INDEX

SAVE THESE INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS

FCC Part 15.21 Statement:

Changes or modications not expressly approved

by the party responsible for compliance could void

the user’s authority to operate the equipment.

FCC / IC Statement:

This device complies with FCC Part 15 and Industry

Canada licence-exempt RSS standard(s). Operation

is subject to the following two conditions: (1) this

device may not cause harmful interference, and (2)

this device must accept any interference received,

including interference that may cause undesired

operation of the device.

Le présent appareil est conforme aux CNR

d’Industrie Canada applicables aux appareils radio

exempts de licence. L’exploitation est autorisée

aux deux conditions suivantes : (1) l’appareil ne

doit pas produire de brouillage, et (2) l’utilisateur

de l’appareil doit accepter tout brouillage

radioélectrique subi, même si le brouillage est

susceptible d’en compromettre le fonctionnement.

1

2

3

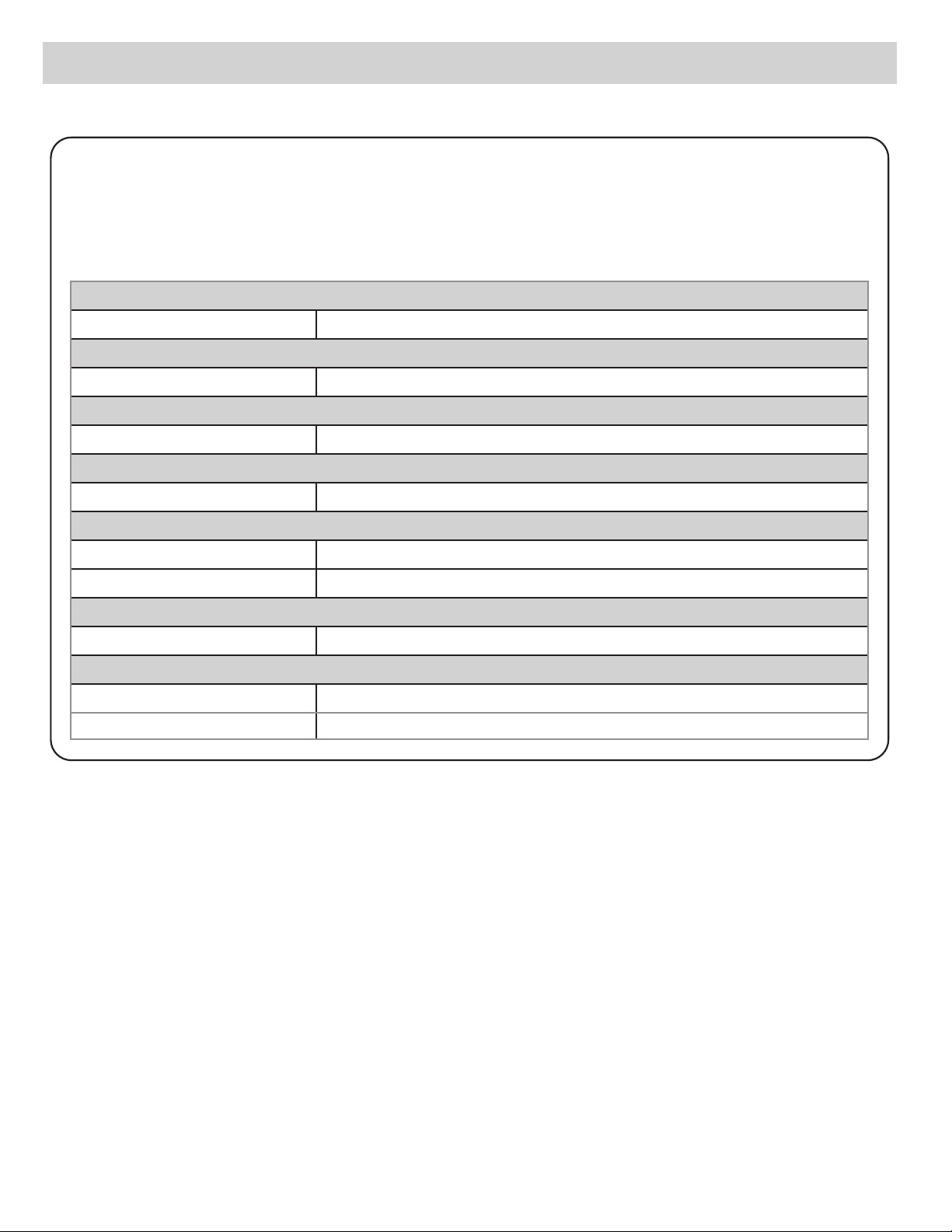

General Information & Instructions:..................1

Safety & General Information:

Safety Information and Instructions...................1-4

Important Installation Instructions.........................5

Approved Safety Devices ...........................................6

Assembly & Installation Of Operator:...............7

Pre-Installation Considerations................................7

Assemble Operator ......................................................8

Install Rail Assembly to Operator ...........................8

Install Header Bracket .................................................9

Determine Highest Point of Travel .........................9

Install Operator Rail to Header Bracket ............. 10

Mount Operator to the Ceiling ............................. 11

Attach Bracket and Draw Bar Arm to Door 12-13

Wire Operator, Install & Wire Accessories:... 14

Tools Required & Typical Installation................... 14

Install and Wire Wired Wall Console..................... 15

Install And Wire Monitored Safety Device......... 16

Wired Monitored Photocells (Std. Equip.)....... 16

Wired Monitored Reective Photocells (Optional)

16

Wired NEMA 4X Photocells (Optional)............. 17

Wired Monitored Light Curtain (Optional)..... 18

Wired Safety Edge Instructions (Optional)..... 19

Wireless Monitored Safety Edge (Optional)... 20

Install Light Bulbs and Lens Cover ....................... 21

Installing Battery Back Up (Optional).................. 22

Apply Power to Operator......................................... 23

Optional Permanent Input Wiring........................ 23

Programming Operator and Accessories:.... 24

Down Travel Limit....................................................... 25

Up Travel limit.......................................................................26

Force Control Adjustments..................................... 27

Contact Reverse Test ................................................. 27

Contact Reverse Adjustment ................................. 27

Transmitter Programming (if applicable) .......... 28

Accessory Programming

Wireless keypad (if applicable) ........................... 29

Built in Vehicle Transmitter (if applicable)...... 29

Wireless Wall Console (if applicable) ................ 30

Integrated Aladdin Connect (if applicable)..

31-32

Connect Battery Backup to Operator.................. 32

For patent information go to

www.geniecompany.com

/

patents

4

5

6

7

Special Installation Information:...................... 33

Changing Force Settings ......................................... 33

Clearing Memory of Accessories ......................... 34

Toggle Enable/Disable STB-Triggered

Work Light Features...................................................... 34

Adjusting Speed Control ........................................ 35

Maintenance: ............................................................. 36

Door Inspection.......................................................... 37

Replacing Batteries.................................................... 38

Changing Light Bulbs ............................................... 38

Troubleshooting & LED Signals: .................39-40

Replacement Parts:...........................................41-42

DASMA Safety Guidelines: ............................43-44

Warranty: ..................................................................... 45

8

9