- 24 -

English

Introduction

1

1.1 Glossary and abbreviations ................................................................................................................................................................25

1.2 Safety notices ......................................................................................................................................................................................25

Safety precautions

2

2.1 General safety precautions.................................................................................................................................................................26

2.2 Installer’s requisites .............................................................................................................................................................................26

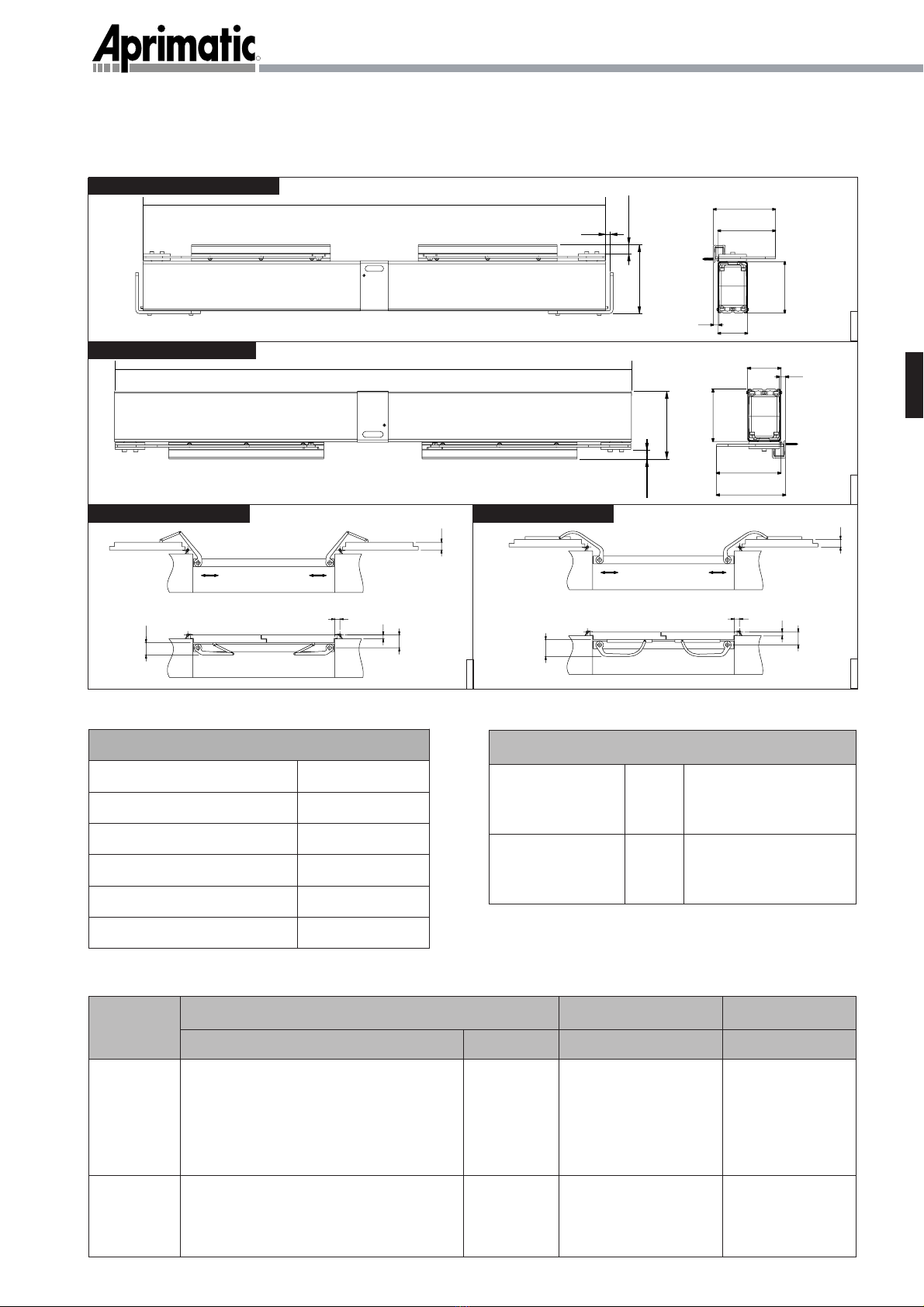

2.3 Working clothes...................................................................................................................................................................................26

2.4 Permitted uses ....................................................................................................................................................................................27

3

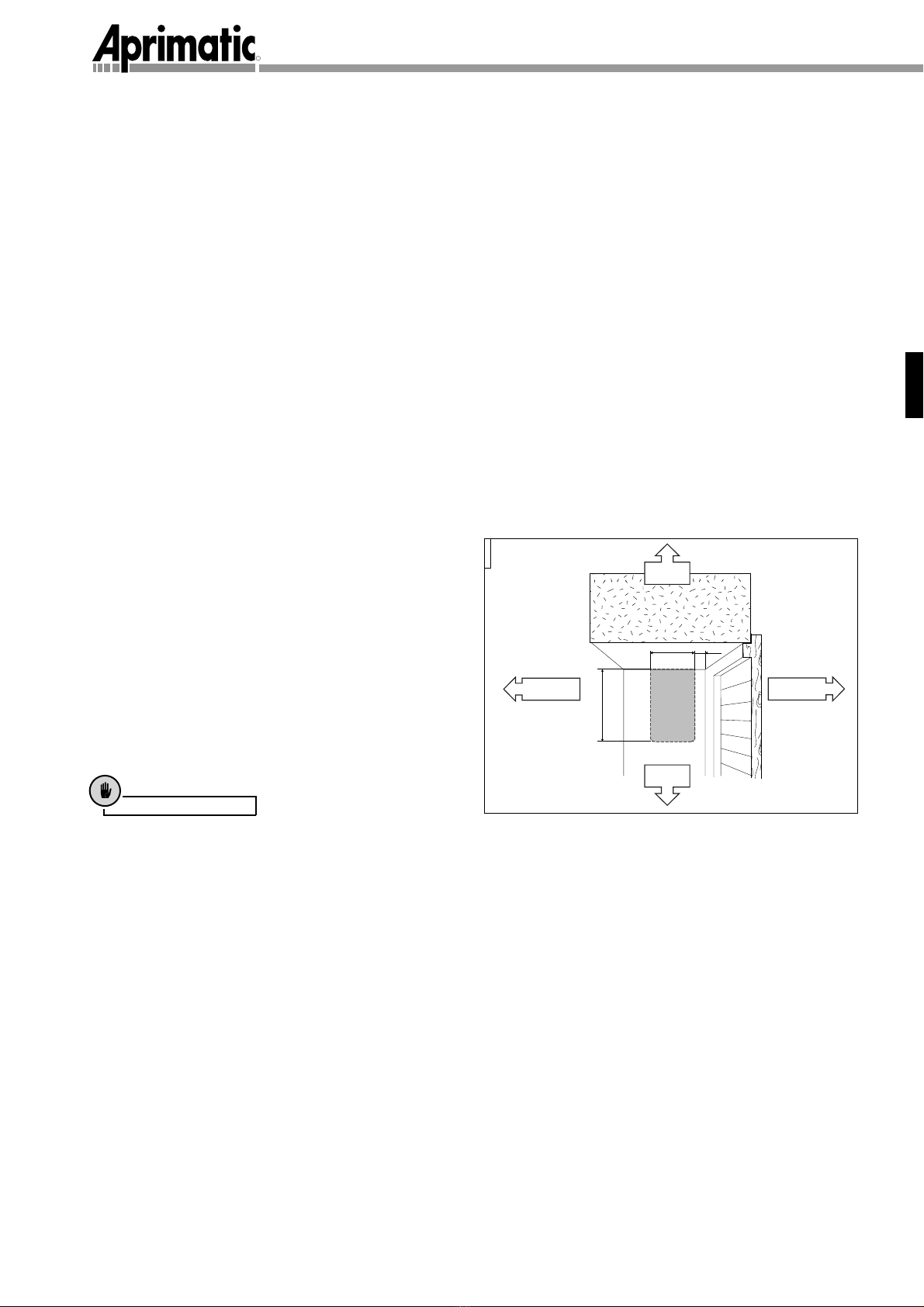

3.1 General description.............................................................................................................................................................................28

3.2 Technical characteristics .....................................................................................................................................................................29

3.2.1 Overall dimensions..............................................................................................................................................................................29

3.2.2 Technical data .....................................................................................................................................................................................29

3.2.3 Application field ...................................................................................................................................................................................30

3.3 Preliminary operations ........................................................................................................................................................................30

3.3.1 Mounting tools .....................................................................................................................................................................................30

3.3.2 Checking the electrical installation .....................................................................................................................................................31

3.3.3 Preliminary checks..............................................................................................................................................................................31

4

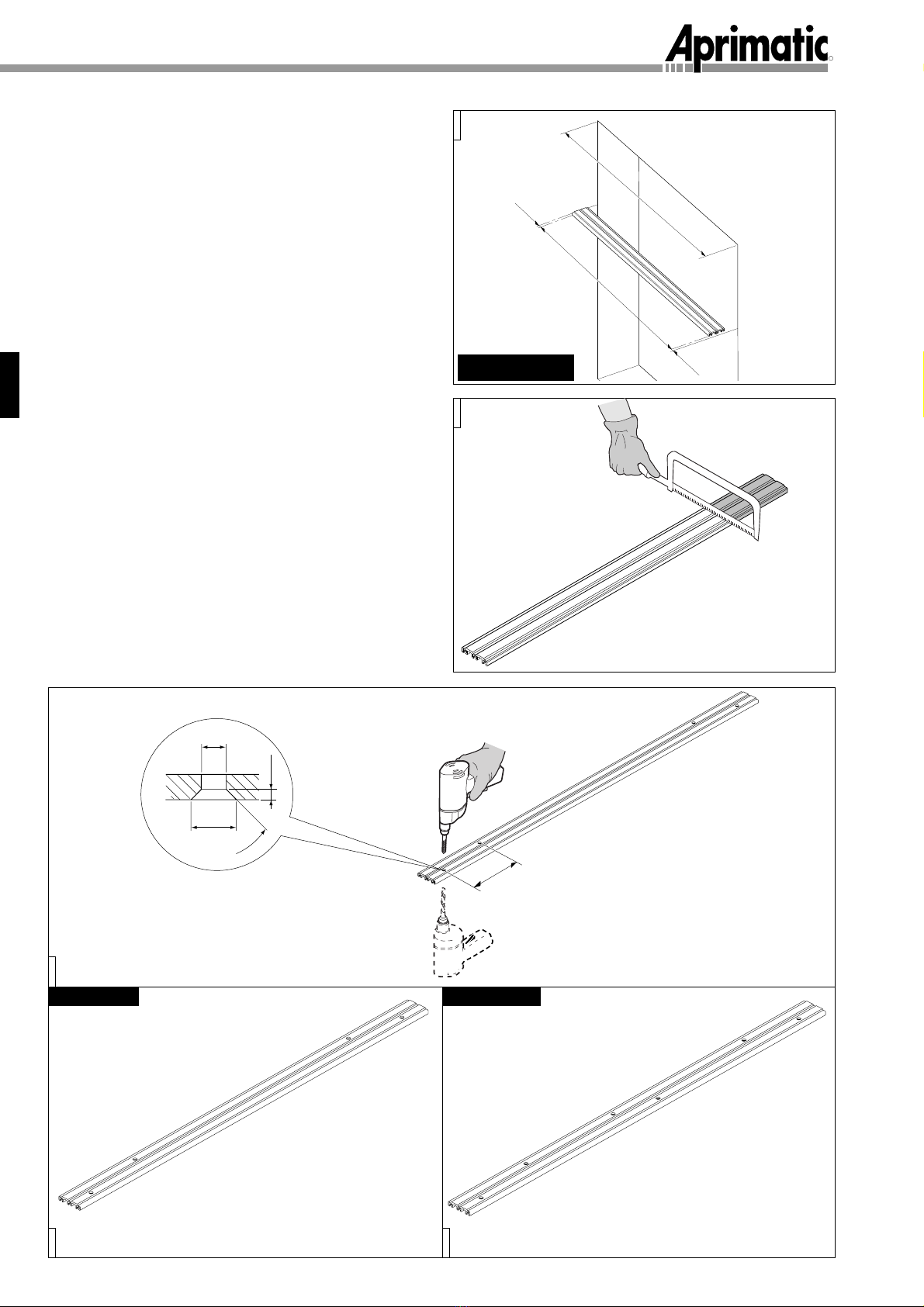

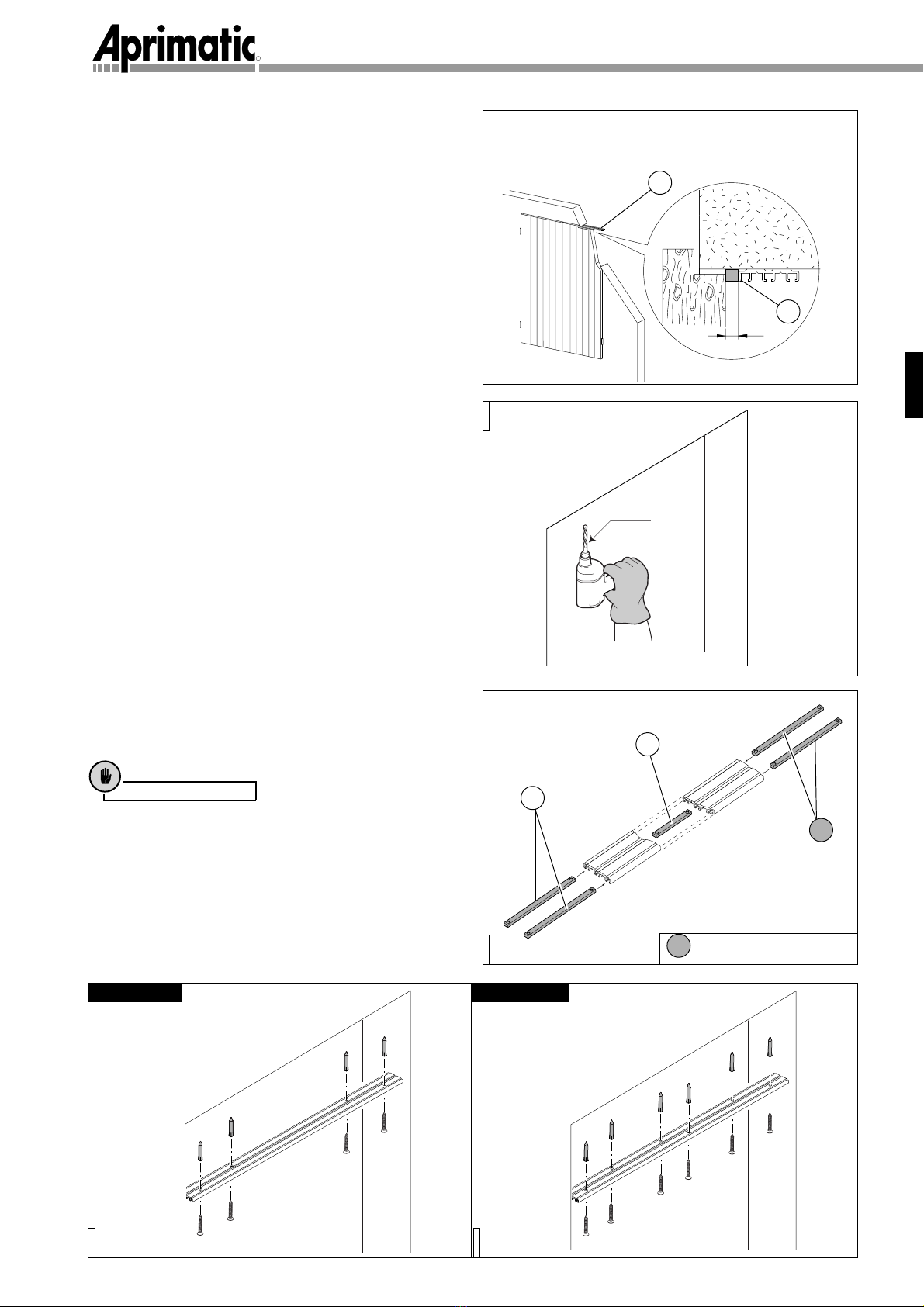

4.1 Assembly on lintel ...............................................................................................................................................................................32

4.1.1 Installing the geared motor ................................................................................................................................................................34

4.1.2 Positioning the geared motors ...........................................................................................................................................................35

4.1.3 Installing the control unit .....................................................................................................................................................................36

4.2 Cantilevered assembly........................................................................................................................................................................38

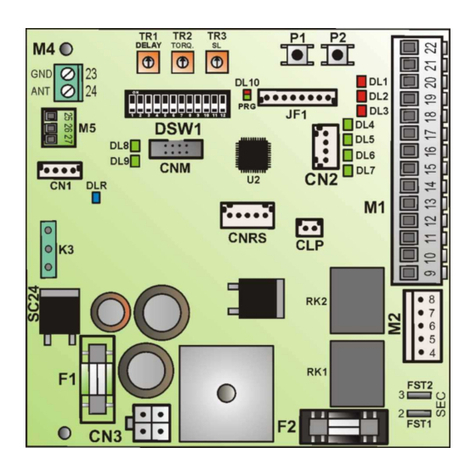

4.3 Electrical connections ........................................................................................................................................................................40

4.3.1 Useful advice.......................................................................................................................................................................................40

4.3.2 Connecting the motor cables..............................................................................................................................................................40

4.3.3 Connecting the control accessories ...................................................................................................................................................40

4.3.4 Connection to the power network.......................................................................................................................................................40

4.3.5 Programming the functioning..............................................................................................................................................................41

4.4 Checking the functioning ....................................................................................................................................................................42

4.4.1 Local control functioning .....................................................................................................................................................................42

4.4.2 Centralised control functioning ..........................................................................................................................................................42

4.4.3 Obstacle recognition ...........................................................................................................................................................................42

4.5 Mounting the casing............................................................................................................................................................................42

4.5.1 Version with electric stop ....................................................................................................................................................................43

4.5.2 Version without electric stop ...............................................................................................................................................................44

General features

Installation

Index/Introduction

5

5.1 Notes for the use .................................................................................................................................................................................45

5.1.1 What to do in case of power failure ....................................................................................................................................................45

Notes for the user