEP.

• WIDE-ANGLE-DIAL™ HAS A 15% LARGER VIEWING AREA ON A 2 1/16” GAUGE.

• PROGRAMMABLE 7 COLOR DIAL AND RED POINTER ILLUMINATION.

• OPTIONAL OUTPUT CONTROL MODULE.

INSTALLATION INSTRUCTIONS:

1 DISCONNECT NEGATIVE (-) BATTERY TERMINAL.

2 VARIOUS MOUNTING SOLUTIONS ARE PRESENTED BY PROPARTS

DASH INSTALLATION: SELECT LOCATION IN THE DASH TO MOUNT GAUGE AND CUT A 2 1/16” HOLE.

USE A FILE TO INCREASE THE HOLE SIZE IF REQUIRED. BE SURE THERE IS SUFFICIENT ROOM

BEHIND THE HOLE FOR THE METER CASE AND THE CONNECTORS YOU WILL USE.

3 IF A SUITABLE HOLE IN THE FIRE WALL IS NOT AVAILABLE, CUT AN 11/16 HOLE.

4 GROMMET MUST BE CUT TO PERMIT INSTALLATION OF WIRING HARNESS. (SEE DIAGRAM 1)

7

PACKAGE CONTAINS:

• Pressure Gauge

• Pressure Sender

• Wiring Harness

• Mounting Cup

• ( 1 ) N e o p r e n e E D P M G r o m m e t

5 INSTALL GROMMET AND MOUNTING CUP ON THE WIRING HARNESS AS SHOWN IN DIAGRAM 1.

GROMMET IS FOR THE HOLE IN THE FIREWALL

6 DO NOT CONNECT WIRING HARNESS TO THE GAUGE UNTIL THE OTHER CONNECTIONS HAVE

BEEN MADE AND TESTED.

7. LOCATE THE FUEL PRESSURE SENSOR.

8. DISCONNECT THE FACTORY FUEL SENSOR HARNESS CONNECTOR BY PUSHING IN THE LOCK-

ING CLIP AND PULLING THE CONNECTOR AWAY FROM THE SENSOR. CONNECT ONE END OF THE

SPEK-PRO SUPPLIED WIRING HARNESS PLUG TO THE FACTORY SENSOR AND THE OTHER END INTO

THE EXISTING FACTORY WIRING HARNESS. THIS INSURES THAT THE VEHICLE’S COMPUTER STILL

RECEIVES THE PROPER INFORMATION. MAKE CERTAIN THAT CONNECTOR LOCKING TABS ARE SET.

FAILURE TO DO SO WILL RESULT IN ROUGH IDLING OR INABILITY TO START ENGINE.

CAUTION: TAKE PRECAUTION TO PROTECT FUEL RAIL PRESSURE SENSOR WIRING. IMPROPER IN-

STALLATION CAN LEAD TO SHORT CIRCUIT THAT COULD CAUSE ENGINE DAMAGE

9 CONNECT THE RED (+12 VOLT SUPPLY) WIRE TO “ON” CIRCUIT THAT GETS POWER WHEN THE

IGNITION IS TURNED ON. THIS CIRCUIT MUST BE FUSED BEFORE THE IGNITION SWITCH

(3 AMP, FAST ACTING FUSE).

10 CONNECT THE BLACK WIRE TO A GOOD GROUNDING POINT ON THE CAR’S CHASSIS.

11 CONNECT THE WHITE WIRE TO THE DIMMER VOLTAGE GOING TO THE DASH LIGHTS.

12 PLUG THE WIRING HARNESS INTO THE GAUGE AND MOUNT IN POD OR DASH. USE CARE WHEN

CONNECTING OR DISCONNECTING THE WIRING HARNESS.

13 FOR DASH MOUNTING, ATTACH MOUNTING CUP OVER THE BACK OF THE GAUGE AND HAND

TIGHTEN. DO NOT OVER-TIGHTEN. MOUNT CUP BEFORE INSTALLING GROMMET. FAILURE TO DO

SO WILL TWIST WIRES CAUSING A SHORT CIRCUIT.

14 POWER UP THE GAUGE AND INSPECT ALL CONNECTIONS. IF GAUGE IS OPERATING NORMAL,

PROCEED TO “PROGRAMMING MANUAL.”

TROUBLESHOOTING:

THE GAUGE FACEPLATE WILL FLASH ALTERNATELY “RED” THEN “GREEN” IF THE SENSOR PROBE

IS NOT CONNECTED TO THE WIRING HARNESS.

8

Wiring Installation Instructions for : Pressure

2 1/16” Spek Pro Fuel Rail Pressure Gauge

9

Wiring Installation Instructions for : Pressure

2 1/16” Spek Pro Fuel Rail Pressure Gauge

Black-Chassis Ground

Firewall

Grommet

12-Pin Wiring

Harness & Plug

GAUGE

+12VDC

85

86

87A

30

87

Gauge

PIN 8 Output/Purple

CUP

Grommet

+12VDC

Fused +12V

Scramble Boost

(Option)

Red-12V

Ignition Switch

White-12V

Dash Lighting

Headlight

Switch

Fuse

Relay can use Dedenbear

HPR relay or equivalent.

ALL SPEK GAUGES HAVE A

PROGRAMMABLE LIMIT SETTING .

WHEN A SETTING IS TRIPPED,

AN OUTPUT SIGNAL IS

GENERATED. THIS CAN BE

USED TO SWITCH ON A

RUGGED 35 AMP RELAY

TO ACTIVATE A LOW OIL ENGINE

KILL, ALARMS, CUT THROTTLE

BODY SENSOR TO DEFUEL

KILL BOOST VALVE.

WARNING: OUTPUT CONTROL MODULE

NOT TO EXCEED 1.5 AMPS AT 12 VOLTS DC.

WARRANTY WILL BE VOID IF INCREASED

OUTPUT VOLTAGE OR CURRENT IS APPLIED.

A

To Output

Control Module

A

To Red

Ignition Switch

+12VDC

Pin 2

Fuel Pressure

Input/Green-

Wire Pin 3

Ground/

Black

Fuel Pressure

Sensor Connector

Factory Wiring

Connector

Wiring Harness Interface

CAUTION: 12 VOLT DC POWER

MUST BE CONNECTED TO THE

IGNITION POWER AFTER THE

FUSE.

DIAGRAM 1

© 2009

PATENTED WIDE ANGLE DIAL

FOR SUPERIOR VISIBILITY

U.S PATENT #7,278,749

DIAGRAM 2

Wiring Installation Instructions for : Pressure

2 1/16” Spek Pro Fuel Rail Pressure Gauge

10

1 2 3 4 5 6

7 8 9 10 11 12

J1 CONNECTOR

TROUBLESHOOTING:

THE GAUGE FACEPLATE WILL FLASH ALTERNATELY “RED” THEN “GREEN” IF THE FUEL PRESSURE SENSOR

AND /OR WIRING HARNESS ARE NOT COMMUNICATING WITH THE GAUGE

11

Wiring Installation Instructions for : Pressure

2 1/16” Spek Pro Fuel Rail Pressure Gauge

THERE ARE THREE SECTIONS TO THIS MANUAL: WIRING INSTRUCTIONS, PROGRAMMING

INSTRUCTIONS AND FLOW CHART PROGRAMMING INSTRUCTIONS. PLEASE READ EACH

SECTION CAREFULLY BEFORE ATTEMPTING TO INSTALL OR OPERATE THIS PRODUCT.

WARNING:

• ALL INSTRUCTIONS IN THIS MANUAL MUST BE FOLLOWED TO INSURE SAFE INSTALLA-

TION AND OPERATION OF THIS PRODUCT.

• NEVER DISASSEMBLE MODIFY OR TAMPER WITH THIS PRODUCT. THIS COULD CAUSE

DAMAGE AND MAKE THEM UNSAFE TO USE. TAMPERING WITH THE PRODUCT WILL VOID

THE LIMITED WARRANTY.

• INSTALLATION MUST BE PERFORMED BY AN EXPERIENCED AUTOMOTIVE TECHNICIAN.

• INSTALLER MUST USE SAFETY GLASSES.

• DISCONNECT THE NEGATIVE BATTERY TERMINAL BEFORE BEGINNING INSTALLATION.

PROPARTS LLC IS NOT RESPONSIBLE FOR DAMAGE TO ENGINE, VEHICLE OR UNIT CAUSED

BY ELECTRICAL SHORTS.

• DURING INSTALLATION, DO NOT INTERFERE WITH ANY EXISTING CONNECTIONS OR

WIRES.

• ALL ELECTRICAL CONNECTIONS USE SOLDER LESS CONNECTORS AND INSULATE ALL

CONNECTIONS WITH ELECTRICAL TAPE.

• AVOID WIRING NEAR ENGINE, EXHAUST SYSTEM, TURBINE OR ANY AREA THAT MAY RE-

SULT IN DAMAGE.

• DISCONTINUE USE OF THE PRODUCT IF SMOKE OR A STRANGE ODOR IN PRESENT.

CAUTION

• PROPARTS LLC IS NOT RESPONSIBLE FOR INCORRECT INSTALLATION OR PROGRAMMING

OF SPEK™ GAUGES OR CONTROLLERS.

• SPEK™ GAUGES AND CONTROLLERS ARE DESIGNED FOR 12V DC ELECTRICAL SYSTEMS

WITH A NEGATIVE GROUND.

• DO NOT ADJUST THE GAUGES OR GAUGE PROGRAM WHILE DRIVING

• OBEY ALL RULES AND REGULATIONS OF HIGHWAY AND STREET DRIVING.

• INSTALL SENSOR AND WIRE AWAY FROM HIGH HEAT AND / OR VIBRATION AREAS.

• USE CARE WHEN CONNECTING OR DISCONNECTING THE WIRING HARNESS. PULL OUT

EACH CONNECTOR WHILE PRESSING THE LOCK OF THE CONNECTOR FIRMLY.

• IF THE BATTERY TERMINAL IS DISCONNECTED, THE AUDIO, CLOCK AND OTHER MEMORY

DATA MAY BE LOST. THE NECESSARY DATA WILL HAVE TO BE RESET AFTER INSTALLA-

TION.

WARNING:FUEL AND FUEL VAPOR ARE EXTREMELY FLAMMABLE. INSTALLER MUST

TAKE EVERY PRECAUTION TO REMOVE ANY HOT MATERIAL. OPEN FLAME OR ANY-

THING THAT IGNITE FUEL OR FUEL VAPOR.

Wiring Installation Instructions for : Pressure

2 1/16” Spek Pro Professional Racing Gauge

Table of contents

Other AutoMeter Measuring Instrument manuals

AutoMeter

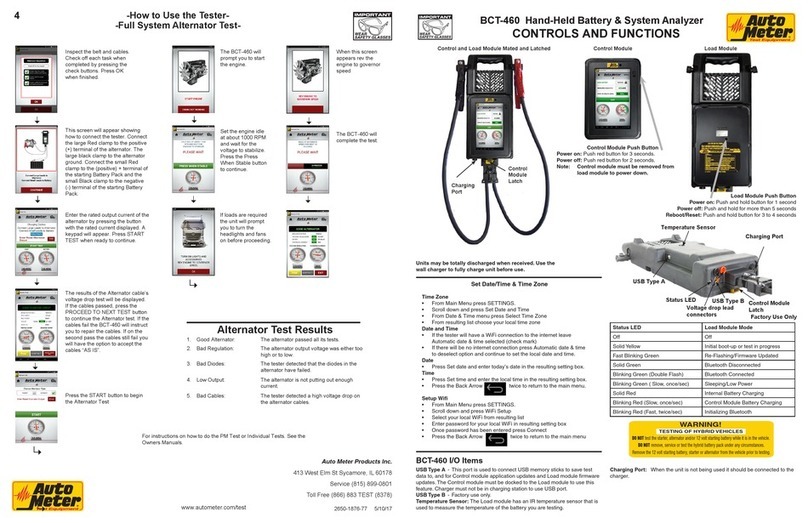

AutoMeter BCT-460 Use and maintenance manual

AutoMeter

AutoMeter 5336 User manual

AutoMeter

AutoMeter Remy BCT-200J User manual

AutoMeter

AutoMeter 6858 User manual

AutoMeter

AutoMeter BVA-230OZR User manual

AutoMeter

AutoMeter BVA-200EX User manual

AutoMeter

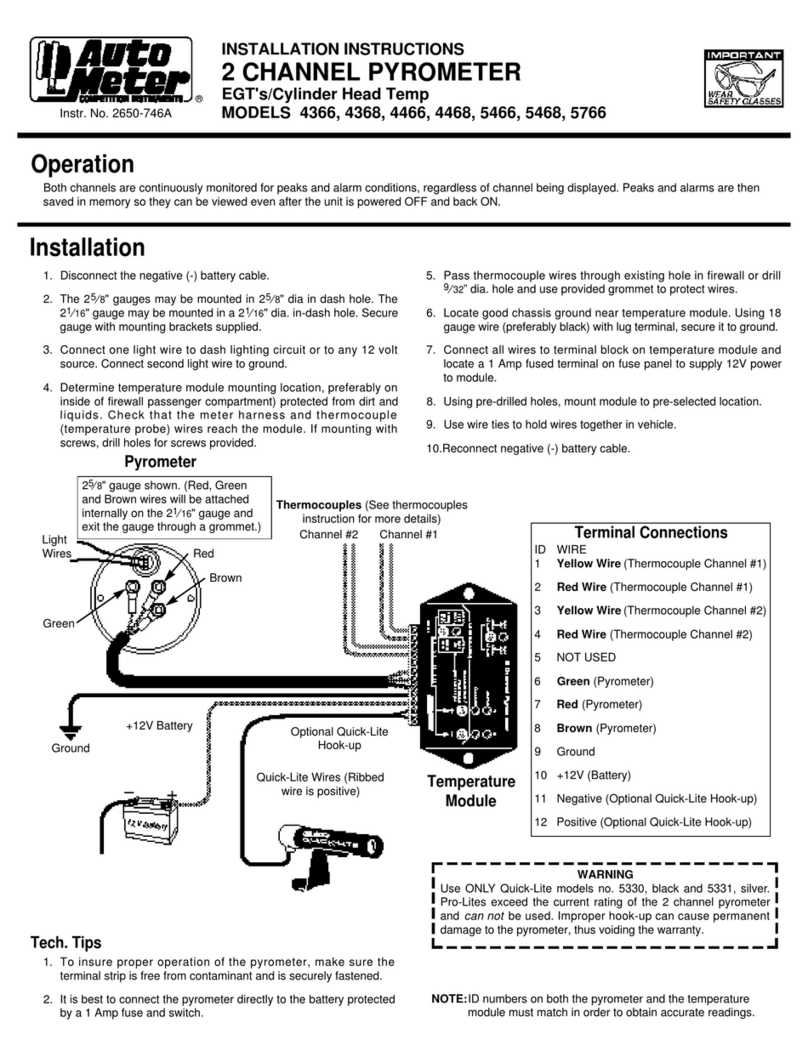

AutoMeter 4366 User manual

AutoMeter

AutoMeter BVA-350 User manual

AutoMeter

AutoMeter 5798 User manual

AutoMeter

AutoMeter SB-52 User manual