For product information and a complete list of distributors, please go to our web site: www.avagotech.com

Avago, Avago Technologies, and the A logo are trademarks of Avago Technologies in the United States and other countries.

Data subject to change. Copyright © 2005-2014 AvagoTechnologies. All rights reserved.

AV02-3824EN - October 28, 2014

Figure 4. Base plate after screw tightening and centering tool removed

Step 2. Remove the centering tool

Step 3. Encoder body unit assembly

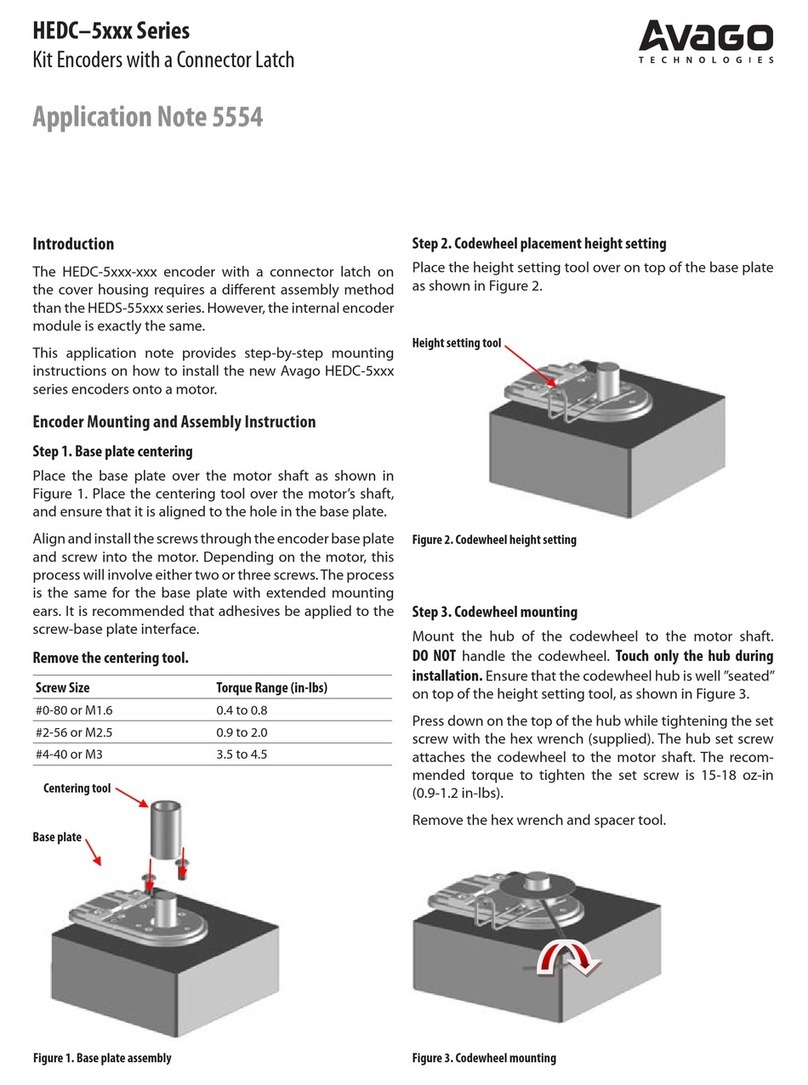

With the base plate centered to the shaft as seen in Figure

4, mount the encoder body unit to the motor’s shaft. See

gure 5.

Figure 5. Mounting encoder body unit to the base plate

Step 4. Lock codewheel onto the motor shaft

Insert the hex wrench into the set-screw opening of the

encoder body unit and apply a downward force (as indi-

cated by arrow), then tighten the set screw. See Figure 6.

The recommended torque is 15-18 oz-in (0.9-1.2 in-lbs).

Figure 7. Closing up the set screw outlet

Figure 8. Completed assembly

Figure 6. Tightening encoder body unit set-screw to the motor’s shaft

Perform the same action on the opposite side of the en-

coder. Note that you will need to pull the“L-shape”mecha-

nism down and to the right instead.

The closure is considered complete when the “hinge” is

clearly visible through the set-screw openings on both

sides of the encoder body unit. See gure 7 (AFTER)

The completed encoder assembly is now ready for opera-

tion. See gure 8.

Screw head,

max height

= 2.1mm

Shown here

are two snap

points

Press body

unit down

Set screw

outlet

opening

Tightened

clockwise

Hex Wrench

(1.5mm)

Set screw

“Hinge”

Hex wrench to pull the cover leftwards “L-shape”

BEFORE AFTER

Press t the encoder body unit to the base plate, ensuring

that all four snap points are well locked.

The set screw tightening process will:

1. Lock the code wheel's hub to the motor shaft

2. Physically align the code wheel's index position to that

of the detector IC (index channel may not necessarily

be triggered electrically).

Step 5. Release codewheel and close set-screw outlet

Using the hex wrench, pull the“L-shape”protrusion down

and to the left. See gure 7 (BEFORE). This action releas-

es the internal codewheel holding mechanism and also

serves to close the set-screw opening.

* 1.5mm Hex wrench should be used to fasten M3 set screw in Figure 6