Autopack 45WLO20FP User manual

Packaging Systems

Technical Manual

Wrapper Model no.: 45WLO20FP

Shrink Tunnel Model no.: 45TLW20VL

Serial no.: 1554196

Serial no.: 1554197

This document is valid for:

Series No/ Machine No Sign.

Technical Manual

Packaging Systems

1 . Introduction

2 . Safety precautions

3 . Unpacking and Check

4 . Maintenance instructions

5 . Electrical Components

6 . Spare Parts

7 . Human Machine Interface(HMI)

8 . Diagrams & Drawing

1-1

1

1 Introduction

Immediate danger to life!

To ensure maximum safety, always read the Safety precautions

before doing any work on the machine or making any adjustments.

!

DANGER!

1-2

1 Introduction

1

This page intentionally left blank

1 Introduction

1-3

1

1.1Document information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Design modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Document producer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Machine introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Shrink Tunnels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2-1 System Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

For Wrapper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

For Tunnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2-2 Machine Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Machine Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Machine Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4 Machine orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1-4

1 Introduction

1

This page intentionally left blank

1 Introduction

1-5

1

1.1 Document information

About this Manual

The Autopack Manual consists of the following chapters:

• Introduction

• Safety Precautions

• Installation

• Maintenance & Check

• Electrical Components

•Spareparts

• Human Machine Interface(HMI)

• Diagrams & Drawings

The purpose of the introduction is to provide the user of the manual with general

information about the manual as well as the machine.

The purpose of the safety precautions is to provide the user of the manual with

information so it is safe to install, operate, and maintain the machine.

The purpose of the installation instructions is to provide the service technicians with

information on the on-site installation process.

The purpose of the maintenance instructions is to provide service technicians and

electricians with information on the equipment required for service and

maintenance.

The purpose of the electrical components is to provide service technicians and

electricians with information on the electrical equipment required for service and

maintenance.

The purpose of the spare part lists is to provide the service technicians and contact

personnel with information on how to find and order spare parts for service of the

unit.

The purpose of the Human machine interface is to provide the user of the manual

with information on how to use HMI for machine settings and alarm monitoring.

The purpose of the Diagrams & Drawings is to provide the user of the manual with

diagrams and drawings for the System.

Design modifications

The directives in this document are in accordance with the design and construction

of the unit at the time it was released by an Autopack machine production facility.

Document producer

This document has been produced by:

Autopack Co., Ltd.

98/50 Moo 11 Phutthamonthon Sai 5 Rd.,

Raikhing, Samphran, Nakornpathom

73210 THAILAND

1-6

1 Introduction

1

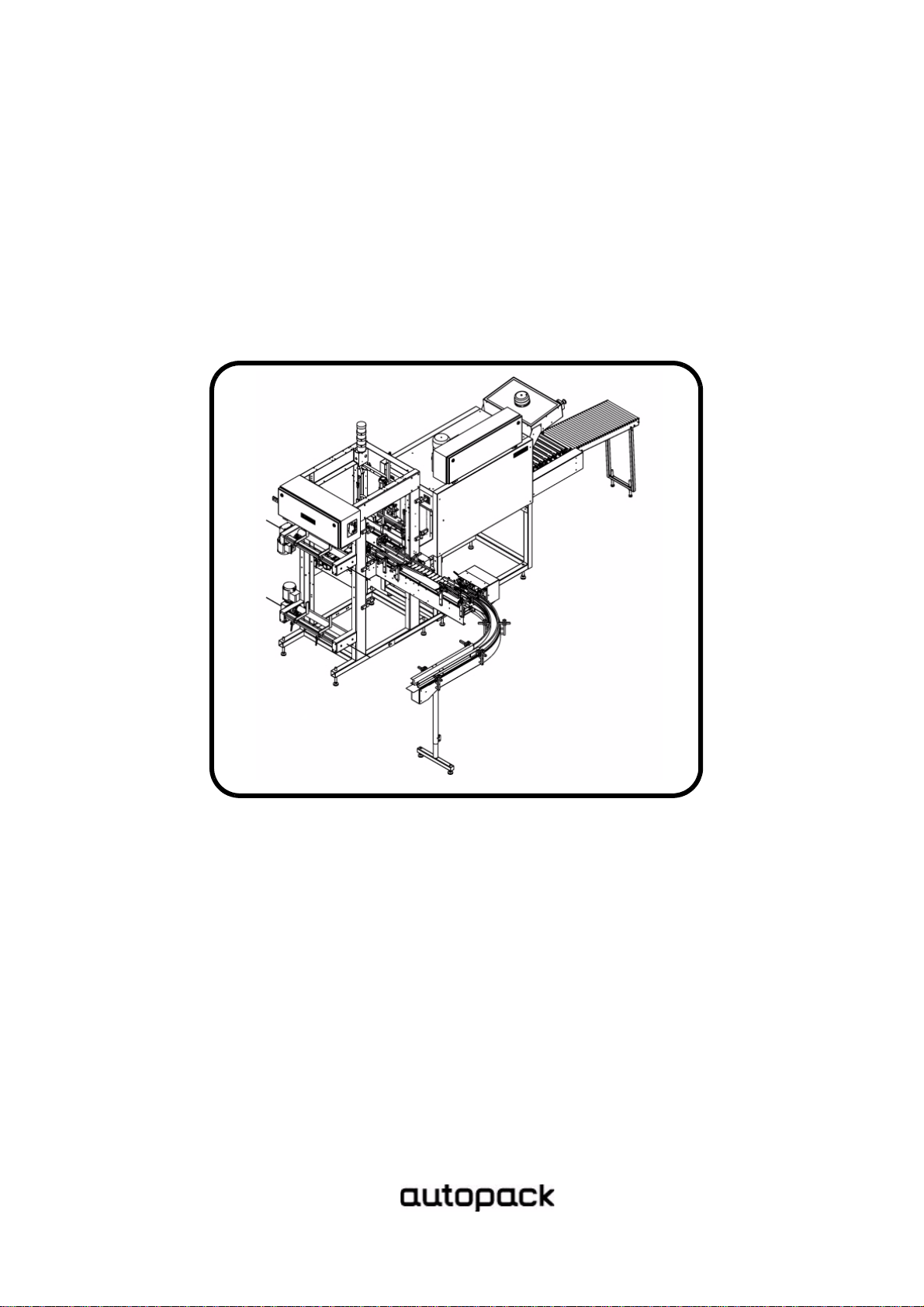

1.2 Machine introduction

General Information

Sleeve Wrappers

AUTOPACK series of Sleeve Wrappers, covers a family of Fully Automatic

machines designed for collating product into a desired formation, then wrapping in a

sleeve of shrinkable film. The machines are of simple modular design which permits

customizing to suit user requirements. A number of options is available which can

be installed even after the machine has been put to use.

• Oval bottle wrapping option (WLO)

This machine has a specifically designed infeed and grouping section to enable

fast and effecient handling of oval shaped products resulting in attractive and

tight packs.

Note! For best results AUTOPACK Sleeve Wrappers should be matched with

AUTOPACK Shrink Tunnels to form high efficiency shrink Packaging

Systems of unequalled versatility.

Shrink Tunnels

AUTOPACK Shrink Tunnels are available in three basic models:

•Short length tunnel (TLX) designed for slower pharmaceutical and cosmetic

packing lines or label shrinking.

•Medium to high speed general purpose tunnels (TMX) suitable for most

shrink packaging applications

•Long series, heavy duty tunnels (THX), applicable at all speeds where

thicker films and heavy packs are used.

The machines are of simple modular design permitting customized user application

requirements. AUTOPACK Shrink Tunnels have a number of operating features

which are not normally found on similar type equipment. These are:

– Quiet and efficient operation

– Small external size compared to product handling capacity

– Symmetrical, fixed air flow pattern

– Drop down bottom for easy cleaning

– Cooling station with a roller accumulation conveyor

Because of its unique air flow, AUTOPACK tunnels can be used with a variety of

films and machines such as L bar sealers, flow wrappers, but the airflow symmetry

really excess with Sleeve Wrapped product, resulting in tight, unique form pack with

small holes on either side.

1.2-1 System Used

For Wrapper

a) Control System - PLC control Inductive proximity sensors. Some models have

simple relay control option.

b) Welding Bar Motion - Pneumatic cylinder activation of welding bar and rear

pack clamp.

c) Product Pusher and Lifter if fitted - Pneumatically operated, and guided units

with clip in product plates. This allows for quick change of product and pack

size.

1 Introduction

1-7

1

d) Film Welding and Cutting - Permanently heated bar with PID Electronic

temperature control. Quickly removable, welding-cutting tip ease of

maintenance. Welding bar height is adjustable with a quick-set clamp.

e) Film Feed - Centre shaft, film roll support with gravity feed, controlled by

multiloop film accumulators. AC motor driven twin roller cradle type support is

optional.

f) Film Loading - film rolls are mounted right at front of machine to facilitate ease

of loading and minimize risk of operator injury.

g) Transfer Surfaces - Collating table is lined with UHMW polyethylene to

minimize friction and wear. Outfeed table and slide are stainless steel.

h) Safety - Low pressure welding bar descent with electrical trip, two Stop

Buttons. Electrically interlocked transparent doors around collation table area.

For Tunnel

a) Control System - simple Relay/contactor circuit with some electronic control

b) Conveyor Drive - gear motor. fixed or variable speed depending on application

c) Conveyor Belt - stainless steel mesh for general purpose tunnels. STH uses

heavy duty chain with flat bars for product conveying.

d) Air Circulation - two or Four centrifugal force impellers are used to provide

symmetrical air pattern.

e) Heating - finned type air heating elements controlled by PID Electronic

Temperature control unit.

f) Outfeed accumulation conveyor - free running roller type accumulation

conveyor is provided.

g) Safety - the machine is well guarded. Where possible standard stainless

conveyor of small pitch is used. Two stop buttons are provided on either side of

the tunnel for emergency use.

1.2-2 Machine Design

AUTOPACK designers pay particular attention to specifying materials and finishes

that are durable, does not affect the packaged product and remain serviceable for

long time.

Manufacturer

This equipment was produced by:

Autopack Co., Ltd.

98/50 Moo 11 Putthamonthon Sai 5 Rd.,

Samphran, Nakornpathom

73210 THAILAND

1-8

1 Introduction

1

1.3 Machine Identification

Machine Plate

Each machine has its delivery information inscribed on the machine plate. When

contacting Autopack please provide Model and Serial no indicated for the specific

information.

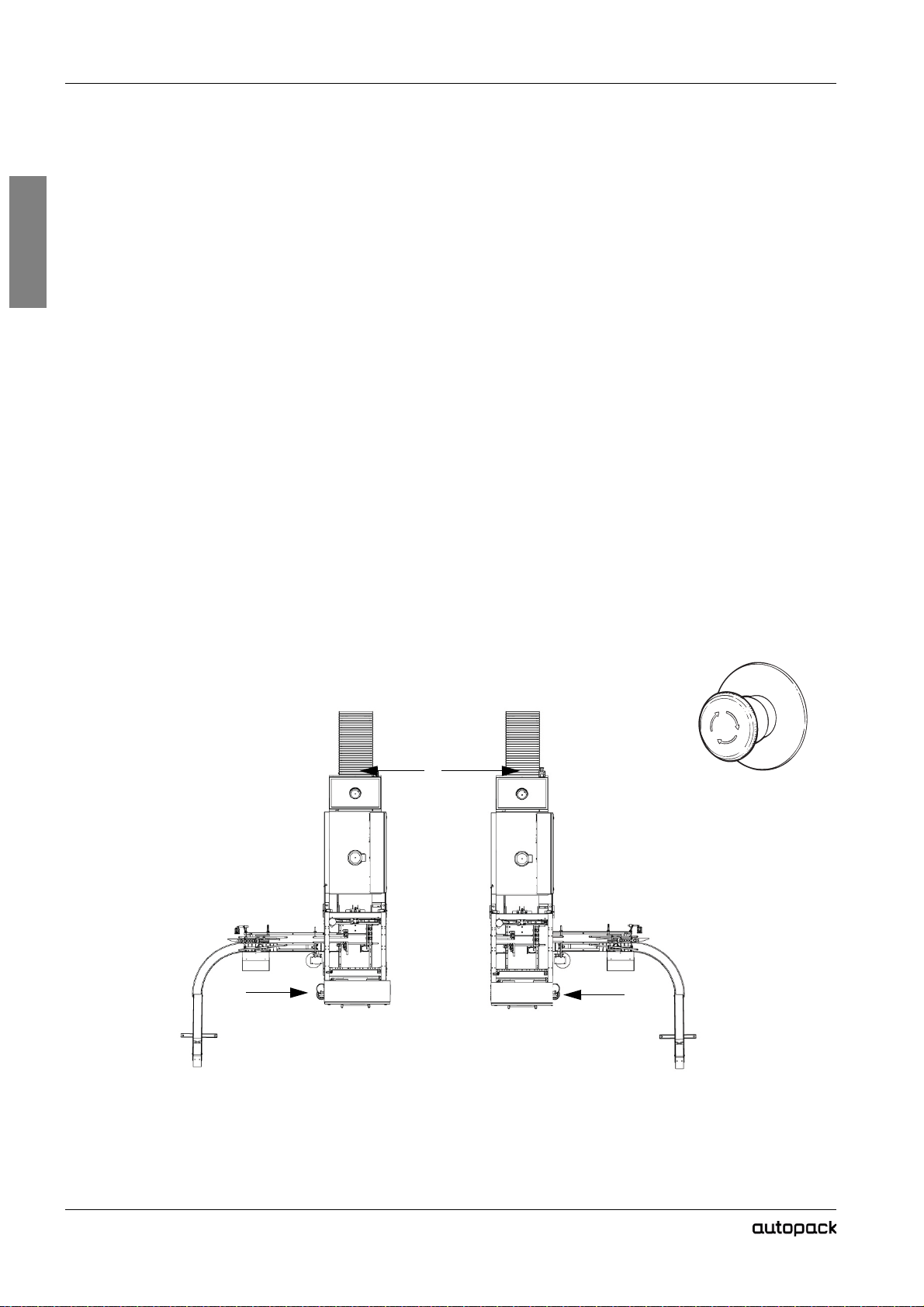

1.4 Machine orientation

Definition of direction

The below illustrations show the machine from above.

Aindicates the Rear of the machine.

Bindicates the Front of the machine.

Cindicates the Left of the machine.

Dindicates the Right of the machine.

Eindicates the Infeed of the machine.

Findicates the Discharge of the machine.

1

2

3

4

5

1 Machine Model

2 Supply voltage & frequency

3 Serial number

4 Maximum current rating

A

B

CD

E

F

A

B

F

E

CD

2-1

2

2 Safety precautions

2-2

2 Safety precautions

2

This page intentionally left blank

2 Safety precautions

2-3

2

2.1 Information 5

2.1-1 General 5

2.1-2 Hazard information 5

2.2 Warning signs 6

2.2-1 Warning signs 6

2.2-2 Prohibition signs 7

2.2-3 Warning and prohibition signs on the machine 8

2.3 Requirements on personnel 9

2.3-1 General 9

3.3-2 Service technician 9

2.3-3 Electrician 9

2.3-4 Machine operator 10

2.3-5 Fork lift driver 10

2.4 Emergency stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.5 Main switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.6 Door and covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.7 Electrical cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.8 Hot areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.9 Shrink tunnel belt conveyor . . . . . . . . . . . . . . . . . . . . . . . . .14

2.10 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.10-1 Chemical products . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2-4

2 Safety precautions

2

This page intentionally left blank

2 Safety precautions

2-5

2

2.1 Information

2.1-1 General

Incorrect use of the equipment will put your life in danger!

Autopack will take no responsibility for any fatal accidents, injuries to

personnel or damage to the machine if the machine or associated

equipment is installed, operated, and serviced without following the

instructions in this Technical Manual.

Risk of immediate danger to life!

Never inch or run the machine if any safety components included in

the safety system is non-operational. Non-operational safety

components must be changed immediately.

2.1-2 Hazard information

Hazard information in this document has the following significance:

Immediate danger to life!

Failure to observe this information will put your life in danger!

Risk of serious personal injury!

Failure to observe this information could result in serious personal

injury!

Caution! Risk of minor personal injury!

Failure to observe this information may result in minor personal

injury!

Important! Risk of damage to equipment!

Failure to observe this information could result in damage to

equipment!

Note! Is used to emphasize important information. A Note is not to be regarded as

hazard information.

!

DANGER!

!

DANGER!

!

DANGER!

!

WARNING!

2-6

2 Safety precautions

2

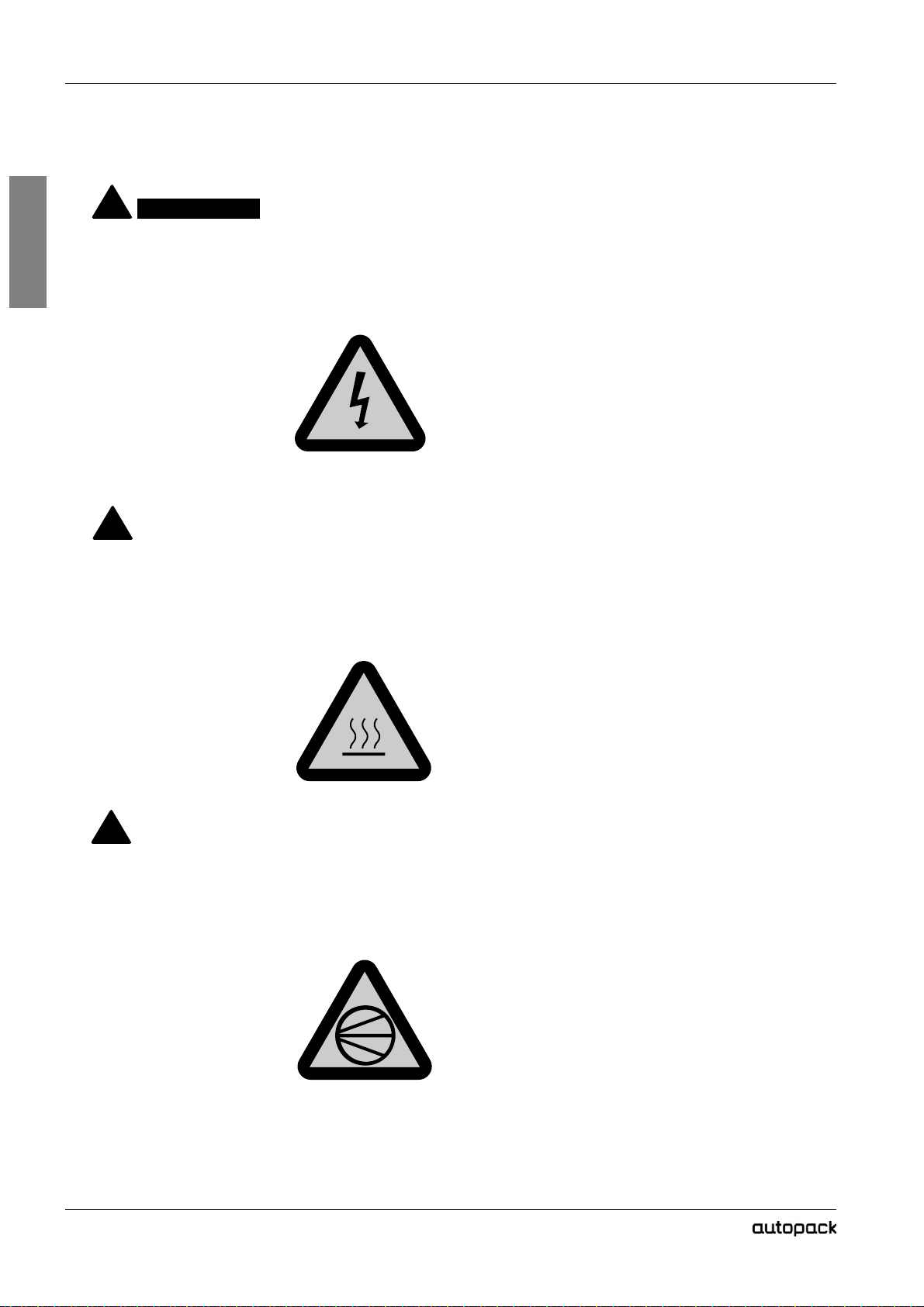

2.2 Warning signs

2.2-1 Warning signs

Risk of electrical shock!

Failure to observe will put your life in danger.

Enclosures which do not clearly show that they contain electrical devices are

marked with the warning sign below.

Hot surface!

Failure to observe could result in injuries caused by burning.

Hot surfaces are marked with the warning sign below. The temperature may exceed

60°C.

Pneumatic energy!

Failure to observe could result in injuries caused by moving parts!

The warning sign below indicates entrapped pneumatic energy in the area where

the warning sign is placed.

!

DANGER!

!

WARNING!

!

WARNING!

2 Safety precautions

2-7

2

2.2-2 Prohibition signs

Keep dry!

Failure to observe will put to your life in danger.

Never flush water or any other liquid towards an area with the prohibition sign

below.

Do not touch!

Failure to observe could result in loss of fingers or other body parts.

The prohibition sign below indicates a risk of personal injury in the area where the

prohibition sign is placed.

!

DANGER!

!

WARNING!

2-8

2 Safety precautions

2

2.2-3 Warning and prohibition signs on the machine

In the figure below shows the warning and prohibition signs location which are

delivered with the machine.

2 Safety precautions

2-9

2

2.3 Requirements on personnel

Risk of immediate danger to life!

Not following the Safety precautions will put your life in danger.

All personnel must regard all electrical equipment as live.

The work is to be carried out in such a way that there will be no risk of

personnel injury.

2.3-1 General

During maintenance or service work, the service technician and the electrician are

responsible not only for the machine, but also for the personnel in the vicinity of the

machine as well!

It is also the responsibility of the service technician and the electrician to assure that

the machine safety devices are fully operational before he/she finishes the

maintenance or service work.

3.3-2 Service technician

Only trained or instructed service technicians are allowed to work on the machine.

Service technicians may be:

• technicians employed by Autopack

The Autopack technicians are Autopack employees who have proper

knowledge and training for the service of the Autopack machines.

• technicians employed by the customer

Technicians employed by the customer must have the following skills:

– capable of reading (English or native) technical information

– understand technical drawings

– basic knowledge of mechanics and electronics

– basic knowledge of mathematics

– capable of handling (special) tools

2.3-3 Electrician

Electricians should:

• be certified according to local regulations

• have experience of similar types of installations

• have proven skills in reading and working from drawings and cable lists

• have knowledge of local safety regulations for power and automation

Work with the electrical equipment in the machine must be performed by skilled

persons only.

The use of a key or tool to carry out work by skilled persons for which it may not be

suitable to disconnect the equipment

The supply disconnecting mains may be operated as needed while the door is

open.

Examples of such operations are:

• resetting of protective devices

• adjustment of device settings

• fault finding and diagnostic testing

!

DANGER!

2-10

2 Safety precautions

2

2.3-4 Machine operator

Only trained or instructed persons are allowed to operate the equipment.

The machine operator is an individual that has enough training and/or knowledge to

run the equipment in the correct way.

2.3-5 Fork lift driver

Fork lift driver should be certified according to local regulations.

The fork lift driver´s role during installation is:

• to unload transport vehicle

• to plan and transport the machine or machine parts within the plant in a safe

and smooth way

• to assist when assembling Autopack equipment

2.4 Emergency stop

In case of danger to people or risk of damage to the machine, one of the four

Emergency stop buttons must immediately be pushed.

In order to stop the machine immediately in an emergency situation, you must

know the exact location of the Emergency stop buttons.

Emergency stop must only be used in case of danger to people or machine. To

stop production in the normal way, see the Stop section in chapter operation

instructions.

Note! Emergency stops do not disconnect the electrical supply to the machine.

Location Emergency stop buttons

1 E- Stop - Wrapper Electrical Cabinet

2 E- Stop - Cooling fan unit

11

2

This manual suits for next models

1

Table of contents

Popular Packaging Equipment manuals by other brands

CE CLEVELAND

CE CLEVELAND CE-225 Operation manual

Signode

Signode TENSION-WELD VT-32 Operation, parts and safety manual

Minipack-Torre

Minipack-Torre Galileo Installation, operation and maintenance

U-Line

U-Line S-15179 quick start guide

HSM

HSM StoreEx HDS 230 operating instructions

Orion

Orion L55S-13 instruction manual

hawo

hawo hd 680 DE-V instruction manual

MAILLIS

MAILLIS SIAT K11 Instructions and Spare Parts List

ITATOOLS

ITATOOLS ITA52 Operation manual

Pregis

Pregis AirSpeed SMART Quick Start User Manual and Safety Guide

Numatic

Numatic NES 570 Original instructions

Mercury

Mercury TP-702-59 Operation, Safety & Spare Parts Manual