17hh

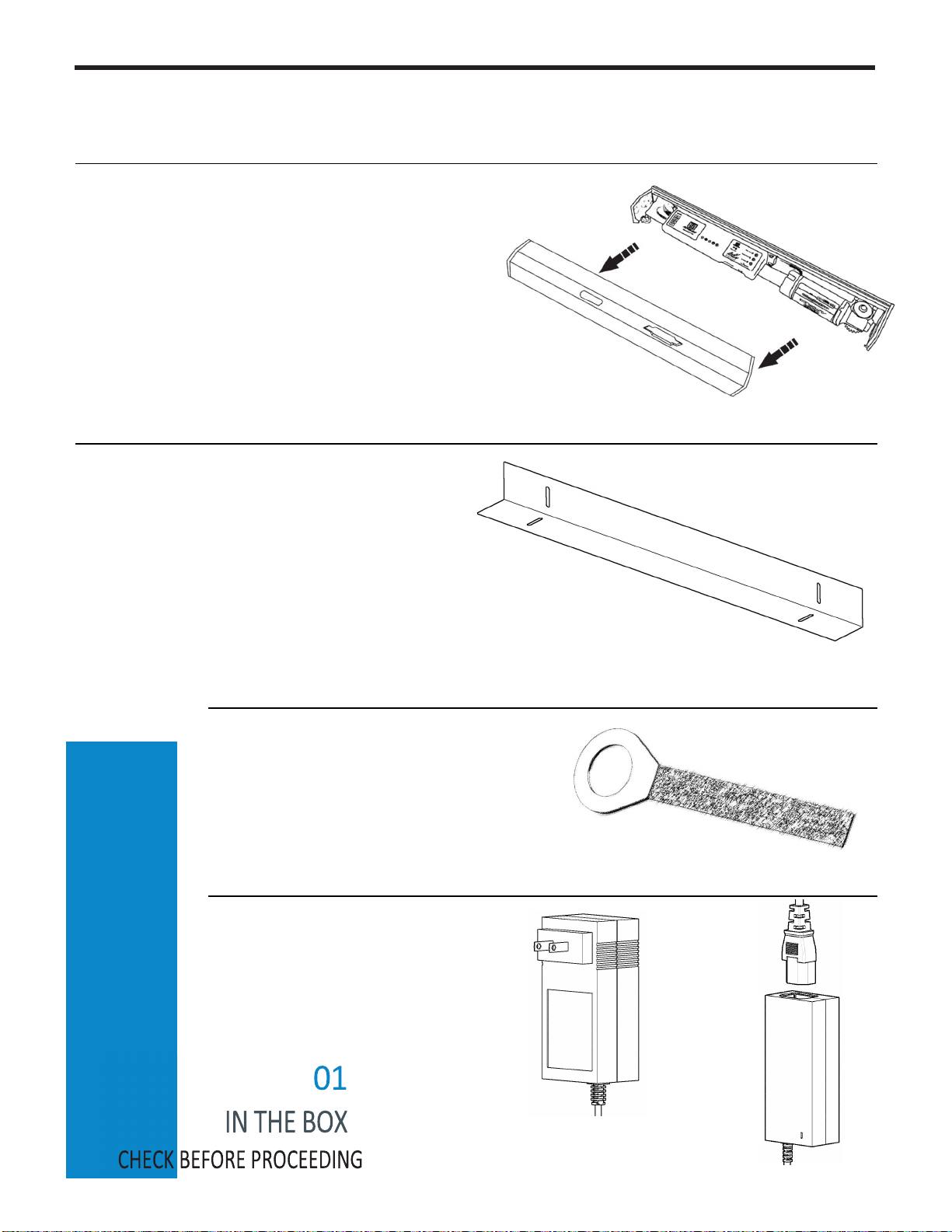

LOCKING, MODE, AND SENSOR PORT GUIDE

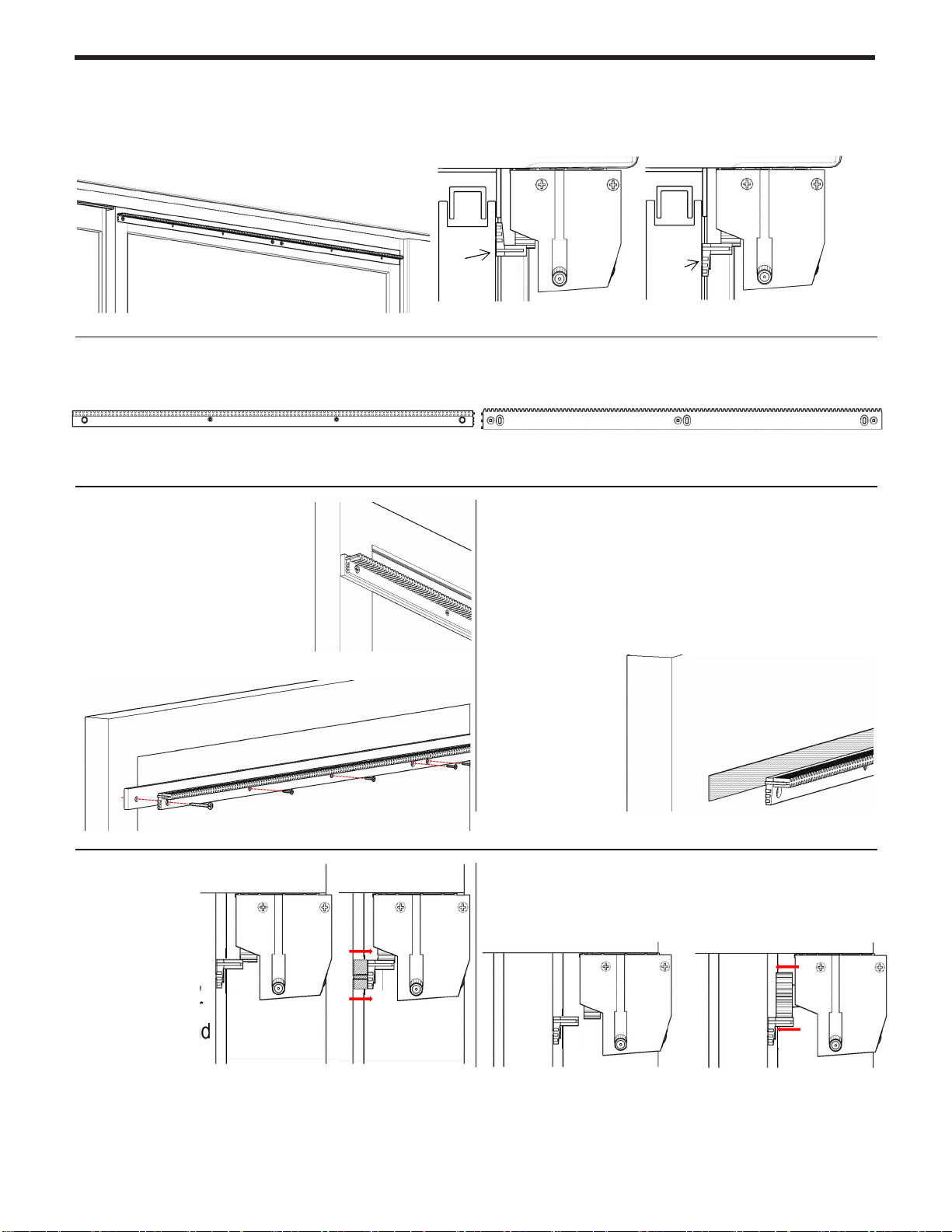

The AutoSlide Standard iLock and Autoslide Elite

iLock include a dynamic breaking lock built into the

motor. This will lock the door when closed, provided

the AutoSlide is in a locking mode. An iLock system

will always include a chrome cylindrical segment

towards the end of the motor barrel:

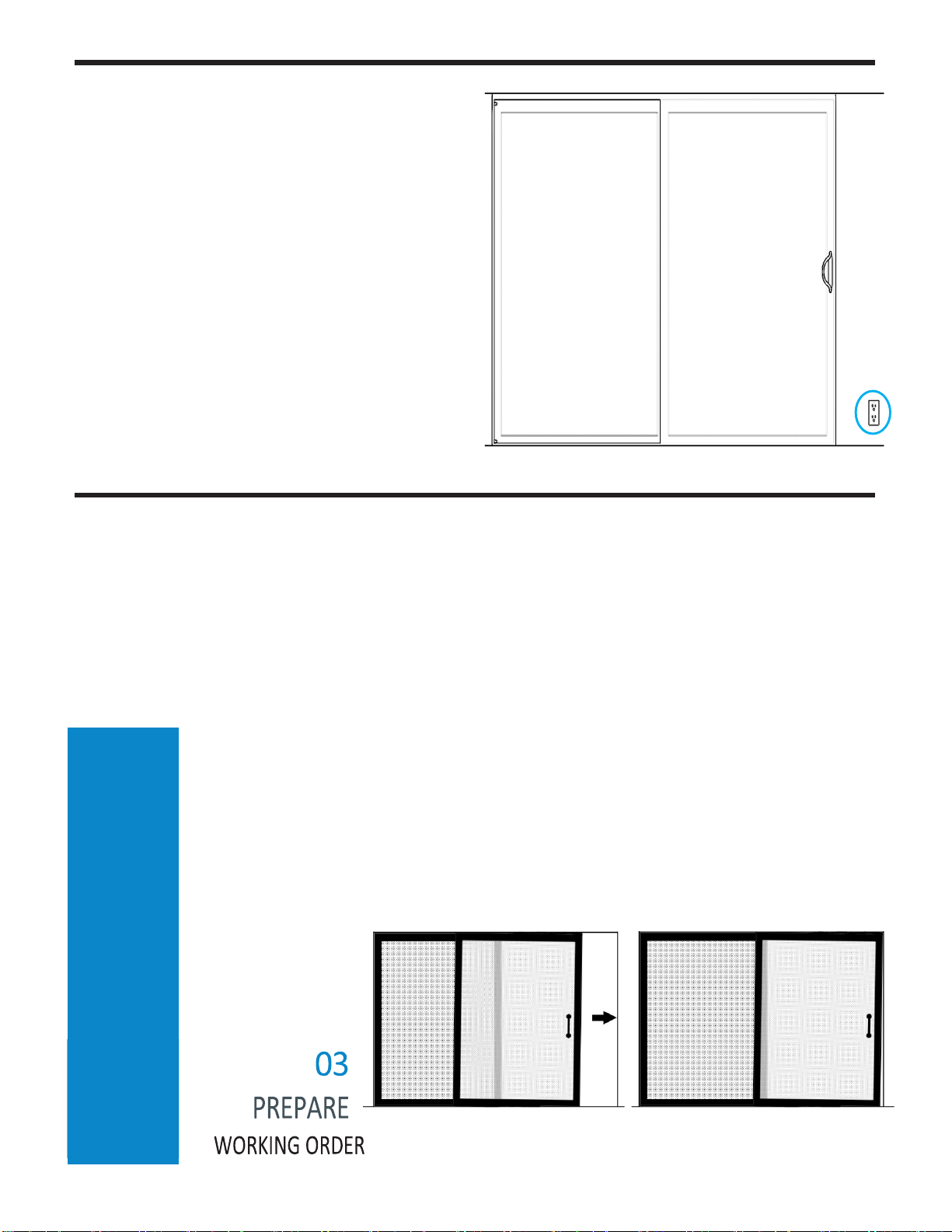

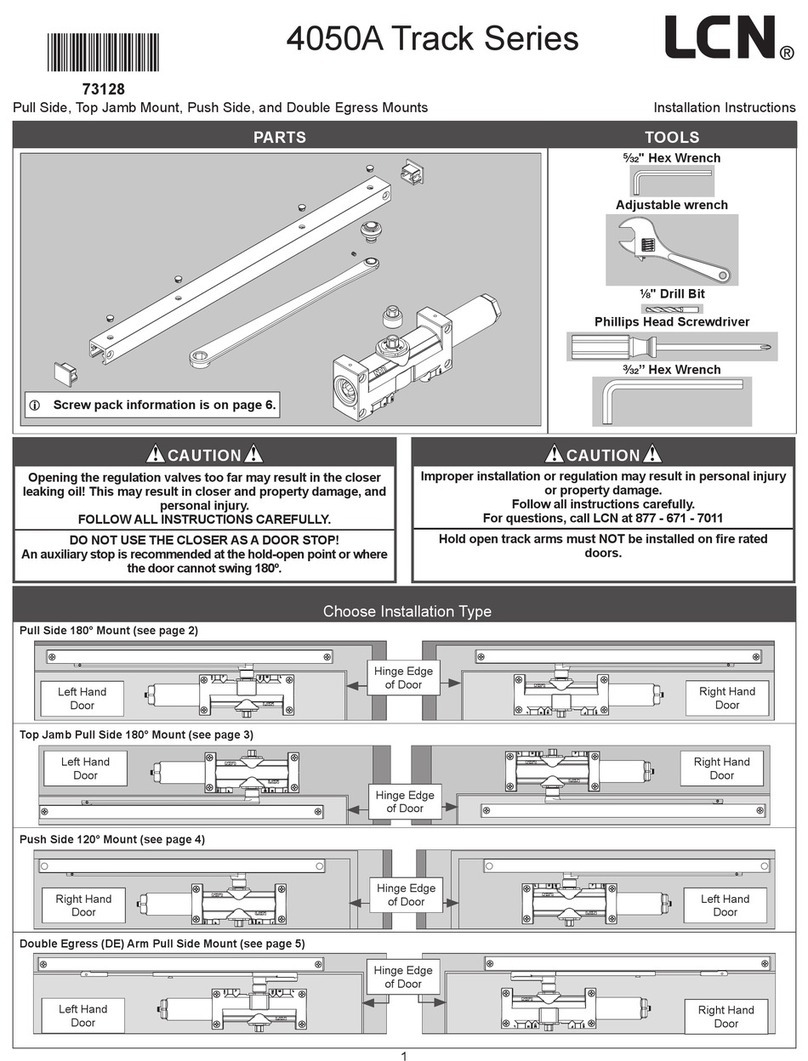

The AutoSlide system uses four unique modes:

A mode for everyday human use. Pet sensors

are disabled, open-assist is enabled, and the

door doesn’t lock. Most commonly used mode.

By default, keeps the door fully open. A sensor

connected to the Stacker Port can operate the

door like a garage door, leaving it open partially.

A security mode designed for use with iLock

units. Outside sensors are disabled, open-

assist is disabled, and the door is locked.

Primary mode for pet use. Pet and Inside

sensors are enabled. Outside sensors can be

disabled. Pet distance enabled. Door is locked.

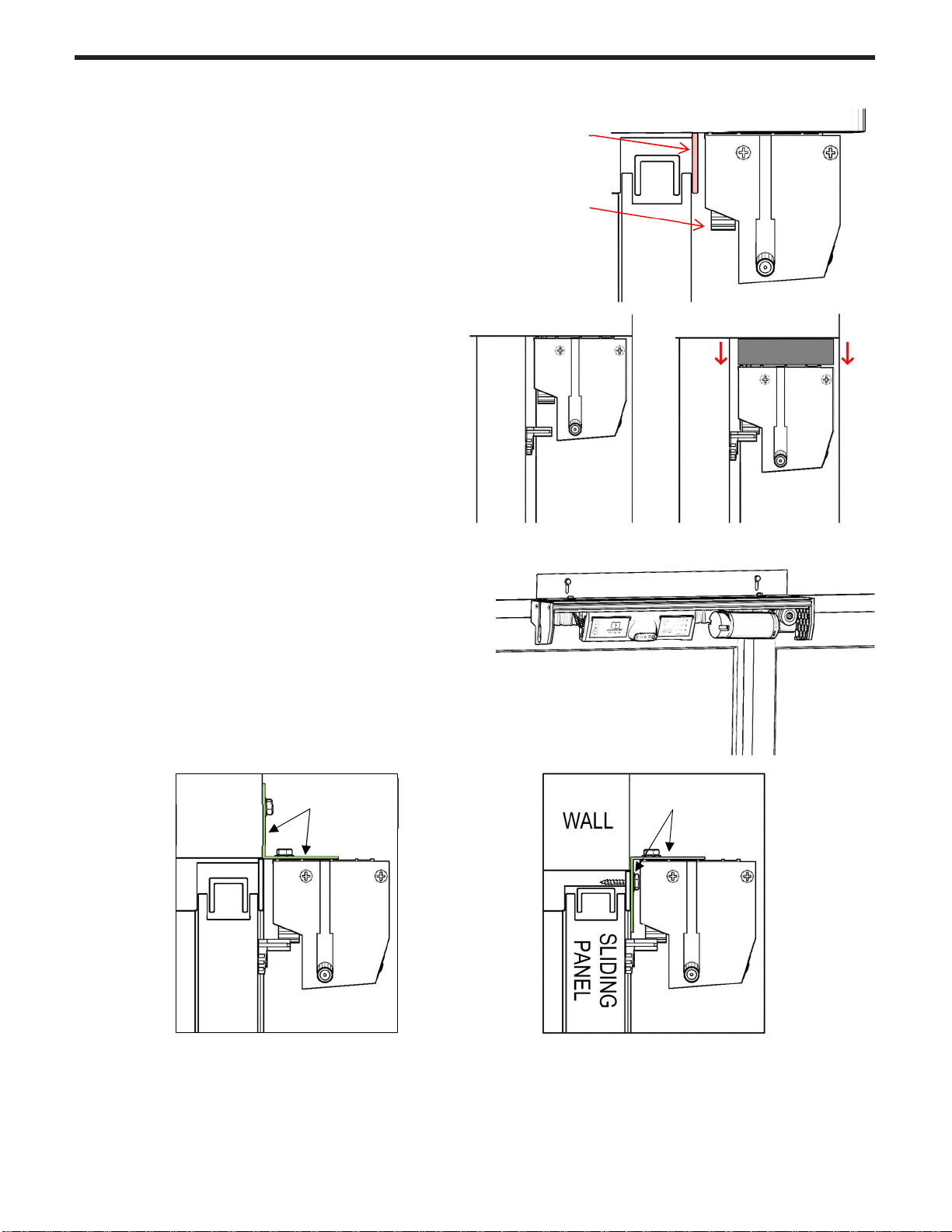

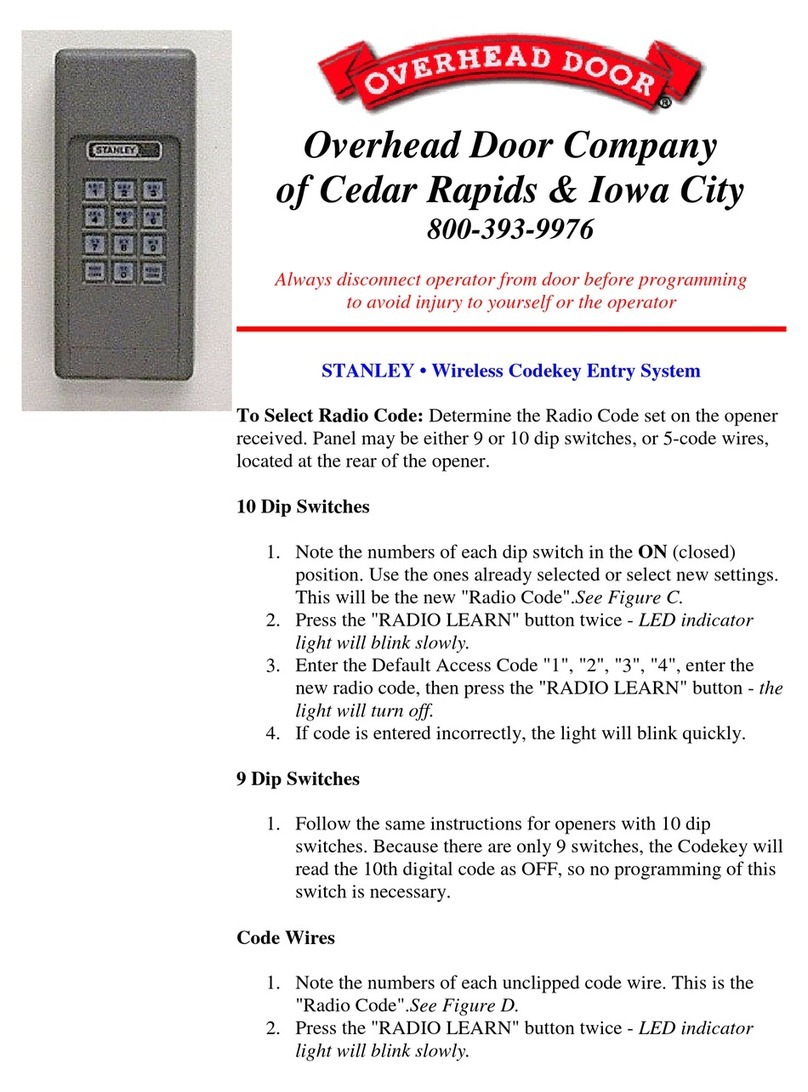

These are indicated by the four mode

icons on the front of the control panel:

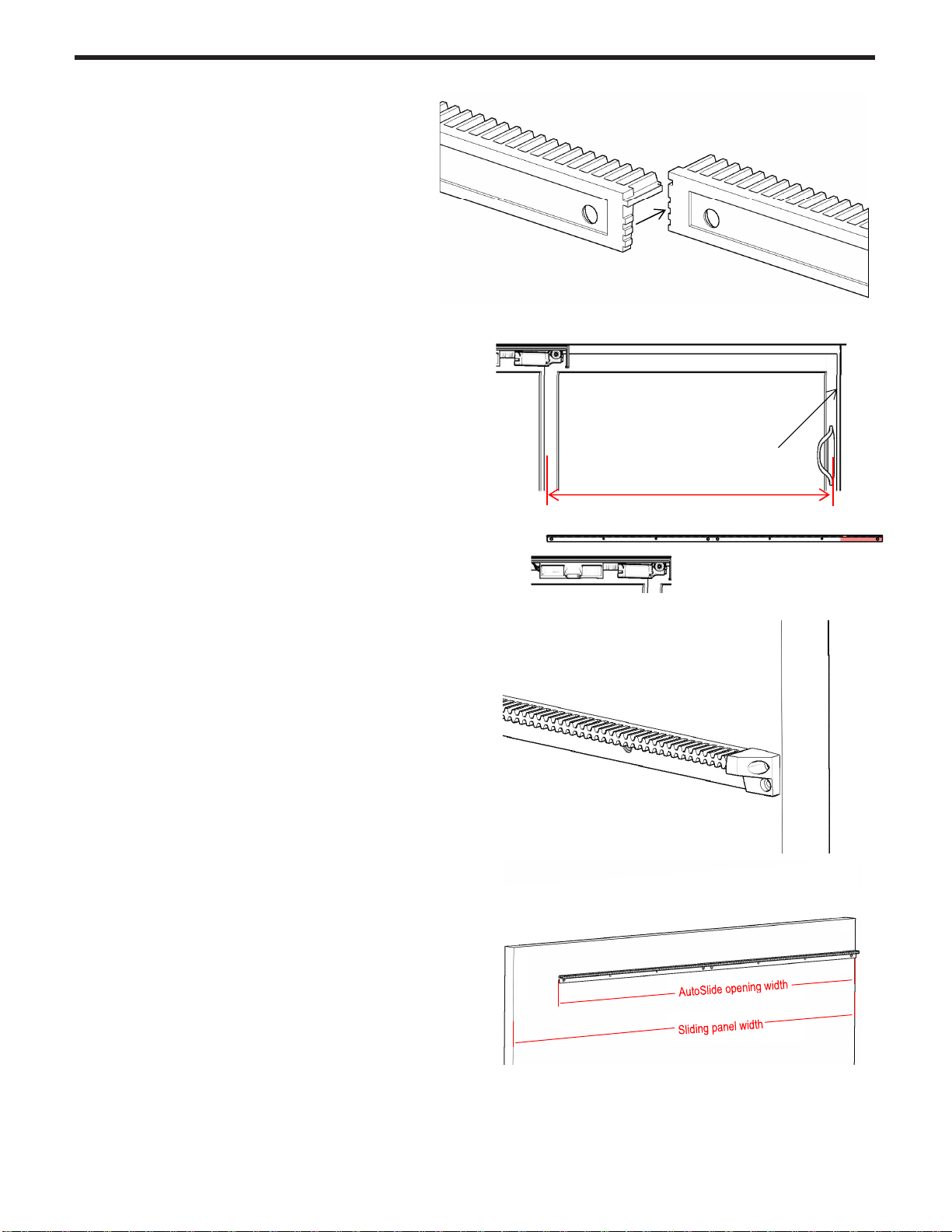

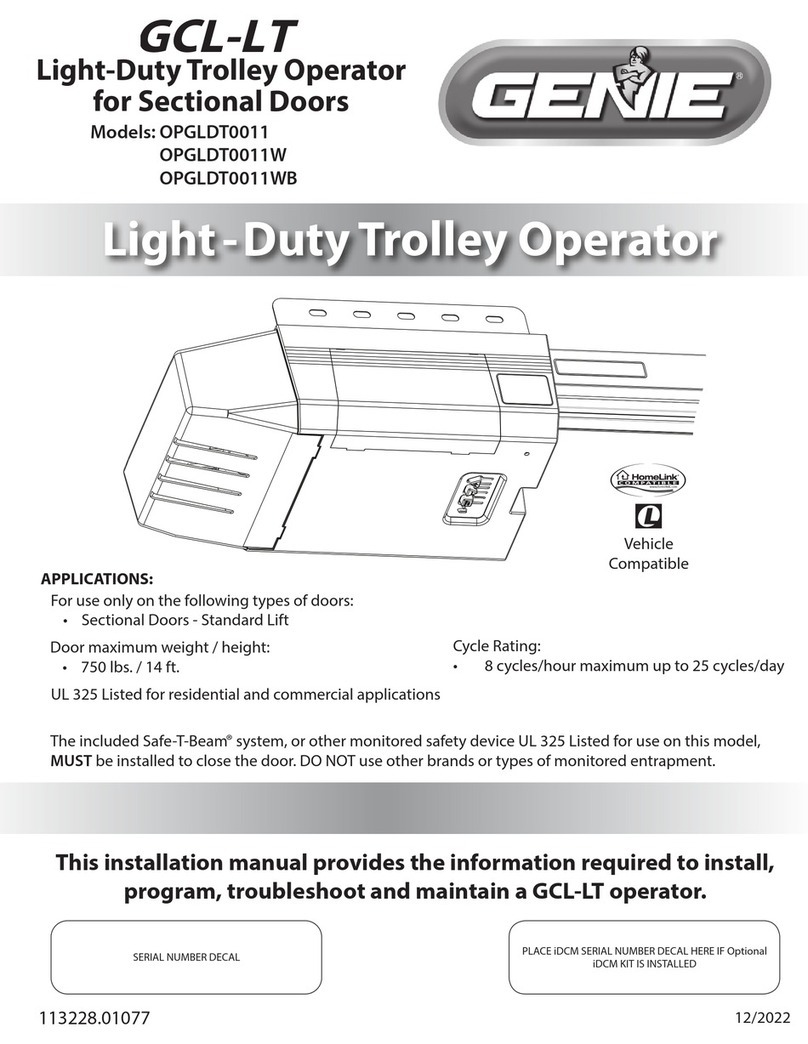

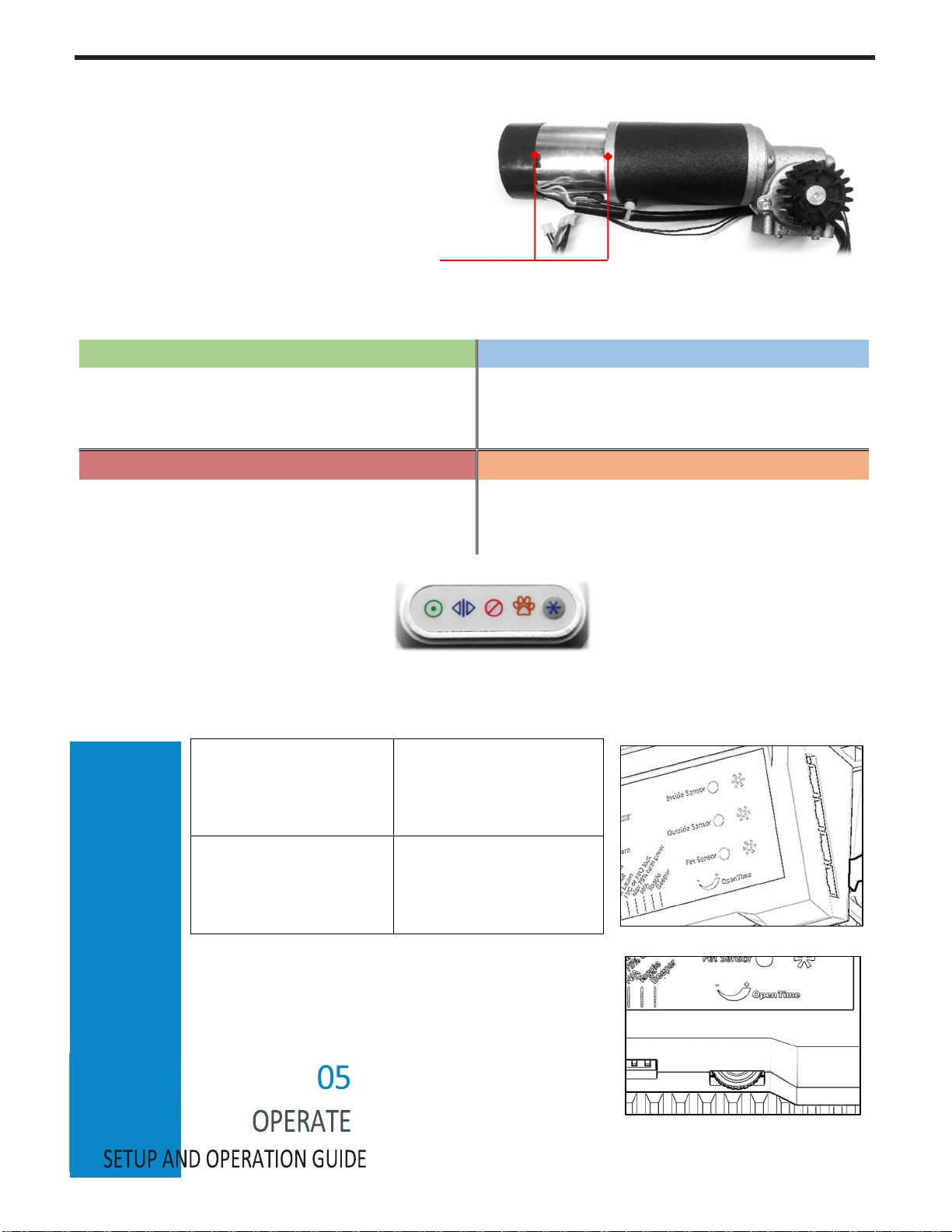

There are four sensor ports located on the right side of the control panel:

Inside Sensor (top port):

A master channel enabled in

Green, Red, and Pet Mode.

Opens to the programmed full

width.

Outside Sensor (2nd port

down): A secondary channel

enabled in Green and Pet (if

desired) Mode. Opens to

programmed full width.

Pet Sensor (3rd port

down): A special channel

enabled in Pet Mode only.

Opens to the programmed

partial pet width.

port): A specialized channel

enabled in Blue Mode only.

Can be used to keep the door

open partially if desired.

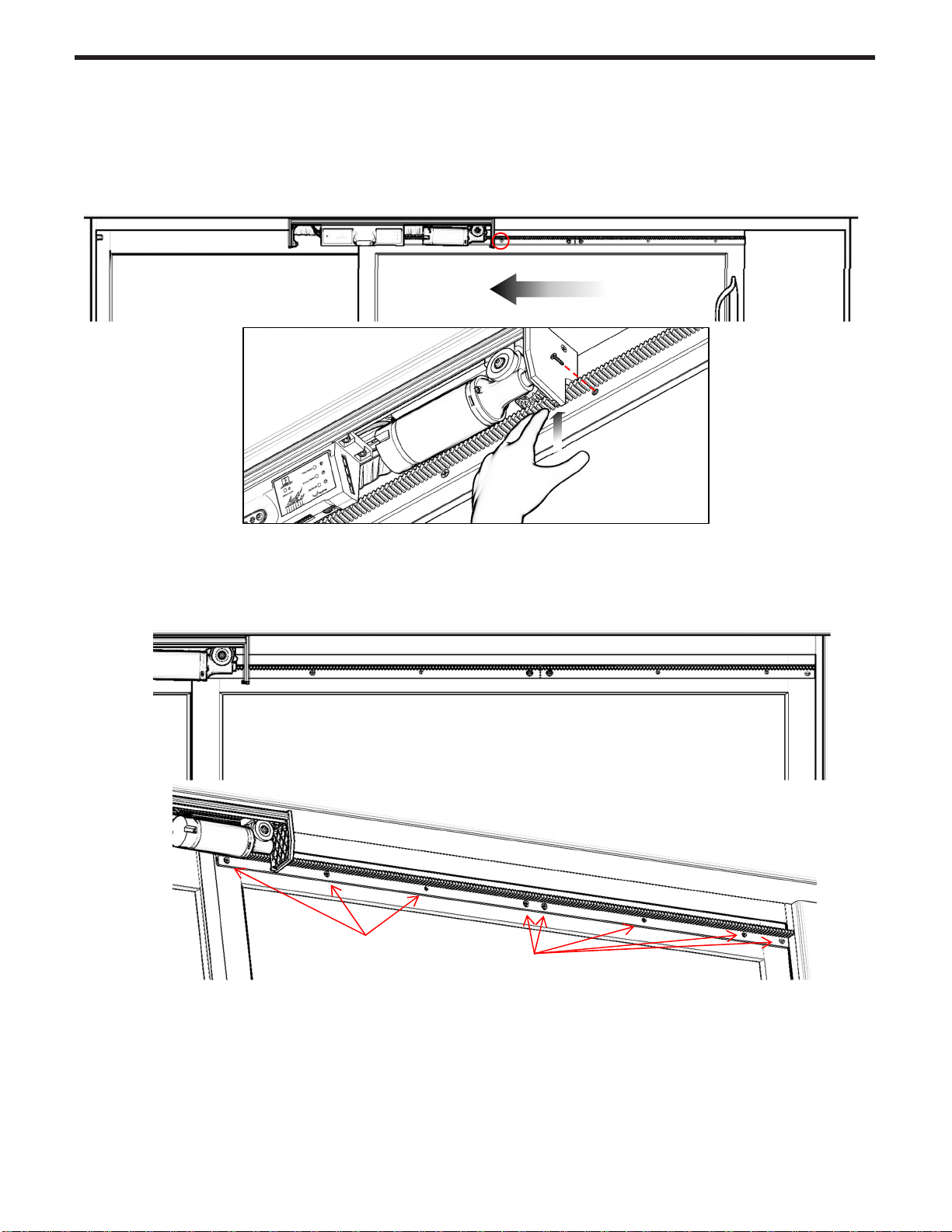

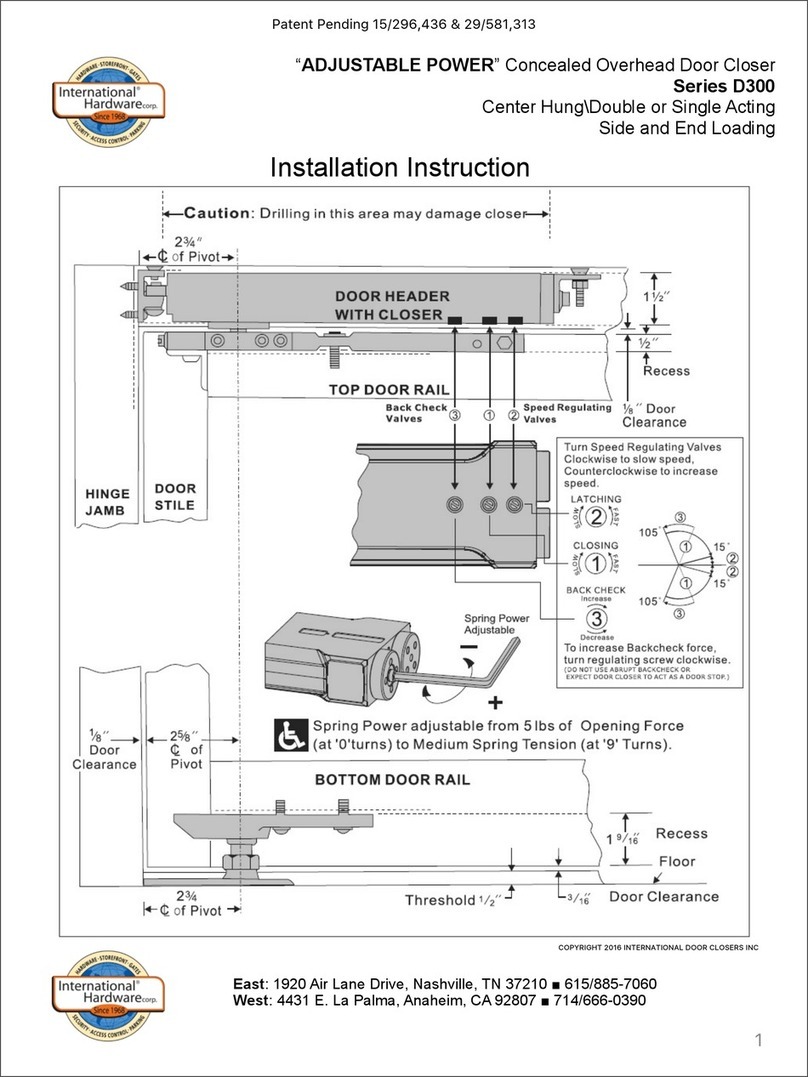

The Open Time dial is located at the bottom of the control panel

and keeps the door open between 0-24 seconds before closing. If

the dial is turned to the max, the system enters into Toggle Mode,

The door then operates per activation of sensor, push to open

and push to close. This can be used in Green and Red Modes.

The desired mode is selected by

successive presses of the Mode button (to

the right of the mode icons). The modes will

cycle in the order displayed, though Pet

Mode will be skipped if not programmed.

Elite iLocking Motor