Rixson ASSA ABLOY 50 User manual

Installation Instructions

50 (06-09)

50 Floor Closer

Center Hung

Single or Double Acting

Non-Handed

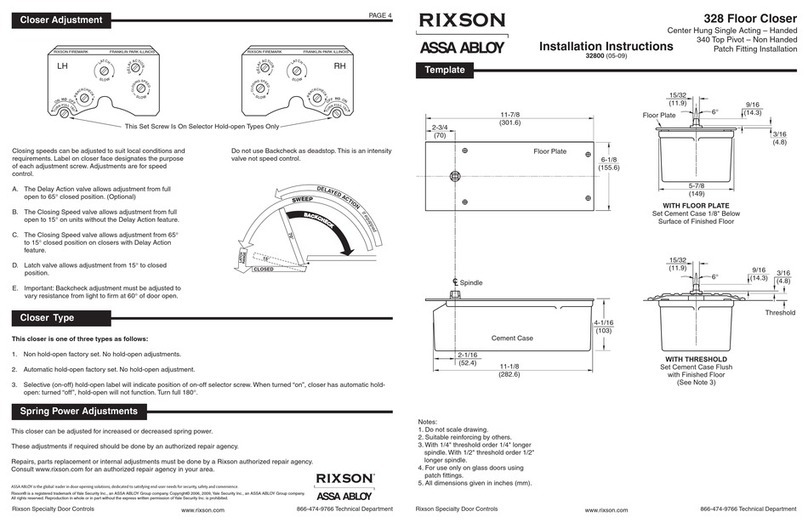

Closing speeds can be adjusted to suit local conditions and

requirements. Label on closer face designates the purpose

of each adjustment screw. Adjustments are for speed

control.

A. The stroke valve allows adjustment from open to 15°.

B. The latch valve allows adjustment from 15° to closed

position.

C. IMPORTANT: Back check valve option must be adjusted

to vary resistance from light to firm at 70° of door

opening.

D. The delay valve option allows closing speed adjustment

from o en position to 65°.p

Repairs, parts replacement or internal adjustments must be done by a Rixson authorized repair agency. Consult www.rixson.com

for an authorized repair agency in your area.

Closer Adjustment

Conversion from inches to metric: inch x 25.4.

Template

PAGE 4

Rixson Specialty Door Controls 866-474-9766 Technical Department

www.rixson.com

Rixson Specialty Door Controls 866-474-9766 Technical Department

www.rixson.com

FS

LATCH FS

STROKE

FS

DELAY

+-

BACK

CHECK

1/4-20 x 5/8" FHMS or

#14 x 1/2" FHWS

15/32

1-15/32 6-3/4

JAMB PORTION 9/32

9/32

1-5/16

21/32

9/32

12-24 x 5/8" FHMS or

#12 x 1-1/4" FHWS

(2 Places)

DOOR PORTION

5/8

5/8

1-1/8

4-13/16

5-9/32

1-1/4

1/4-20 x 5/8" FHMS or

#14 x 1-1/2" FHWS

(2 Places)

See

Note 4 Tighten Spindle

Screw Firmly

Arm

Spindle

Washer

Spindle

Adapter

Set Cement Case Flush

with Finished Floor

See Note 5

WITH THRESHOLD

Threshold

3/16

Door Mortised

Deep for Arm

B

A

1/4 Threshold

1/2 Threshold

A B

1-13/16

1-9/16

1-1/8

7/8

See Note 5

340 TOP PIVOT

Pivot Shown Engaged

Finish Plate

7/8 Dia.

1-1/4 Dia.

1-1/32

1-7/16

1/8

3/4

1/4

9/16

2-5/8

2-3/4

1/16

9/32

Arm Floor Plate

Jamb

2-5/8 R.

Max.

19-1/4

4-1/2

C

LSpindle

2

19-1/8

Fasten Front

Mounting

Screws First Cement Case

2-3/4

Arm Plate

7/16

3/16

1/8 2-5/8

10-3/4

7-7/16

Provide

3/8” Dia.

Hole

With Threshold

Use Top (2) Holes With Floor Plate

Use Bottom

(2) Holes

1-9/16

1-1/16

(11/16 w/

Threshold)

C

LSpindle

ARM PLATE H

3/16

1-25/32 1-7/32

1-1/4

1-19/32 1-13/32

2-3/32

3-13/16

11/32

5/8

29/32

1/4-20 x 1” FHMS

or #14 x 2” FWHS

(4 Places)

WITH FLOOR PLATE

Set Cement Case Flush

with Finished Floor

Cement Case

Floor

Plate

Door Mortised

1-9/16” Deep

for Arm

3/16

4-3/8

7/8

1-3/8” Min. Clearance

Required for Arm, Arm

Plate H and Shims

Notes:

1. Do not scale drawing.

2. Suitable reinforcing by others.

3. Rixson design threshold available on

request.

4. Tighten adjusting screw to notched “V”

line on arm to acquire standard initial

location of door. Screw moves door

towards and away from jamb to equalize

door clearances.

5. Provide 5/8” dia. holes for alignment

screws (2 places).

6. Do not remove grind plate until closer is

installed.

7. External stop by others required.

8. All dimensions given in inches.

ASSA ABLOY

RIXSON®

Rixson® is a registered trademark of Yale Security Inc., an ASSA ABLOY Group company. Copyright© 2005, 2009, Yale Security Inc., an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written permission of Yale Security Inc. is prohibited.

ASSA ABLOY

RIXSON®

PAGE 3

PAGE 2

How To Determine

Hand of Door

LH RH

Face a door swinging open away from you. If it opens to the

right, it is right hand. If it opens to the left, it is left hand.

Top Pivot Jamb Portion

Top Pivot Door Portion

IMPORTANT:

Use plumb line to make

sure that center line of

top pivot pin lines up

with center line of closer

spindle.

Installation Instructions

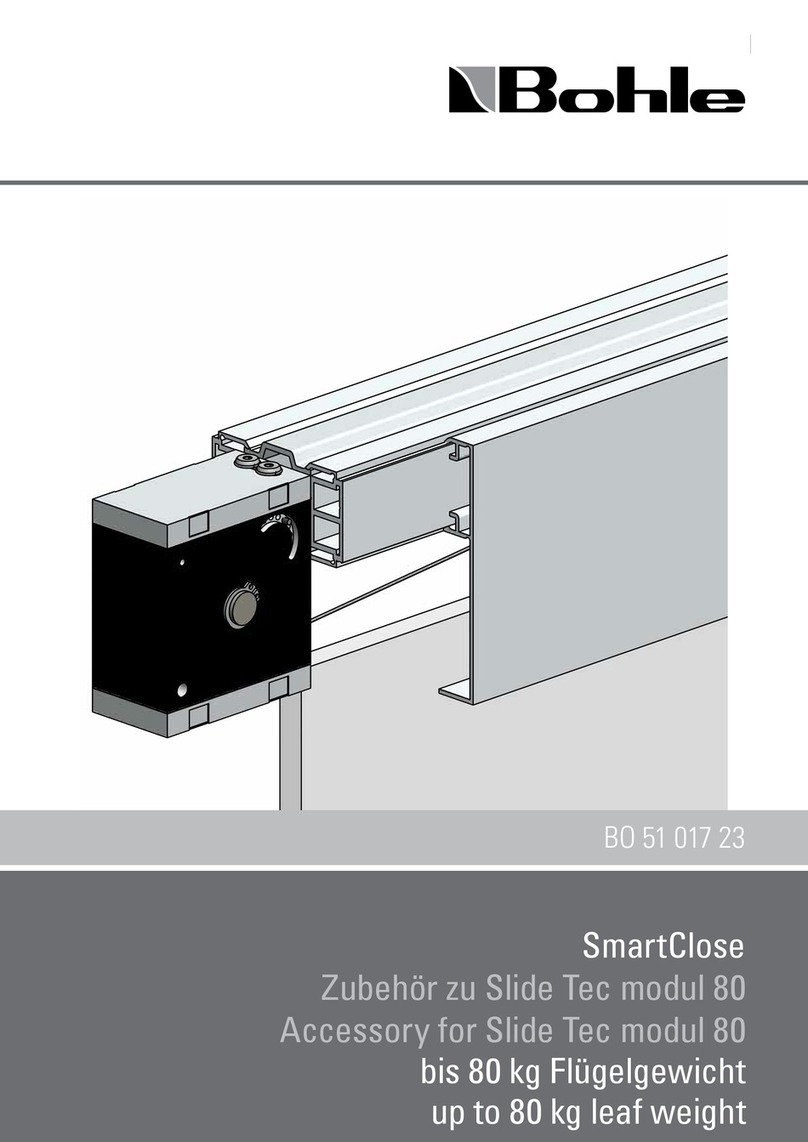

1. Locating Closer

Spindle Position

2-3/4” From Face of

Jamb to C of Spindle

L

Door

Jamb A. Measure 2-3/4” out from door jamb on centerline of door.

This is the location of the spindle center.

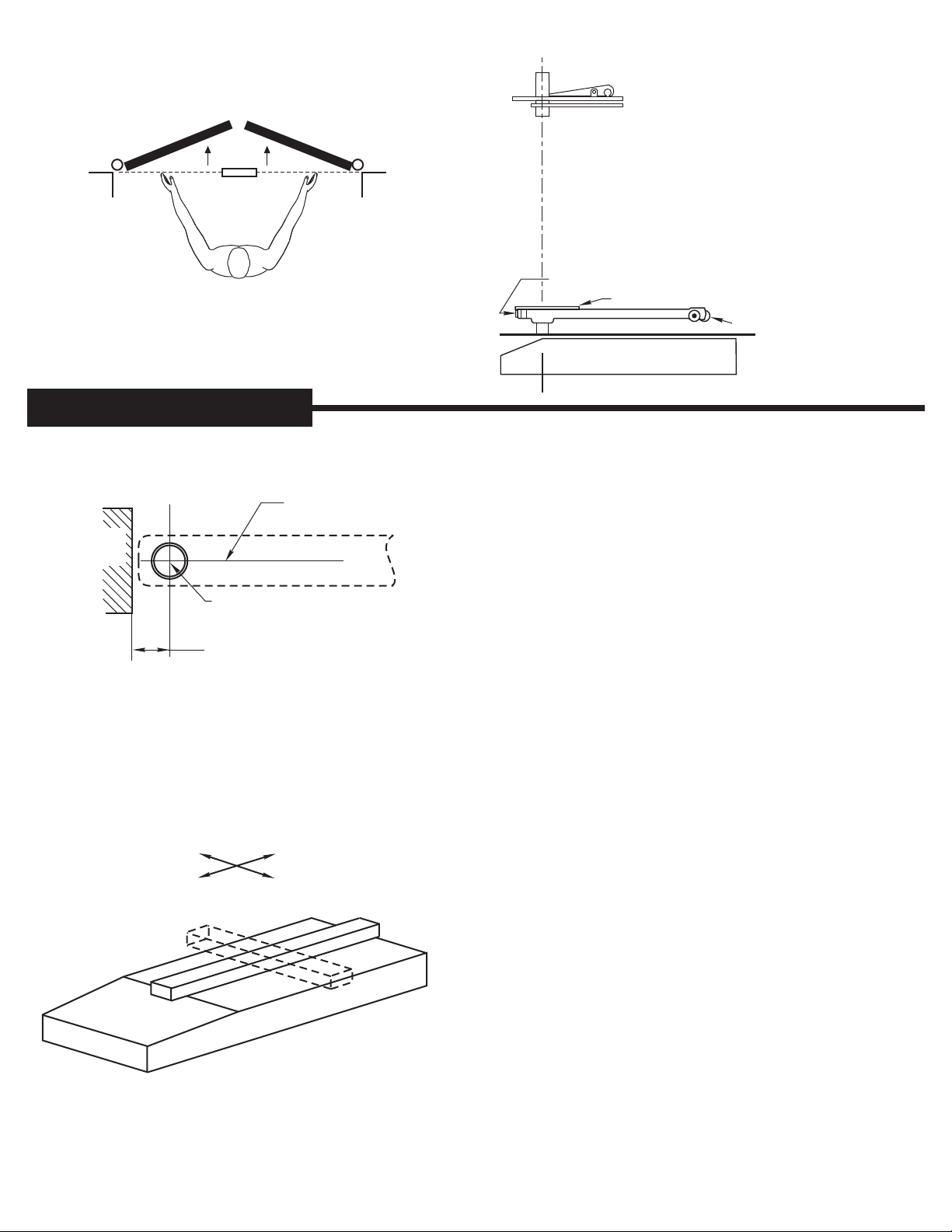

2. Install Cement Case in Floor

A. Cement case is set flush with finished floor.

B. Set cement case with closer in floor and block in position.

C. Case should be parallel with center line of door.

D. CEMENT CASE SHOULD BE LEVEL. Place levels per

Illustration.

E. Grout in cement case with closer. Cement should not get

between closer and case.

LEVEL IN BOTH

DIRECTIONS

A. Install top pivot in door per template.

B. Install top pivot in jamb per template.

C. Centerline of pivot pin should line up with centerline

of spindle. Use plumb line to assure accuracy. If

center lines don’t line up, loosen hold down screws

(4) and reposition closer. Tighten hold down screws

closest to spindle first. Then tighten screws at cylinder

end. Note: Closer must be lifted approx. 1/8” before

repositioning.

D. Mortise door for arm, arm plate H, and wood door

arm plate. Refer to template.

E. Drill two 5/8” dia. holes for arm alignment screws. Drill

3/8” hole at heel edge of door for adjusting screw.

F. Attach

arm alignment screws and washers to hold arm in

place.

Install arm, arm plate H, and shims if required.

4. Hang Door

CAUTION: Closer is shipped with "valve" screws down.

DO NOT FORCE VALVE DOWN.

A. Close both valve screws. NEVER FORCE VALVE

SCREW DOWN AS THIS WILL DAMAGE TIP

SEATING.

B. With arm on spindle, turn spindle until arm is in 30°

open position (see illustration).

C. Set door on spindle. DO NOT ATTEMPT TO CLOSE

DOOR.

D. Align two portions of top pivot and turn pin retracting

screw clockwise to engage top pivot pin.

E. Open door to 60° or more and turn valve screws

counterclockwise. Door will then close.

F. If necessary, turn adjusting screw at bottom of heel

edge of door to equalize side jamb clearances.

G. Adjust

center door in doorway.

arm alignment screws equally from each side

to

Rixson Specialty Door Controls Rixson Specialty Door Controls

Pin Retracting

Screw

Top Pivot

Pin

Centerline of Door

and Spindle

3. Install Top Pivot and Closer Arm

Centerline

of Door

DOOR

30°

Closer in

Floor

Alignment Screws

Adjusting Screw

Alignment Screws

Adjusting Screw

Spindle

Arm Plate “H”

Arm

Arm Plate “H”

866-474-9766 Technical Department

www.rixson.com

866-474-9766 Technical Department

www.rixson.com

PAGE 3

PAGE 2

How To Determine

Hand of Door

LH RH

Face a door swinging open away from you. If it opens to the

right, it is right hand. If it opens to the left, it is left hand.

Top Pivot Jamb Portion

Top Pivot Door Portion

IMPORTANT:

Use plumb line to make

sure that center line of

top pivot pin lines up

with center line of closer

spindle.

Installation Instructions

1. Locating Closer

Spindle Position

2-3/4” From Face of

Jamb to C of Spindle

L

Door

Jamb A. Measure 2-3/4” out from door jamb on centerline of door.

This is the location of the spindle center.

2. Install Cement Case in Floor

A. Cement case is set flush with finished floor.

B. Set cement case with closer in floor and block in position.

C. Case should be parallel with center line of door.

D. CEMENT CASE SHOULD BE LEVEL. Place levels per

Illustration.

E. Grout in cement case with closer. Cement should not get

between closer and case.

LEVEL IN BOTH

DIRECTIONS

A. Install top pivot in door per template.

B. Install top pivot in jamb per template.

C. Centerline of pivot pin should line up with centerline

of spindle. Use plumb line to assure accuracy. If

center lines don’t line up, loosen hold down screws

(4) and reposition closer. Tighten hold down screws

closest to spindle first. Then tighten screws at cylinder

end. Note: Closer must be lifted approx. 1/8” before

repositioning.

D. Mortise door for arm, arm plate H, and wood door

arm plate. Refer to template.

E. Drill two 5/8” dia. holes for arm alignment screws. Drill

3/8” hole at heel edge of door for adjusting screw.

F. Attach

arm alignment screws and washers to hold arm in

place.

Install arm, arm plate H, and shims if required.

4. Hang Door

CAUTION: Closer is shipped with "valve" screws down.

DO NOT FORCE VALVE DOWN.

A. Close both valve screws. NEVER FORCE VALVE

SCREW DOWN AS THIS WILL DAMAGE TIP

SEATING.

B. With arm on spindle, turn spindle until arm is in 30°

open position (see illustration).

C. Set door on spindle. DO NOT ATTEMPT TO CLOSE

DOOR.

D. Align two portions of top pivot and turn pin retracting

screw clockwise to engage top pivot pin.

E. Open door to 60° or more and turn valve screws

counterclockwise. Door will then close.

F. If necessary, turn adjusting screw at bottom of heel

edge of door to equalize side jamb clearances.

G. Adjust

center door in doorway.

arm alignment screws equally from each side

to

Rixson Specialty Door Controls Rixson Specialty Door Controls

Pin Retracting

Screw

Top Pivot

Pin

Centerline of Door

and Spindle

3. Install Top Pivot and Closer Arm

Centerline

of Door

DOOR

30°

Closer in

Floor

Alignment Screws

Adjusting Screw

Alignment Screws

Adjusting Screw

Spindle

Arm Plate “H”

Arm

Arm Plate “H”

866-474-9766 Technical Department

www.rixson.com

866-474-9766 Technical Department

www.rixson.com

Installation Instructions

50 (06-09)

50 Floor Closer

Center Hung

Single or Double Acting

Non-Handed

Closing speeds can be adjusted to suit local conditions and

requirements. Label on closer face designates the purpose

of each adjustment screw. Adjustments are for speed

control.

A. The stroke valve allows adjustment from open to 15°.

B. The latch valve allows adjustment from 15° to closed

position.

C. IMPORTANT: Back check valve option must be adjusted

to vary resistance from light to firm at 70° of door

opening.

D. The delay valve option allows closing speed adjustment

from o en position to 65°.p

Repairs, parts replacement or internal adjustments must be done by a Rixson authorized repair agency. Consult www.rixson.com

for an authorized repair agency in your area.

Closer Adjustment

Conversion from inches to metric: inch x 25.4.

Template

PAGE 4

Rixson Specialty Door Controls 866-474-9766 Technical Department

www.rixson.com

Rixson Specialty Door Controls 866-474-9766 Technical Department

www.rixson.com

FS

LATCH FS

STROKE

FS

DELAY

+-

BACK

CHECK

1/4-20 x 5/8" FHMS or

#14 x 1/2" FHWS

15/32

1-15/32 6-3/4

JAMB PORTION 9/32

9/32

1-5/16

21/32

9/32

12-24 x 5/8" FHMS or

#12 x 1-1/4" FHWS

(2 Places)

DOOR PORTION

5/8

5/8

1-1/8

4-13/16

5-9/32

1-1/4

1/4-20 x 5/8" FHMS or

#14 x 1-1/2" FHWS

(2 Places)

See

Note 4 Tighten Spindle

Screw Firmly

Arm

Spindle

Washer

Spindle

Adapter

Set Cement Case Flush

with Finished Floor

See Note 5

WITH THRESHOLD

Threshold

3/16

Door Mortised

Deep for Arm

B

A

1/4 Threshold

1/2 Threshold

A B

1-13/16

1-9/16

1-1/8

7/8

See Note 5

340 TOP PIVOT

Pivot Shown Engaged

Finish Plate

7/8 Dia.

1-1/4 Dia.

1-1/32

1-7/16

1/8

3/4

1/4

9/16

2-5/8

2-3/4

1/16

9/32

Arm Floor Plate

Jamb

2-5/8 R.

Max.

19-1/4

4-1/2

C

LSpindle

2

19-1/8

Fasten Front

Mounting

Screws First Cement Case

2-3/4

Arm Plate

7/16

3/16

1/8 2-5/8

10-3/4

7-7/16

Provide

3/8” Dia.

Hole

With Threshold

Use Top (2) Holes With Floor Plate

Use Bottom

(2) Holes

1-9/16

1-1/16

(11/16 w/

Threshold)

C

LSpindle

ARM PLATE H

3/16

1-25/32 1-7/32

1-1/4

1-19/32 1-13/32

2-3/32

3-13/16

11/32

5/8

29/32

1/4-20 x 1” FHMS

or #14 x 2” FWHS

(4 Places)

WITH FLOOR PLATE

Set Cement Case Flush

with Finished Floor

Cement Case

Floor

Plate

Door Mortised

1-9/16” Deep

for Arm

3/16

4-3/8

7/8

1-3/8” Min. Clearance

Required for Arm, Arm

Plate H and Shims

Notes:

1. Do not scale drawing.

2. Suitable reinforcing by others.

3. Rixson design threshold available on

request.

4. Tighten adjusting screw to notched “V”

line on arm to acquire standard initial

location of door. Screw moves door

towards and away from jamb to equalize

door clearances.

5. Provide 5/8” dia. holes for alignment

screws (2 places).

6. Do not remove grind plate until closer is

installed.

7. External stop by others required.

8. All dimensions given in inches.

ASSA ABLOY

RIXSON®

Rixson® is a registered trademark of Yale Security Inc., an ASSA ABLOY Group company. Copyright© 2005, 2009, Yale Security Inc., an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written permission of Yale Security Inc. is prohibited.

ASSA ABLOY

RIXSON®

Installation Instructions

50W (06-09)

W50 Floor Closer

Center Hung

Single or Double Acting

Non-Handed

Wood Door Installation

Closing speeds can be adjusted to suit local conditions and

requirements. Label on closer face designates the purpose

of each adjustment screw. Adjustments are for speed

control.

A. The stroke valve allows adjustment from open to 15°.

B. The latch valve allows adjustment from 15° to closed

position.

C. IMPORTANT: Back check valve option must be adjusted

to vary resistance from light to firm at 70° of door

opening.

D. The delay valve option allows closing speed adjustment

from open position to 65°.

Repairs, parts replacement or internal adjustments must be done by a Rixson authorized repair agency. Consult www.rixson.com

for an authorized repair agency in your area.

Closer Adjustment

Conversion from inches to metric: inch x 25.4.

Template

PAGE 4

Rixson Specialty Door ControlsRixson Specialty Door Controls

Notes:

1. Do not scale drawing.

2. Suitable reinforcing by others.

3. Rixson design threshold available on request.

4. Tighten adjusting screw to notched “V” line

on arm to acquire standard initial location

of door. Screw moves door towards and

away from jamb to equalize door clearances.

5. Auxiliary stop required.

6. All dimensions given in inches.

TOP PIVOT

Finish Plate

7/8 Dia.

1-1/4 Dia.

1-1/32

1-7/16

1/8

3/4

1/4

9/16

2-5/8

2-3/4

1/16

9/32

1/4-20 x 5/8" FHMS or

#14 x 1/2" FHWS

15/32

1-15/32 6-3/4

JAMB PORTION 9/32

9/32

1-5/16

21/32

9/32

12-24 x 5/8" FHMS or

#12 x 1-1/4" FHWS

(2 Places)

DOOR PORTION

5/8

5/8

1-1/8

4-13/16

5-9/32

1-1/4

1/4-20 x 5/8" FHMS or

#14 x 1-1/2" FHWS

(2 Places)

Arm Floor Plate

Jamb

2-5/8 R.

Max.

19-1/4

4-1/2

C

LSpindle

2

19-1/8

Fasten Front

Mounting

Screws First Cement Case

2-3/4

Spindle Shoulder Collar

Arm Plate

Shim

Wood Door

Arm Plate

7/16

3/16

1/8 2-5/8 9*

2-1/4* 7-7/16 *Mortised

Provide

3/8” Dia.

Hole

Use Top

(2) Holes

See

Note 4 Tighten Spindle

Screw Firmly

Arm

Spindle

C

LDoor

C

LSpindle

WOOD DOOR ARM PLATE

10-1/2

6-7/32

1-19/32

1-13/32

11/16

1-3/8

9/32

9/16

2-3/32

1-25/32

4-7/32

1-7/32

#14 x 2-1/2” FWHS

(6 Places)

WITH FLOOR PLATE

Set Cement Case Flush

with Finished Floor

Cement Case

Floor

Plate

Door Mortised

1-7/8” Deep

for Arm

3/16

4-3/8

1-1/4

Provide 9/16

Dia. Hole for

Alignment

Screw

(2 Places)

1-3/8” Min. Clearance

Required for Arm, Arm

Plate H and Shims

WITH THRESHOLD

Set Cement Case Flush

with Finished Floor

Threshold

3/16

Door Mortised

Deep for Arm

Provide 9/16

Dia. Hole for

Alignment

Screw

(2 Places)

BA

1/4 Threshold

1/2 Threshold

A B

1-3/4

1-1/2

1-1/8

7/8

FS

LATCH FS

STROKE

FS

DELAY

+-

BACK

CHECK

866-474-9766 Technical Department

www.rixson.com

866-474-9766 Technical Department

www.rixson.com

ASSA ABLOY

RIXSON®

Rixson® is a registered trademark of Yale Security Inc., an ASSA ABLOY Group company. Copyright© 2005, 2009, Yale Security Inc., an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written permission of Yale Security Inc. is prohibited.

ASSA ABLOY

RIXSON®

PAGE 3

PAGE 2

How To Determine

Hand of Door

LH RH

Face a door swinging open away from you. If it opens to the

right, it is right hand. If it opens to the left, it is left hand.

Top Pivot Jamb Portion

Top Pivot Door Portion

IMPORTANT:

Use plumb line to make

sure that center line of

top pivot pin lines up

with center line of closer

spindle.

Installation Instructions

1. Locating Closer

Spindle Position

2-3/4” From Face of

Jamb to C of Spindle

L

Door

Jamb A. Measure 2-3/4” out from door jamb on centerline of door.

This is the location of the spindle center.

2. Install Cement Case in Floor

A. Cement case is set flush with finished floor.

B. Set cement case in floor and block in position.

C. Case should be parallel with center line of door.

D. CEMENT CASE SHOULD BE LEVEL. Place levels per

Illustration.

E. Grout in cement case with closer. Cement should not get

between closer and case.

LEVEL IN BOTH

DIRECTIONS

A. Install top pivot in door per template.

B. Install top pivot in jamb per template.

C. Centerline of pivot pin should line up with centerline

of spindle. Use plumb line to assure accuracy. If

center lines don’t line up, loosen hold down screws

(4) and reposition closer. Tighten hold down screws

closest to spindle first. Then tighten screws at cylinder

end. Note: Closer must be lifted approx. 1/8” before

repositioning.

D. Mortise door for arm, arm plate H, and wood door

arm plate. Refer to template.

E. Drill two 9/16” dia. holes for arm alignment screws.

Drill 3/8” hole at heel edge of door for adjusting screw.

F. Attach arm to spindle using spindle screw supplied

and tighten securely. Install arm plate H, wood door

arm plate, and shim.

4. Hang Door

CAUTION: Closer is shipped with "valve" screws down.

DO NOT FORCE VALVE DOWN.

A. Close both valve screws. NEVER FORCE VALVE

SCREW DOWN AS THIS WILL DAMAGE TIP

SEATING.

B. With arm on spindle, turn spindle until arm is in 30°

open position (see illustration).

C. Set door on spindle. DO NOT ATTEMPT TO CLOSE

DOOR.

D. Align two portions of top pivot and turn pin retracting

screw clockwise to engage top pivot pin.

E. Open door to 60° or more and turn valve screws

counterclockwise. Door will then close.

F. If necessary, turn adjusting screw at bottom of heel

edge of door to equalize side jamb clearances.

G. Adjust

center door in doorway.

arm alignment screws equally from each side

to

Rixson Specialty Door Controls Rixson Specialty Door Controls

Pin Retracting

Screw

Top Pivot

Pin

Centerline of Door

and Spindle

3. Install Top Pivot and Closer Arm

Centerline

of Door

DOOR

30°

Closer in

Floor

Alignment Screws

Adjusting Screw

Alignment Screws

Arm Plate “H”

Adjusting Screw

Shim

Wood Door Arm Plate

Spindle

Shim

Arm Plate “H”

Wood Door Arm Plate

Arm

Arm Plate “H”

866-474-9766 Technical Department

www.rixson.com

866-474-9766 Technical Department

www.rixson.com

PAGE 3

PAGE 2

How To Determine

Hand of Door

LH RH

Face a door swinging open away from you. If it opens to the

right, it is right hand. If it opens to the left, it is left hand.

Top Pivot Jamb Portion

Top Pivot Door Portion

IMPORTANT:

Use plumb line to make

sure that center line of

top pivot pin lines up

with center line of closer

spindle.

Installation Instructions

1. Locating Closer

Spindle Position

2-3/4” From Face of

Jamb to C of Spindle

L

Door

Jamb A. Measure 2-3/4” out from door jamb on centerline of door.

This is the location of the spindle center.

2. Install Cement Case in Floor

A. Cement case is set flush with finished floor.

B. Set cement case in floor and block in position.

C. Case should be parallel with center line of door.

D. CEMENT CASE SHOULD BE LEVEL. Place levels per

Illustration.

E. Grout in cement case with closer. Cement should not get

between closer and case.

LEVEL IN BOTH

DIRECTIONS

A. Install top pivot in door per template.

B. Install top pivot in jamb per template.

C. Centerline of pivot pin should line up with centerline

of spindle. Use plumb line to assure accuracy. If

center lines don’t line up, loosen hold down screws

(4) and reposition closer. Tighten hold down screws

closest to spindle first. Then tighten screws at cylinder

end. Note: Closer must be lifted approx. 1/8” before

repositioning.

D. Mortise door for arm, arm plate H, and wood door

arm plate. Refer to template.

E. Drill two 9/16” dia. holes for arm alignment screws.

Drill 3/8” hole at heel edge of door for adjusting screw.

F. Attach arm to spindle using spindle screw supplied

and tighten securely. Install arm plate H, wood door

arm plate, and shim.

4. Hang Door

CAUTION: Closer is shipped with "valve" screws down.

DO NOT FORCE VALVE DOWN.

A. Close both valve screws. NEVER FORCE VALVE

SCREW DOWN AS THIS WILL DAMAGE TIP

SEATING.

B. With arm on spindle, turn spindle until arm is in 30°

open position (see illustration).

C. Set door on spindle. DO NOT ATTEMPT TO CLOSE

DOOR.

D. Align two portions of top pivot and turn pin retracting

screw clockwise to engage top pivot pin.

E. Open door to 60° or more and turn valve screws

counterclockwise. Door will then close.

F. If necessary, turn adjusting screw at bottom of heel

edge of door to equalize side jamb clearances.

G. Adjust

center door in doorway.

arm alignment screws equally from each side

to

Rixson Specialty Door Controls Rixson Specialty Door Controls

Pin Retracting

Screw

Top Pivot

Pin

Centerline of Door

and Spindle

3. Install Top Pivot and Closer Arm

Centerline

of Door

DOOR

30°

Closer in

Floor

Alignment Screws

Adjusting Screw

Alignment Screws

Arm Plate “H”

Adjusting Screw

Shim

Wood Door Arm Plate

Spindle

Shim

Arm Plate “H”

Wood Door Arm Plate

Arm

Arm Plate “H”

866-474-9766 Technical Department

www.rixson.com

866-474-9766 Technical Department

www.rixson.com

Installation Instructions

50W (06-09)

W50 Floor Closer

Center Hung

Single or Double Acting

Non-Handed

Wood Door Installation

Closing speeds can be adjusted to suit local conditions and

requirements. Label on closer face designates the purpose

of each adjustment screw. Adjustments are for speed

control.

A. The stroke valve allows adjustment from open to 15°.

B. The latch valve allows adjustment from 15° to closed

position.

C. IMPORTANT: Back check valve option must be adjusted

to vary resistance from light to firm at 70° of door

opening.

D. The delay valve option allows closing speed adjustment

from open position to 65°.

Repairs, parts replacement or internal adjustments must be done by a Rixson authorized repair agency. Consult www.rixson.com

for an authorized repair agency in your area.

Closer Adjustment

Conversion from inches to metric: inch x 25.4.

Template

PAGE 4

Rixson Specialty Door ControlsRixson Specialty Door Controls

Notes:

1. Do not scale drawing.

2. Suitable reinforcing by others.

3. Rixson design threshold available on request.

4. Tighten adjusting screw to notched “V” line

on arm to acquire standard initial location

of door. Screw moves door towards and

away from jamb to equalize door clearances.

5. Auxiliary stop required.

6. All dimensions given in inches.

TOP PIVOT

Finish Plate

7/8 Dia.

1-1/4 Dia.

1-1/32

1-7/16

1/8

3/4

1/4

9/16

2-5/8

2-3/4

1/16

9/32

1/4-20 x 5/8" FHMS or

#14 x 1/2" FHWS

15/32

1-15/32 6-3/4

JAMB PORTION 9/32

9/32

1-5/16

21/32

9/32

12-24 x 5/8" FHMS or

#12 x 1-1/4" FHWS

(2 Places)

DOOR PORTION

5/8

5/8

1-1/8

4-13/16

5-9/32

1-1/4

1/4-20 x 5/8" FHMS or

#14 x 1-1/2" FHWS

(2 Places)

Arm Floor Plate

Jamb

2-5/8 R.

Max.

19-1/4

4-1/2

C

LSpindle

2

19-1/8

Fasten Front

Mounting

Screws First Cement Case

2-3/4

Spindle Shoulder Collar

Arm Plate

Shim

Wood Door

Arm Plate

7/16

3/16

1/8 2-5/8 9*

2-1/4* 7-7/16 *Mortised

Provide

3/8” Dia.

Hole

Use Top

(2) Holes

See

Note 4 Tighten Spindle

Screw Firmly

Arm

Spindle

C

LDoor

C

LSpindle

WOOD DOOR ARM PLATE

10-1/2

6-7/32

1-19/32

1-13/32

11/16

1-3/8

9/32

9/16

2-3/32

1-25/32

4-7/32

1-7/32

#14 x 2-1/2” FWHS

(6 Places)

WITH FLOOR PLATE

Set Cement Case Flush

with Finished Floor

Cement Case

Floor

Plate

Door Mortised

1-7/8” Deep

for Arm

3/16

4-3/8

1-1/4

Provide 9/16

Dia. Hole for

Alignment

Screw

(2 Places)

1-3/8” Min. Clearance

Required for Arm, Arm

Plate H and Shims

WITH THRESHOLD

Set Cement Case Flush

with Finished Floor

Threshold

3/16

Door Mortised

Deep for Arm

Provide 9/16

Dia. Hole for

Alignment

Screw

(2 Places)

BA

1/4 Threshold

1/2 Threshold

A B

1-3/4

1-1/2

1-1/8

7/8

FS

LATCH FS

STROKE

FS

DELAY

+-

BACK

CHECK

866-474-9766 Technical Department

www.rixson.com

866-474-9766 Technical Department

www.rixson.com

ASSA ABLOY

RIXSON®

Rixson® is a registered trademark of Yale Security Inc., an ASSA ABLOY Group company. Copyright© 2005, 2009, Yale Security Inc., an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written permission of Yale Security Inc. is prohibited.

ASSA ABLOY

RIXSON®

Table of contents

Other Rixson Door Opening System manuals

Popular Door Opening System manuals by other brands

Johnson Controls

Johnson Controls MC-302E PG+ installation guide

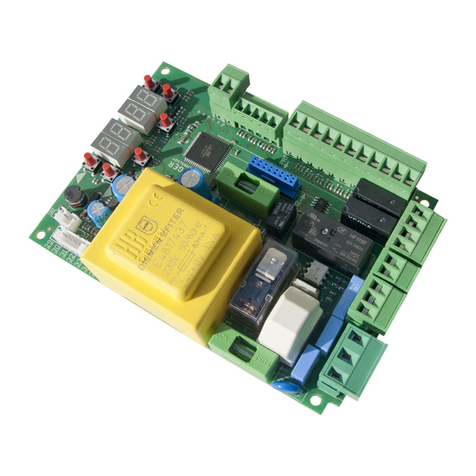

Bohle

Bohle SmartClose manual

Roger Technology

Roger Technology H70/104AC Instruction and warnings for the installer

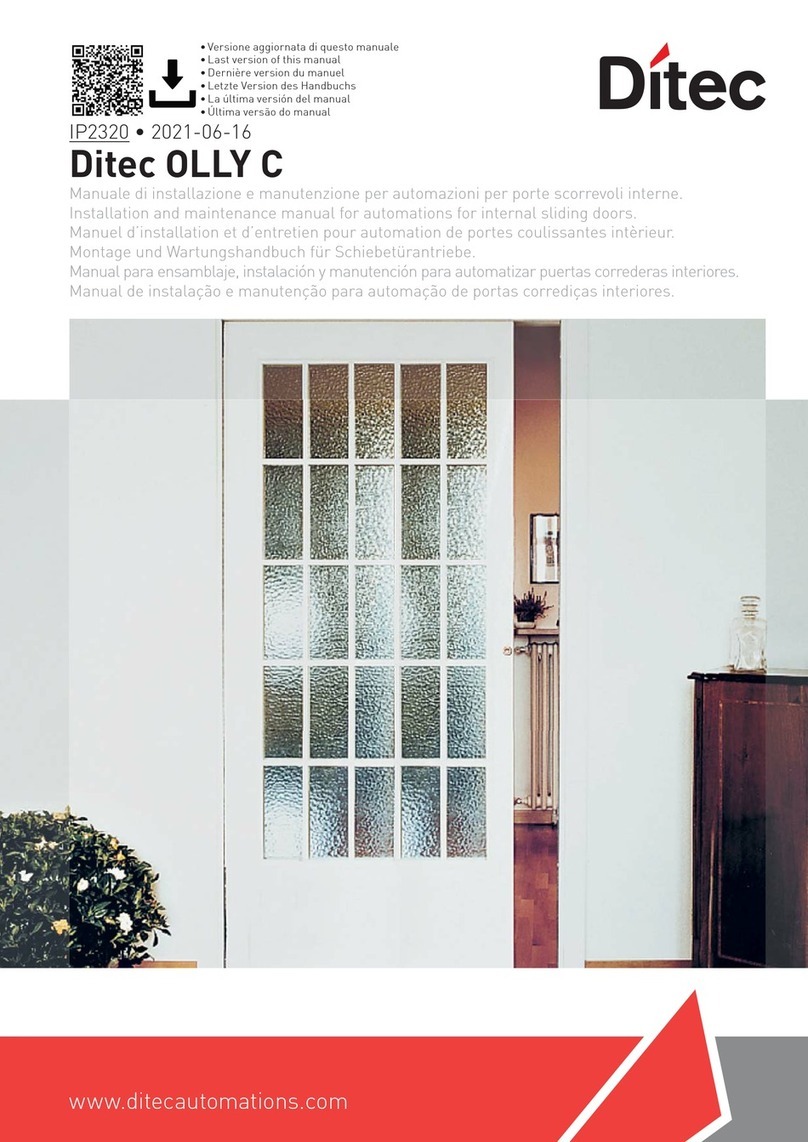

DITEC

DITEC OLLY C Installation and maintenance manual

Assa Abloy

Assa Abloy SARGENT 351 installation instructions

BFT

BFT SUB EL manual