HEDC–5xxx Series

Kit Encoders with a Connector Latch

Application Note 5554

Introduction

The HEDC-5xxx-xxx encoder with a connector latch on

the cover housing requires a dierent assembly method

than the HEDS-55xxx series. However, the internal encoder

module is exactly the same.

This application note provides step-by-step mounting

instructions on how to install the new Avago HEDC-5xxx

series encoders onto a motor.

Encoder Mounting and Assembly Instruction

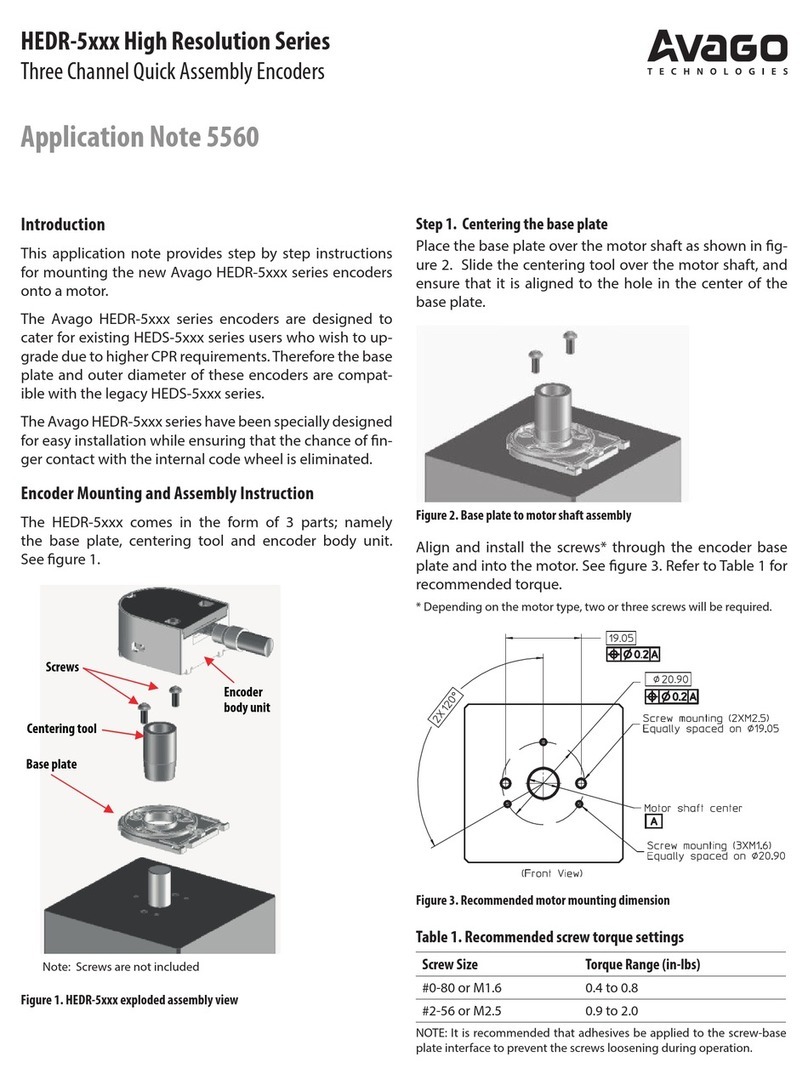

Step 1. Base plate centering

Place the base plate over the motor shaft as shown in

Figure 1. Place the centering tool over the motor’s shaft,

and ensure that it is aligned to the hole in the base plate.

Align and install the screws through the encoder base plate

and screw into the motor. Depending on the motor, this

process will involve either two or three screws. The process

is the same for the base plate with extended mounting

ears. It is recommended that adhesives be applied to the

screw-base plate interface.

Remove the centering tool.

Screw Size Torque Range (in-lbs)

#0-80 or M1.6 0.4 to 0.8

#2-56 or M2.5 0.9 to 2.0

#4-40 or M3 3.5 to 4.5

Centering tool

Base plate

Figure 1. Base plate assembly

Figure 2. Codewheel height setting

Step 2. Codewheel placement height setting

Place the height setting tool over on top of the base plate

as shown in Figure 2.

Height setting tool

Figure 3. Codewheel mounting

Step 3. Codewheel mounting

Mount the hub of the codewheel to the motor shaft.

DO NOT handle the codewheel. Touch only the hub during

installation. Ensure that the codewheel hub is well ”seated”

on top of the height setting tool, as shown in Figure 3.

Press down on the top of the hub while tightening the set

screw with the hex wrench (supplied). The hub set screw

attaches the codewheel to the motor shaft. The recom-

mended torque to tighten the set screw is 15-18 oz-in

(0.9-1.2 in-lbs).

Remove the hex wrench and spacer tool.