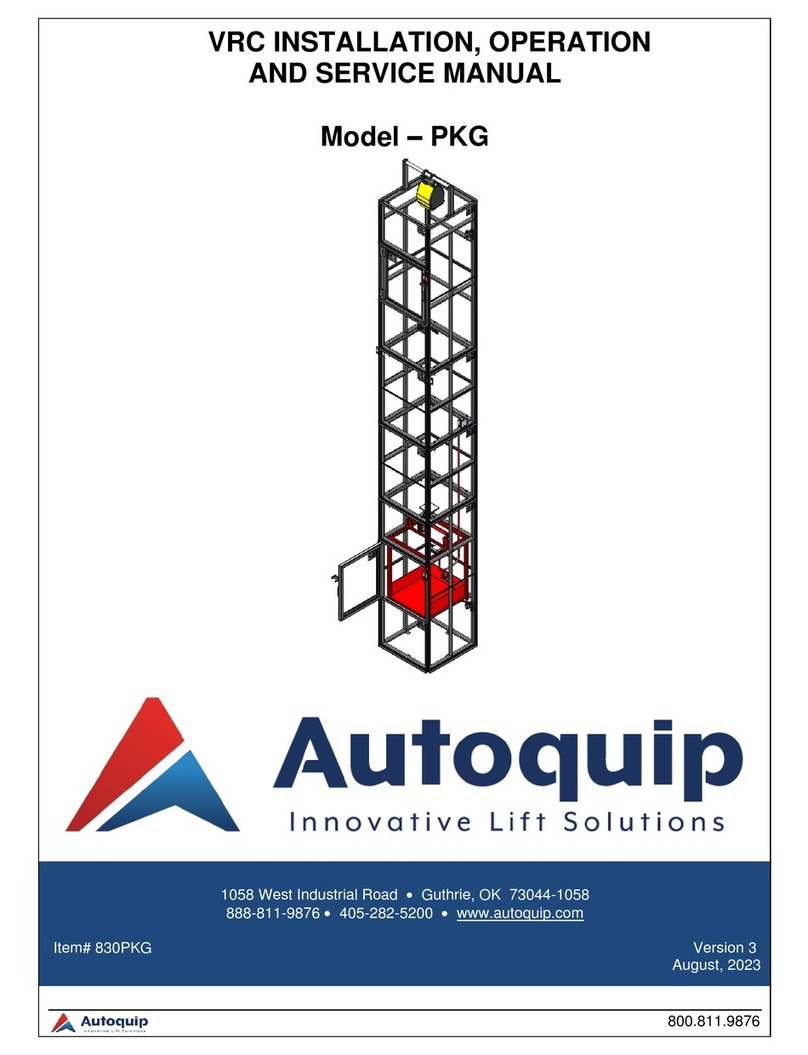

Autoquip FLT Setup guide

800.811.9876

Contents

1. Introduction.....................................................................................................................................1

1.1 Contact Information .......................................................................................................................1

1.2 Code Requirements/Compliance...................................................................................................1

1.3 Important .......................................................................................................................................1

1.4 Identification ..................................................................................................................................2

1.5 Inspection......................................................................................................................................2

1.6 Modifications..................................................................................................................................2

2. Responsibility of Owners/Users.....................................................................................................3

2.1 Inspection & Maintenance..............................................................................................................3

2.2 Removal from Service ...................................................................................................................3

2.3 Repairs..........................................................................................................................................3

2.4 Operators ......................................................................................................................................3

2.5 Before Operation ...........................................................................................................................3

2.6 During Operation ...........................................................................................................................3

2.7 Modifications or Alterations............................................................................................................3

3. Safety...............................................................................................................................................4

3.1 Safety Signal Words......................................................................................................................4

3.2 Safety Features.............................................................................................................................7

3.3 Safety Labels.................................................................................................................................9

4. Installation.....................................................................................................................................13

4.1 Pre-installation Activity.................................................................................................................13

4.2 Shipment and Initial Inspection....................................................................................................13

4.3 Equipment Layout........................................................................................................................14

4.4 Structural Installation...................................................................................................................14

4.5 Personnel & Equipment Safeties .................................................................................................14

4.6Testing.........................................................................................................................................15

4.7 Clean-up & Hand-off....................................................................................................................15

4.8 Tools Required............................................................................................................................15

4.9 Laying Out Platform Position & Marking Floors for Alignment......................................................16

4.10 Mechanical Installation Details.....................................................................................................18

4.11 Spliced Beams (when used) ........................................................................................................19

4.12 Bracing the Beams ......................................................................................................................20

4.13 Shimming and Anchoring.............................................................................................................22

4.14 Hydraulic Installation Details........................................................................................................24

4.15 Electrical Installation Details ........................................................................................................25

4.16 Installing Level/Lift Status Limit Switches.....................................................................................27

4.17 Test Run (Empty).........................................................................................................................29

4.18 Final Adjustments........................................................................................................................29

4.18.1 Relief Valve Adjustments......................................................................................................30

4.18.2 Pressure Switch Setting........................................................................................................31

4.19 Gate & Enclosure (Guarding) Installation.....................................................................................31

4.20 Shaft Way Barrier Bar Kit (for shaft way applications)..................................................................32

4.21 Back-Stop Kit (when ordered)......................................................................................................33

4.22 Installation Wrap-Up....................................................................................................................34

5. Blocking Instructions....................................................................................................................35

5.1 Lower the Platform.......................................................................................................................35

5.2 When the Platform Must be Raised .............................................................................................35

6. Operation.......................................................................................................................................38

6.1 Moving Up ...................................................................................................................................38

6.2 Moving Down...............................................................................................................................39

6.3 Emergency Stop..........................................................................................................................39

6.4 STORAGE...................................................................................................................................39

7. Maintenance ..................................................................................................................................40

7.1 Planned Maintenance Program....................................................................................................40

7.2 Routine Maintenance...................................................................................................................40

7.3 General Maintenance ..................................................................................................................41

800.811.9876

7.3.1 Oil Recommendations.......................................................................................................... 41

7.3.2 If a Platform Hangs Up or Jams............................................................................................ 41

7.3.3 Hydraulic Velocity Fuse (HVF) Replacement........................................................................ 42

7.3.4 Bleeding Air from System..................................................................................................... 43

7.4 Cylinder and/or Seal Replacement.............................................................................................. 44

7.4.1 Cylinder Removal................................................................................................................. 44

7.4.2 Seal Replacement................................................................................................................ 44

7.4.3 Re-Installing the Cylinder ..................................................................................................... 45

7.5 Schematics and Field Wiring Details ........................................................................................... 46

8. Troubleshooting............................................................................................................................ 47

9. Parts Lists ..................................................................................................................................... 52

9.1 General Assembly....................................................................................................................... 52

9.2 Typical Power Unit....................................................................................................................... 53

10. Warranty........................................................................................................................................ 54

1 800.811.9876

1. INTRODUCTION

Please read and understand this manual prior to installation or operation of this lift. Failure

to do so could lead to property damage and/or serious personal injury.

The control panel instructions are in the controller manual sent with the order.

These are required for installation.

1.1 Contact Information

If you have any questions, contact a local representative or use the Autoquip contact information below.

Autoquip Corporation

1058 West Industrial Road

Guthrie, OK 73044-1058

888.811.9876

405.282.5200

aqservices@autoquip.com

(FLT documentation page)

1.2 Code Requirements/Compliance

Vertical Reciprocating Conveyors (VRCs) are NOT elevators. This conveyor (lift) is designed for the

transfer of material only from one level to another. Absolutely NO RIDERS! VRCs have their own national

safety code (ANSI/ASME B20.1) and are specifically exempt from the National Elevator Code.

Some states require special components and have specific guidelines regarding how the equipment must

be installed, inspected, and tested. The owner is ultimately responsible for understanding these

requirements for the specific job location, and Autoquip will incorporate any special requirements into the

order as requested and approved by the customer.

Note: Contact Autoquip (see 1.1 Contact Information) with any questions you may have concerning VRC

code requirements.

1.3 Important

Autoquip Corporation has designed and manufactured the VRC to safely and efficiently move materials

between multiple floors or levels. It has been built to provide many years of dependable service.

OPERATORS - Please read and understand this manual prior to operation of this VRC. Failure to do so

could lead to property damage and/or serious personal injury.

Situations may arise which are not covered in this manual. If you have questions, please contact Autoquip

Customer Service (see 1.1 Contact Information).

iWARNING

NOTICE

2 800.811.9876

NOTE: Unless otherwise stated, mechanical installation does not include unloading, permits, seismic

calculations, or extensive acceptance testing. The requirements of each contract should be carefully

reviewed for possible conflicts of interpretation.

1.4 Identification

When ordering parts or requesting information or service on this lift, PLEASE REFER TO THE MODEL

AND SERIAL NUMBER. This information is on a nameplate attached to the control panel. Replacement

parts are available from a local representative or Autoquip (see 1.1 Contact Information).

Please record the following information and refer to it when contacting your representative or Autoquip.

Model Number: _______________________ Serial Number: ________________________

Installation Date: _____/_____/_____

1.5 Inspection

The “Bill of Lading” will state the number of pieces shipped. TWO ITEMS MAY BE BANDED

TOGETHER AND COUNT AS ONE PIECE.

Upon receipt of the shipment, check for exposed damage or shortages and make note of it on the trucking

company Bill of Lading or the Shipping Papers. Reports of concealed damage to items contained in crates

must be reported within 48 hours. DO NOT destroy the crating while opening it to inspect the contents. If

damage is suspected or found, report it directly to the carrier. DO NOT contact Autoquip Corporation!! All

shipments are FOB from the Autoquip plant. Any claims for damage must be filed with the carrier.

Any parts shipped from Autoquip that are intended to replace damaged or lost items will be

invoiced to the ordering party.

Assuming no damage has occurred to the crate(s), check the components against the packing list. This

will provide assurance that every item shipped has been received, report any shortages to Autoquip

Corporation within 10 days. (Autoquip is not responsible for parts lost, stolen or damaged during

transportation, storage, installation, or during any other circumstances that are be beyond corporate

control.)

1.6 Modifications

Do not modify lift. Autoquip cannot foresee and is not responsible for

injury or damage which results from unauthorized modifications or

misuse of lift.

NOTICE

iWARNING

3 800.811.9876

2. RESPONSIBILITY OF OWNERS/USERS

2.1 Inspection & Maintenance

The lift shall be inspected and maintained in accordance with this manual and with other applicable safe

operating practices.

2.2 Removal from Service

Any lift not in safe operating condition such as, but not limited to, excessive leakage, missing parts or

fasteners, any bent or cracked structural members, cut or frayed electric, hydraulic, or pneumatic lines,

damaged or malfunctioning controls or safety devices, etc. shall be removed from service until it is

repaired to the original manufacturer’s standards.

2.3 Repairs

All repairs must be made by a qualified technician in conformance with Autoquip’s instructions.

ASME B20.1 defines a qualified person:

Qualified person - a person who, by possession of a recognized degree or certificate of professional

standing or by extensive knowledge, training, and experience, has successfully demonstrated the ability to

solve problems relating to the subject matter and work.

2.4 Operators

Only authorized personnel shall be permitted to operate lift.

Authorized personnel - a trained or qualified person approved or assigned to perform a specific duty or

duties.

Trained personnel - personnel who have been trained by a qualified person and have demonstrated the

ability to perform a particular function on or around a VRC.

2.5 Before Operation

Before using lift, operator shall:

•Read and/or had explained, and understood, manufacturer’s operating instructions and safety

rules.

•Inspect lift for proper operation and condition. Any suspect item must be carefully examined and a

determination made by a qualified person as to whether it constitutes a hazard. All items not in

conformance with Autoquip’s specification must be corrected before operating lift.

2.6 During Operation

Use lift in accordance with this manual.

•Do not overload lift.

•Do not allow any portion of the load to overhang the perimeter of the platform.

•Verify all safety devices are operational and in place.

2.7 Modifications or Alterations

Modifications or alterations to this equipment may be made only with written permission of Autoquip.

Unauthorized modification or alteration will void warranty.

4 800.811.9876

3. SAFETY

3.1 Safety Signal Words

Before installing, operating or servicing lift, you must read, understand and follow the instructions and

safety warnings in this manual. Your lift may not be equipped with some optional equipment shown in this

manual.

The safety information in this manual is denoted by the safety alert symbol: i

The level of risk is indicated by the following signal words.

DANGER –Indicates a hazardous situation, which, if not avoided, will result in death or serious injury.

WARNING –Indicates a hazardous situation, which, if not avoided, could result in death or serious injury.

CAUTION –Indicates a hazardous situation, which, if not avoided, could result in minor or moderate injury.

NOTICE –Indicates a situation that could result in damage to the lift or other property.

The following alerts will be identified in this manual.

•Never go under lift platform until load is removed and mechanism is securely blocked in raised position with

maintenance devices (see 5 Blocking Instructions).

•All maintenance procedures described in this section should only be performed by qualified service personnel.

•Failure to properly adhere to lift blocking procedures is to risk the sudden and uncontrolled descent of the lift

during maintenance or inspection. A falling lift can cause severe injury or death.

•Do not stand beneath the platform while setting the maintenance device into position.

•Check the stability of the supports. If there is any chance of the support tipping or otherwise not providing a safe

and stable condition, do not go under the platform!

•Turn off the power and lock out the power at the primary power disconnect switch before service or

maintenance per OSHA Lock-Out, Tag-Out procedures.

•Never operate unit when parts are broken or damaged! Do not operate this equipment when non-factory

approved or damaged parts are in use! Contact local representative to rectify all such situations or contact

Autoquip (see 1.1 Contact Information).

•DO NOT walk out onto the platform or attempt to physically free the jam until load is removed and mechanism is

securely blocked with maintenance devices (see 5 Blocking Instructions).

iDANGER

iWARNING

iCAUTION

NOTICE

iDANGER

5 800.811.9876

•Please read and understand this manual prior to installation or operation of this lift. Failure to do so could lead to

property damage and/or serious personal injury.

•Do not modify lift. Autoquip cannot foresee and is not responsible for injury or damage which results from

unauthorized modifications or misuse of lift.

•Never run the unit with the gates or doors open! Do not operate unit with doors open or with the interlocks

“defeated” (bypassed)!

•Shaft way door barrier bars are not intended to be used as a primary means of personnel protection. It is the

responsibility of the operator to ensure that all gate/door interlocks have been installed and are functioning

properly. Serious injury or death could result if upper level gates/doors can be opened when the lift is not

present at that level.

•To protect against death or serious injury, all labels must be on lift and must be legible.

•If any of these labels are missing or cannot be read, contact Autoquip for replacement labels (see 1.1 Contact

Information).

•Do not weld on the guide flanges of the masts! Interfering with the free travel of the wheel guides could cause

permanent damage to the lift and prevent safety devices from operating as intended.

•Spilled hydraulic fluid is slippery and may also present a fire hazard. Clean up spilled hydraulic fluid.

•Use properly rated hoses only! Never use fittings or hoses that are not properly rated for the intended use.

•Do not over travel! Mechanical stops must be in place to prevent the platform from over traveling. Over-

traveling can cause permanent damage to the platform or failure of the lifting cylinders.

•Never operate the lift by “manual-ing” the electrical controls (using the contactors located inside the control

panel). All safety devices are by-passed in this mode of operation and lift damage or severe personal injury

could occur.

•Ensure one “WARNING – Do Not Tamper” label is adjacent to (within 6-12 inches) each sensing device (limit

switches, door status switches, door interlocks, etc.) in a location that is visible to the operator.

•GUARDS, INTERLOCKS, SAFETY DEVICES and ELECTRICAL CIRCUIT must be restored to correct

operation when installing parts or making adjustments or repairs.

•Failure to relieve operating system pressure could result in the sudden and unexpected release of high-pressure

fluids during maintenance and/or repair of the lift which may result in severe injury or death. Assume that all

hydraulic hoses and components are pressurized.

•Wear personal protective equipment, such as gloves and safety glasses, whenever installing, servicing, or

checking a hydraulic system.

•Never try to stop or check for a hydraulic leak with any part of your body; use a piece of cardboard to check for

hydraulic leaks.

•Small hydraulic hose leaks are extremely dangerous, and can inject hydraulic oil under the skin even through

gloves. Infection and gangrene are possible when hydraulic oil penetrates the skin. See a doctor immediately to

prevent loss of limb or death.

•Ingesting hydraulic fluid is toxic and hazardous to people and wildlife. Symptoms may be skin irritation,

weakness in the hands, intestinal bleeding, pneumonia, or death. Seek first aid immediately. Dispose of spilled

fluids appropriately.

•No riders! The VRC is provided for the sole purpose of transporting goods between floor elevations. At no time

should it be used to transport personnel.

•Before operating VRC, all personnel interacting with lift must read, understand and follow instructions and safety

warnings in this manual.

•Close all gates when not in use. Never leave the VRC unattended with gates left open.

•Do not use a swivel fitting between velocity fuse and cylinder. If installed improperly, it will not lock up in the

event of a hydraulic line failure.

•Velocity fuse is not repairable. Replace velocity fuse if defective.

iWARNING

6 800.811.9876

•Never use concrete anchor bolts on a cinderblock or brick wall! The wall will not withstand the pull force

developed by the lift. Use only recommended anchoring and bracing methods illustrated in this manual.

Equipment damage or personal injury could result.

•The pressure switch is not functional with temporary power! The power unit will continue to run as long as the

contact button is pressed. Permanent damage to the lift may result if power to the electric motor is not shut off

once the platform makes contact with the stop bolts.

•Purge air in the system! The presence of air in the system can lead to a lock-up of the velocity fuses. (Air reacts

like a spring when it is compressed.)

•Do not operate the VRC until the platform is leveled and the guide beams are plumbed and secure.

•Take extreme caution when running the unit before mechanical stops are installed and adjusted properly! Lift

over-travel can cause severe damage

•Do not operate motor at relief pressure! The motor should not be operated for more than a few seconds when

the unit is operating at relief pressure. Longer running times could result in damage to the pump.

•Do not operate motor without cover reinstalled on relief valve.

•Do not operate the VRC until all sensing switches have been confirmed to be installed and adjusted correctly.

•Do not use Teflon tape. Tape fragments can cause malfunctioning of the hydraulic system. Loctite PST #567

pipe thread sealant or equivalent is recommended.

•The control panel instructions are in the controller manual sent with the order. These are required for

installation.

•The “Bill of Lading” will state the number of pieces shipped. TWO ITEMS MAY BE BANDED TOGETHER AND

COUNT AS ONE PIECE.

•Autoquip recommends replacing any NPT fittings that have been disassembled due to their inherent design for

sealing.

•Use approved fluids only. Use of unauthorized fluids may cause damage to seals and hosing.

•Always find out why the E-Stop button may have been pressed, and be sure to correct the problem

(malfunction, interference, etc.) before making the lift operational again.

•In order for the lift to operate:

oAll gates/doors guarding the lift must be closed.

oLoads cannot hang over the edge or sides of the platform.

oThe load must be within the specified load capacity of the lift.

oAll electrical safeties, sensors, and switches must be in their “normal” condition.

•Per ASME B20.1, operator pushbutton stations must be located such that they cannot be activated while

standing on the platform.

•Make sure the top cylinder rod bolt is re-installed.

iCAUTION

NOTICE

7 800.811.9876

3.2 Safety Features

There are several active safety features and devices to help protect personnel, property, and the

equipment.

Zero Drift Feature

A zero-drift feature has been incorporated into the VRC. The zero drift uses a limit switch mounted at the

upper level and the pressure switch circuit. The limit switch is tripped closed when the platform is at the

upper level. The electrical circuit energizes if the pressure switch closes due to a pressure drop or leak.

The motor will start and build pressure until the pressure switch shuts the motor off. This keeps the

platform from drifting downward from the upper level. When the operator closes all gates and energizes

the down pushbutton, the zero drift circuit is disabled and the platform will lower.

Hydraulic Velocity Fuses

Each hydraulic cylinder has a hydraulic velocity fuse (HVF) installed in the cylinder port. These HVFs are

installed at a predetermined flow velocity as the oil returns to the reservoir. They do not affect incoming oil.

Should a catastrophic rupture or breach occur in the hydraulic system, and oil flows through the breach

that exceeds the HVF rating, the HVF will trigger and lock up. This lock up will occur within one to two

inches of downward movement of the platform.

NOTE: Air in the system will also cause a lock up. Air acts like a spring when compressed. To remove

air from the system, (see 7.3.4 Bleeding Air from System).

NOTE: Small fitting leaks will not trigger the HVFs. In an air-free system, the breach must be large

enough to cause an uncontrolled or destructive lowering speed. Should a triggering and lockup occur, it

can only be released by applying upward hydraulic flow in a functional system.

Safety Release Bypass Valve (SRBV)

The SRBV is a part of the hydraulic system. Should the system pressure exceed the predetermined

pressure setting, the SRBV will bypass the pump output back to the oil reservoir. The SRBV is factory set

to the proper pressure, which will prevent damage to the mechanical, hydraulic, and electrical systems due

to overloading, obstruction, or other circumstances. This setting should be tested once installation is

complete (see Installation section).

Power Supply Secondary Circuit Breaker

This circuit breaker is down stream of the power supply and protects the 24 volt DC control circuit from

damage should a fault occur which would result in excessive electric current flow. Should the circuit

breaker trip it will prevent operation and the interlock circuit will not operate. These circuit breakers are

located in the control enclosure.

Motor Overload Relays (MOR)

These are current sensing devices that are located in line with the three legs of the electric motor primary

power circuit (208, 230, or 460 volt). They protect the motor from excessive current draw and overheating

if it becomes overloaded or has a short circuit. Should an over-current situation be detected on any leg

the MOR will trip and open the path to ground for the contactor coil via an auxiliary contact.

8 800.811.9876

Safety Interlocks/Latches-Gates or Doors (where applicable)

These are electro/mechanical devices that prevent operation of the VRC when the gates or doors are left

open on any level. They also prevent the gates or doors from being opened at any level unless the

platform is in place at that floor level.

Never run the unit with the gates or doors open! Do not operate unit with

doors open or with the interlocks “defeated” (bypassed)!

Shaft Way Door Barrier Bars (where applicable)

Shaft way door barrier bars are designed to provide a secondary means of personnel protection at the

upper level landing of a VRC shaft way installation. When the platform is not present at the upper level,

the two barrier bars rest in permanent brackets attached to both sides of the door frame on the outside

(shaft side) of the upper level door. The barrier bars form rigid barriers at approximately 24inchs and

48inches above floor level. In the unlikely event that the upper level door is able to be opened when the

platform is not at the upper landing, the bars provide an additional means of personnel protection against

stepping or backing into the shaft way where the platform could be assumed to be present.

When properly installed, the barrier bars are lifted up along their tracks by the platform as it approaches

the upper landing until it is completely above the load height as the lift stops. As the lift moves to the lower

level, it carries the bars back to their stationary brackets attached to the outside of the door.

Shaft way door barrier bars are not intended to be used as a primary

means of personnel protection. It is the responsibility of the operator to

ensure that all gate/door interlocks have been installed and are

functioning properly. Serious injury or death could result if upper level

gates/doors can be opened when the lift is not present at that level.

Personnel Guards

Depending on the application, one or more of the following personnel protection features is included in the

design of this equipment (different states may vary on the exact design and orientation of these features –

IT IS IMPORTANT TO BECOME FAMILIAR WHITH THE SPECIFIC CODE REQUIREMENTS OF YOUR

STATE):

•GATES & ENCLOSURES: Required per ASME B20.1 to protect personnel from inadvertent

physical contact with a moving lift & moving load at all lift landings.

•PLATFORM RAILINGS & SNAP CHAINS: Required per ASME B20.1 to protect personnel

whenever personnel walk onto the lift platform when in the raised position. Railings or side guards

protect non-operating sides, snap chains protect operating sides.

•PLATFORM BACK-STOP PANELS: Additional safety feature required at all upper levels to

provide additional fixed guarding 2 inch (max.) away from & across all unused, operating sides of

the lift (typical with non-shaft way, “Z”, & 90-degree load patterns).

iWARNING

iWARNING

9 800.811.9876

3.3 Safety Labels

To protect against death or serious injury, all labels must be on lift and

must be legible.

If any of these labels are missing or cannot be read, contact Autoquip for

replacement labels (see 1.1 Contact Information).

FLT labels (platform)

Item #

Qty.

Description

Part No.

1

1

Autoquip Logo Label

36403220

2

1

Warning –No Riders

36404093

3

1

Capacity

DECAL_CAPACITY

4

1

Caution –Familiarize Yourself . . .

36401487

5

1/rail

Warning: Platform Personnel Guarding

36403720

iWARNING

10 800.811.9876

1 –36404093

2 –36403220

3 –DECAL_CAPACITY

4 –36401487

5 –36403720

11 800.811.9876

FLT labels (other locations)

Item #

Qty

Description

Part #

1

1

WARNING, ONLY AUTHORIZED AND TRAINED….

36405670

2

1

DANGER, THIS DOOR MUST BE CLOSED….

36405680

3

1

WARNING, NO RIDERS

36405705

4

1

WARNING, NO RIDERS

36404093

5

1

DANGER, ARC FLASH, SHOCK

36430303

6

1

WARNING, DO NOT OPERATE W/O PLATFORM….

36403720

7

1

WARNING, DO NOT TAMPER w/ THIS SAFETY DEVICE

36405695

8

1

AUTOQUIP SERIAL NUMBER NAME PLATE

36401570

12 800.811.9876

3 - 36405705

1 –36405670

2 - 36405680

4 –36404093 5 –36430303

6 –36403720

7 - 36405695

8 –36401570

13 800.811.9876

4. INSTALLATION

The control panel instructions are in the controller manual sent with the order.

These are required for installation.

Proper installation of Vertical Reciprocating Conveyors (VRCs) is vital to the safety of the operators, the

efficiency of the unit, and the ultimate satisfaction of the end user. These guidelines have been prepared

by member companies of the Material Handling Industry’s VRC Subcommittee to assist the VRC installers

in understanding their role and responsibility in providing customers with a safe and reliable VRC.

4.1 Pre-installation Activity

1. Whenever possible, make a pre-installation visit or contact someone at the site. Installers must be

familiar with everything relative to proper installation of this equipment. It is the installer’s

responsibility to check the site for problems and work out solutions with the appropriate people –

preferably before installation begins.

2. Check floor-to-floor dimensions on the general arrangement drawings to make sure that they match

on-site conditions. VRC’s are designed and built to individual applications and specific customer

requirements. It is difficult and expensive to modify the lift after it arrives for installation.

3. Installation may or may not include unloading, permits, seismic calculations, or extensive acceptance

testing. The requirements of each contract should be carefully reviewed for possible conflicts of

interpretation.

4. Each state, county, or municipality may have unique codes governing the installation and

acceptance of VRC’s. Acquaint yourself with the permitting and/or licensing requirements (and

expenses) of the local regulatory agencies.

Note: some agencies may require inspection or testing before and/or after lift start-up. Contact

Autoquip (see 1.1 Contact Information) with any questions you may have concerning VRC code

requirements.

5. Make sure there is adequate ingress/egress to the installation site. Verify that the equipment can get

through the existing doorways, halls, and shaft openings. Think through how the lift will be unloaded,

carted/moved, raised into position, and accessed for installation, operation & maintenance.

6. Verify the construction and integrity of building columns, joists, walls, or mezzanines that will be used

to help support the VRC mast guide beams.

4.2 Shipment and Initial Inspection

1. Upon receipt of the shipment, check for exposed damage or shortages and make note of it on

receiving paperwork from the trucking company, any claims for damage must be filed with the

carrier. Unless otherwise stated, the VRC Manufacturer is not responsible for parts lost, stolen or

damaged during transportation, storage, or installation.

2. Assuming no damage has occurred to the crate, check the components against the packing list. This

will help ensure that every item shipped has been received.

NOTICE

14 800.811.9876

3. Make sure you have a copy of the latest version of the general arrangement and electrical drawings

before beginning installation, changes could have been made since original purchase order submittal

and order entry.

4. Read and understand this manual thoroughly prior to starting the installation.

4.3 Equipment Layout

1. Make sure pit and/or lift are properly squared and vertically aligned with upper landings to ensure

that the platform will clear the upper landings by the required distance.

2. Be sure to take into consideration any other obstructions (pipes, ductwork, ceiling joists/beams, etc.)

that may be located around the lift.

3. Inspect the installation for any overhanging floor landing or other obstruction (pipes, ductwork, ceiling

joists/beams, etc.) which could potentially jam a load that is slightly overhanging the platform deck as

it raises to the next floor level. Any potential jam point should have some type of slanted or beveled

guarding placed beneath the obstruction to push the overhanging load back onto the platform.

4.4 Structural Installation

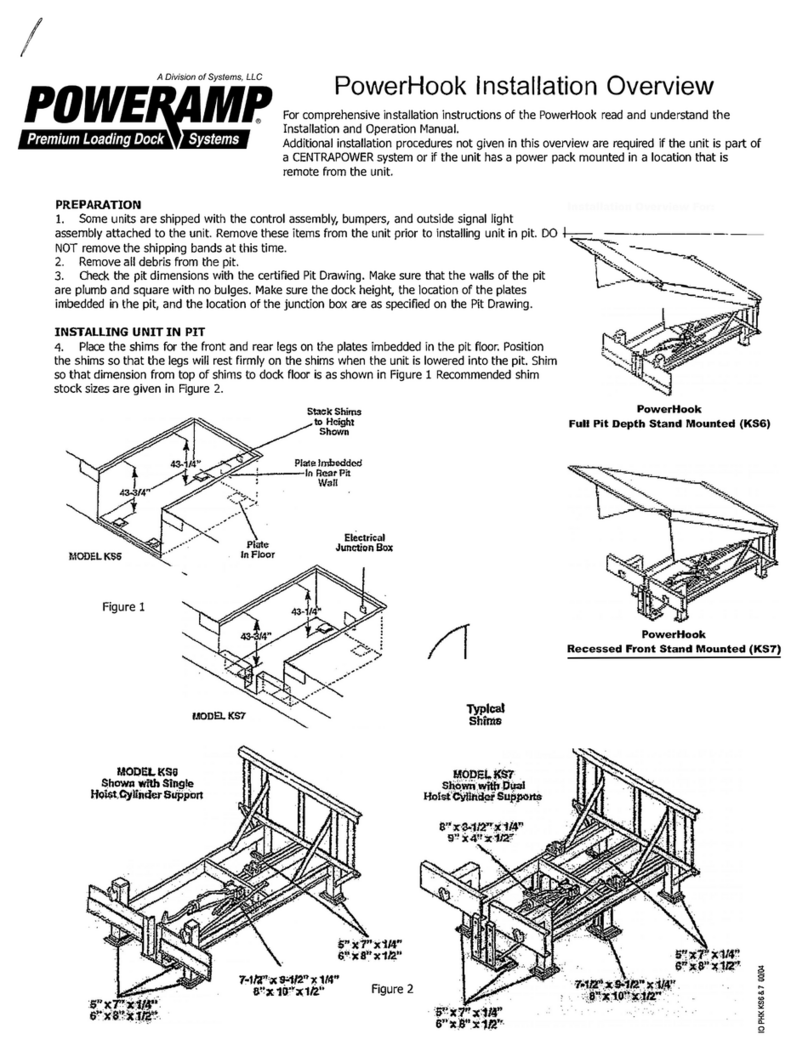

1. Follow the bracing recommendations shown on the general arrangement drawings and in the

installation & Service manual. Site conditions may also require customization to standard anchoring

and bracing. The installers are ultimately responsible for the proper and safe anchoring and bracing

of the equipment and should consult the manufacturer if there is any doubt as to the structural

integrity of the installation.

2. When anchoring guide beams to walls, you must be sure that the walls can support the reaction

loads imparted on them.

3. If spliced masts are provided, be sure to assemble and field install them exactly to the

Manufacturer’s recommendations. Failure to do so will reduce the safety and performance of the

VRC. See Installation Section for acceptable limits.

4. Make sure guide beam pairs are plumb, parallel, and straight after you are finished with all welding.

See Installation Section for acceptable limits.

5. Do not modify any component of the lift without expressed written consent from the Manufacturer.

4.5 Personnel & Equipment Safeties

1. ASME B20.1 requires that all VRC installations be completely guarded to prevent injury from

inadvertent contact with the lift or its load. ASME also requires that doors or gates at all unloading

stations be interlocked so that these doors can only be opened when the lift platform is stopped at

that level & that the platform is incapable of being operated or moved so long as these doors or

gates remain open. It is the responsibility of the installer to ensure that the installation meet these

requirements, regardless of who (manufacturer, customer, architect, general contractor, etc.)

provides the doors/gates and means of enclosure. Consult Autoquip whenever there is a question as

to whether the gate & enclosure installation meets ASME B20.1.

2. Where the application requires personnel to walk onto the platform in the raised position, the installer

must ensure that the platform is adequately provided with railings, guards, and snap chains that are

a minimum of 42 inch high.

3. Travel limit switches must be installed and working properly.

15 800.811.9876

4.6 Testing

1. Test up and down speeds.

2. Test all electrical switches and sensors, gate interlocks, gate status switches, and any other safety

features or devices as described in the Installation section of this manual. Also consult any manuals

which may have been shipped separately for the gate installation & operation.

3. Some states or municipalities may require testing of the platform free-fall arrest system (locking

cams) –consult the local regulatory agency or the manufacturer.

4.7 Clean-up & Hand-off

1. Conduct a final inspection of the lift installation using the Installation Checklist in the Appendix of this

manual. Correct any deficiencies before clean-up & hand-off.

2. Apply proper signage to all locations of the installation per the guidelines in the Label Identification

section and per any instructions shipped separately with the gate interlock kits. Contact Autoquip

(see 1.1 Contact Information) if labels appear to be missing or damaged.

3. Clean up any spilled oil from the area.

4. Train key personnel on the operation of the system and all safety features and procedures by

referencing the corresponding sections in this manual.

4.8 Tools Required

Listed below are some of the tools needed to install the VRC in a professional and prompt manner.

Individual site situations and a basic variation in the types of units may dictate the need for additional

items.

Welding Machine and Equipment

Disk Grinder

Cutting Torch with full Tanks

Drill and Drill Bits

Fire Extinguisher

Extension Cords

Forklift

Sledgehammer

Chain Fall

Open or box end wrench

Come-A-Long

Drift Punch

Cables or Hook Chains with 1,000# Cap.

Carpenter’s Square

Hack Saw, Reciprocating Saw, or portable band saw

Chalk Line

“C” Clamps (12 inch opening)

Plumb Bobs

Socket Set (½ inch drive, sockets to 1⅛inch)

4 foot Level

Pinch Bar

25 foot Measuring Tape

Hammer Drill & Bits for ¼, ⅜, and ½ inch anchors

Broom

The following supplies will also be needed:

•Concrete anchors (8 minimum) sized for the required minimum pullout of the base floor channels

and upper level bracing. Refer to the approval drawing since the size of the anchors can vary for

each installation.

•Concrete anchors for accessories, such as enclosures, approach ramps, etc. (Usually ⅜inch

diameter anchors and at least 12 anchors, minimum.)

16 800.811.9876

•Shim stock for the floor channel, platform corners, and/or approach ramp (if a part of this

installation)

•Hydraulic oil (see oil recommendations and tank capacity in “Specifications” section)

•Paint (standard colors available in spray can, and 1 or 5 gallons)

•Steel angle iron or channel for additional bracing

ALSO - BEFORE YOU BEGIN:

•Beams are too heavy to lift manually and require lifting equipment. Check for availability of

overhead attachment of chain fall or of fork truck before you start.

•Before you will be able to complete the installation, the unit must be operated. Power to the motor

(even if temporary) is required. Arrange for power before starting installation.

NOTE: All illustrations contained in this manual are for reference purposes only. Specific applications and

site conditions may require different anchoring and bracing procedures. The ultimate responsibility for the

anchoring and bracing rests with the installation crew.

See 9.1 General Assembly for part identification and nomenclature.

4.9 Laying Out Platform Position & Marking Floors for Alignment

The following illustrates how to lay out and mark the reference lines so that the lift will clear the upper

landing and any obstructions that may be located around the lift. The General Arrangement (GA) Record

Drawings should indicate the necessary clearance needed for the particular application.

1. Layout the position of the lift at the second level landing/opening, marking the edges of the platform.

NOTE: Depending on your load pattern, the platform may not be centered on the opening.

2. Drop a plumb line from each corner of every edge at the second floor holding the plumb line 1 inch

out from the edge of the landing (this is a standard distance for clearance - deviations may occur).

3. Using a chalk line, snap a line between the plumb lines at the lower level.

4. Check the clearance from the first level all the way up ensuring there is 1 inch of clearance for the

entire travel.

NOTE: To ensure platform clearance between floors, remove any protrusions from the

floor, wall, etc., or move the plumb lines out beyond the protrusions.

17 800.811.9876

This manual suits for next models

1

Table of contents

Other Autoquip Lifting System manuals

Popular Lifting System manuals by other brands

logitrans

logitrans LOGITILT LT1001 manual

HADEF

HADEF 27/12-EX Installation, Operating and Maintenance Instruction

Prowise

Prowise iPro Toddler Lift user manual

Maxon

Maxon Tuk-A-Way GPT Series installation manual

StoreYourBoard

StoreYourBoard Hi-Lift PRO quick guide

Atlas Escalateurs

Atlas Escalateurs VISTA installation manual