DEUTSCHTEC SLH Series User manual

Installation manual

Deutschtec GmbH

Am Fuchsbau 13

15345 Petershagen/

Eggersdorf Deutschland

Phone: +49 (0)3341 30 22 4 - 0

Fax: +49 (0)3341 30 22 4 - 25

www.deutschtec.de

SLH Series

Contents

1EN.09.09052022 2EN.09.09052022

INTRODUCTION 3

SYMBOLS OF THE MANUAL 3

1 GENERAL INFORMATION OF THE PRODUCT 4

1.1 Product Introduction 4

1.1.1 SLH239 4

1.1.2 SLH240 4

1.1.3 SLH240/H 4

1.1.4 SLH240ES 4

1.2 Technical Specications 5

1.3 Copyright 6

1.4 Standards 6

1.5 Warranty Guidelines 6

1.6 Declaration of Incorporation 7

1.7 Certication 8

1.8 Signage 9

2 CONTENTS OF DELIVERY 10

2.1 Operator Kit 10

2.2 SLH Prole Set 12

2.3 Accessories 13

3 ASSEMBLY AND INSTALLATION 14

3.1 Precautionary Measures 14

3.2 Required Tools 15

3.3 Technical Drawings 16

3.3.1 Two-leaves door version (TBS Frame) 17

3.3.2 One-leaf door version (TBS Frame) 17

3.4 Installation Steps 17

3.4.1 On-Site Preparation 17

3.4.2 Aluminum Base Prole 17

3.4.3 Stainless Steel Prole & Rubber Prole 19

3.4.4 Rubber Track Prole & Aluminum Track Prole 19

3.4.5 Standard Distance for Opening (mm) 20

3.4.6 Check the Layouts 20

3.4.7 Installing the Stopper 21

3.4.8 Idler Pulley 21

3.4.9 Power Supply 22

3.4.10 Gear Motor 22

3.4.11 Control Unit 22

3.4.12 Backup Gear Motor 23

3.4.13 Battery 23

3.4.14 Hanger, Roller and Belt Holder 23

3.4.15 Inspecting the Mechanical System 25

3.4.16 Inspecting the Electrical System 25

3.4.17 Mounting the Frame Fixed Leaves 26

3.4.18 Mounting the Frame Movable Leaves 26

3.4.19 Electric Lock (Optional) 27

3.4.20 Timing Belt 28

3.5 Starting Up the Operator 28

3.5.1 Standard Version 28

3.5.1.1 Without digital key 28

3.5.1.2 With digital key 28

3.5.2 Escape version 29

3.6 Modifying the Parameters 39

3.7 Sensors Setup Table 40

3.8 Wiring diagrams 41

3.8.1 ZENSAFE Sensor 41

3.8.2 BEA ZEN/ZENSAFE sensor 41

3.8.3 BEA IXIO-DT3 Sensor 49

3.8.4 BEA VIO sensor 50

3.8.5 Optex OA-Flex Sensor 51

3.9 Block Diagram 53

3.9.1 Standard Version 53

3.9.2 Escape Version 53

4 MAINTENANCE SERVICE 54

4.1 Precautionary Measures 54

4.2 Fuse Replacement 54

4.2.1 Changing primary side fuse 54

4.2.2 Changing secondary side fuse 54

4.3 Maintenance Check 55

4.4 Timing Belt Tension 56

4.5 Mechanical Faults 56

4.6 Troubleshooting 57

4.6.1 Malfunctions 58

4.6.2 LED status (error codes) 59

5 USER INSTRUCTIONS 61

5.1 Precautionary measures 61

5.2 Main elements of the system 62

5.3 Mechanical key switch 63

5.4 Digital key switch 66

5.4.1 Operating the system with the digital key switch 66

5.4.2 Main menu 67

5.5 System behavior 68

5.5.1 Closing cycle 68

5.5.2 Opening cycle 68

5.6 Failures 69

5.7 Error handling 69

5.7.1 Handling errors by mechanical key switch 69

5.7.2 Handling errors by digital key switch 69

5.8 Mandatory Routine Maintenance 69

5.9 Cleaning 70

6 DISABLING AND DISMANTLING 70

Contents

1EN.09.09052022 2EN.09.09052022

INTRODUCTION 3

SYMBOLS OF THE MANUAL 3

1 GENERAL INFORMATION OF THE PRODUCT 4

1.1 Product Introduction 4

1.1.1 SLH239 4

1.1.2 SLH240 4

1.1.3 SLH240/H 4

1.1.4 SLH240ES 4

1.2 Technical Specications 5

1.3 Copyright 6

1.4 Standards 6

1.5 Warranty Guidelines 6

1.6 Declaration of Incorporation 7

1.7 Certication 8

1.8 Signage 9

2 CONTENTS OF DELIVERY 10

2.1 Operator Kit 10

2.2 SLH Prole Set 12

2.3 Accessories 13

3 ASSEMBLY AND INSTALLATION 14

3.1 Precautionary Measures 14

3.2 Required Tools 15

3.3 Technical Drawings 16

3.3.1 Two-leaves door version (TBS Frame) 17

3.3.2 One-leaf door version (TBS Frame) 17

3.4 Installation Steps 17

3.4.1 On-Site Preparation 17

3.4.2 Aluminum Base Prole 17

3.4.3 Stainless Steel Prole & Rubber Prole 19

3.4.4 Rubber Track Prole & Aluminum Track Prole 19

3.4.5 Standard Distance for Opening (mm) 20

3.4.6 Check the Layouts 20

3.4.7 Installing the Stopper 21

3.4.8 Idler Pulley 21

3.4.9 Power Supply 22

3.4.10 Gear Motor 22

3.4.11 Control Unit 22

3.4.12 Backup Gear Motor 23

3.4.13 Battery 23

3.4.14 Hanger, Roller and Belt Holder 23

3.4.15 Inspecting the Mechanical System 25

3.4.16 Inspecting the Electrical System 25

3.4.17 Mounting the Frame Fixed Leaves 26

3.4.18 Mounting the Frame Movable Leaves 26

3.4.19 Electric Lock (Optional) 27

3.4.20 Timing Belt 28

3.5 Starting Up the Operator 28

3.5.1 Standard Version 28

3.5.1.1 Without digital key 28

3.5.1.2 With digital key 28

3.5.2 Escape version 29

3.6 Modifying the Parameters 39

3.7 Sensors Setup Table 40

3.8 Wiring diagrams 41

3.8.1 ZENSAFE Sensor 41

3.8.2 BEA ZEN/ZENSAFE sensor 41

3.8.3 BEA IXIO-DT3 Sensor 49

3.8.4 BEA VIO sensor 50

3.8.5 Optex OA-Flex Sensor 51

3.9 Block Diagram 53

3.9.1 Standard Version 53

3.9.2 Escape Version 53

4 MAINTENANCE SERVICE 54

4.1 Precautionary Measures 54

4.2 Fuse Replacement 54

4.2.1 Changing primary side fuse 54

4.2.2 Changing secondary side fuse 54

4.3 Maintenance Check 55

4.4 Timing Belt Tension 56

4.5 Mechanical Faults 56

4.6 Troubleshooting 57

4.6.1 Malfunctions 58

4.6.2 LED status (error codes) 59

5 USER INSTRUCTIONS 61

5.1 Precautionary measures 61

5.2 Main elements of the system 62

5.3 Mechanical key switch 63

5.4 Digital key switch 66

5.4.1 Operating the system with the digital key switch 66

5.4.2 Main menu 67

5.5 System behavior 68

5.5.1 Closing cycle 68

5.5.2 Opening cycle 68

5.6 Failures 69

5.7 Error handling 69

5.7.1 Handling errors by mechanical key switch 69

5.7.2 Handling errors by digital key switch 69

5.8 Mandatory Routine Maintenance 69

5.9 Cleaning 70

6 DISABLING AND DISMANTLING 70

3

- Maintenance

In this booklet, the installation process is predesignated for the engineers who install service SLH239, SLH240,

SLH240/H and SLH240ES operators.

Introduction

- System specifications

This guide is for service engineers who service SLH239, SLH240, SLH240/H and SLH240ES operators and

gives information on:

- Assembly, installation and settings

- User guidance

This manual uses the following symbols and the keywords indicate hazards that pose a risk to life and limb:

Symbols of the manual

NOTICE: An important hint.

INFORMATION: An important information.

DANGER: A hint representing a danger that immediately leads to death or

severe injury.

WARNING: A hint representing a danger that can lead to death or severe

injury.

EN.09.09052022

DANGER

WARNING

4

1 General Information of the Product

1.1 Product Introduction

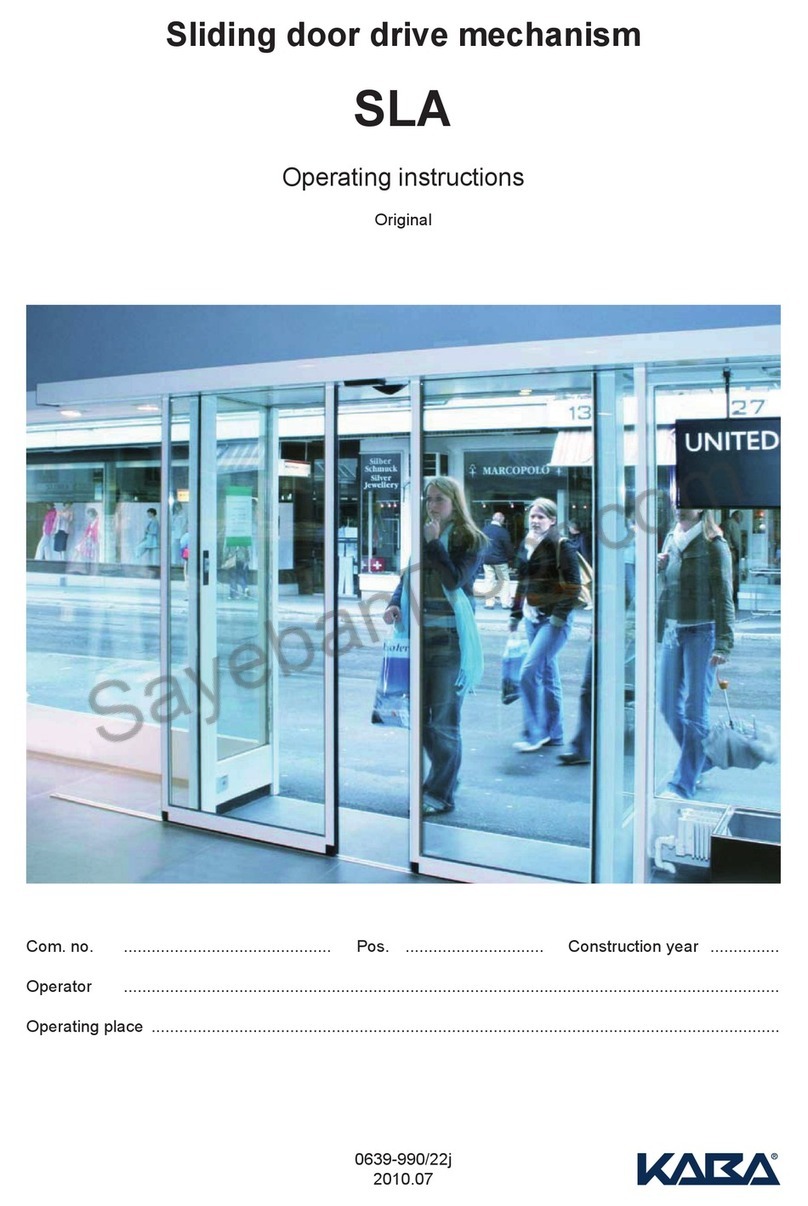

Outstanding quality and unique design have made the perfect combination in Deutschtec SLH products.

These highly intelligent models enjoy incredible strength as well. Employing world-famous German

technology has made Deutschtec SLH series into robust and sturdy products which will easily handle heavy

weights.

Deutschtec SLH239 is your best option for interior or exterior applications with high traffic where normal glass

and average-sized door will do just fine. This reliable model is an excellent combination of futuristic design

and top-notch technology. Its stainless steel track profile offers strength and longevity. Its rubber

profile has the gift of quietness with it. SLH239's highest standards ensure its top-of-the-range quality.

1.1.2 SLH240

Deutschtec SLH240 is your ultimate solution for demanding interior or exterior applications or where tall or

wide heavy doors and double or especially triple-glazing glass is a necessity. This model has brought superior

strength and incredible resistance to wear together with beauty and elegance. Due to its rubber profile, you

hear nothing more than a whisper. Its stainless steel track profile promises to stay with you for all time and

make your choice energy-saving and cost-effective. SLH240 has been certified as a product which satisfies all

safety needs.

Deutschtec SLH240/H is your ultimate solution for demanding interior or exterior applications or where tall or

wide heavy doors and double or especially, triple glazing glass is a necessity. This model has brought

superior strength and incredible resistance to wear together with beauty and elegance.

Deutschtec SLH240ES is your ultimate solution for having highest levels of safety in escape routes. This system

drives doors by one Gear Motor and Controller (Slave) for opening cycles and the other Gear Motor and

Controller (Master) for closing cycles. Such function ensures more than doubled life time and silent operation.

In emergency cases both sets are able to open the door.

1.1.3 SLH240/H

1.1.1 SLH239

1.1.4 SLH240ES

EN.09.09052022

3

- Maintenance

In this booklet, the installation process is predesignated for the engineers who install service SLH239, SLH240,

SLH240/H and SLH240ES operators.

Introduction

- System specifications

This guide is for service engineers who service SLH239, SLH240, SLH240/H and SLH240ES operators and

gives information on:

- Assembly, installation and settings

- User guidance

This manual uses the following symbols and the keywords indicate hazards that pose a risk to life and limb:

Symbols of the manual

NOTICE: An important hint.

INFORMATION: An important information.

DANGER: A hint representing a danger that immediately leads to death or

severe injury.

WARNING: A hint representing a danger that can lead to death or severe

injury.

EN.09.09052022

DANGER

WARNING

4

1 General Information of the Product

1.1 Product Introduction

Outstanding quality and unique design have made the perfect combination in Deutschtec SLH products.

These highly intelligent models enjoy incredible strength as well. Employing world-famous German

technology has made Deutschtec SLH series into robust and sturdy products which will easily handle heavy

weights.

Deutschtec SLH239 is your best option for interior or exterior applications with high traffic where normal glass

and average-sized door will do just fine. This reliable model is an excellent combination of futuristic design

and top-notch technology. Its stainless steel track profile offers strength and longevity. Its rubber

profile has the gift of quietness with it. SLH239's highest standards ensure its top-of-the-range quality.

1.1.2 SLH240

Deutschtec SLH240 is your ultimate solution for demanding interior or exterior applications or where tall or

wide heavy doors and double or especially triple-glazing glass is a necessity. This model has brought superior

strength and incredible resistance to wear together with beauty and elegance. Due to its rubber profile, you

hear nothing more than a whisper. Its stainless steel track profile promises to stay with you for all time and

make your choice energy-saving and cost-effective. SLH240 has been certified as a product which satisfies all

safety needs.

Deutschtec SLH240/H is your ultimate solution for demanding interior or exterior applications or where tall or

wide heavy doors and double or especially, triple glazing glass is a necessity. This model has brought

superior strength and incredible resistance to wear together with beauty and elegance.

Deutschtec SLH240ES is your ultimate solution for having highest levels of safety in escape routes. This system

drives doors by one Gear Motor and Controller (Slave) for opening cycles and the other Gear Motor and

Controller (Master) for closing cycles. Such function ensures more than doubled life time and silent operation.

In emergency cases both sets are able to open the door.

1.1.3 SLH240/H

1.1.1 SLH239

1.1.4 SLH240ES

EN.09.09052022

6

1.3 Copyright

This manual was prepared and issued by Deutschtec GmbH. All rights are reserved. The information in this

manual is the property of Deutschtec GmbH; located in Germany. Disclosure of this information or any part of

it to third parties is not permitted, except with prior and explicit written permission of Deutschtec GmbH.

Deutschtec GmbH has the reserved rights to improve its products without notice. Therefore, it is possible that

the installed products show some differences from the description in this manual. This manual is based on the

standard product.

1.4 Standards

These operators in agreement with following standards:

- DIN 18650

- EN 16005

- EN ISO 13849

- EU low voltage directives

- EU EMC directives

- EN 60335

1.5 Warranty Guidelines

Conformance with the following installation and service procedures must be maintained to assure a proper

installation and to maintain the Deutschtec warranty.

Not following installation manual may result in faulty operation, injuries and

voiding warranty.

EN.09.09052022

Specification

Specification

5EN.09.09052022

1.2 Technical Specification

SLH 240

SLH 240

SLH 240/H

SLH 240/H

SLH 240 ES

SLH 240 ES

SLH 239

SLH 239

Opening width - single panel

Opening width - double panel

Max leaf weight, single

Max leaf weight, double

Operator height

Operator depth

Opening speed

Closing speed

Hold-open time

Ambient temperature

Type of Protection

Track prole

Anti-noise rubber prole

Power supply

Power Consumption max. 250 W max. 600 W max. 250 W max. 200 W

Gear motor power

160 mm

155 mm

anti-crash

Stainless Steel /

Aluminium

1 x 150 Kg

2 x 100 Kg

1000 - 3000 mm

800 - 2000 mm

0 - 30 s

IP 20

50 W

230V/33V,50VA

(Peak 120VA)

160 mm

155 mm

anti-crash

Stainless Steel

1 x 200 Kg

2 x 150 Kg

1000 - 3000 mm

800 - 2000 mm

0 - 30 s

IP 20

100 W

230V / 28V, 120VA

Variable up to 1.1m/s

(Double leaves )

Variable up to 1.1m/s

(Double leaves )

Variable up to 1.1m/s

(Double leaves )

Variable up to 1.1m/s

(Double leaves )

Variable up to 1.1m/s

(Double leaves )

Variable up to 1.1m/s

(Double leaves )

Variable up to 1.1m/s

(Double leaves )

Variable up to 1.1m/s

(Double leaves )

160 mm

155 mm

anti-crash

Stainless Steel

1 x 200 Kg

2 x 150 Kg

1000 - 3000 mm

800 - 2000 mm

0 - 30 s

IP 20

100 W

230V/33V,50VA

(Peak 120VA)

160 mm

155 mm

anti-crash

Stainless Steel

1 x 500 Kg

2 x 300 Kg

1000 - 3000 mm

800 - 2000 mm

0 - 30 s

IP 20

100 W

230V/33V,100VA

Emergency exit routes in both directions

Mechanical key switch (Optional)

24V DC output for external accessories

Possibility of using

electromechanical lock (Optional)

Lock monitoring

Possibility of using digital

programme switch (Optional)

Read-out error memory with error

codes (with digital programme switch)

Programmable output (Optional)

Power Lock

Programmable input (Optional)

Possibility of using more software

and hardware options by using

DEAP device (Optional)

Max operation cycles with 2.2 Ah

battery (Optional)

Max operation cycles with 7.2 Ah

battery (Optional)

Possibility to adjust force limitation

according to DIN18650 and EN16005

400

1000

-

400400

10001000

-

-

-

-

-15 to + 50 C -15 to + 50 C -15 to + 50 C -15 to + 50 C

6

1.3 Copyright

This manual was prepared and issued by Deutschtec GmbH. All rights are reserved. The information in this

manual is the property of Deutschtec GmbH; located in Germany. Disclosure of this information or any part of

it to third parties is not permitted, except with prior and explicit written permission of Deutschtec GmbH.

Deutschtec GmbH has the reserved rights to improve its products without notice. Therefore, it is possible that

the installed products show some differences from the description in this manual. This manual is based on the

standard product.

1.4 Standards

These operators in agreement with following standards:

- DIN 18650

- EN 16005

- EN ISO 13849

- EU low voltage directives

- EU EMC directives

- EN 60335

1.5 Warranty Guidelines

Conformance with the following installation and service procedures must be maintained to assure a proper

installation and to maintain the Deutschtec warranty.

Not following installation manual may result in faulty operation, injuries and

voiding warranty.

EN.09.09052022

Specification

Specification

5EN.09.09052022

1.2 Technical Specification

SLH 240

SLH 240

SLH 240/H

SLH 240/H

SLH 240 ES

SLH 240 ES

SLH 239

SLH 239

Opening width - single panel

Opening width - double panel

Max leaf weight, single

Max leaf weight, double

Operator height

Operator depth

Opening speed

Closing speed

Hold-open time

Ambient temperature

Type of Protection

Track prole

Anti-noise rubber prole

Power supply

Power Consumption max. 250 W max. 600 W max. 250 W max. 200 W

Gear motor power

160 mm

155 mm

anti-crash

Stainless Steel /

Aluminium

1 x 150 Kg

2 x 100 Kg

1000 - 3000 mm

800 - 2000 mm

0 - 30 s

IP 20

50 W

230V/33V,50VA

(Peak 120VA)

160 mm

155 mm

anti-crash

Stainless Steel

1 x 200 Kg

2 x 150 Kg

1000 - 3000 mm

800 - 2000 mm

0 - 30 s

IP 20

100 W

230V / 28V, 120VA

Variable up to 1.1m/s

(Double leaves )

Variable up to 1.1m/s

(Double leaves )

Variable up to 1.1m/s

(Double leaves )

Variable up to 1.1m/s

(Double leaves )

Variable up to 1.1m/s

(Double leaves )

Variable up to 1.1m/s

(Double leaves )

Variable up to 1.1m/s

(Double leaves )

Variable up to 1.1m/s

(Double leaves )

160 mm

155 mm

anti-crash

Stainless Steel

1 x 200 Kg

2 x 150 Kg

1000 - 3000 mm

800 - 2000 mm

0 - 30 s

IP 20

100 W

230V/33V,50VA

(Peak 120VA)

160 mm

155 mm

anti-crash

Stainless Steel

1 x 500 Kg

2 x 300 Kg

1000 - 3000 mm

800 - 2000 mm

0 - 30 s

IP 20

100 W

230V/33V,100VA

Emergency exit routes in both directions

Mechanical key switch (Optional)

24V DC output for external accessories

Possibility of using

electromechanical lock (Optional)

Lock monitoring

Possibility of using digital

programme switch (Optional)

Read-out error memory with error

codes (with digital programme switch)

Programmable output (Optional)

Power Lock

Programmable input (Optional)

Possibility of using more software

and hardware options by using

DEAP device (Optional)

Max operation cycles with 2.2 Ah

battery (Optional)

Max operation cycles with 7.2 Ah

battery (Optional)

Possibility to adjust force limitation

according to DIN18650 and EN16005

400

1000

-

400400

10001000

-

-

-

-

-15 to + 50 C -15 to + 50 C -15 to + 50 C -15 to + 50 C

8

1.7 Certification

EN.09.09052022

7

1.6 Declaration of Incorporation

EN.09.09052022

Declaraon of Incorporaon

In accordance with Annex II section 1.B. of the EC Machinery Directive 2006/42/EC

Authors and persons responsible for creating the relevant technical documents:

Deutschtec GmbH

Am

Fuchsbau

13

15345Petershagen/Eggersdorf

Germany

We hereby declare that the incomplete machine:

Sliding Door Operator Type: SLH239, SLH240, SLH240/H and SLH240ES

as long

as

supply

is

possible

within

the

scope

of

delivery,

and

corresponds

to

the basic

requirements

of

the

following

directives

(refer

to

the

Annex

regarding

which

requirements were

met):

Harmonized standards that were used, whose references have been published in

the Ofcial Journal of the EU:

Petershagen/Eggersdorf, 17.01.2021 (Place, Date)

Requirements of Annex I of 2006/42 EC, which have been complied with. The

numbers refer to the sections of Annex:

I: 1.1.5, 1.3.4, 1.3.7, 1.5.14, 1.3.1, 1.3.2, 3.4.5, 1.2.1, 1.3.8.2, 1.4.1, 1.4.3, 1.5.1,

1.5.2, 1.5.5, 1.5.6, 1.5.7, 1.5.8, 1.5.9, 1.5.10, 1.5.13, 1.1.3, 1.1.6, 1.2.6, 1.6.3,

1.5.15, 1.3.2, 1.3.3, 1.6.1, 1.2.4.1, 1.2.4.3, 1.2.4.4, 1.2.3, (partially)

2006/42/EC Machinery Directive

2014/30/EU Electromagnetic Compatiblity Directive

EN ISO 12100:2010

EN ISO 13849-1:2015

EN 16005:2012

EN ISO 13857:2019

EN 60335-1:2020

IEC 60335-2-103:2015

8

1.7 Certification

EN.09.09052022

7

1.6 Declaration of Incorporation

EN.09.09052022

Declaraon of Incorporaon

In accordance with Annex II section 1.B. of the EC Machinery Directive 2006/42/EC

Authors and persons responsible for creating the relevant technical documents:

Deutschtec GmbH

Am

Fuchsbau

13

15345Petershagen/Eggersdorf

Germany

We hereby declare that the incomplete machine:

Sliding Door Operator Type: SLH239, SLH240, SLH240/H and SLH240ES

as long

as

supply

is

possible

within

the

scope

of

delivery,

and

corresponds

to

the basic

requirements

of

the

following

directives

(refer

to

the

Annex

regarding

which

requirements were

met):

Harmonized standards that were used, whose references have been published in

the Ofcial Journal of the EU:

Petershagen/Eggersdorf, 17.01.2021 (Place, Date)

Requirements of Annex I of 2006/42 EC, which have been complied with. The

numbers refer to the sections of Annex:

I: 1.1.5, 1.3.4, 1.3.7, 1.5.14, 1.3.1, 1.3.2, 3.4.5, 1.2.1, 1.3.8.2, 1.4.1, 1.4.3, 1.5.1,

1.5.2, 1.5.5, 1.5.6, 1.5.7, 1.5.8, 1.5.9, 1.5.10, 1.5.13, 1.1.3, 1.1.6, 1.2.6, 1.6.3,

1.5.15, 1.3.2, 1.3.3, 1.6.1, 1.2.4.1, 1.2.4.3, 1.2.4.4, 1.2.3, (partially)

2006/42/EC Machinery Directive

2014/30/EU Electromagnetic Compatiblity Directive

EN ISO 12100:2010

EN ISO 13849-1:2015

EN 16005:2012

EN ISO 13857:2019

EN 60335-1:2020

IEC 60335-2-103:2015

10

2. Contents of Delivery

Components of SLH series are delivered in three main categories as follows:

2.1 Operator Kit

Article NO. Description Kit/set incl.

Quantity

Note: Screws and dowels are required for fastening that will be provided by the supplier.

EN.09.09052022

9

1.8 Signage

Clear signage on automatic doors is a key component of the safety system. Deutschtec has prepared several

warning signs (in accordance with ISO 7010:2020) that must be attached to the relevant parts of this product.

Signage are defined below:

Signage Interpretation Location to be attached on

This warning sign is used to show

the risk of electric shock advising to

avoid touching the component.

This warning sign shows the risk of

hand injury with moving parts.

T h i s o p a q ue d e c al i n fo r m s

pedestrians about the presence of

the transparent glazing.

This decal might be presented with

different designs.

This pictogram is mandatory for

doors with an emergency break-out

function.

This signage should be attached on

the power supply.

This signage should be attached on

the hangers inside the operator.

This opaque decal should be

placed at 1270mm ± 305mm

from the floor to the centerline of

the sign visible from both sides of

each fixed leaves.

This signage should be placed at

1270mm ± 305mm from the floor

to the centerline of the sign visible

from the opening side of the door.

Risk of Electric Shock

Risk of Crushing Hands

In Emergency Push to Open

EN.09.09052022

1000000038

1000000206

1000000057

1000000076

1000000081

1000000094

1000000108

1000000115

1000000118

1000000119

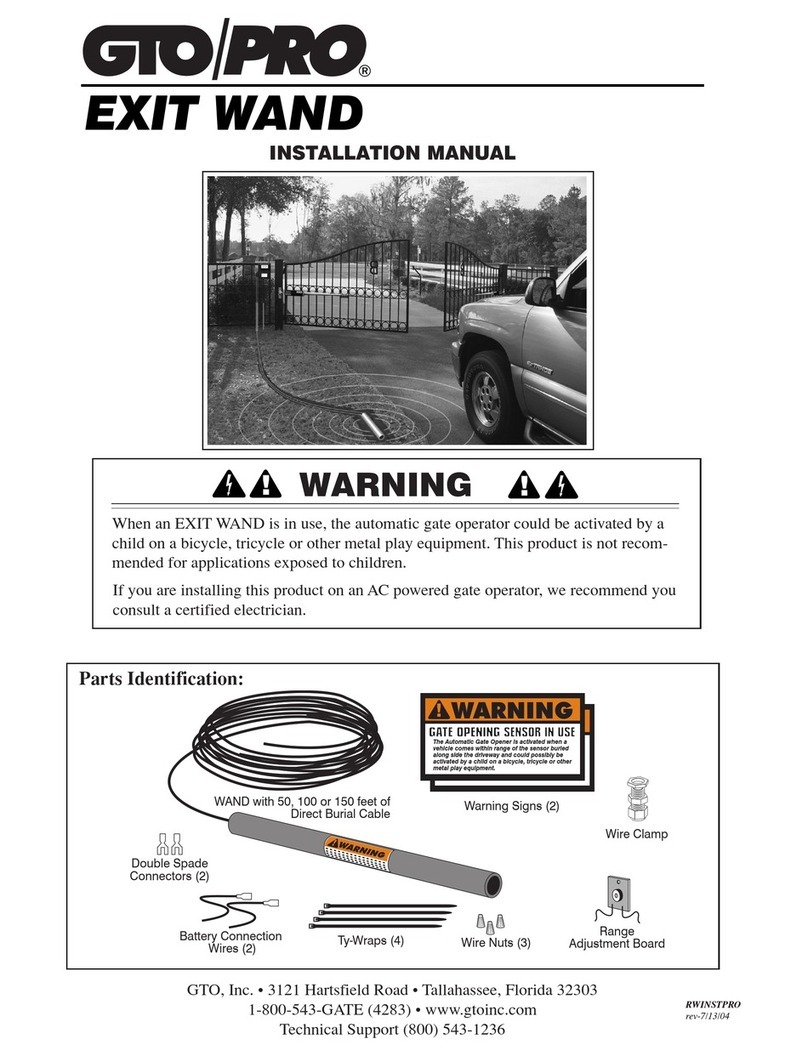

SLH Assembled Motor

100W -40V

SLH Assembled Motor

100W 24V

SLH Assembled Motor

50W -24V

SLH/PR Control Unit -

Steel Case

SLH/PR

P ower Pack Steel

Case

SLH Hanger & Roller

SLH Belt Clamp Set

SLH Stopper Pack

SLH Cover and Cable Clip

SLH Side Cover Pack

SLH/Prime Standard

Cable Pack

2 PCS

2

PCS

1 PCS

1 Pcs.

2

PCS

1

PCS

1

PCS

1

PCS

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs

4 Pcs.

4 Pcs.

4 Pcs.

6 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

2 Pcs.

1 Pcs.

1 Pcs.

2 Pcs.

SLH240H

SLH240ES

SLH240

SLH239

SLH240ES

SLH240

SLH239

SLH240H

SLH240ES

SLH240

SLH239

SLH240H

SLH240ES

SLH240

SLH239

SLH240H

SLH240ES

SLH240

SLH23 9

SLH240H

SLH240ES

SLH240

SLH239

SLH240H

SLH240ES

SLH240

SLH239

SLH240H

SLH240ES

SLH240

SLH239

SLH240H

SLH240ES

SLH240

SLH239

SLH240H

10

2. Contents of Delivery

Components of SLH series are delivered in three main categories as follows:

2.1 Operator Kit

Article NO. Description Kit/set incl.

Quantity

Note: Screws and dowels are required for fastening that will be provided by the supplier.

EN.09.09052022

9

1.8 Signage

Clear signage on automatic doors is a key component of the safety system. Deutschtec has prepared several

warning signs (in accordance with ISO 7010:2020) that must be attached to the relevant parts of this product.

Signage are defined below:

Signage Interpretation Location to be attached on

This warning sign is used to show

the risk of electric shock advising to

avoid touching the component.

This warning sign shows the risk of

hand injury with moving parts.

T h i s o p a q ue d e c al i n fo r m s

pedestrians about the presence of

the transparent glazing.

This decal might be presented with

different designs.

This pictogram is mandatory for

doors with an emergency break-out

function.

This signage should be attached on

the power supply.

This signage should be attached on

the hangers inside the operator.

This opaque decal should be

placed at 1270mm ± 305mm

from the floor to the centerline of

the sign visible from both sides of

each fixed leaves.

This signage should be placed at

1270mm ± 305mm from the floor

to the centerline of the sign visible

from the opening side of the door.

Risk of Electric Shock

Risk of Crushing Hands

In Emergency Push to Open

EN.09.09052022

1000000038

1000000206

1000000057

1000000076

1000000081

1000000094

1000000108

1000000115

1000000118

1000000119

SLH Assembled Motor

100W -40V

SLH Assembled Motor

100W 24V

SLH Assembled Motor

50W -24V

SLH/PR Control Unit -

Steel Case

SLH/PR

P ower Pack Steel

Case

SLH Hanger & Roller

SLH Belt Clamp Set

SLH Stopper Pack

SLH Cover and Cable Clip

SLH Side Cover Pack

SLH/Prime Standard

Cable Pack

2 PCS

2

PCS

1 PCS

1 Pcs.

2

PCS

1

PCS

1

PCS

1

PCS

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs

4 Pcs.

4 Pcs.

4 Pcs.

6 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

2 Pcs.

1 Pcs.

1 Pcs.

2 Pcs.

SLH240H

SLH240ES

SLH240

SLH239

SLH240ES

SLH240

SLH239

SLH240H

SLH240ES

SLH240

SLH239

SLH240H

SLH240ES

SLH240

SLH239

SLH240H

SLH240ES

SLH240

SLH23 9

SLH240H

SLH240ES

SLH240

SLH239

SLH240H

SLH240ES

SLH240

SLH239

SLH240H

SLH240ES

SLH240

SLH239

SLH240H

SLH240ES

SLH240

SLH239

SLH240H

12 EN.09.09052022

11 EN.09.09052022

Article NO. Description

Description

1000000131

SLH Pack Screw

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

SLH240ES

SLH240

SLH240H

SLH239

1000000636 1 Pcs.

SLH240ES

1000000333 1 Pcs.

SLH240ES

1000000124 1 Pcs.

SLH240ES

1000000116

GN Cable Clip

6 Pcs.

6 Pcs.

6 Pcs.

6 Pcs.

SLH240ES

SLH240

SLH239

SLH240H

1000000100

SLH Idler Pully

1 Pcs.

1 Pcs.

SLH240

SLH239

SLH-240ES Data Connection

Cable and 26 Pin Connector

SLH 240 ES- Power Connection

Cable and 4 Pin Connectors

Battery Pack - GN

Quantity

Quantity

Kit/set incl.

Kit/set incl.

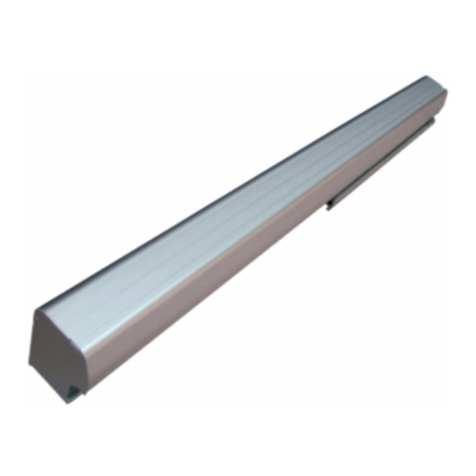

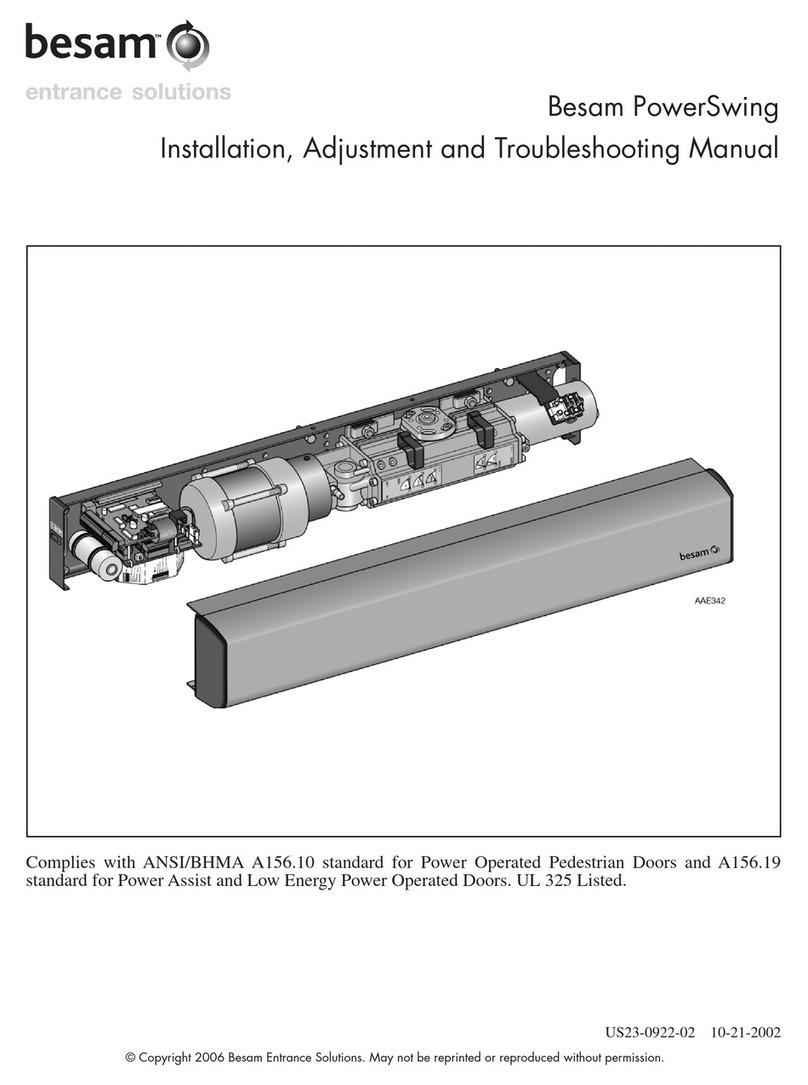

4 m SLH Rail Prole, AL Stainless Steel Prole Set

Aluminium Prole Set

Stainless Steel Prole Set

Aluminium Prole Set

Stainless Steel Prole Set

Stainless Steel Prole Set

Aluminium Prole Set

Aluminium Prole Set

Optional

4 m SLH Cover Prole, AL

4 m General Track Prole, SS

4 m General Track Prole, AL

General Rubber Prole, for SS

General Rubber Prole, for AL

4 m SLH-Back Prole

1000000002 1 Pcs.

1000000003 1 Pcs.

1000000023 1 Pcs.

1000000004 1 Pcs.

1000000024 4 Meter

1000000005 4 Meter

1000000035

Article NO.

2.2 SLH Profile Set

12 EN.09.09052022

11 EN.09.09052022

Article NO. Description

Description

1000000131

SLH Pack Screw

1 Pcs.

1 Pcs.

1 Pcs.

1 Pcs.

SLH240ES

SLH240

SLH240H

SLH239

1000000636 1 Pcs.

SLH240ES

1000000333 1 Pcs.

SLH240ES

1000000124 1 Pcs.

SLH240ES

1000000116

GN Cable Clip

6 Pcs.

6 Pcs.

6 Pcs.

6 Pcs.

SLH240ES

SLH240

SLH239

SLH240H

1000000100

SLH Idler Pully

1 Pcs.

1 Pcs.

SLH240

SLH239

SLH-240ES Data Connection

Cable and 26 Pin Connector

SLH 240 ES- Power Connection

Cable and 4 Pin Connectors

Battery Pack - GN

Quantity

Quantity

Kit/set incl.

Kit/set incl.

4 m SLH Rail Prole, AL Stainless Steel Prole Set

Aluminium Prole Set

Stainless Steel Prole Set

Aluminium Prole Set

Stainless Steel Prole Set

Stainless Steel Prole Set

Aluminium Prole Set

Aluminium Prole Set

Optional

4 m SLH Cover Prole, AL

4 m General Track Prole, SS

4 m General Track Prole, AL

General Rubber Prole, for SS

General Rubber Prole, for AL

4 m SLH-Back Prole

1000000002 1 Pcs.

1000000003 1 Pcs.

1000000023 1 Pcs.

1000000004 1 Pcs.

1000000024 4 Meter

1000000005 4 Meter

1000000035

Article NO.

2.2 SLH Profile Set

3 Assembly and Installation

This section presents guide for engineers who assemble and install SLH series doorsets.

3.1 Precautionary Measures

Special attention must be given to this section. Deutschtec GmbH shall not be liable for accidents caused by

ignorance of this part.

This section presents the precautionary measures that must be taken into account for the installation of the product.

- All tasks of installation should be carried out by trained professionals authorized by Deutschtec. Following these

instructions avoids material damage and personal injuries. Any other person, under any circumstances, must not be

involved in the technical affairs of this product.

- There has to be secured space and enough time for installation of this product without any interruptions by unauthorized

individuals.

-Local building code requirements for automatic doors must be taken into consideration.

Not following installation manual may result in faulty operation, injuries and voiding warranty.

14 EN.09.09052022

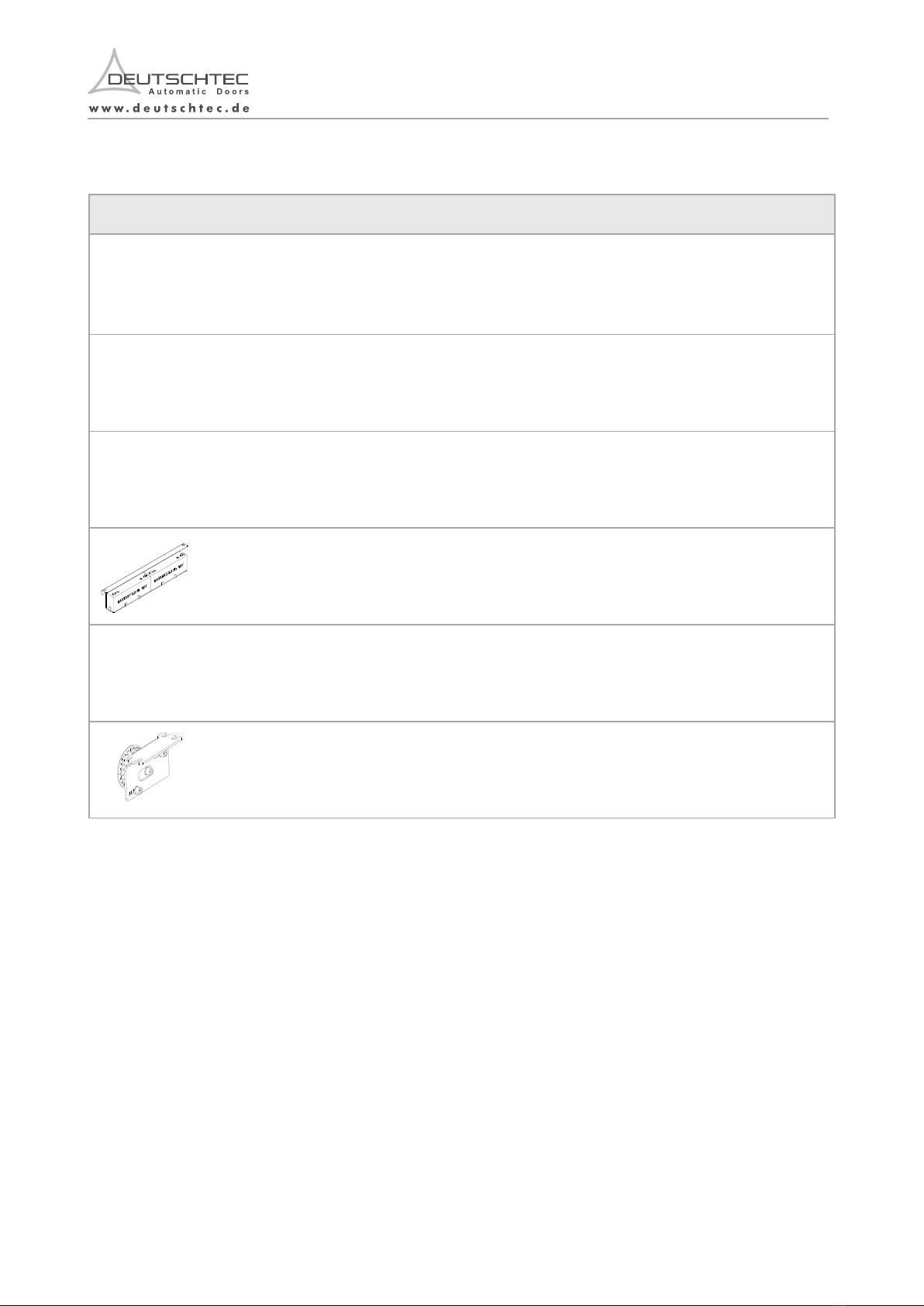

Mechanical Key Switch ( Deutschtec logo)

Optional

Optional

Optional

Optional

Optional

Optional

Optional

Optional

Digital Programme Switch (Deutschtec logo)

Electromechanical Lock-GN

HSML_Complete Lock for SLH

Battery Pack - GN

Battery Set - GN

Frameless Glass Clamp Set - IR

Timing Belt HTD 8 M, 12 mm, 4.5 m

2.3 Accessories

1000000147

1000000166

1000000174

1000000944

1000000124

1000000392

1000000198

1000000195

Description Kit/set incl.

Article NO.

- Do not install the drive on a wall that is damp or may get wet.

- Ensure the installation area is safe for workers, technicians and pedestrians.

- Assembly and installation of the system has to be performed by trained technicians using protective equipment, such as:

- Hard hats

- Ensure equipment stability to prevent any unintended dangerous movement or collapse of any part of the equipment.

- Goggles

- Make sure the workspace is well-lit.

- The areas with a risk of injury must be visually labeled by safety barricades and signs to keep pedestrians away from

hazardous areas.

- Before lifting heavy modules identify the center of gravity of the object and beware to control the object movements.

- Gloves

- While moving long components of the product, watch both sides of them.

- Never perform the high risk tasks alone.

- Make sure the floor is not slippery.

- Ensure the stability of the installed operator parts on the wall. Secure the parts against falling.

- Pay attention to the hazard signage attached to the components inside the operator.

- Safety footwear

Before working with electrical system, make sure the drive is disconnected from the power supply.

signage and pictograms to the locations specified in section 1.8.

DANGER

13

3 Assembly and Installation

This section presents guide for engineers who assemble and install SLH series doorsets.

3.1 Precautionary Measures

Special attention must be given to this section. Deutschtec GmbH shall not be liable for accidents caused by

ignorance of this part.

This section presents the precautionary measures that must be taken into account for the installation of the product.

- All tasks of installation should be carried out by trained professionals authorized by Deutschtec. Following these

instructions avoids material damage and personal injuries. Any other person, under any circumstances, must not be

involved in the technical affairs of this product.

- There has to be secured space and enough time for installation of this product without any interruptions by unauthorized

individuals.

-Local building code requirements for automatic doors must be taken into consideration.

Not following installation manual may result in faulty operation, injuries and voiding warranty.

14 EN.09.09052022

Mechanical Key Switch ( Deutschtec logo)

Optional

Optional

Optional

Optional

Optional

Optional

Optional

Optional

Digital Programme Switch (Deutschtec logo)

Electromechanical Lock-GN

HSML_Complete Lock for SLH

Battery Pack - GN

Battery Set - GN

Frameless Glass Clamp Set - IR

Timing Belt HTD 8 M, 12 mm, 4.5 m

2.3 Accessories

1000000147

1000000166

1000000174

1000000944

1000000124

1000000392

1000000198

1000000195

Description Kit/set incl.

Article NO.

- Do not install the drive on a wall that is damp or may get wet.

- Ensure the installation area is safe for workers, technicians and pedestrians.

- Assembly and installation of the system has to be performed by trained technicians using protective equipment, such as:

- Hard hats

- Ensure equipment stability to prevent any unintended dangerous movement or collapse of any part of the equipment.

- Goggles

- Make sure the workspace is well-lit.

- The areas with a risk of injury must be visually labeled by safety barricades and signs to keep pedestrians away from

hazardous areas.

- Before lifting heavy modules identify the center of gravity of the object and beware to control the object movements.

- Gloves

- While moving long components of the product, watch both sides of them.

- Never perform the high risk tasks alone.

- Make sure the floor is not slippery.

- Ensure the stability of the installed operator parts on the wall. Secure the parts against falling.

- Pay attention to the hazard signage attached to the components inside the operator.

- Safety footwear

Before working with electrical system, make sure the drive is disconnected from the power supply.

signage and pictograms to the locations specified in section 1.8.

DANGER

13

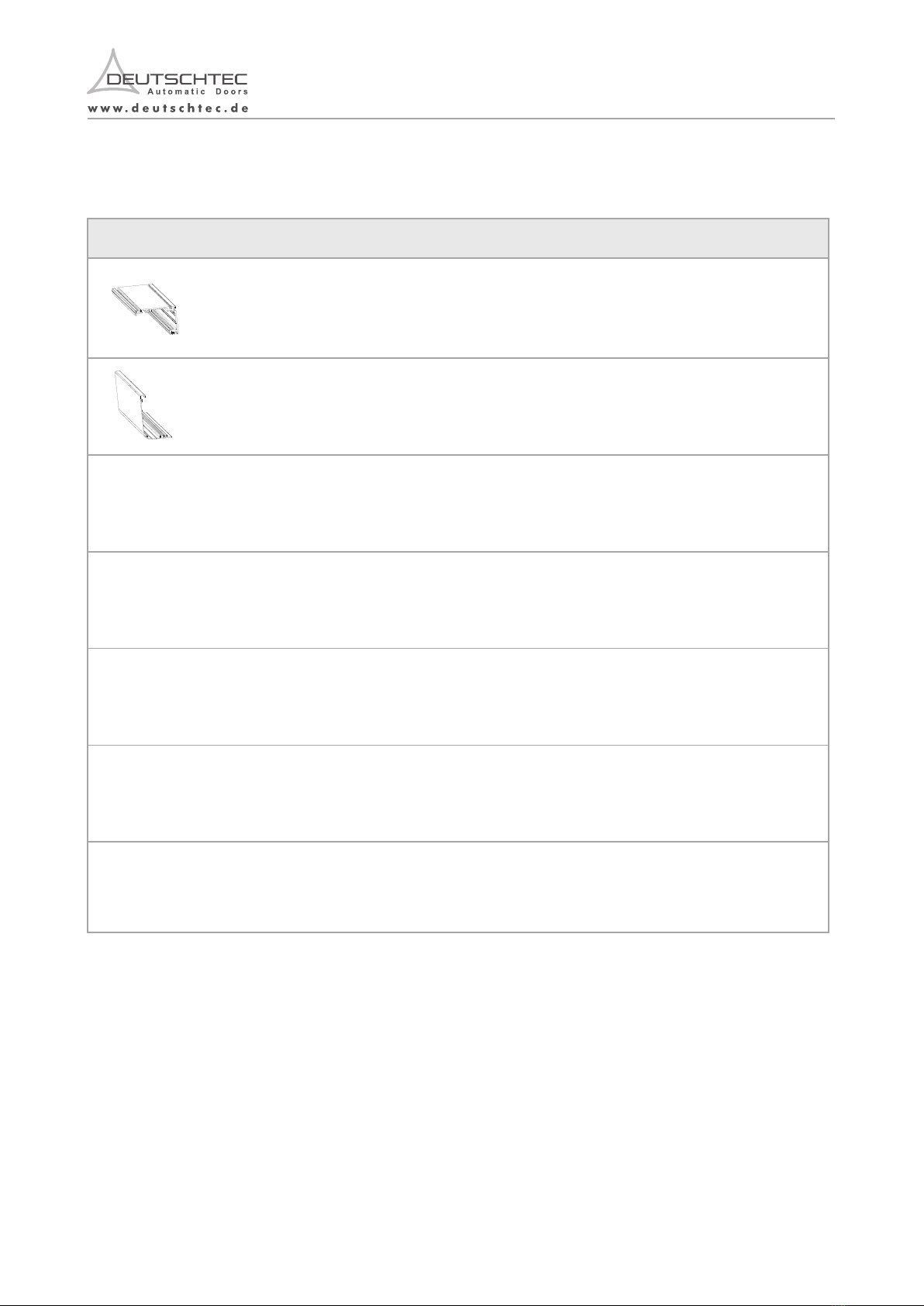

3.2 Required Tools

2.5 & 3 & 4 & 5 & 6

Drill (+ masonry drill)

6, 8 und 10 mm

These are required tools for the door installation.

15 EN.09.09052022

- Do not touch the electronic board. Make sure to touch an earthed metal prior to having contact with the module.

- Secure the cables inside the drive by the cable ties.

- Before activating the mechanical part, make sure that the surrounding is clear of any object. Moving parts can draw

loose cables, hair or clothing into the system.

- Do not carry/move the glazing alone.

- Beware of glass breakage and resulting injuries.

- Beware of sharp components in the drive.

- Attach signage and pictograms to the locations specified in section 1.8.

- Beware of moving parts in the drive.

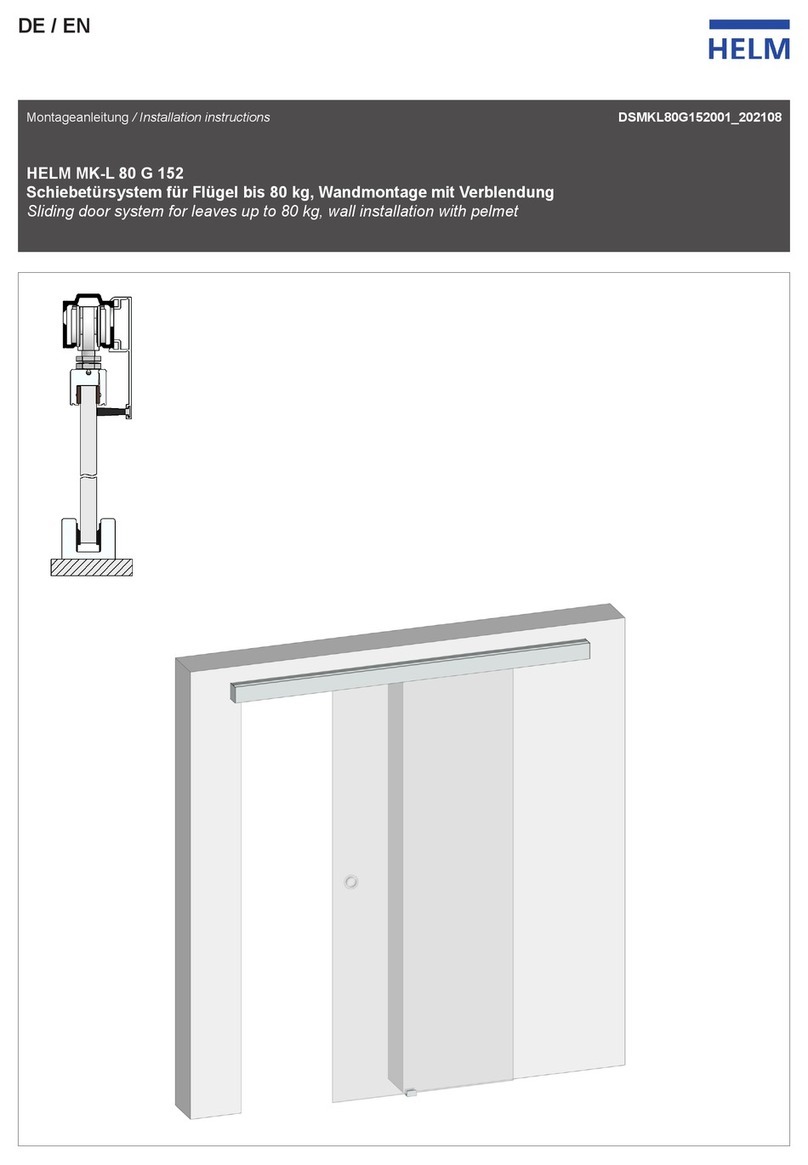

3.3 Technical Drawings

3.3.1 Two-leaves door version (TBS Frame)

16 EN.09.09052022

3.2 Required Tools

2.5 & 3 & 4 & 5 & 6

Drill (+ masonry drill)

6, 8 und 10 mm

These are required tools for the door installation.

15 EN.09.09052022

- Do not touch the electronic board. Make sure to touch an earthed metal prior to having contact with the module.

- Secure the cables inside the drive by the cable ties.

- Before activating the mechanical part, make sure that the surrounding is clear of any object. Moving parts can draw

loose cables, hair or clothing into the system.

- Do not carry/move the glazing alone.

- Beware of glass breakage and resulting injuries.

- Beware of sharp components in the drive.

- Attach signage and pictograms to the locations specified in section 1.8.

- Beware of moving parts in the drive.

3.3 Technical Drawings

3.3.1 Two-leaves door version (TBS Frame)

16 EN.09.09052022

17

3.3.2 One-leaf door version (TBS Frame)

This manual focuses on two leaves version of the door. However, it is roughly analogous with one leaf

version regardless of positional differences on the rail.

Before starting the installation process, carefully check the condition of the installation site and the strength of the

materials.

3.4.1 On-Site Preparation

The installation steps of Airdrive68NG/FR & NG/H operators are as follow.

3.4 Installation Steps

EN.09.09052022

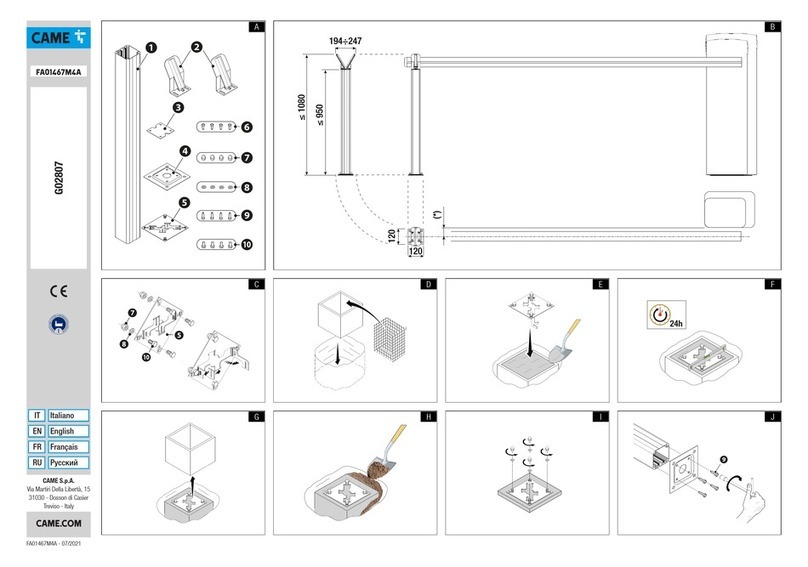

If the profile set does not have the desired installation length, it must be sawed to the desired dimension. If this

has not already been done at the factory, it should be done prior to the surface treatment. In accordance with

the peculiarities of structure, the fixing hole (D=6.5 mm) should be drilled at the aluminum base profile. The

bore should then be transferred to the mounting frame at the required installations regarding tasks performed

at heights greater than 2 m.

3.4.2 Aluminum Base Profile

18 EN.09.09052022

Adjust the installation height when using an in-house prole system.

When implementing the base profile, you must use T-wall brackets for a base profile with a thermal separation

and a self-supporting mounting position that is between two walls without a ledge. The drive will be hooked in

the rail.

17

3.3.2 One-leaf door version (TBS Frame)

This manual focuses on two leaves version of the door. However, it is roughly analogous with one leaf

version regardless of positional differences on the rail.

Before starting the installation process, carefully check the condition of the installation site and the strength of the

materials.

3.4.1 On-Site Preparation

The installation steps of Airdrive68NG/FR & NG/H operators are as follow.

3.4 Installation Steps

EN.09.09052022

If the profile set does not have the desired installation length, it must be sawed to the desired dimension. If this

has not already been done at the factory, it should be done prior to the surface treatment. In accordance with

the peculiarities of structure, the fixing hole (D=6.5 mm) should be drilled at the aluminum base profile. The

bore should then be transferred to the mounting frame at the required installations regarding tasks performed

at heights greater than 2 m.

3.4.2 Aluminum Base Profile

18 EN.09.09052022

Adjust the installation height when using an in-house prole system.

When implementing the base profile, you must use T-wall brackets for a base profile with a thermal separation

and a self-supporting mounting position that is between two walls without a ledge. The drive will be hooked in

the rail.

19 EN.09.09052022 20 EN.09.09052022

Then insert the rubber track profile and the stainless steel track profile. Tighten the stopper elements and fix it

with the supplied M6x10 socked screw and special nuts.

3.4.3 Stainless Steel Profile & Rubber Profile

3.4.4 Rubber Track Profile & Aluminium Track Profile

Then insert the rubber track profile and the aluminium track profile. Bolt down the stopper and secure them

using M6 x 10 hexagon socket screws and special nuts.

While inserting the rubber track profile, pull it slightly along the length. This makes it easier to install the

rubber track profile into the stainless steel track profile.

SLH239 & 240

3.4.6 Check the Layouts

SLH240/ES

SLH240/H

While inserting the rubber track profile, pull it slightly along the length. This makes it easier to install the

rubber track profile into the stainless steel track profile.

After installing the aluminum base profile, you can install the other components one by one. The following

figure and the table can help you plan the internal components.

Rubber profile

Stainless steel profile

3.4.5 Standard distance for opening (mm)

W=

800

900

1000

1100

1200

1300

1400

1500

1600 1700 1800

1900

2000

L=

2000 2100 2200 2500 2700 2900 3100 3300

3500 3700 3900

4100 4300

L*=

2100 2200 2300 2600 2800 3000 3200 3400

3600 3800 4000

4200 4400

m = 750 800 850 900 950 1000 1050 1100 1150 1200 1250 1300 1350

u = 750 800 850 900 950 1000 1050 1100 1150 1200 1250 1300 1350

f = 3200 3400 3600 3800 4000 4200 4400 4600 4800 5000 5200 5400 5600

c =

288

338

388

438

488

538 588 638 688 738 788 838

888

Orice of the Adjustment Track

Length of the Base Prole – no. (2000)

Length of the Base Prole with

Emergency Opening

Size of the Operator

Second Operator

Length of the Belt

Distance between the Attachments

This manual suits for next models

3

Table of contents

Other DEUTSCHTEC Door Opening System manuals