Autoslide MultiDrive User manual

MultiDriveTM

Installation instructions

© 2018 Autoslide Pty Ltd 2

Contents

The MultiDrive 3

Repairs and returns 3

Questions and comments 3

Warranty 3

About the MultiDrive 5

What’s included 6

Door requirements 8

Sliding door friction 8

Space under the transom 8

Coating the cover 9

Installation instructions 10

1. Cut parts to size 10

2. Attach parts to the base 12

3. Attach the base to the door 22

4. Attach the brackets and cover 24

5. Install the mode pad 27

Programming the controller 30

1. Learn wireless inputs 30

2. Set DIP switches 31

3. Set the controller for pets 32

4. MultiDrive mode settings 32

© 2018 Autoslide Pty Ltd MultiDrive 3

The MultiDrive

This document explains how to assemble the MultiDrive automatic door opening

system. It is important to follow these instructions closely.

Repairs and returns

Contact us by either:

Email: [email protected]

Web: www.autoslide.com

Phone:

–(833) 337-5433 (USA)

–1 300 288 675 (Australia)

Questions and comments

If you have questions about installation, programming, or operation

of your MultiDrive or about any parts or accessories, email us at

Warranty

The MultiDrive is produced by Autoslide Pty Limited and is subject

to the following warranty and conditions of operation. The product

is warranted against failure due to faulty material or workmanship

for a period of 24 months from date of purchase. This warranty will

cover the repair or replacement of any defective parts at an

authorized Autoslide Pty Limited facility and is subject to the

following conditions, provided that:

•the MultiDrive is fitted to a sliding door strictly following the

supplied instructions, and

•the sliding door slides within the friction limits specified in the

instructions, and

•the MultiDrive is for residential and light traffic commercial

applications (ie. doctor’s office, hotel room, etc.), and

•the warranty is limited to an amount totaling no more than the

unit cost price.

This warranty shall be null and void and to no effect if:

•the MultiDrive is abused or in any way used outside the limits

of the specification and design, or

•the electric wiring has been interfered with and is not wired in

accordance with the original factory settings, or

•defects are not caused by normal wear and tear, or

•the purchaser in any way alters the MultiDrive, or adds or

removes parts or materials of the MultiDrive, or

© 2018 Autoslide Pty Ltd MultiDrive 4

•the purchaser fails to notify Autoslide Pty Limited immediately

if there is a failure of any component.

Conditions:

•Delivery costs of all warranty items will be covered by

Autoslide Pty Limited for the first 90 days from purchase. After

90 days, delivery costs of warranty items will be at the

purchaser’s expense.

•The purchaser will be responsible for inspecting the MultiDrive

package to ensure that the package is complete and not

damaged and that all parts are present.

•The buyer shall immediately notify Autoslide Pty Limited in

writing or by phone about any defect in the goods.

•In the event a MultiDrive unit is returned to Autoslide Pty

Limited for a warranty claim, the MultiDrive unit must be

received free from damage.

•The purchaser expressly acknowledges and agrees that

Autoslide Pty Limited is not liable for any advice given by its

agents in relation to the suitability of the product or its

application to certain doors and such advice is relied upon at

the purchaser’s risk.

•The buyer shall not carry out any remedial work on the alleged

defective goods without first obtaining the written consent and

instruction from Autoslide Pty Limited.

•The warranty on any battery is subject to the warranty provided

by the original manufacturer of the battery. Two year

© 2018 Autoslide Pty Ltd MultiDrive 5

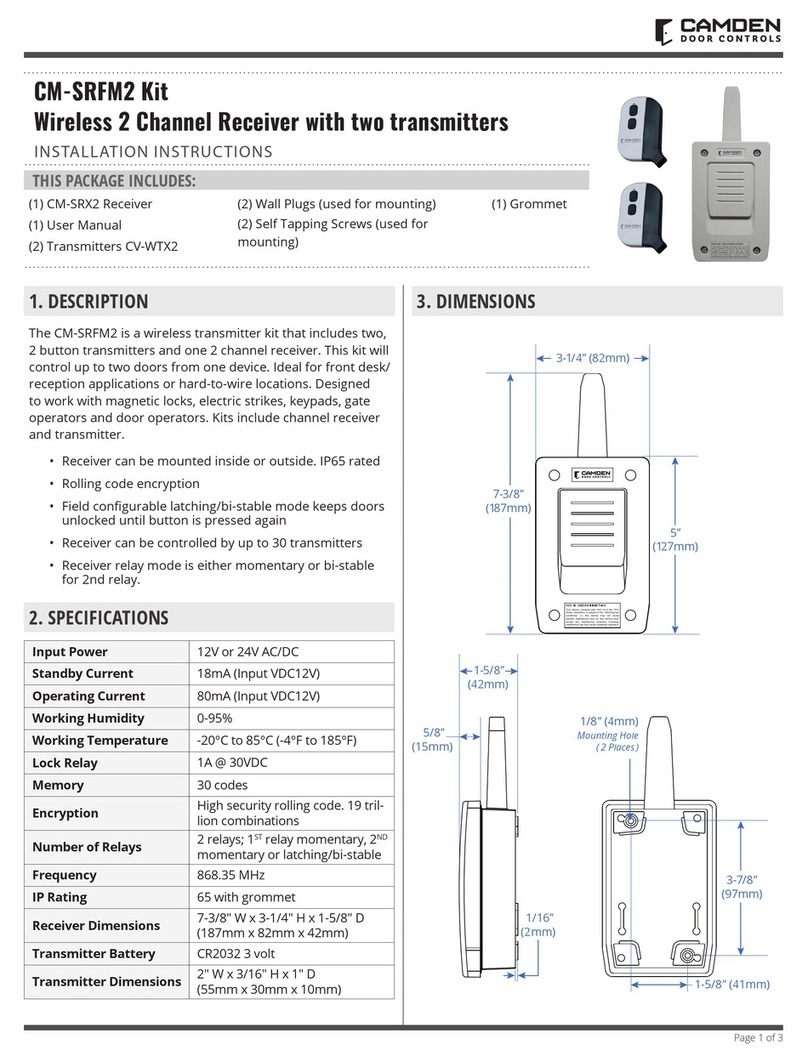

About the MultiDrive

The MultiDrive is an automatic door opening system for

residential and light-use commercial sliding doors.

Once installed, the MultiDrive mechanism is hidden discretely

behind an aluminum cover which blends in with the sliding door

frame. This cover comes in a mill finish and will need to be powder

coated to match the door and/or frame.

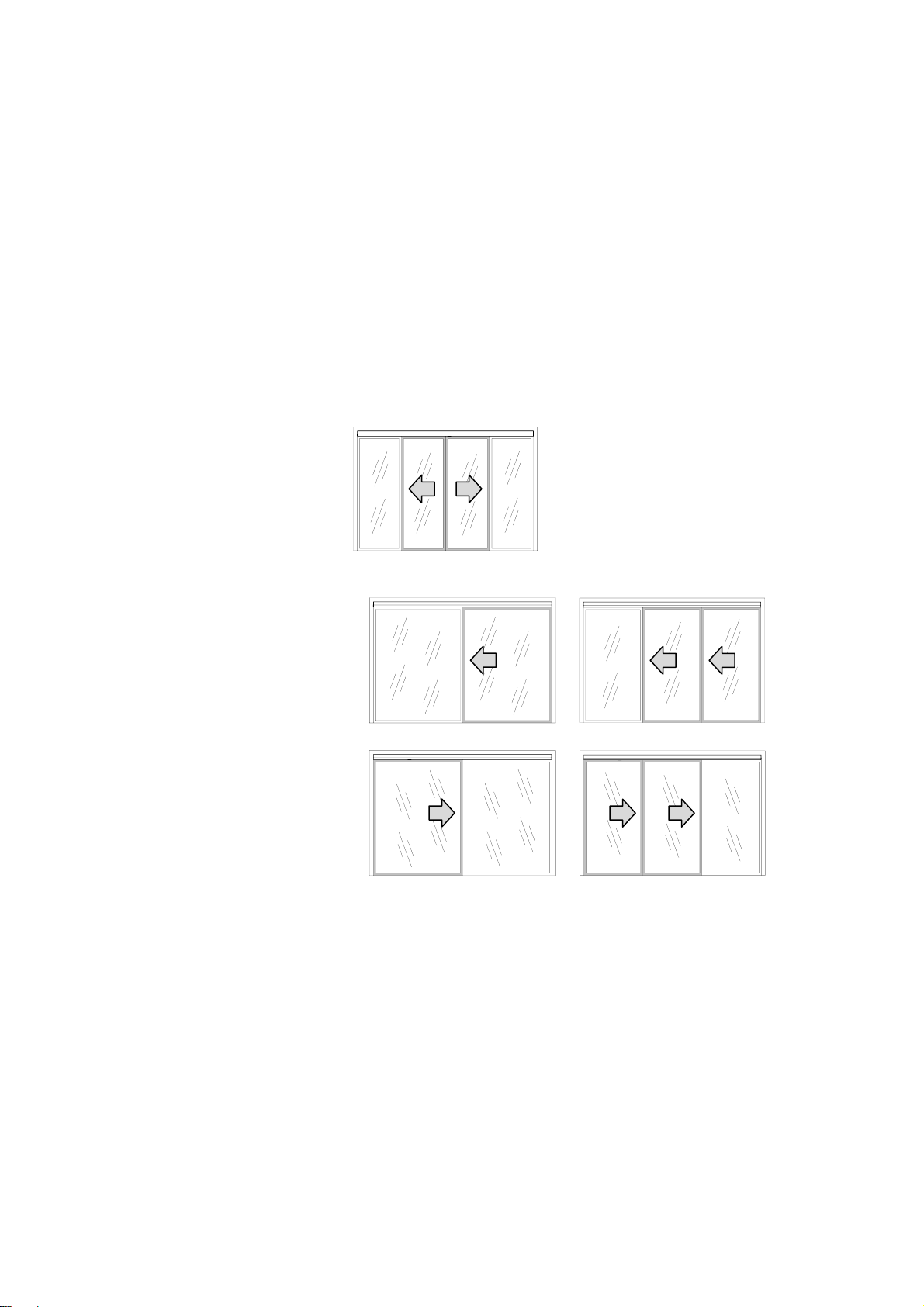

The MultiDrive can be retro-fitted to any framed sliding door,

including bi-parting doors (Figure 1) and non-bi-parting doors

(Figure 2).

Figure 1: Bi-parting doors with the MultiDrive.

a) b)

c) d)

Figure 2: Non-bi-parting doors with the MultiDrive: a) single left-

sliding door, b) telescopic left-sliding door, c) single right-sliding

door, and d) telescopic right-sliding door.

Warnings

•Any manual lock on the sliding door should be removed or

deactivated, otherwise the MultiDrive may be damaged if

activated while the lock is closed.

•The MultiDrive should not be used in high-traffic

environments such as large office building entrances or big-

box stores.

•The MultiDrive may be used in light commercial

environments. Speak with an authorized Autoslide Pty

representative about your application prior to purchase.

© 2018 Autoslide Pty Ltd MultiDrive 6

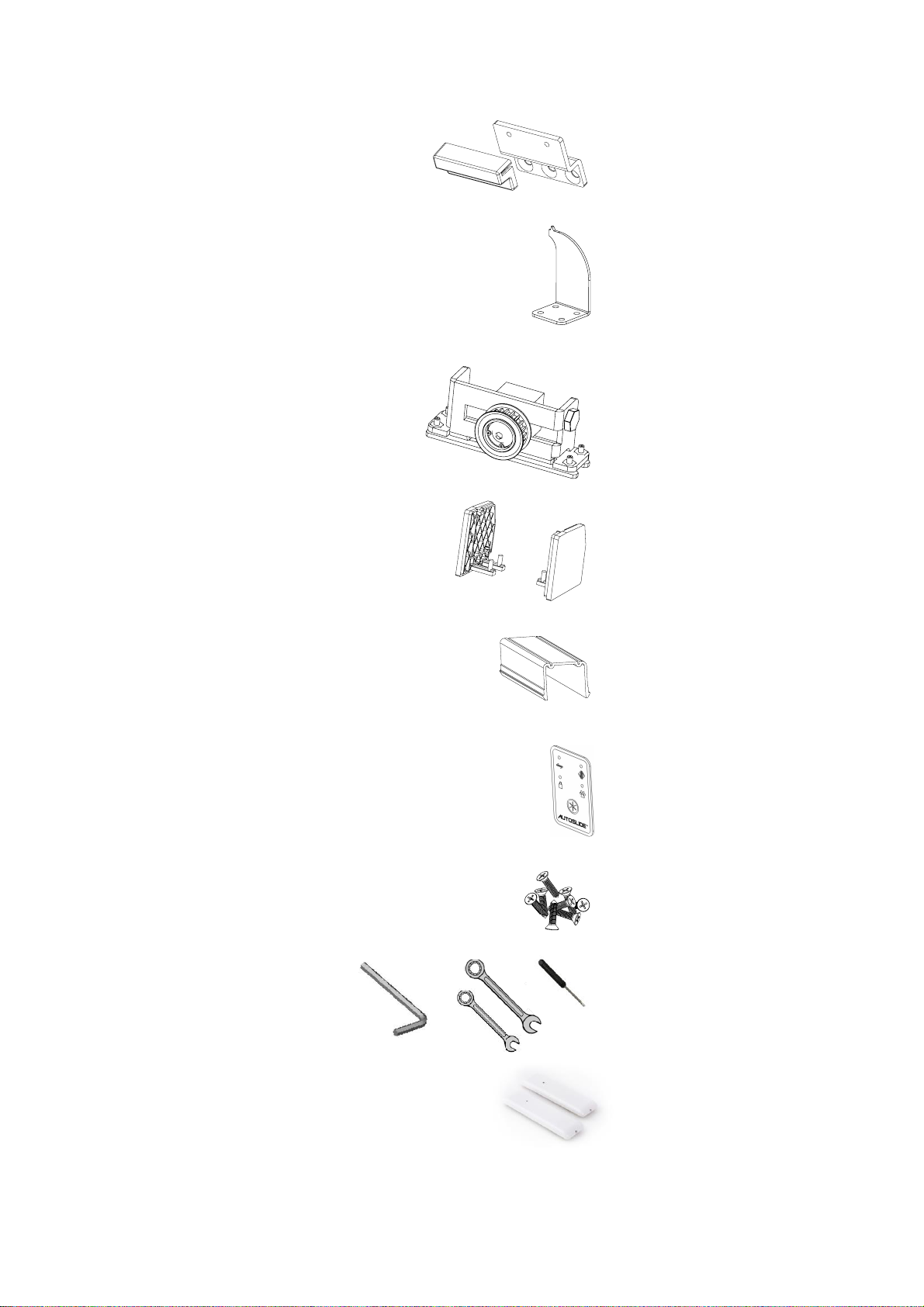

What’s included

Base

x 1

Cover

x 1

AC adapter

x 1

Controller

x 1

Motor

x 1

Belt

x 1

Top bracket

x 1

© 2018 Autoslide Pty Ltd MultiDrive 7

Bottom

bracket

x 1

Cover clip

x 2

Belt

tensioner

x 1

End cap

x 2

Cable cover

x 3

Mode pad

x 1

Screw

Packet

x 1

Tool Packet

x 1

Wall Button

X 2

© 2018 Autoslide Pty Ltd MultiDrive 8

Door requirements

Sliding door friction

The MultiDrive should only be installed on a door that slides

smoothly. If the door system does not, it is recommended to have

the door system maintenance prior to the installation of the

MultiDrive System.

The sliding friction should be low enough that the door opens and

closes with a force less than 35 pound-force plus (155 newtons)

at a steady sliding speed of about 4”/second (100 mm/second).

Use a digital scale with a hook to measure the force to open and

close the door. If the force is greater than 35 pound-force, speak

with an authorized Autoslide Pty representative on how to proceed.

Space under the transom

The MultiDrive system sits directly below the head space of a

sliding door and requires a vertical space of 3.15”(80 mm) –see

Figure 3.

The MultiDrive may also be mounted in a flush mount, if the

situation arises.

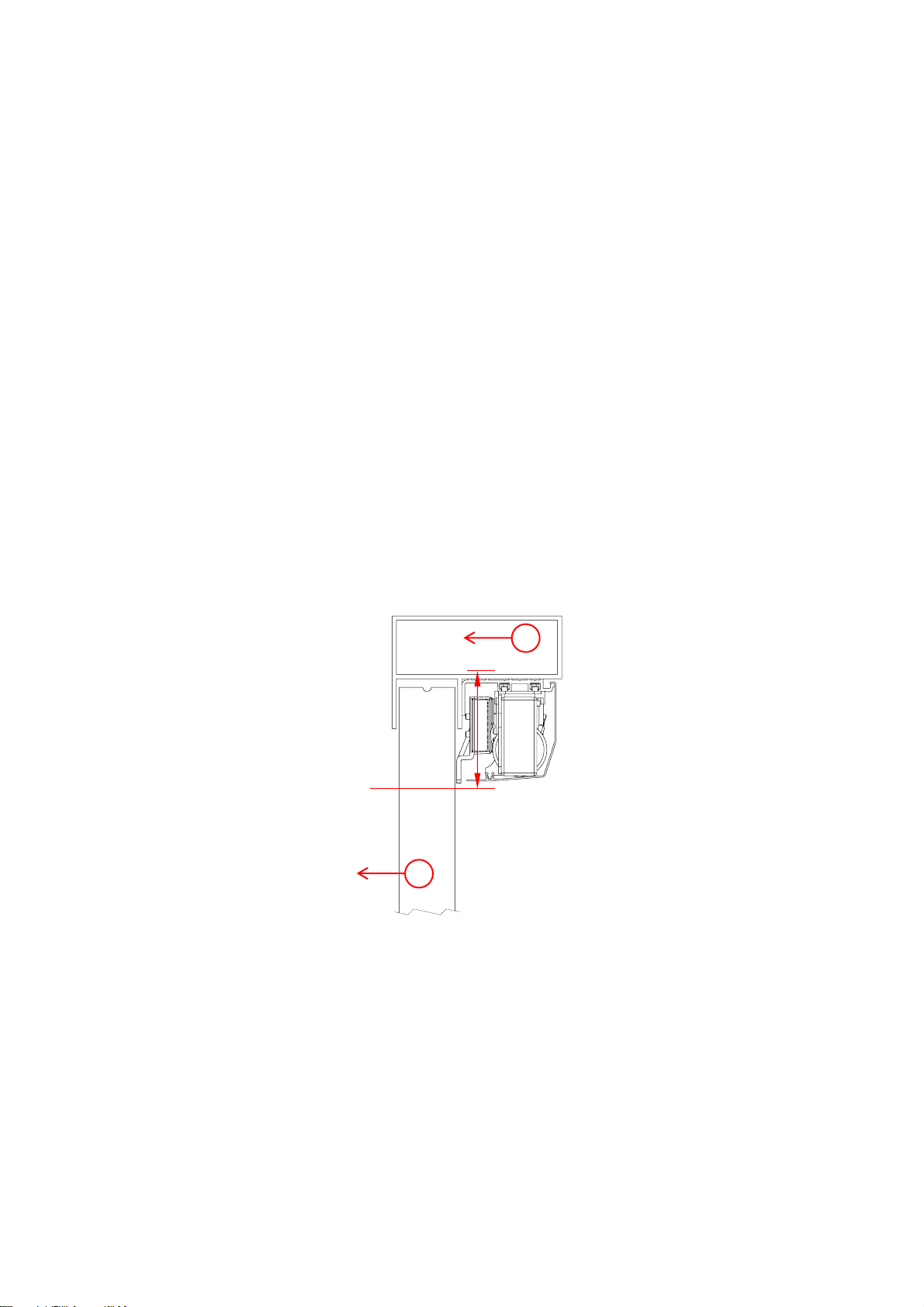

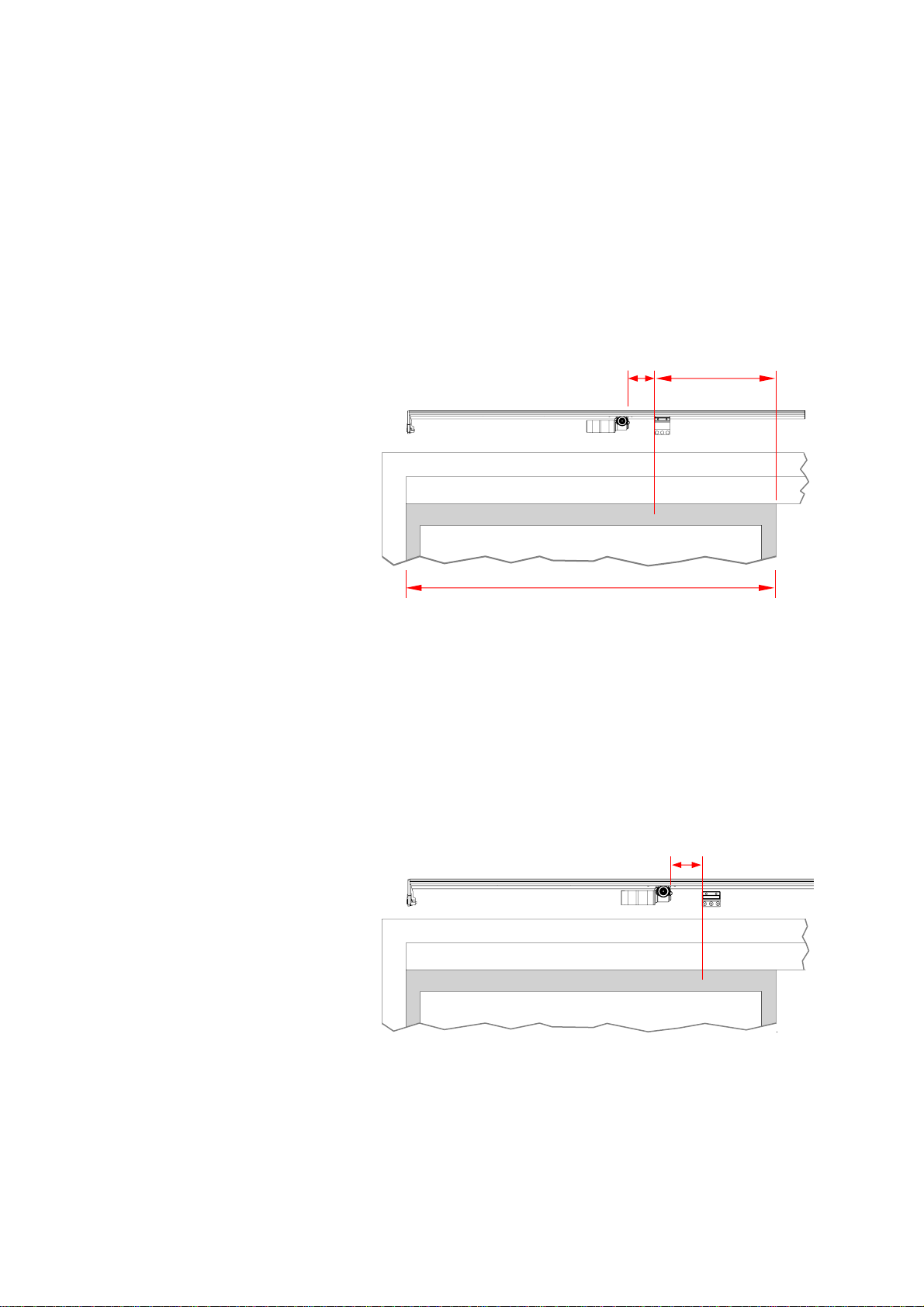

Figure 3: Cross-section of a sliding door (1) with the MultiDrive below

the transom (2). The MultiDrive requires a 3.15-inch (80-mm)

clearance below the transom.

1

2

3.15”

(80 mm)

© 2018 Autoslide Pty Ltd MultiDrive 9

Coating the cover

The MultiDrive includes a cover to conceal the motor and other

mechanisms.

The cover has an uncoated aluminum mill finish. To make the

cover match the sliding door, use a color sample from the door

and/or door trim to match the cover with the door system. The

painting of the cover should be powder coated for optimal durability

and finish.

Leave spare material to hold the ends of the cover during the

coating process.

© 2018 Autoslide Pty Ltd MultiDrive 10

Installation instructions

1. Cut parts to size

(a) Check the MultiDrive fits

a) b)

Figure 4 Examples of a) sufficient space for the Multidrive, b)

insufficient space.

Is there a 3.15-inch (80-mm) space below the transom?

•If yes, the MultiDive should fit. Go to the next step (b).

•If no, see below.

Steps

a) b)

Figure 5: .

3.15”

80 mm

✓

3.15”

80 mm

3.15”

(80 mm)

< 0.08”

(< 2 mm)

© 2018 Autoslide Pty Ltd MultiDrive 11

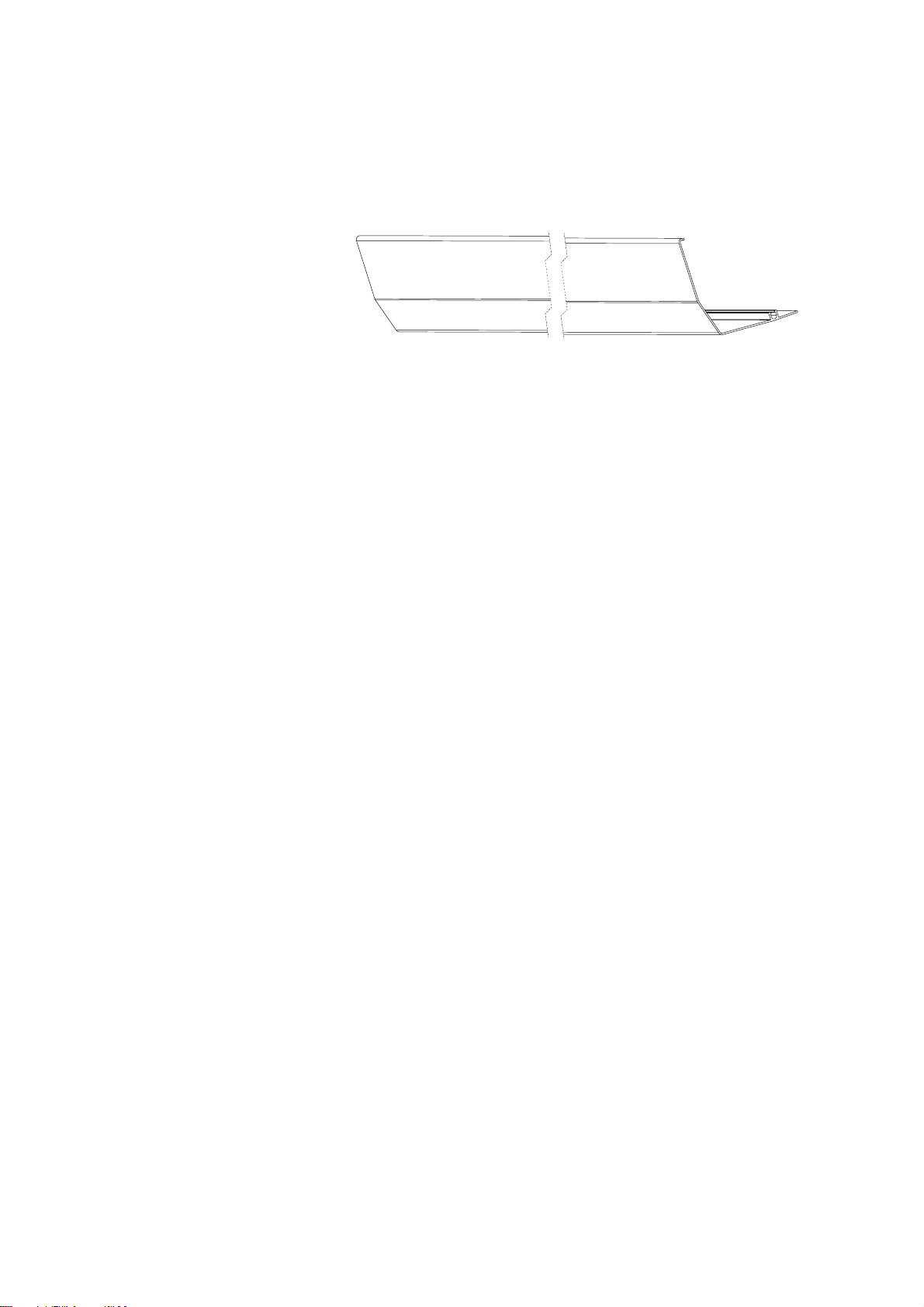

(b) Cut the cover to the correct length

Steps

Cut the cover to a length (L) which is 0.51”to 0.59”(13 to 15 mm)

shorter than the inside width (W) of the sliding door frame (see

Figure 5).

Cut off any pins or clips used to hold the cover during the coating

process.

Figure 6: Cut the cover (shown in grey) to a length Lwhich is 0.51”to

0.59” (13-15 mm) shorter than W.

(c) Cut the base to the same length

Cut the base to the same length Las the cover (0.51”to 0.59”or

13 to 15 mm shorter than W).

W

L

© 2018 Autoslide Pty Ltd MultiDrive 12

2. Attach Parts to the Base Prior to Mounting

The base holds the belt tensioner, motor, controller, AC adapter,

cover clips, Wi-Fi Module, and back up battery (option accessory).

It is important to place these parts in the correct positions

described below.

(a) Preparation

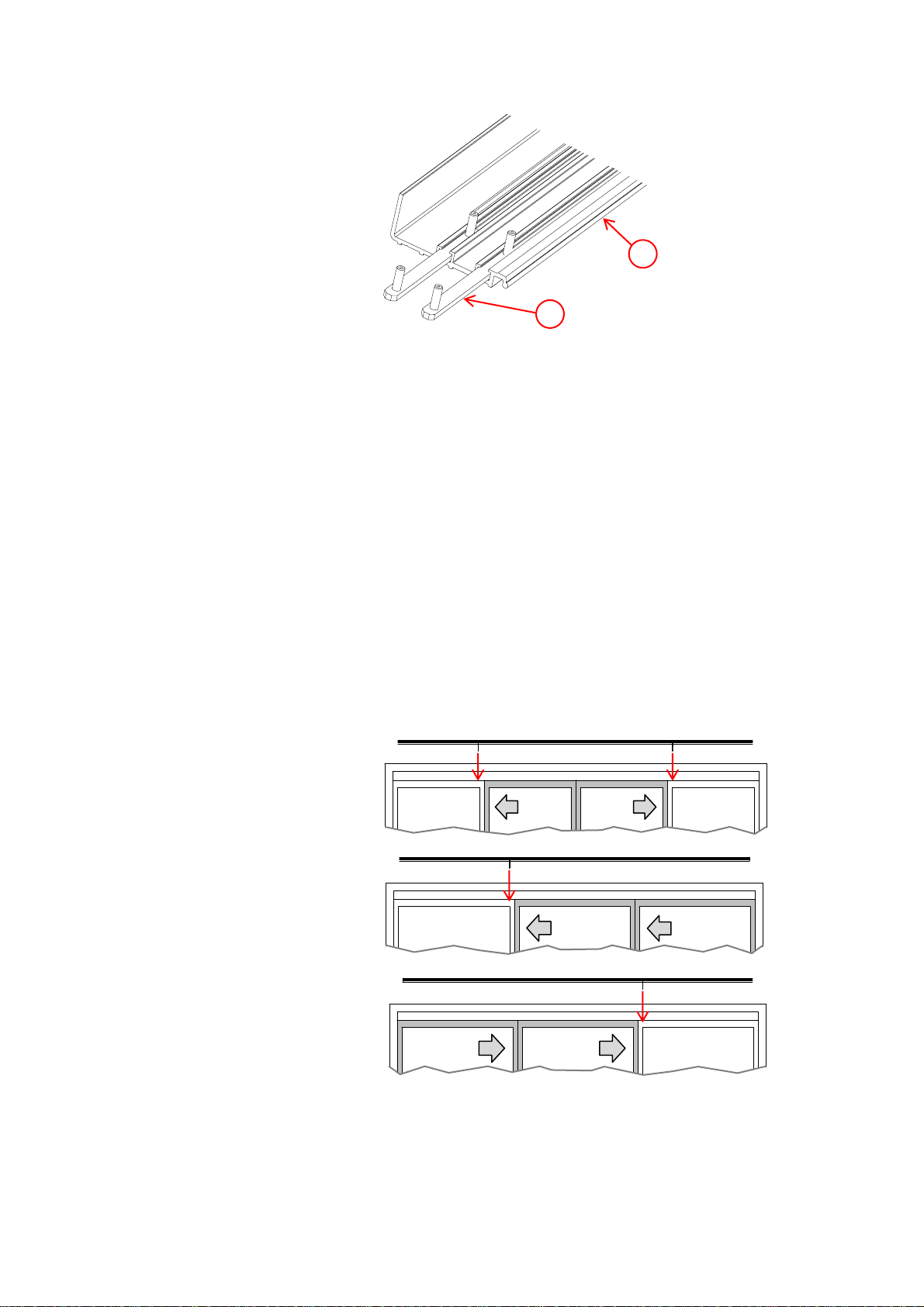

The layout of parts depends on whether the door is bi-parting, right

handed, or left handed.

Figure 7: Bi-parting doors: motor (1) is on the left.

Figure 8: Right handed door: motor (1) is on the left.

Figure 9: Left handed door: motor (1) is on the right.

Steps

1. Lay the base on the floor directly in front of the door frame.

Align the center of the base with the center of the door frame.

2. Each part attaches to the base with one or two “sliders”

(Figure 10), which fit into the tracks on the base. Remove the

nuts from all sliders.

3. If you are installing optional wired sensors, lay the sensor

cable(s) on the base between the two tracks. The sensor

cable(s) will pass underneath the cover clips and motor.

1

1

1

© 2018 Autoslide Pty Ltd MultiDrive 13

Figure 10: Sliders (1) in the two tracks on the base (2).

4. Use the following steps to set the position of each part on the

base.

(a) Cover clips

Guidelines for using cover clips

•Don’t use cover clips over the door opening because they will

be visible from the opposite side of some doors.

•Clips are not needed at the ends of the base because the end

caps support the cover there.

Steps

1. Use a cover clip behind the door frame of each fixed (non-

sliding) door (Figure 11). The door frame of the fixed door

hides the clip from view on the other side of the door.

Slide each cover clip onto the base as in Figure 11. Make sure

the other end of each cover clip (without sliders) points

towards the door.

Figure 11: Place a cover clip behind the door frame of each fixed

door.

DETAIL

H

SCALE

2 : 1

1

2

© 2018 Autoslide Pty Ltd MultiDrive 14

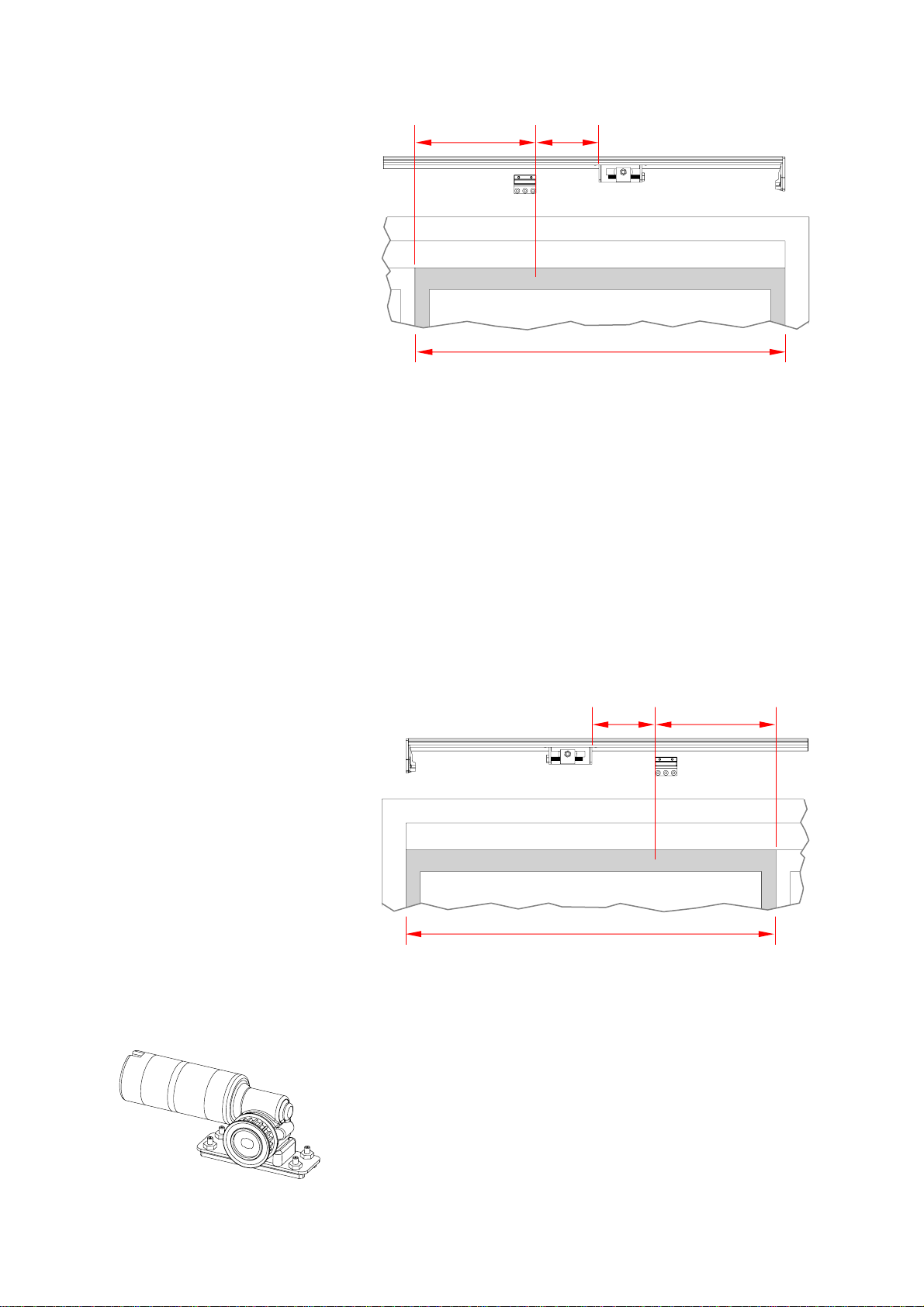

(d) Belt tensioner

For bi-parting doors:

For bi-parting doors, the belt tensioner sits on the right side of the

door frame (viewed from the inside of the door).

1. Open the doors fully.

2. Slide the belt tensioner along the base until it is in front of the

left-hand door as shown in Figure 12, where:

A= 20-30% of the width Bof that door

C = 1.97” (50 mm).

3. Tighten the slider nuts to hold the belt tensioner in place.

4. Mark the position of the bottom bracket on both the base and

the door as in Figure 12.

Figure 12: Bi-parting doors: belt tensioner and bottom bracket.

The right side is shown with the right door open.

For right handed doors (non-bi-parting):

For left-opening doors, the belt tensioner sits on the right side of

the door frame (viewed from the inside of the door).

1. Close the door fully.

2. Slide the belt tensioner along the base until it is in front of

closed sliding door as shown in Figure 13, where:

A= 20-30% of the width Bof that door

C = 1.97” (50 mm).

3. Tighten the slider nuts to hold the belt tensioner in place.

4. Mark the position of the bottom bracket on both the base and

the door as in Figure 13.

A

C

B

© 2018 Autoslide Pty Ltd MultiDrive 15

Figure 13: Left-opening sliding door: belt tensioner and bottom

bracket. The right side is shown with sliding door closed.

For left handed doors (non-bi-parting):

For right-opening doors, the belt tensioner sits on the left side of

the door frame (viewed from the inside of the door).

1. Close the door fully.

2. Slide the belt tensioner along the base until it is in front of

closed sliding door as shown in Figure 14, where:

A= 20-30% of the width Bof that door

C = 1.97” (50 mm).

3. Tighten the slider nuts to hold the belt tensioner in place.

4. Mark the position of the bottom bracket on both the base and

the door as in Figure 14.

Figure 14: Right-opening sliding door: belt tensioner and bottom

bracket. The left side is shown with sliding door closed.

(e) Motor

The motor sits at the opposite end of the base to the belt tensioner.

For bi-parting doors:

Bi-parting doors use a top bracket (unlike other types of doors).

1. Open the doors fully.

A

C

B

A

C

B

© 2018 Autoslide Pty Ltd MultiDrive 16

2. Slide the motor along the base until it is in front of left-hand

sliding door as shown in Figure 15, where:

A= 20-30% of the width Bof that door

C = 1.97” (50 mm).

Note: If the top bracket does not fit in this position (Figure 15),

contact your MultiDrive supplier about obtaining a different

style of bracket that fits onto the right edge of the door.

3. Tighten the slider nuts to hold the motor in place.

4. Mark the position of the top bracket on both the base and the

left-hand sliding door as in Figure 15.

Figure 15: Bi-parting doors: motor and top bracket. The left side

is shown with left door open.

For left-opening doors (non-bi-parting):

1. Open the door fully.

2. Slide the motor along the base until it is 1.97”(50 mm) from

the mark you made on the door for the bottom bracket position

(Figure 13 and Figure 16, where C = 1.97” or 50 mm).

3. Tighten the slider nuts to hold the motor in place.

Note: Non-bi-parting doors do not use a top bracket.

Figure 16: Left-opening sliding door with motor and bottom

bracket. The left side is shown with the sliding door open.

For right-opening doors (non-bi-parting):

1. Open the door fully.

B

A

C

C

© 2018 Autoslide Pty Ltd MultiDrive 17

2. Slide the motor along the base until it is 1.97”(50 mm) from

the mark you made on the door for the bottom bracket position

(Figure 14 and Figure 17, where C = 1.97” or 50 mm).

3. Tighten the slider nuts to hold the motor in place.

Note: Non-bi-parting doors do not use a top bracket.

Figure 17: Right-opening sliding door: motor and bottom

bracket. The right side is shown with the sliding door open.

(f) Controller and AC adapter

The controller and AC adapter sit next to the motor.

Steps:

1. Lay the motor cable on the base in between the two tracks.

2. Slide the controller along the base (over the motor cable) until

it is 1.97”(50 mm) from the motor (see Figures to 18 to 20,

depending on the type of door, where D= 1.97” or 50 mm).

The slider should be in the track furthest from the door.

3. Slide the AC adapter along the base (over the motor cable)

until it is 1.97”(50 mm) from the controller (Figures to 18 to 20

where D= 1.97” or 50 mm). The slider should be in the track

furthest from the door.

4. If you are installing a mode pad on the door jamb, lay the cable

connected to the mode pad on the base between the two

tracks and underneath the AC adapter.

5. Clip the cable cover (cut it if necessary) over exposed cables

on the base to prevent cables touching the belt.

C

© 2018 Autoslide Pty Ltd MultiDrive 18

Figure 18: Bi-parting doors: AC adapter (1), controller (2), and

motor (3).

Figure 19: Right-opening door: AC adapter (1), controller (2), and

motor (3).

Figure 20: Left-opening door: AC adapter (1), controller (2), and

motor (3).

6. Tighten the slider nuts to hold the AC adapter and controller in

place.

7. Plug the motor cable into the controller (Figure 21) in a socket

labeled Motor.

8. Plug the AC adapter cable into the controller (Figure 21) in a

socket labeled Power.

3

2

1

D

D

3

1

2

1

D

D

3

2

3

1

D

D

© 2018 Autoslide Pty Ltd MultiDrive 19

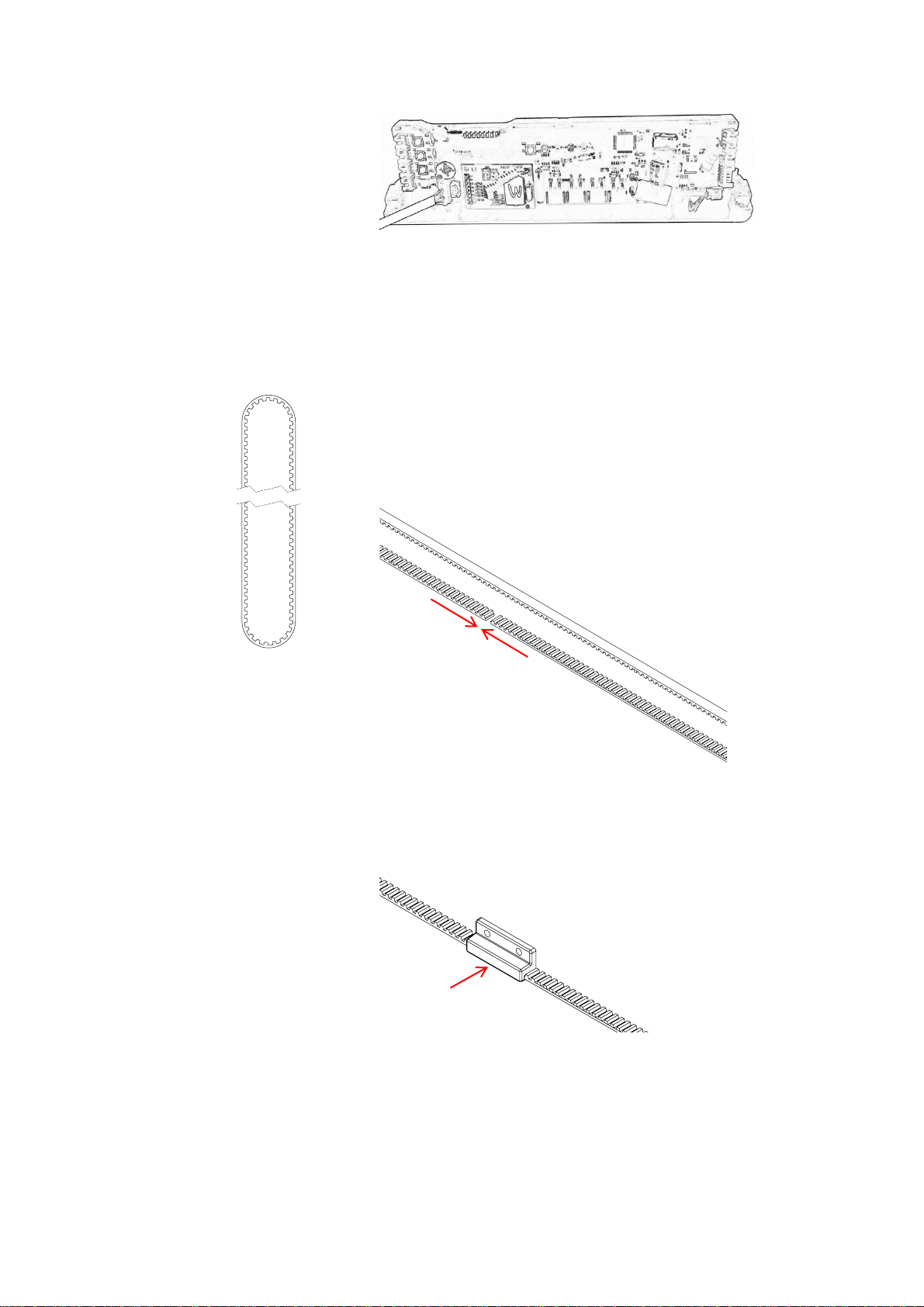

Figure 21: Plug the cables into the controller.

9. Fold up any spare cable from the AC adapter and fit it between

the AC adapter and base.

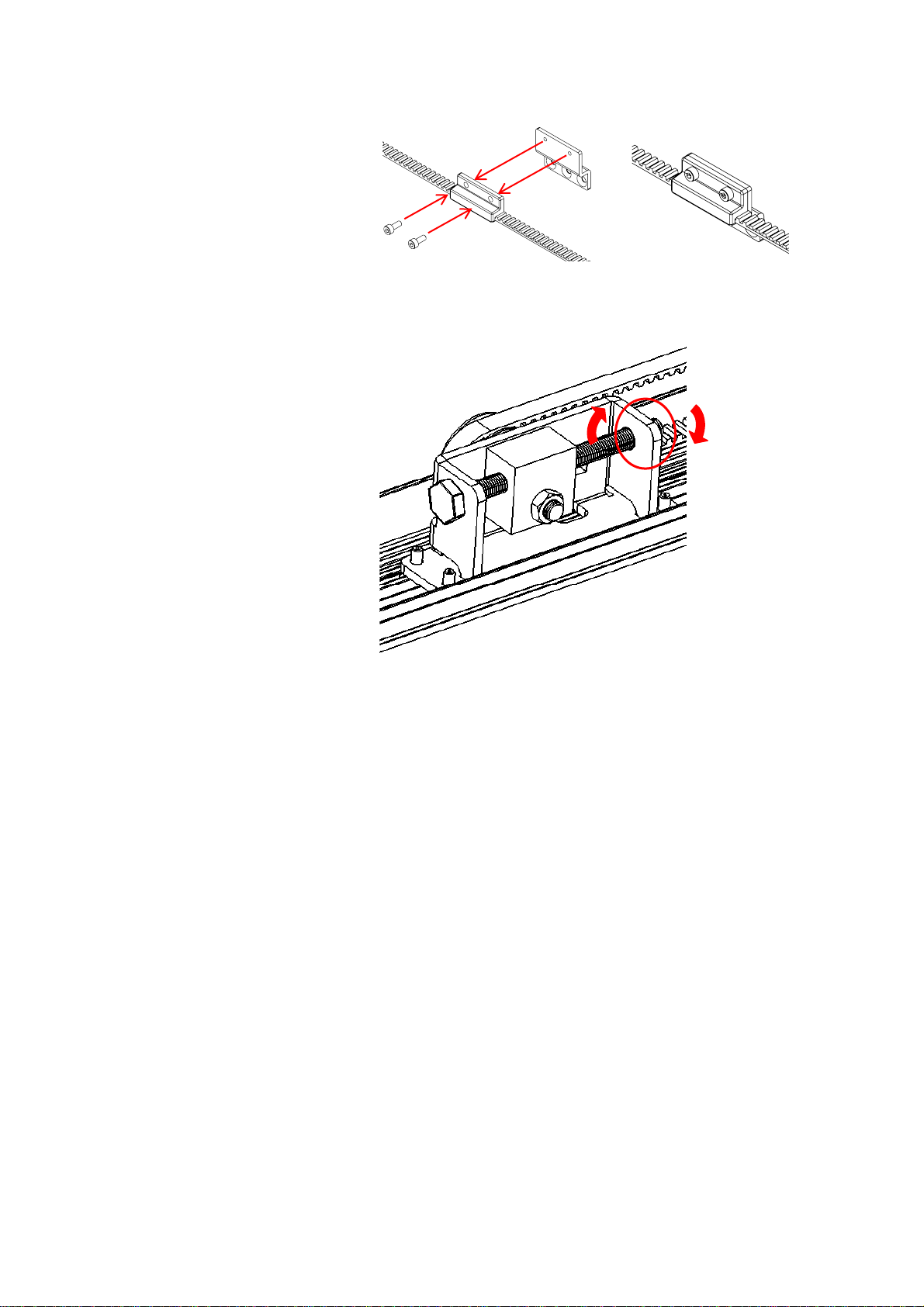

(g) Belt

Steps:

1. Take a length of belt and pass it around the motor pulley and

the belt tensioner pulley to form a loop.

One side of the loop will be closer to the base than the other

side. Keep the unjoined side furthest from the base.

2. Use your hands to gently pull the belt tight. Cut the belt so that

the two ends can touch without overlapping (Figure 22).

Figure 22: Cut the belt so that the two ends touch without

overlapping.

3. Keep two ends of the belt as close as possible to each other

and insert them into the bottom bracket (Figure 23)..

Figure 23: Insert the two ends of the belt into the bottom bracket.

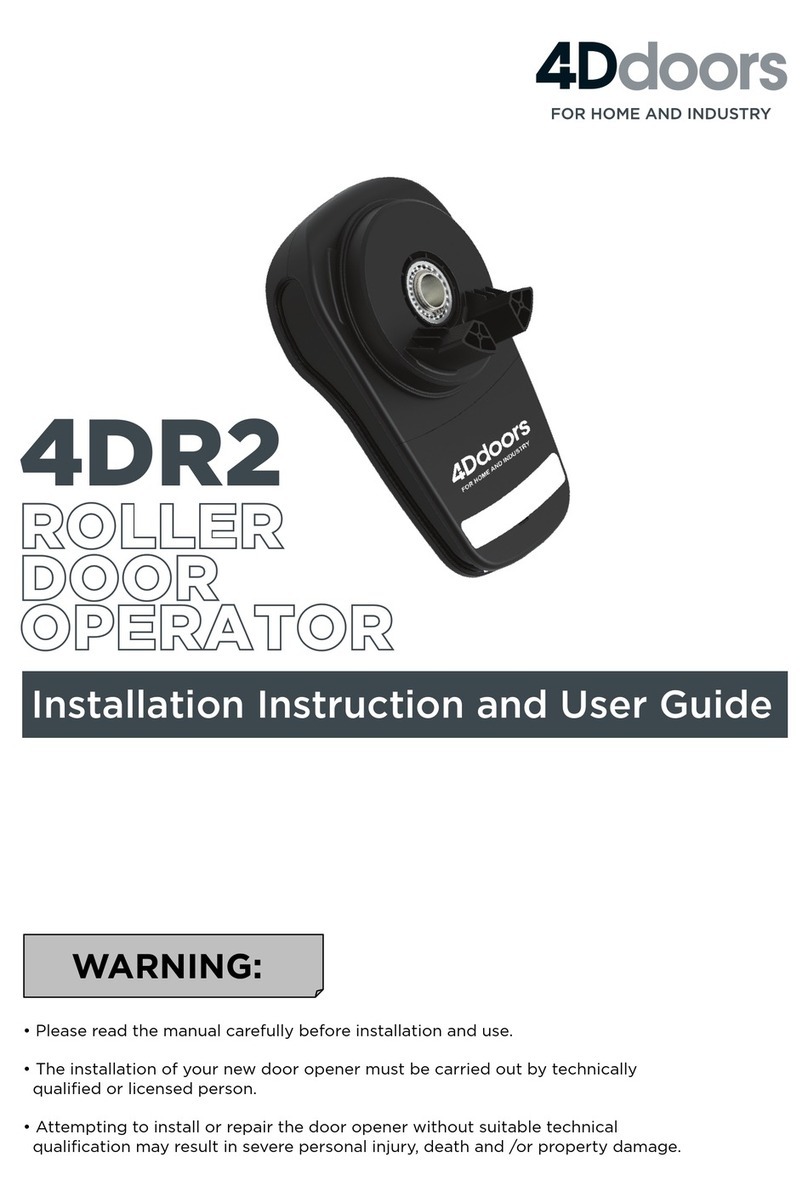

4. Bolt together the two parts of the bottom bracket (Figure 24).

E

A

C

D

B

F

G

H

DETAIL

A

SCALE

1 : 1

DETAIL

B

SCALE

1 : 1

DETAIL

C

SCALE

1 : 1

DETAIL

D

SCALE

1 : 1

DETAIL

E

SCALE

1 : 1

DETAIL

F

SCALE

1 : 1

DETAIL

G

SCALE

1 : 1

DETAIL

H

SCALE

1 : 1

E

A

C

D

B

F

G

H

DETAIL

A

SCALE

1 : 1

DETAIL

B

SCALE

1 : 1

DETAIL

C

SCALE

1 : 1

DETAIL

D

SCALE

1 : 1

DETAIL

E

SCALE

1 : 1

DETAIL

F

SCALE

1 : 1

DETAIL

G

SCALE

1 : 1

DETAIL

H

SCALE

1 : 1

© 2018 Autoslide Pty Ltd MultiDrive 20

Figure 24: Bolt together the two parts of the bottom bracket.

5. On the belt tensioner, loosen the locking nut (located on the

long tensioning bolt –see Figure 25).

Figure 25: Loosen the locking nut.

6. Turn the tensioning bolt clockwise (Figure 26) to put tension

on the belt. Stop when the belt is pulled straight and does

not sag.

Do not keep tensioning the belt after it is pulled straight

(or the motor may get damaged).

Note: If the belt loosens when the tensioning bolt is turned

clockwise, then:

–completely unscrew the tensioning bolt until it is removed

from the tensioning pulley, then

–insert the tensioning bolt into the opposite end of the

tensioning pulley (where the locking nut was previously)

and screw it into place, then

–screw the locking nut back onto the tensioning bolt.

E

A

C

D

B

F

G

H

DETAIL

A

SCALE

1 : 1

DETAIL

B

SCALE

1 : 1

DETAIL

C

SCALE

1 : 1

DETAIL

D

SCALE

1 : 1

DETAIL

E

SCALE

1 : 1

DETAIL

F

SCALE

1 : 1

DETAIL

G

SCALE

1 : 1

DETAIL

H

SCALE

1 : 1

E

A

C

D

B

F

G

H

DETAIL

A

SCALE

1 : 1

DETAIL

B

SCALE

1 : 1

DETAIL

C

SCALE

1 : 1

DETAIL

D

SCALE

1 : 1

DETAIL

E

SCALE

1 : 1

DETAIL

F

SCALE

1 : 1

DETAIL

G

SCALE

1 : 1

DETAIL

H

SCALE

1 : 1

I

DETAIL

I

SCALE

1 : 1

J

DETAIL

J

SCALE

1 : 1

K

DETAIL

K

SCALE

1 : 1

Table of contents

Other Autoslide Door Opening System manuals

Popular Door Opening System manuals by other brands

4Ddoors

4Ddoors 4DR2 Installation instructions and user guide

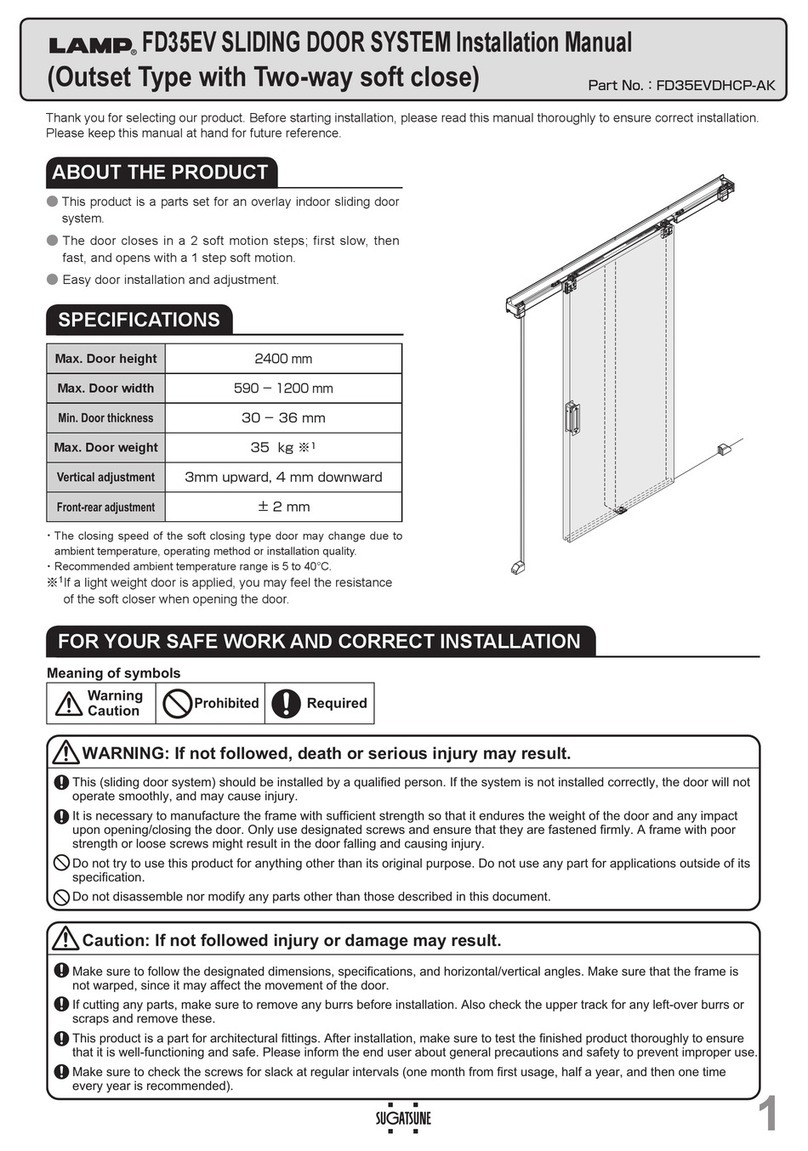

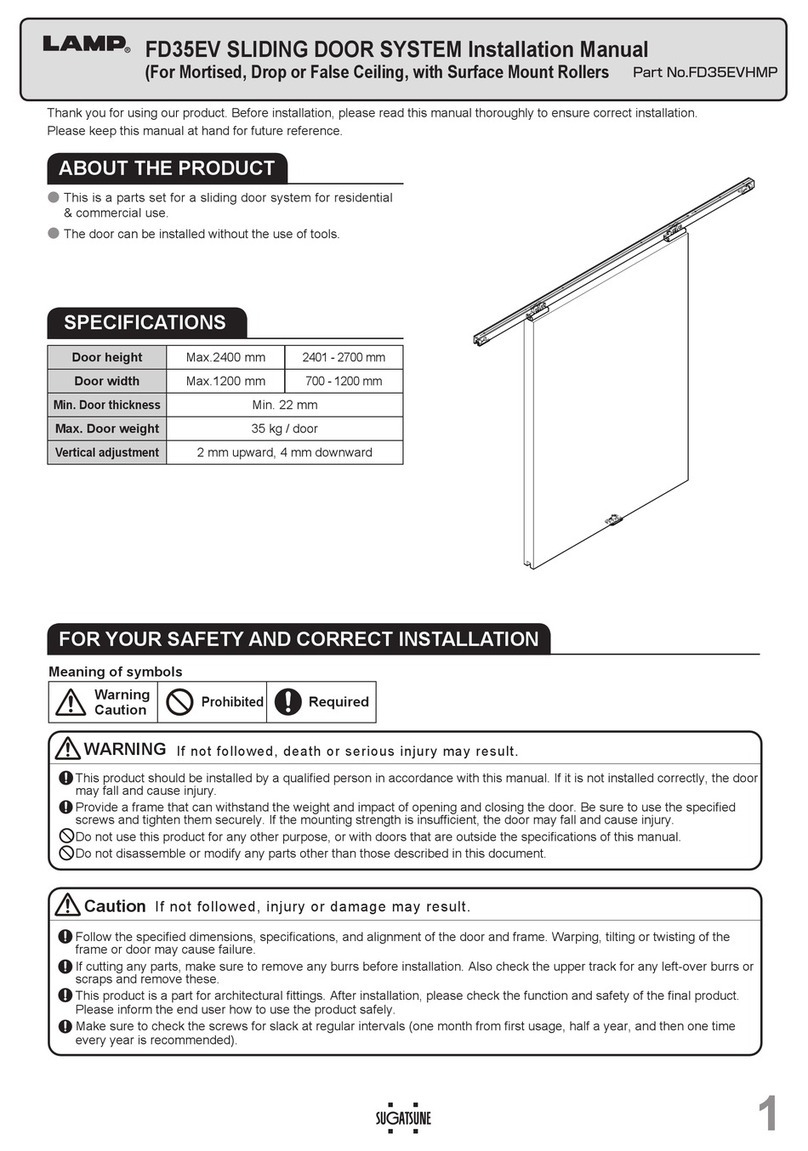

Lamp

Lamp FD35EV installation manual

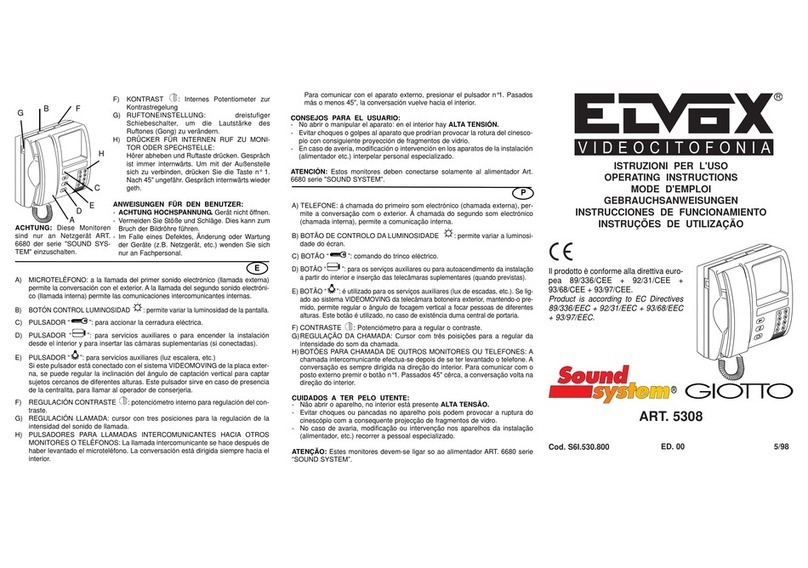

Elvox

Elvox Sound system GIOTTO operating instructions

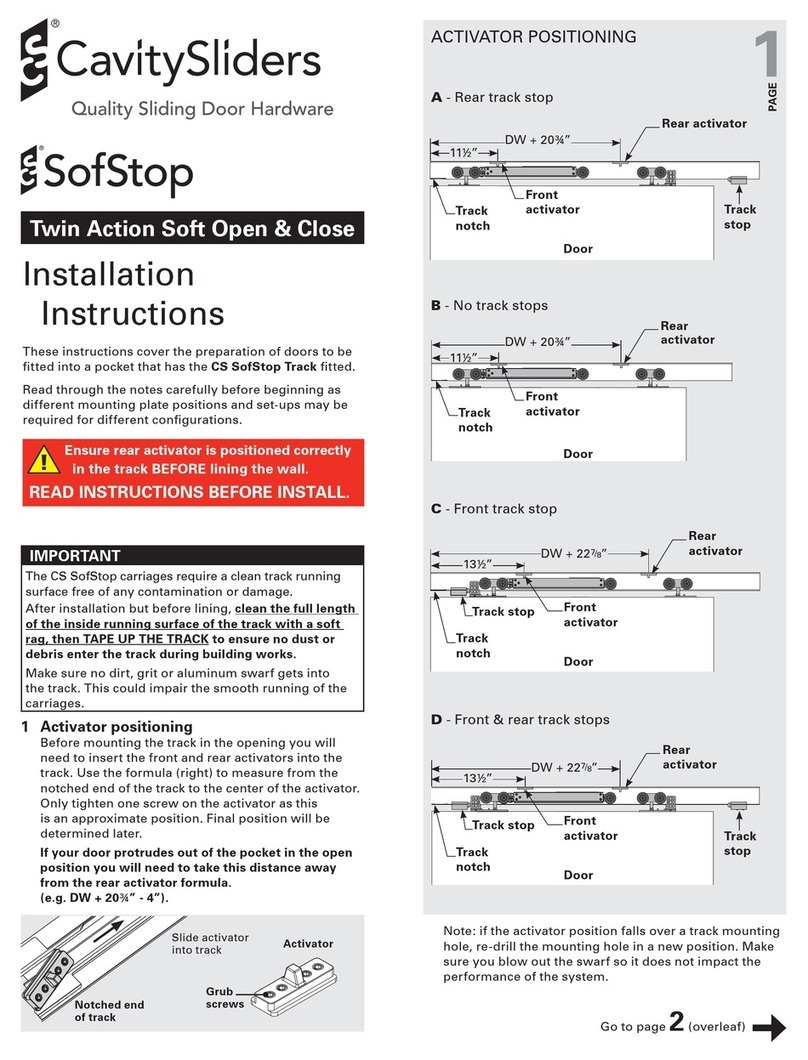

Cavity Sliders

Cavity Sliders SofStop installation instructions

DEUTSCHTEC

DEUTSCHTEC SLH Series installation manual

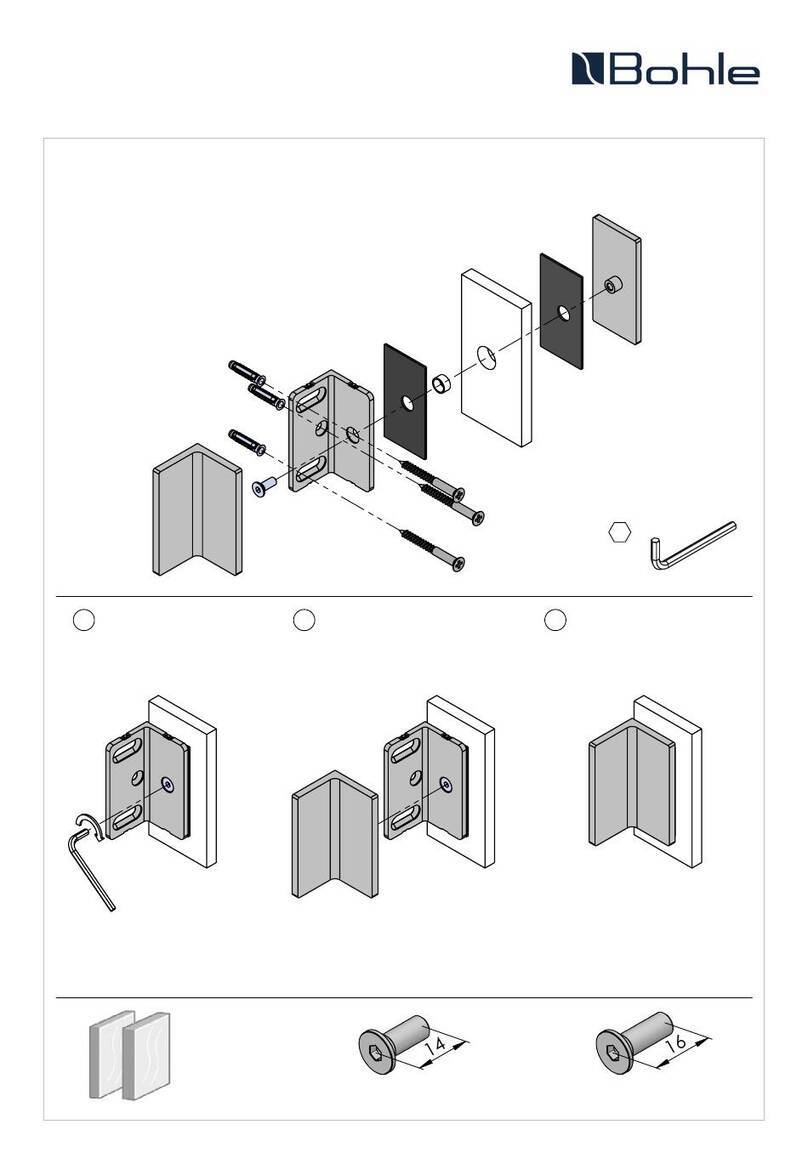

Bohle

Bohle BO 5215433 instruction manual