Allegion Von Duprin 98 Series User manual

*911373-00*

911373-00

© Allegion 2015

Printed in U.S.A.

911373-00 Rev. 11/15-g

#10-24

Dogging Key

(use to lock down pushbar)

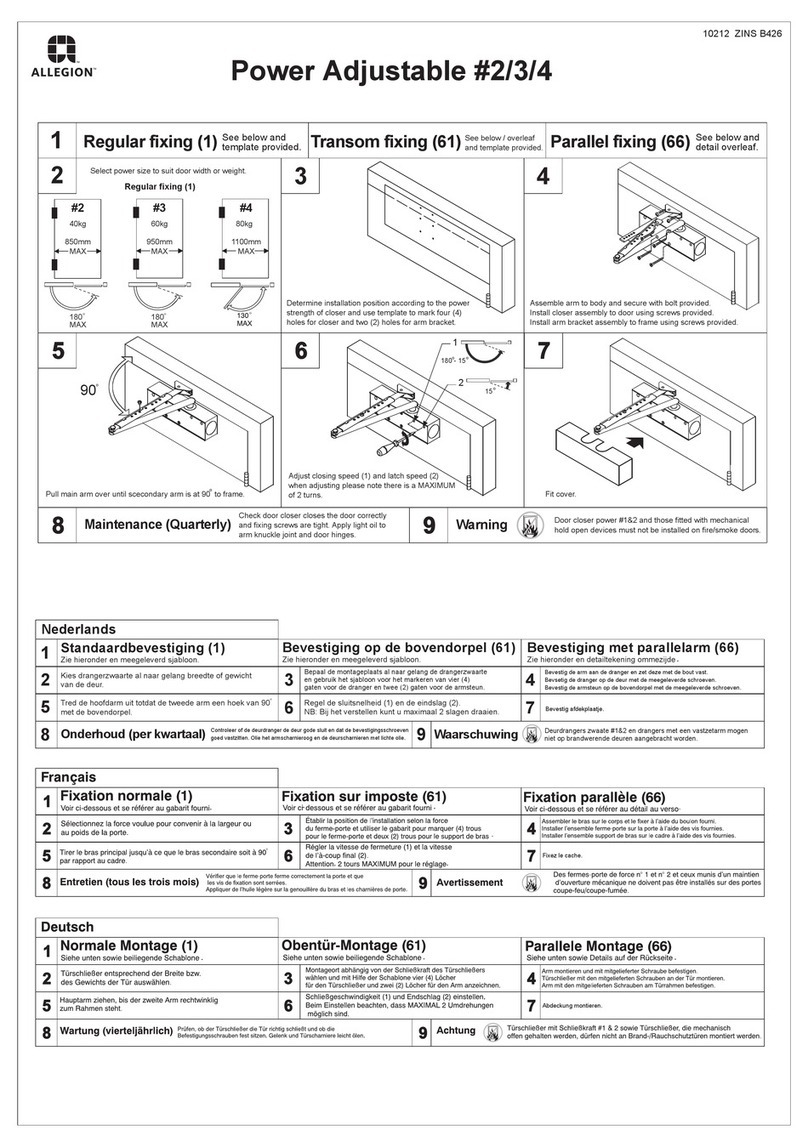

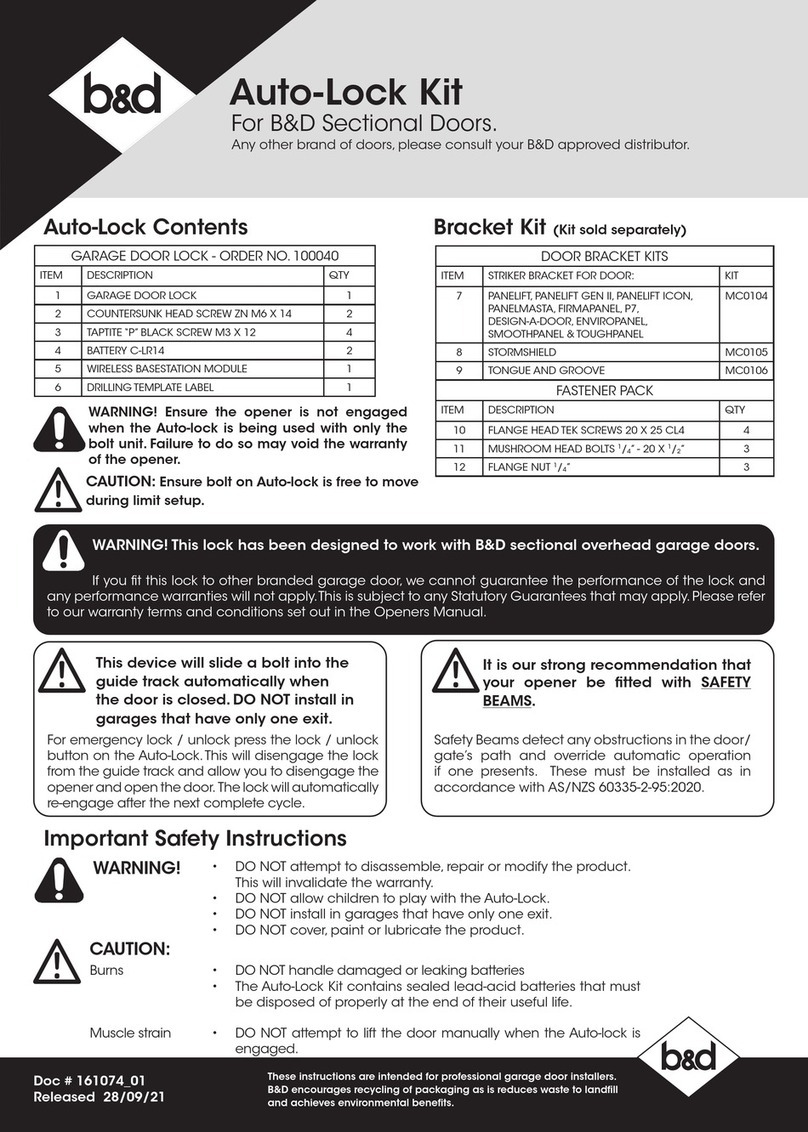

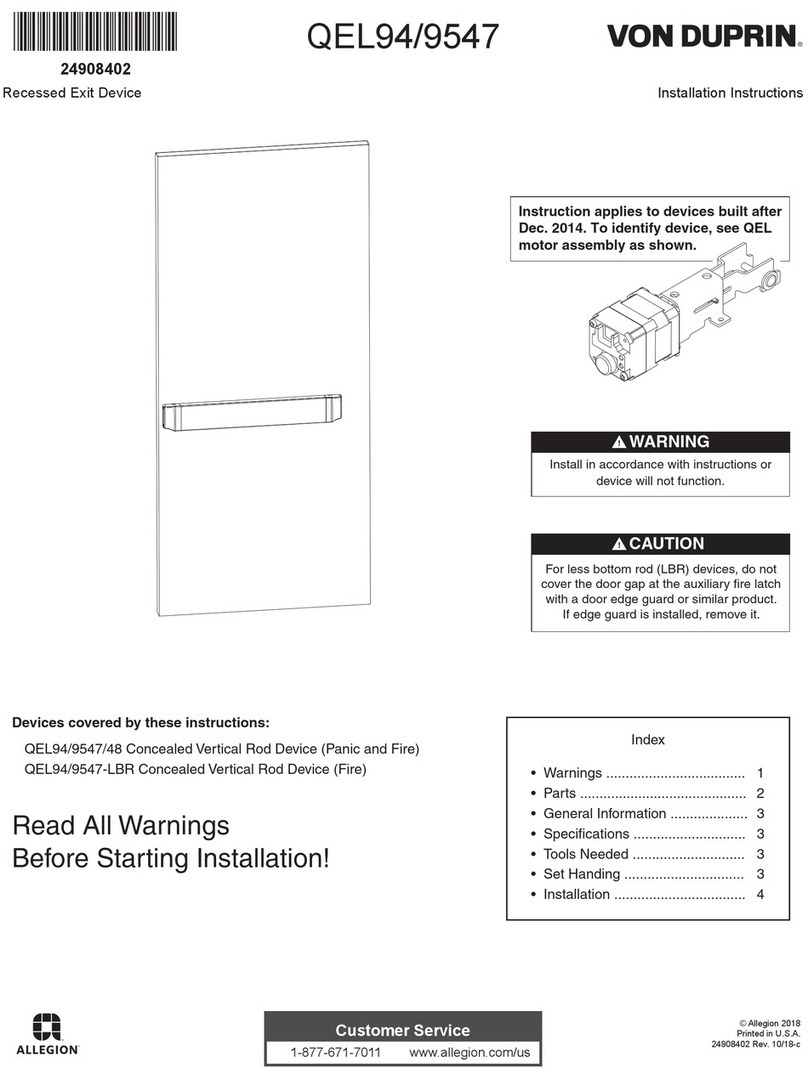

Rim Exit Device Installation Instructions

98/99

Customer Service

1-877-671-7011 www.allegion.com/us

2

SCREW CHART

Device Subassembly Screw Application

499F Strike299 Strike

#10-24 x C\v” (19 mm) Metal frame

#10 x 1Z\x” (38 mm) Wood screw Wood frame

#10-24 x 1” (25 mm) Surface mount or Sex bolts

1C\v” (44 mm) door

#10-24 x 1Z\x” (38 mm) Sex bolts, 2Z\v” (57 mm) door

#10 x 1Z\v” (32 mm) Wood screw Surface mount (wood)

Packaged with 990 Trims:

#10-24 x 1C\,” (35 mm) 1C\v” (44 mm) door, 990 Trim

#10-24 x 1M\,” (48 mm) 2Z\v” (57 mm) door, 990 Trim

#10-24 x C\v” (19 mm) Surface mount or Sex bolts

1C\v” (44 mm) door

#10-24 x 1Z\,” (29 mm) Sex bolts, 2Z\v” (57 mm) door

#10 x 1Z\v” (32 mm) Wood screw Surface mount (wood)

#10-16 x C\,” (10 mm) Thread cutting End cap

#10-24 x 1” (25 mm) Surface mount (metal)

#10 x 1Z\v” (32 mm) Wood screw Surface mount (wood)

#8-18 x C\,” (10 mm) Thread cutting Center case cover

3

1 Draw horizontal device and strike center lines (C

L).

For double doors with a

mullion and strike already

installed, use existing

strike center line.

RHR LHR

RHR

*39ZC\zn” (101.1 cm)

from finished floor

*

2 Align strike on C

Land mark the two slotted

holes.

For 499F strike installation, see page 6.

299

OR

Roller

(against door)

299F

For more information on the strikes shown below, go to

http://w3securitytechnologies.com and look for the

Support area for Von Duprin installation instructions.

1439 1609

264 1606

3 Prepare 2 holes and install 2 screws.

See “Screw Chart” on previous page for screw types and

sizes

Metal #25 #10-24

OR

Wood

Z\,” (3 mm) x 1” (25 mm) deep

4 Position template against strike and on C

Land

mark door.

Mark Vertical C

L

Mark 6 holes

5 If necessary, prepare cutouts for cylinder and trim.

RHR shown, LHR opposite

For outside cylinder applications:

Mark with template and cut out

Metal door (cut device side)

Wood door (cut thru)

For trim applications

with working lever,

thumbpiece, or knob:

Mark with template

and cut out (cut

device side only)

4

6 Prepare 4 center case mounting holes.

See trim instructions

for pull side door

preparation. Line X-X in

trim instructions is same

as vertical device C

L.

Four mounting holes

#25

#10-24

WOOD METAL

WOOD METAL

Z\,” (3 mm) x 1” (25 mm) Deep ZC\cx” (10 mm) Drill Thru

SEX BOLTS or 990 TRIMS

Z\v” (6 mm) Device Side

ZC\cx” (10 mm) Trim Side

OR

SURFACE MOUNT

7 Prepare 2 center case support holes.

Two support holes

#25

#10-24

METAL

Z\,” (3 mm) x 1” (25 mm) Deep

Z\zn” (2 mm)

B\zn” (16 mm)

Exterior

C\,”

(10 mm)

98/99

98/99-F

#825 Sex bolts (2) required

98/99 and 98/99-F

OR WOOD

8 If necessary, remove NL drive screw

With the NL drive screw removed, key locks and unlocks lever, knob, or

thumb piece. For the trims listed below, REMOVE NL drive screw.

996L 696TP 990TP

996K 697TP

With the NL drive screw installed, key retracts latch bolt. DO NOT remove

NL drive screw for the following applications:

NL, EO, DT trims and 98/99-2 double cylinder devices (i.e. TP-2,

L-2, and K-2).

If the trim being installed is "BE" (i.e. 996L-BE), the trim lock tumbler

on the back of the device must be in the UP position before device

is installed. This allows the trim to be unlocked at all times.

*

*996L-BE

*996K-BE

*E996L

*E996L-BE

*696TP-BE

*697TP-BE

*990TP-BE

NL drive screw

Factory installed on

back of center case

Correct

Orientation

(RHR shown)

Incorrect

Orientation

trim lock

tumbler in

UP position

If necessary,

remove drive

screw and

rotate cam

until trim lock

tumbler is in

UP position,

then reinstall

drive screw

360˚

9 If using a cylinder with a tailpiece, prepare device

and cylinder.

9a Install tailpiece guide.

Tailpiece guide

Tailpiece

Rotate tailpiece guide

to match tailpiece

9b Cut tailpiece as needed.

Z\x”

Door

Surface

5

10 If necessary, cut device.

1Z\x” (38 mm)

recommended

Jamb

Jamb

Temporarily remove

anti-rattle clip

Cover plate flush

11 Attach center case to door.

OR

Thru-Bolting Trim

Sex BoltsSurface Mount

12 Mark and prepare two (2) holes.

Prepare holes after lock side of device is mounted and

hinge side is leveled.

c

b

aSURFACE MOUNT

#25

#10-24

WOOD METALWOOD METAL

Z\,” (3 mm) x 1” (25 mm) Deep

ZC\cx” (10 mm) Drill Thru

SEX BOLTS

Z\v” (6 mm) Device Side

ZC\cx” (10 mm) Trim Side

OR

13 Install end cap bracket and end cap.

6

14 Install required support screws and

center case cover.

Remove protective

film from pushbar

15 Adjust strike as needed.

Shim as needed

C\zn” (5 mm)

299/299F Strike

299

299F

16 Install strike support screw.

OR

#25

#10-24

METAL WOOD

Z\,” (3 mm) x

1” (25 mm) Deep

499F STRIKE INSTALLATION

1. Prepare and install screws through two

strike slots.

2. Install strike hook and additional strike

screws.

3. Template aligns as shown.

Roller

(against door)

If using a mullion,

holes may be predrilled

#25 Drill

#10-24 Tap

2 places

#7 Drill

Z\v” (6 mm)-

20 Tap

2 places

ZC\cx” (10 mm)

Drill thru for

sex bolts

2 places

MetalWood

#25 Drill

#10-24 Tap

3 places

Template

(align on C

Land

against strike

7

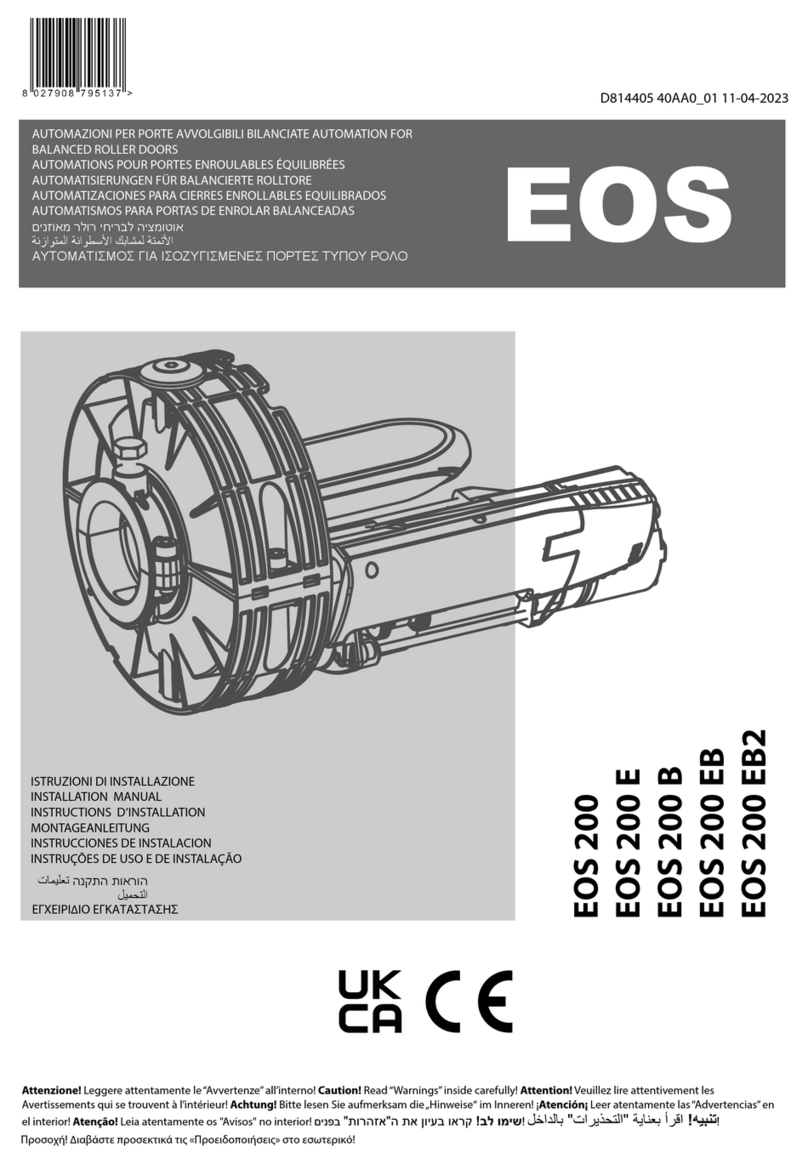

OPTIONAL EQUIPMENT

CD (Cylinder Dogging) Option

Dog Undog

a

b

c

d

e

f

8

OPTIONAL EQUIPMENT

99-2 (Double Cylinder) Option

If using the -2SI with a

keyed rim cylinder,

remove the 2 stop screws

from back of device prior

to installing the cylinder.

B\,” (16 mm)

1C\v” (44 mm)

1C\,” (35 mm)

1Z\v”

(32 mm)

Wood

Z\v” (6 mm)

Deep

#8-32 x B\zn” (8 mm)

PPHMS

a

b

d

Cylinder

Mounting Screws

DO NOT over-tighten

RHR Shown

(LHR opposite)

c

e

#8-18 x C\,” (10 mm)

PPHSMS

2Z\v” (57 mm)

1C\,” (35 mm)

ZC\zn” (21 mm)

Device

and Strike

1B\,”

(41 mm)

Wood

Z\v” (6 mm)

Deep

Device

and Strike

Door Cutout for 99-2 “Double Cylinder” Option

Door Cutout for 99-2SI “Double Cylinder” Option

Z\,” (3 mm) R

4 places

Z\,” (3 mm) R

4 places

For 98/99-2SI models with Classroom Security Indicator, apply supplied labels above and below cylinder to match door handing,

and label on indicator.

Manually affix the label:

Ensure surface is clean of dirt, dust, or oils. Clean with alcohol

if necessary.

Peel the label from the paper backing and apply to the surface.

Minimize handling when applying and use pressure to burnish

label to surface. The adhesive will require up to 8 hours to

achieve the proper bond. RHR shown

Peel and stick

appropriate set of

labels depending on

door handing. Stick labels

above and below cylinder,

and label on indicator.

LHR99-2 RHR99-2

*921265-00*

921265-00

© Allegion 2014

Printed in U.S.A.

921265-00 Rev. 01/14-b

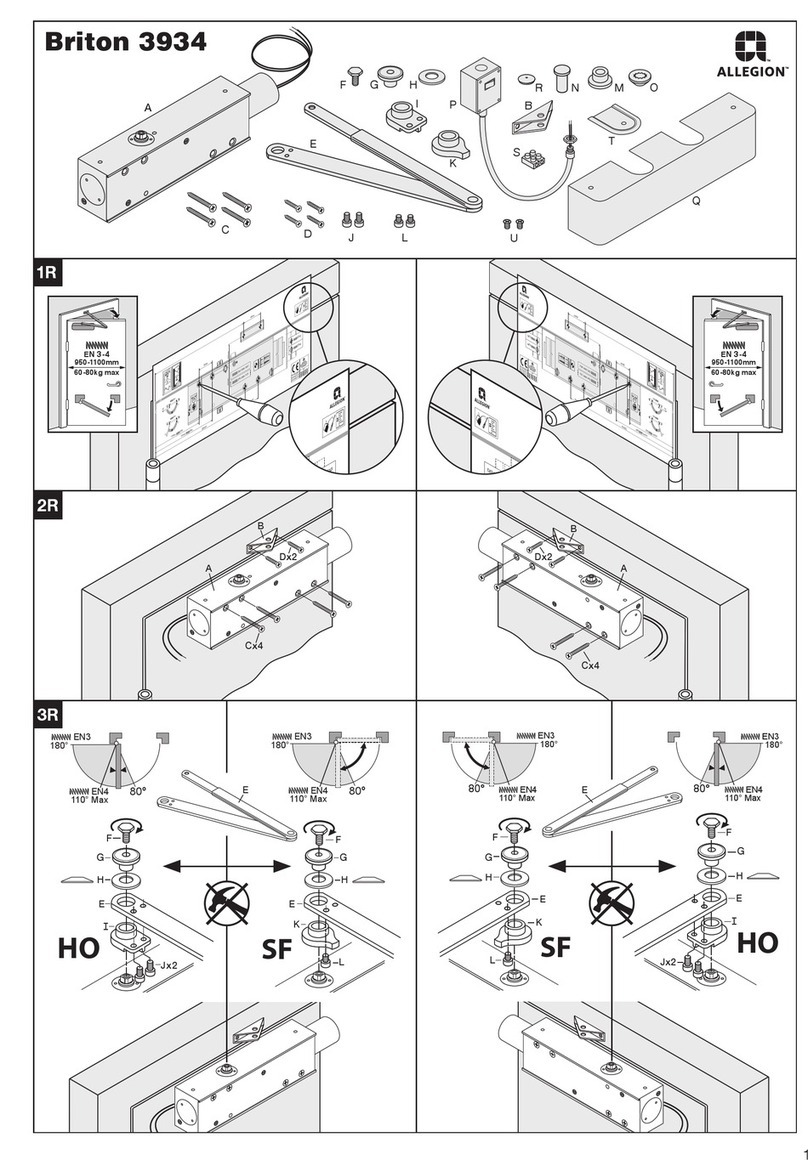

1

Prepare door for exit device. See exit device instructions for

holes, line X-X, and center lines.

2

Prepare door for trim:

2a

Transfer line X-X from inside (exit device side) of door to

outside (trim side) of door. Use extra care if edge of door is

beveled. Be sure line X-X is parallel to edge of door.

2b

Locate and prepare holes as shown.

3

For TP and NL trim, install rim cylinder.

Cylinder

screws

2

required

Cylinder retaining

cup

Tabs on cylinder

retaining cup must

fit into slots on plate

Trim plate assembly

Cut tailpiece to extend

7/16” to 9/16” out of

exit device side of door

Rim

cylinder

Cylinder collar

4

For TP and TP-BE trim on 1-3/4” thick door, cut 1/4” off

humbpiece.

1/4” cutoff required

on

thumbpiece for TP an

d

TP-BE trim on 1-3/4

”

thick doors

1/4”

5

Apply trim.

6

For TP and NL trim, cut cylinder tailpiece to extend 7/16” to

9/16” out of exit device side of door.

7

Apply exit device, thru-bolt to trim (4 places), and use screw

and #12 countersink washer for lower trim mounting stud.

Trim for Rim and Vertical Rod Devices

990TP/TP-BE/NL

Installation Instructions

For cutouts on inside face of door, see exit device instructions

LHR shown, RHR opposite

Corresponds

to center line

of exit device

on exit device

instructions

XX

XX

X

XX

Metal door:1/4” dia.

4 places

1-3/8”

11/16”

Metal door: 3/8” dia.

7”

5-23/32”

4-1/4”

Outside face

of lock stile

Inside face

of lock stile

7”

5-23/32”

3-1/2”

3-1/2”

3-1/2”3-1/2”

5-23/32”5-23/32”

1/4”

1”

4-1/4”

1/4”

7” 7”

1-3/8”

11/16”

1-3/8”

11/16”

1-3/8”

11/16”

XX

XX

XXX

XX

XXX

XX

X

X

Outside face

of lock stile X

Outside face

of lock stile

13/32” dia., 4 places

Metal door: this side

Wood door: thru

TP

TRIM

TP-BE

TRIM

NL

TRIM

13/32” dia., 4 places

Metal door: this side

Wood door: thru

Line X-X corresponds to line X-X on exit device instructions

13/32” dia., 4 places

Metal door: this side

Wood door: thru

7/16” dia.

Metal door: this side

Wood door: thru

7/16” dia.

Metal door: this side

Wood door: thru

7/16” dia.

Metal door: this side

Wood door: thru

TP TRIM TP-BE TRIM NL TRIM

ALL

TRIM

ALL TRIM

1-5/8” dia.

Metal door: this side

Wood door:1-3/8”deep

.dar”2/1.dar”2/1

1-5/8” dia.

Cutout

Metal door: this side

Wood door: 1-3/8” deep

Cutout

Metal door: this side

Wood door: 1-3/8” deep

Device Application Schedule

98/99 Rim Device

98/9927 Surface Vertical Rod Device

98/9947 Concealed Vertical Rod Device

C

L

Customer Service

1-877-671-7011 www.allegion.com

*941255-00*

941255-00

© Allegion 2014

Printed in U.S.A.

941255-00 Rev. 01/14-c

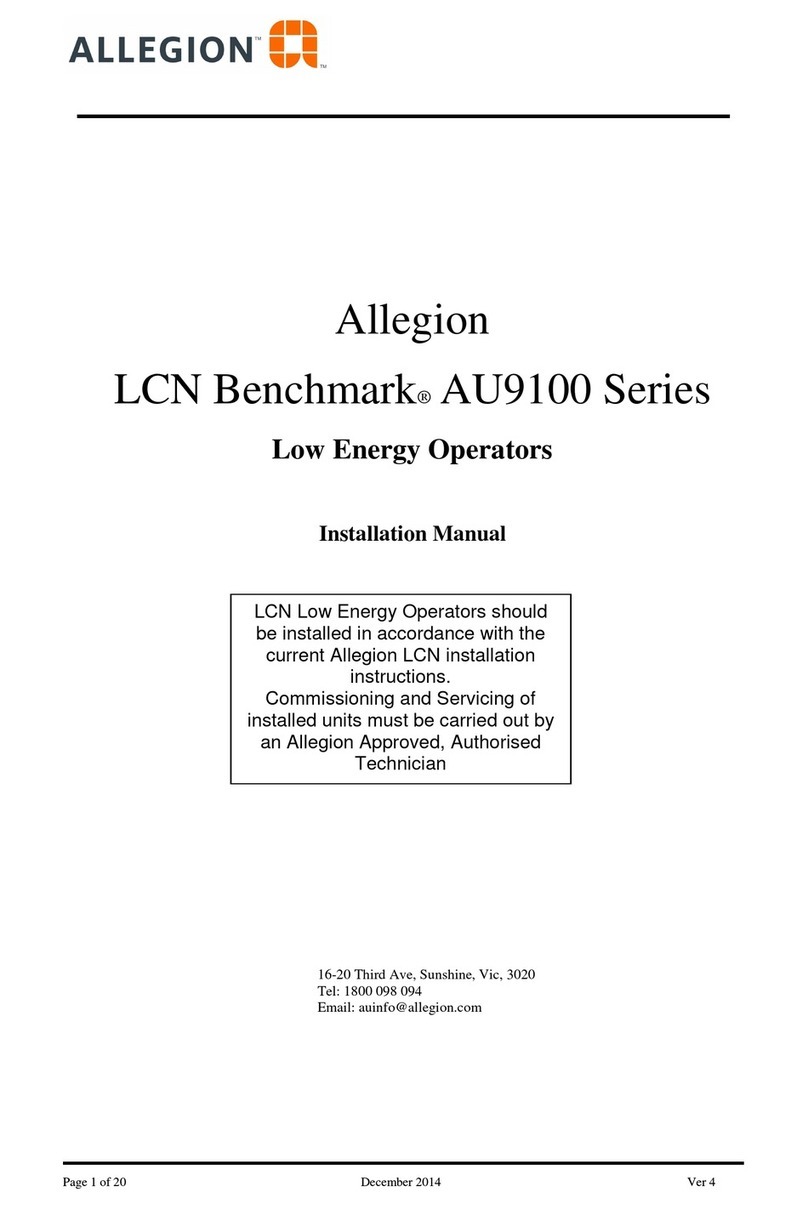

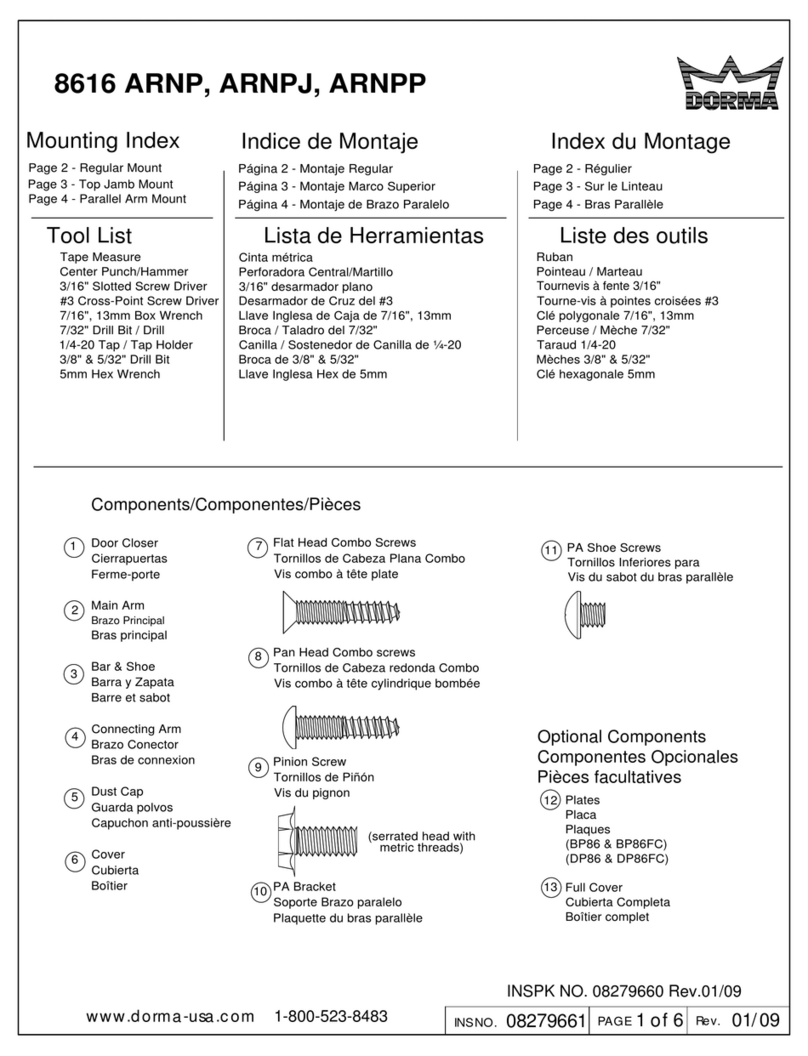

Index

• General Information ...................

• Specifications .............................

• Parts List ....................................

• Warnings ....................................

• Tools Needed .............................

• Installation ..................................

• EL Wiring and Adjustment ..........

Read All

Warnings

Bef

ore Starting Installation! 2

2

2

2

2

3

12

Conversion Kit

EL/HD-EL

Installation Instructions

Customer Service

1-877-671-7011 www.allegion.com/us

2

Flat blade screwdriver Phillips screwdriver

5/8” dia. drill bit

Solenoid:

Continuous duty: 24 VDC

Current inrush: 16 A

Current holding: 0.3 A

This kit converts 33/35, 33A/35A, and 98/99 series devices to electric latch (EL) retraction devices.

Before beginning installation, review “Specifications,” “Parts List,” “Warnings,” and “Tools Needed.”

TOOLS NEEDED

PARTS LIST

SPECIFICATIONS

GENERAL INFORMATION

WARNINGS

1. This kit cannot be used to convert 33/35 Rim devices. Consult factory.

2. Install according to instructions or device will not function and panic or fire label will be void.

3. The solenoid wiring must be attached to the fire alarm system if installed on fire exit hardware.

4. PS914 power supply with 900-2RS logic board must be used for EL device to operate properly.

5. Field wiring between the power supply and the door must be 12 AWG.

DL-12 door loop

*not in kit

Pin and

retaining clip

Circuit

breaker

Cable

Baseplate with solenoid PS914 power supply with 900-2RS logic board

*not in kit

* This part is required for installation but not included in this kit. Contact factory to order.

3

Remove device from door if installed (find correct device on page 3 or 4).

1

98/99 Rim/Mortise Device

9827/9927 Device

9847/9947 Device

Detach rods

(rod guides may also

need removed)

A

Remove end cap and loosen or

remove mounting bracket.

B

Remove 4 screws

(remove trim also if it

is not secure on door)

B

Device and trim must be held securely while removing mounting screws to

prevent device and trim from dropping to the floor.

!WARNING

Remove end cap and loosen or

remove mounting bracket.

C

Remove 4 screws

(remove trim also if it

is not secure on door)

A

Detach rods as

shown below

A

B

Remove 4 screws

(remove trim also if it

is not secure on door)

Remove end cap and loosen or

remove mounting bracket.

C

Trim

Trim

Trim

Rim device shown

4

Continued from page 3.

1

33A/35A Rim DeviceRemove end cap and loosen or

remove mounting bracket.

B

Remove 4 screws

(remove trim also if it

is not secure on door)

A

B

Remove end cap and loosen or

remove mounting bracket.

C

Remove 2 screws

(remove trim also if it

is not secure on door)

3327/3527 & 3327A/3527A Device

B

Remove end cap and loosen or

remove mounting bracket.

C

Remove 2 screws

(remove trim also if it

is not secure on door)

3347/3547 & 3347A/3547A Device

Detach rods as shown below

A

3347/35473347A/3547A

3327/35273327A/3527A

A

Trim

Trim

Trim

Detach rods (rod guides may also need removed)

5

Disassemble device.

2

33/35 Device

33A/35A & 98/99 Device

Remove push bar

B

Slide to remove

Baseplate

assembly

Slide to remove

Remove mechanism case

A

Slide to remove

Slide to remove

Remove push bar

C

Remove

screws from

mechanism

case

A

Baseplate

assembly

Remove mechanism case

B

Used on

33A/35A

only

98/99 device

center case shown

6

3Remove main link retaining ring and pin.

4Remove screws connecting center case to baseplate.

Retaining

ring

Pin

7

Install center case to new EL baseplate.

5

Warning:Make sure retaining ring

is secure in the pin groove. If

retaining ring is not secure it could result

in an exit device that will not allow exit.

This is a serious safety issue.

Note:Remember to install screws

connecting centercase to

baseplate that were removed

in Step 4.

Note:Use this hole

for 33A/35A &

98/99 series

devices.

Note:For 33/35

series devices, place

pin through front hole

and tab through back

hole as shown.

8

Reassemble device.

6

33/35 Device

33A/35A & 98/99 Device

Baseplate

assembly

Slide to install

Install push bar

A

Slide to install

Install

mechanism case

B

Note:Make sure

crosspieces

inside push bar

are placed in

slots in bellcranks.

Push bar guide

Push bar

guide

Install

screws into

mechanism

case

C

Baseplate

assembly

Slide to install

Install push bar

A

Slide to install

Note:Make sure

crosspieces

inside push bar

are placed in

slots in bellcranks.

Push bar

guide

Install

mechanism case

B

Used on

33A/35A

only

98/99 device

center case

shown

9

Drill solenoid cable hole and install device to door.

7

A. Drill 5/8” diameter hole in door centered between end cap bracket mounting holes.

B. Deburr hole.

C. Reattach device and trim to door.

Note:The end cap bracket may be

different than the one shown,

but door preparation for the

solenoid cable is the same.

5/8” Diameter

cable hole End cap bracket

mounting holes

Route cable through hole in door.

8

End cap

bracket

10

Install cover plate and end cap.

9

A. If cover plate has a dogging key hole, rotate cover plate so hole is near end cap for standard EL

device and near pushbar for HD-EL device.

B. Install anti-rattle spring.

C. Install cover plate.

D. Install end cap.

Cover plate

Dogging key hole

Hinge end

of deviceAnti-rattle spring

If spring is this style, it will

slide into the cover plate,

2” minimum recommended

For vertical devices, reattach rods.

10

9827/9927 Device or

3327A/3527A Device

Reattach rods in reverse of when they were detached on pages 3 and 4.

Adjust rods as needed on vertical devices (find correct device on page 10 or 11).

11

9

Adjust top and bottom rod (screw rod into

or out of latch) until adjusted as shown.

Note:On bottom latch, make sure latch bolt

clears floor when door is swung open.

With door

closed:

With door

open:

Latch boltdeadlocked

(will not push in fully)Latch bolt stays

retracted

Release

trigger

extended

3327/3527 Device

Latch bolt

fully extended Latch bolt stays

retracted

Release

trigger

extended

With door

closed:

With door

open:

Adjust top and bottom rod (screw rod into

or out of center case rod connector) until

adjusted as shown.

Note:On bottom latch, make sure latch bolt

clears floor when door is swung open.

11

Continued from page 10.

11

3347/3547 Device

9847/9947 Device or 3347A/3547A Device

Install bottom adjusting screw, retaining clip, and

locking screw (Figure 11-2).

With top latch bolt still retracted, adjust bottom

rod so latch bolt clears floor and bottom strike.

Turn bottom locking screw in. Do not over-tighten.

Open door and release top latch

bolt as shown (Figure 11-1).

Loosen bottom locking

screw (Figure 11-2).

Disconnect bottom vertical

rod by removing bottom

adjusting screw.

Loosen top locking screw.

Rotate top adjusting screw

clockwise until top latch

bolt is fully extended

(Figure 11-1).

Check top latch

bolt for

deadlocking

(latch bolt should

not push in fully).

Turn top

locking screw

in. Do not

over-tighten

Depress pushbar and release.

Make sure top latch bolt stays

retracted as shown.

A.

B.

C.

D.

E.

F.

G.

H.

I.

J.

K.

L.

Close door and push up on bottom latch bolt

to verify it is deadlocked (will not push in fully).

Check device operation by opening and closing door

several times from the outside.

Redo adjustment procedure if :

- Top latch bolt is not held retracted

- Bottom latch bolt does not clear

floor and bottom strike

Bottom

latch bolt

(clears floor

and strike)

Figure 11-3

Figure 11-4

Top latch bolt

Shown fully

extended

Figure 11-1

Latch bolt retracted

(flush with latch case)

Figure 11-2

Bottom

adjusting

screw

Top locking

screw

Top adjusting

screw

Bottom

locking screw

Bottom

retaining clip

With top latch bolt still retracted, push

bottom latch bolt up until it clears floor

and bottom strike and hold it there.

Tighten bottom adjusting screw.

Depress pushbar

and release.

Make sure top

latch bolt stays

retracted as shown.

E.

F.

Close door and push up on bottom latch bolt

to verify it is deadlocked (will not push in fully).

Check device operation by opening and

closing door several times from the outside.

Redo adjustment procedure if :

- Top latch bolt is not held retracted

- Bottom latch bolt does not clear

floor and bottom strike

Bottom

latch bolt

(clears floor

and strike)

Latch bolt retracted

(flush with latch case)

G.

H.

I.

J.

Loosen top and

bottom adjusting

screws.

Open door and

release top latch

bolt as shown.

Check top latch bolt for

deadlocking (latch bolt

should not push in fully).

With top latch bolt still fully extended and pushbar

in full up position (not depressed), tighten top

adjusting screw.

A.

B.

C.

D.

Bottom

adjusting

screw

Top

adjusting

screw

Hex

wrench

M.

N.

Other manuals for Von Duprin 98 Series

1

This manual suits for next models

11

Table of contents

Other Allegion Door Opening System manuals

Allegion

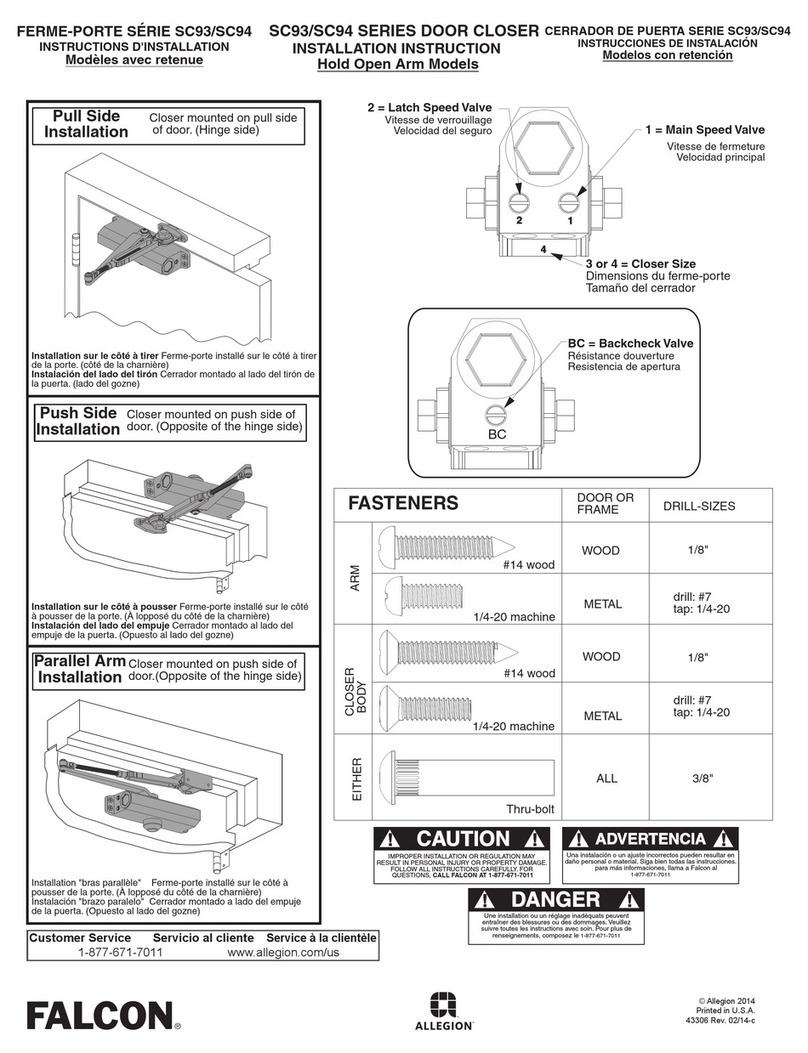

Allegion FALCON SC93 Series User manual

Allegion

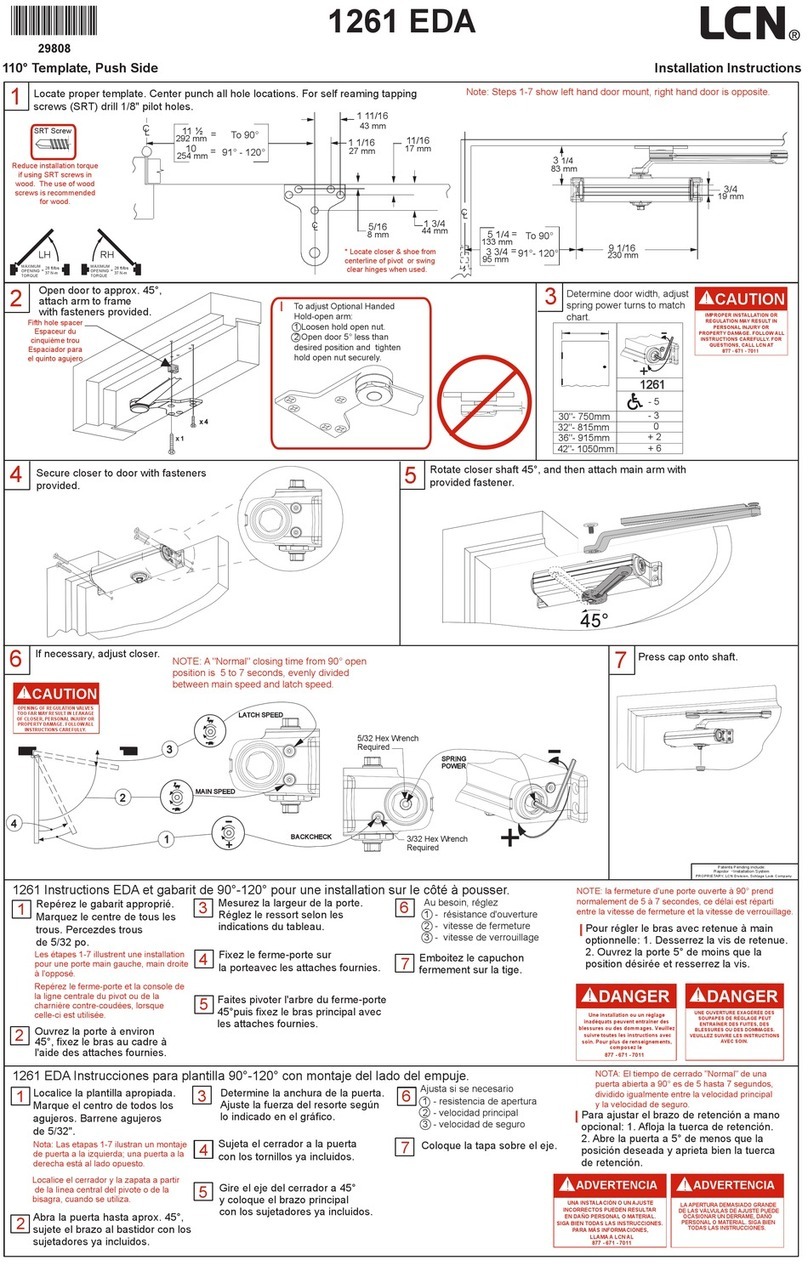

Allegion LCN 1261 EDA User manual

Allegion

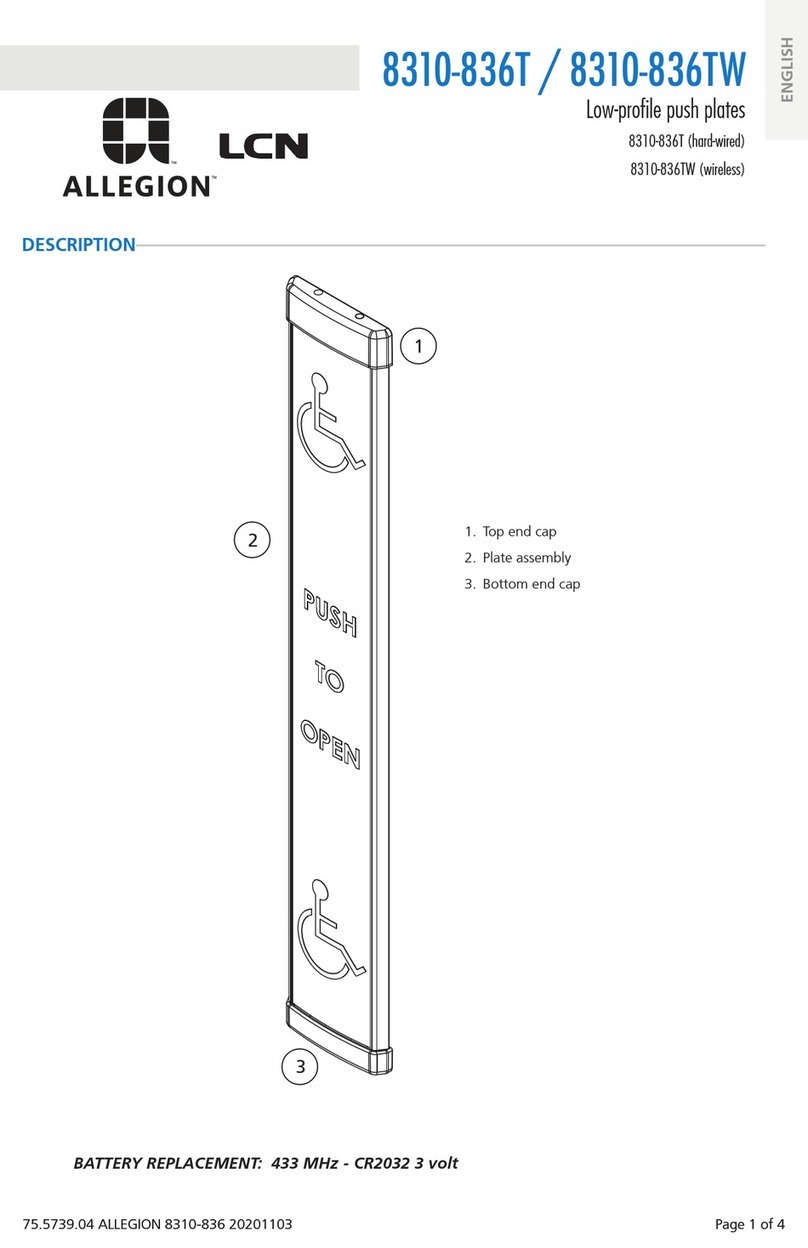

Allegion LCN 8310-836T User manual

Allegion

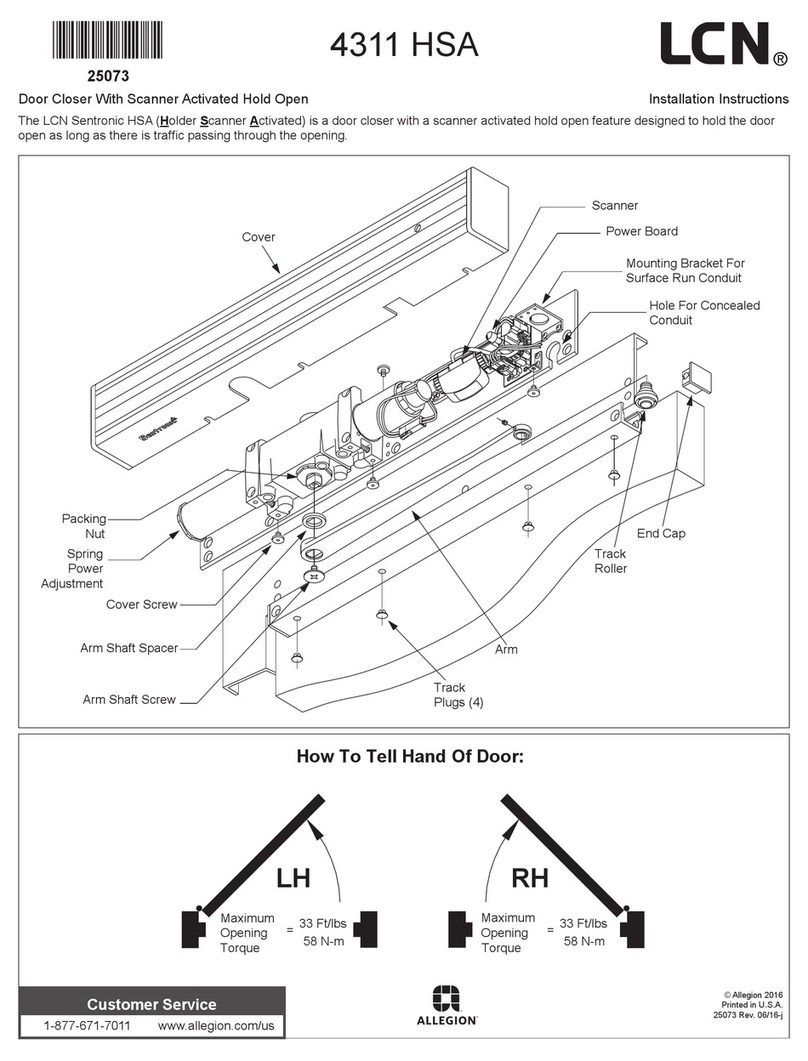

Allegion LCN 4311 HSA User manual

Allegion

Allegion interflex IF-241 User manual

Allegion

Allegion Von Duprin QEL9447 User manual

Allegion

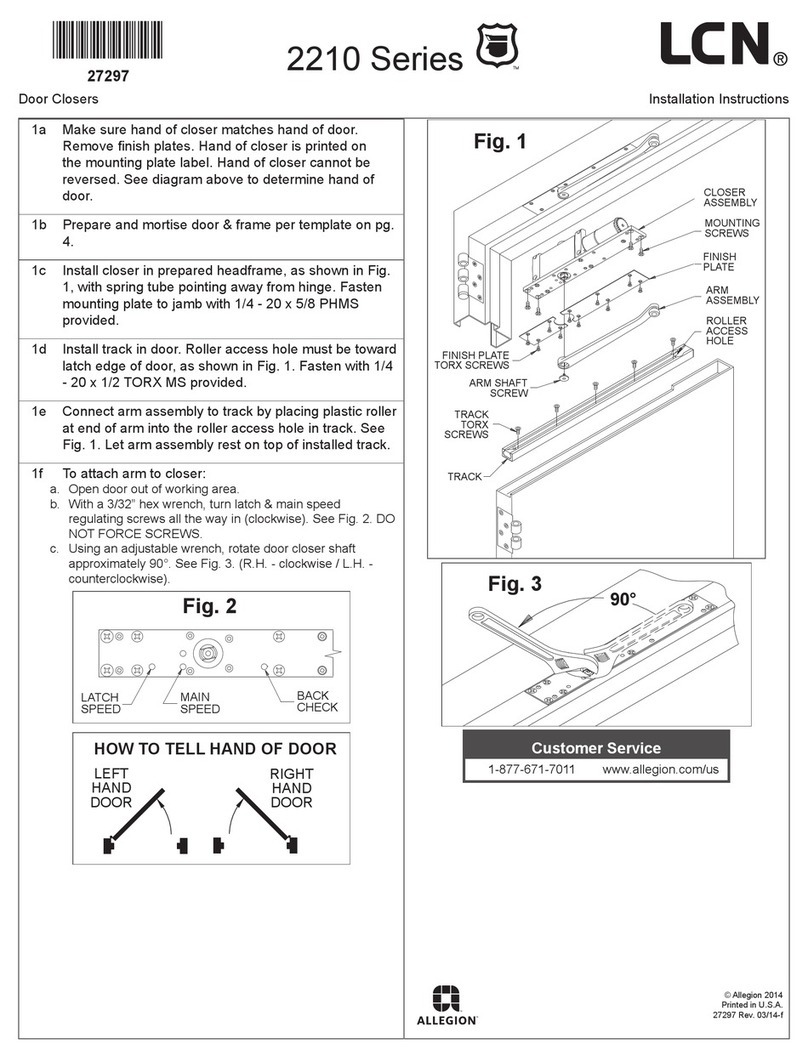

Allegion LCN 2210 Series User manual

Allegion

Allegion LCN 4040SE User manual

Allegion

Allegion VON DUPRIN XP98 Series User manual

Allegion

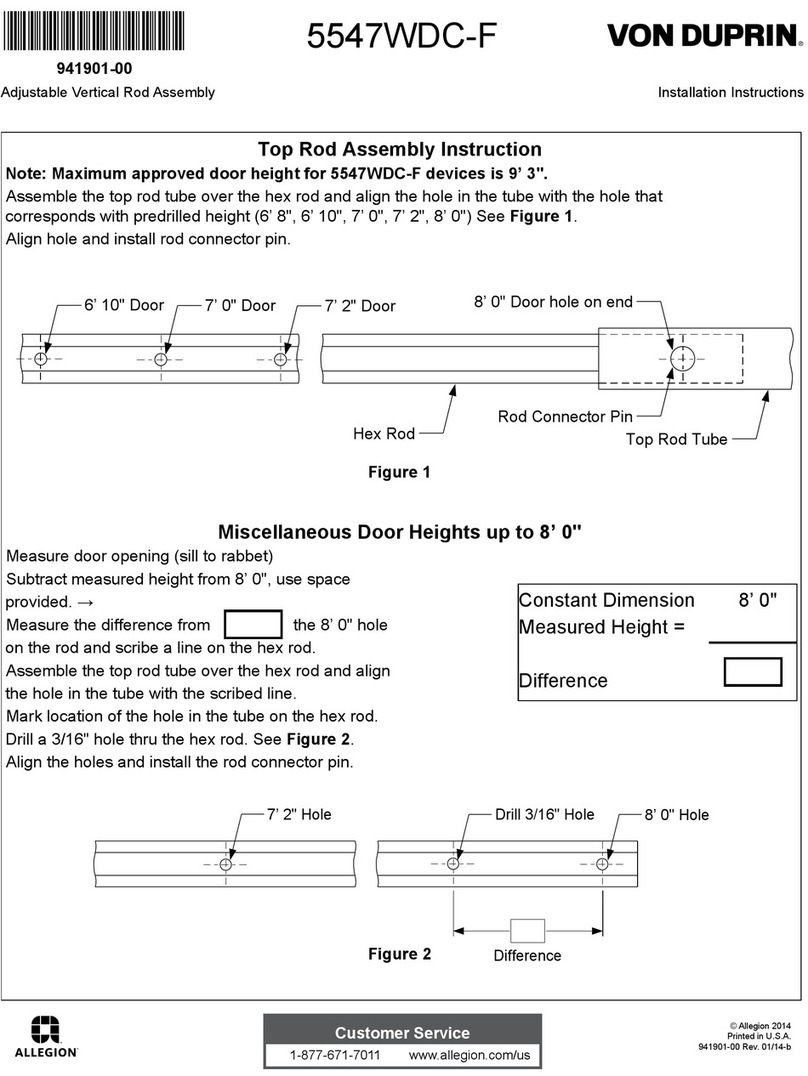

Allegion Von Duprin 5547WDC-F User manual