Version 1, February 2019 User´s manual GDC006 Pág. 3 de 13

* Equipment maintenance can only be done by Auxilab Group or Auxilab

Group authorized agents;

* Do not use the following materials in the centrifuge:

- Flammable and explosive materials;

- Strong chemical action materials;

- Toxic or radioactive substances, or pathogenic microorganisms.

* Only qualified maintenance personnel can use the appropriate tools to

perform maintenance on the MiniFuge-GD06 mini centrifuge system.

* If the operator encounters a situation not mentioned in this manual, please

contact the authorized agent of Auxilab Group or Auxilab Group to inquire

about the correct treatment.

* Try to use the accessories provided by Auxilab Group. If the user wants to

use other accessories, Auxilab Group will not be responsible for the

adverse consequences. However, the user can apply to Auxilab Group to

verify that the accessory meets Auxilab Group's requirements.

* The MiniFuge-GD06 mini centrifuge must be inspected and maintained at

regular intervals.

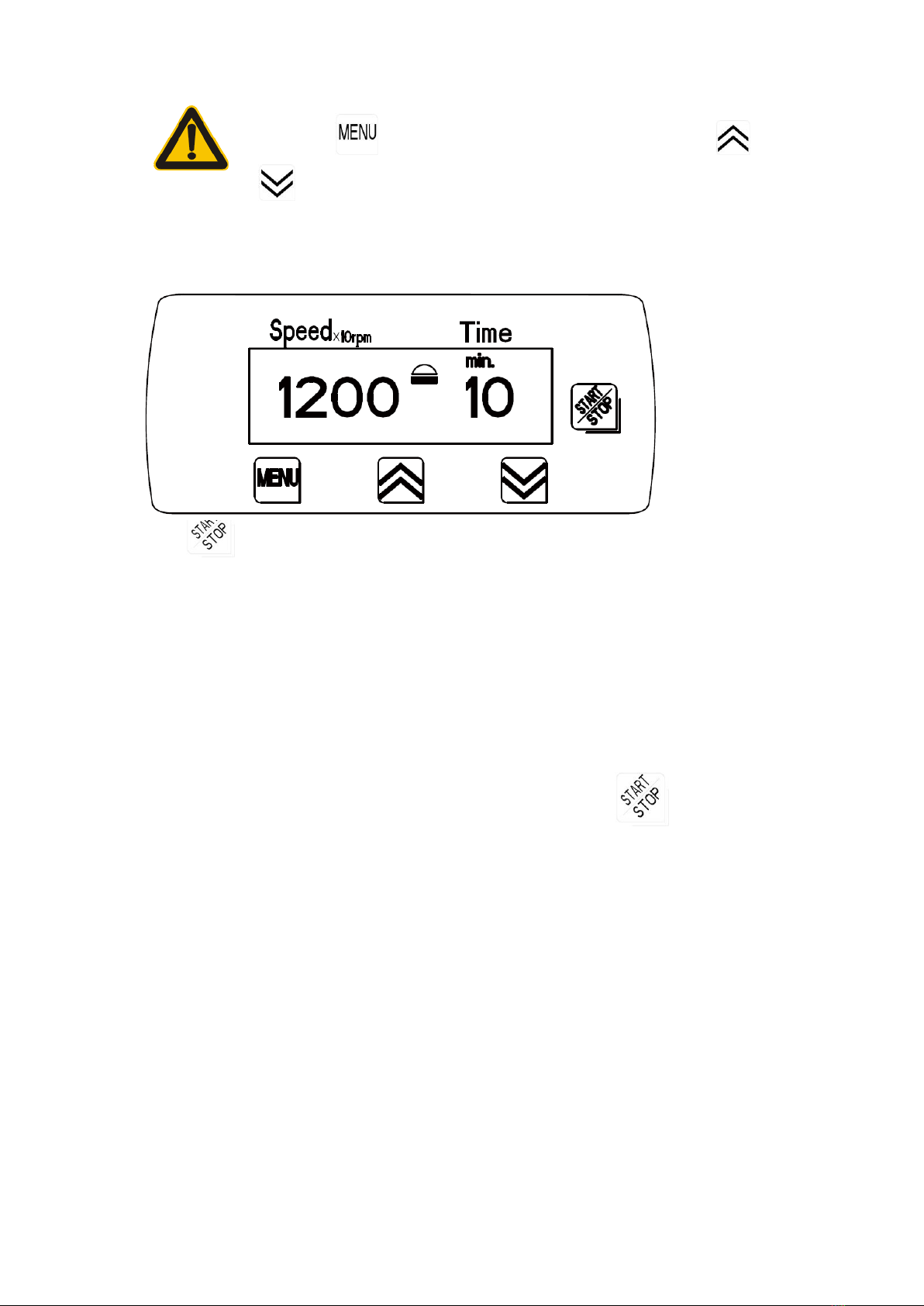

Safety warning sign description

Note: Please read the instruction manual carefully before

using the instrument!

Attention: Danger of high voltage! Risk of electric shock!

Meaning of the safety instructions

In order to avoid damage to surrounding people or damage to surrounding

objects and the environment, please be sure to follow all safety instructions in

this user manual.

In addition to accident prevention, environmental protection, and recognized

professional rules in safety and occupation, including the country where the

user is located and the local laws and regulations for the installation of the

centrifuge, they must be carefully observed.