Table of contents

2

hydraulic breaker

TABLE OF CONTENTS

OPERATION .......................................................................................................................3

1.FOREWORD............................................................................................................................................................4

1.1 IMPORTANT SAFETY INFORMATION ...........................................................................................................4

1.2 WARRANTY ......................................................................................................................................................5

1.3 SPARE PART ORDERS.......................................................................................................................................5

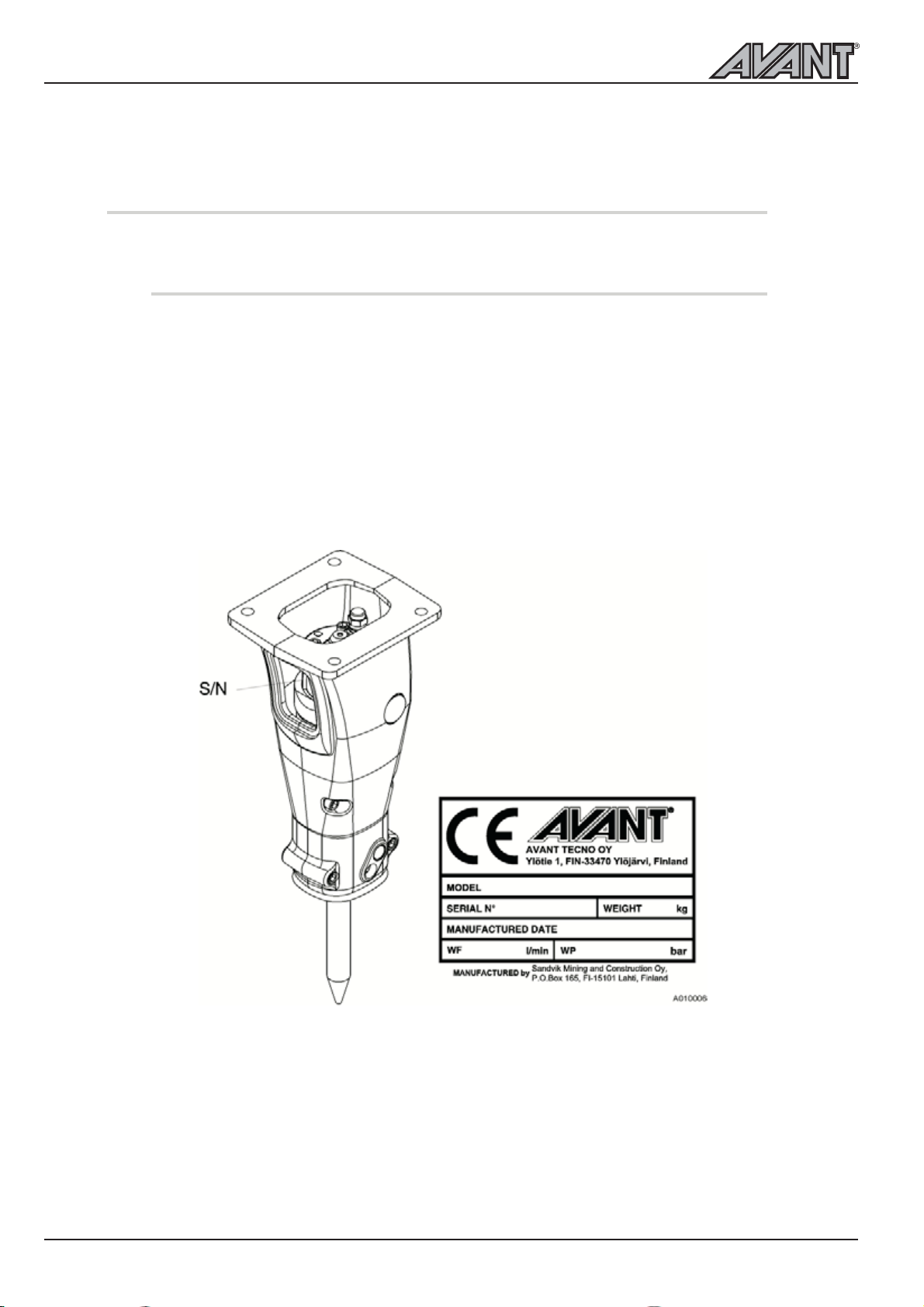

2. MACHINE NUMBERS............................................................................................................................................6

2. 1 MODEL AND SERIAL NUMBER......................................................................................................................6

3. PRODUCT INTRODUCTION ..............................................................................................................................7

3.1 OVERVIEW ........................................................................................................................................................7

3.2 REMOVAL FROM PACKA E ............................................................................................................................7

3.3 LIFTIN INSTRUCTIONS ................................................................................................................................7

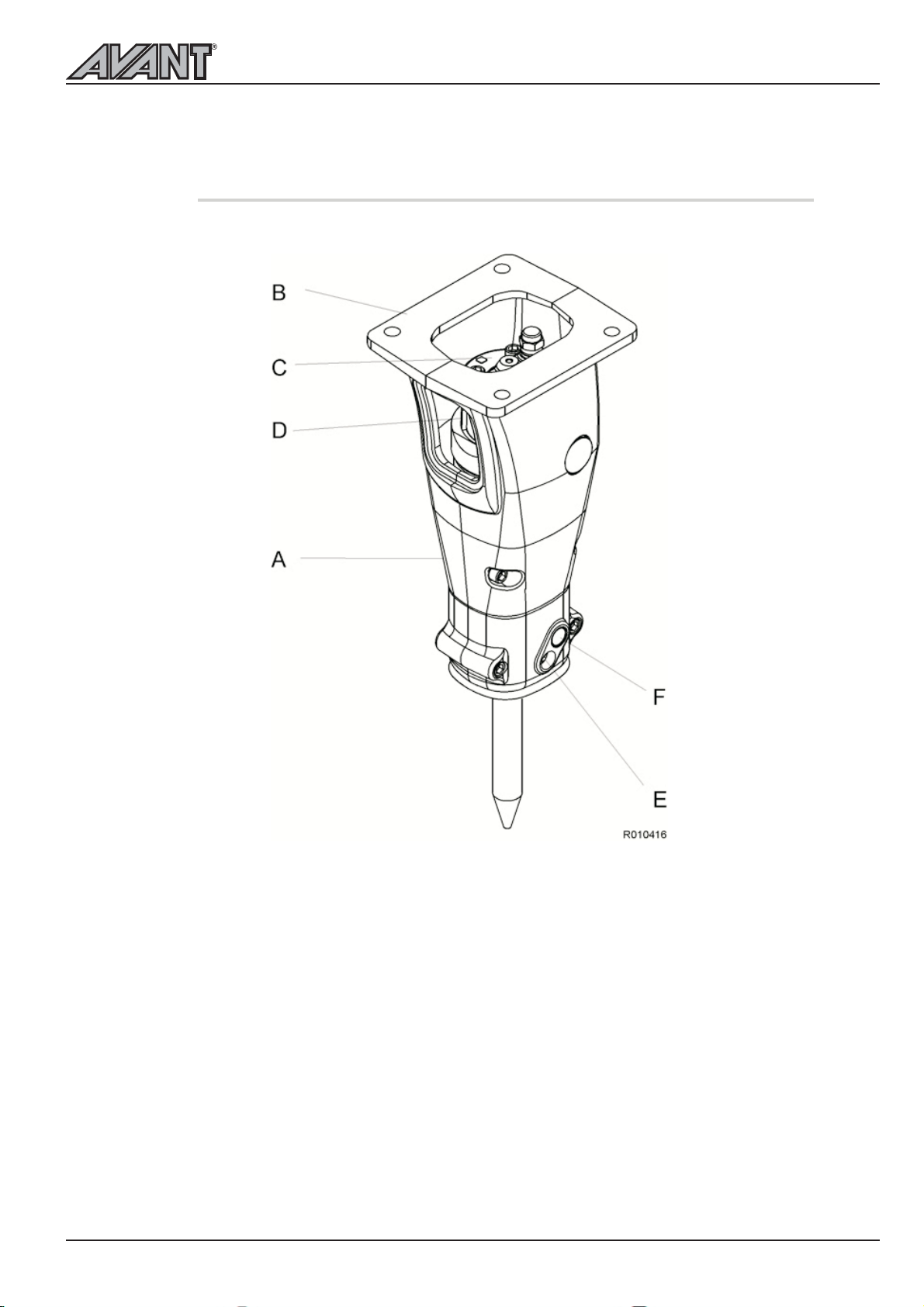

3.4 MAIN PARTS......................................................................................................................................................9

4. SAFETY .................................................................................................................................................................10

4.1 ENERAL SAFETY ..........................................................................................................................................10

4.2 SAFETY INSTRUCTIONS ...............................................................................................................................10

5. OPERATION.........................................................................................................................................................18

5.1 OPERATIN INSTRUCTIONS .......................................................................................................................18

5.2 DAILY OPERATION ........................................................................................................................................19

5.3 MOUNTIN AND DISMOUNTIN THE HAMMER....................................................................................24

5.4 MOVEMENT....................................................................................................................................................25

5.5 SPECIAL CONDITIONS OF USE ...................................................................................................................25

5.6 STORA E ........................................................................................................................................................26

LUBRICATION..................................................................................................................27

1. HAMMER TOOL REASIN ...............................................................................................................................28

1.1 RECOMMENDED REASES...........................................................................................................................28

1.2 MANUAL REASIN ......................................................................................................................................28

2. CARRIER HYDRAULIC OIL..................................................................................................................................30

2.1 REQUIREMENTS FOR HYDRAULIC OIL.......................................................................................................30

2.2 OIL COOLER...................................................................................................................................................32

MAINTENANCE ...............................................................................................................33

1. ROUTINE MAINTENANCE ................................................................................................................................34

1.1 OVERVIEW ......................................................................................................................................................34

1.2 INSPECTION AND MAINTENANCE BY THE OPERATOR .........................................................................34

1.3 INSPECTION AND MAINTENANCE BY THE DEALER ...............................................................................35

1.4 MAINTENANCE INTERVALS IN SPECIAL APPLICATIONS .........................................................................35

1.5 OTHER MAINTENANCE PROCEDURES......................................................................................................36

2. REMOVAL OF TOOL...........................................................................................................................................37

3. LOWER TOOL BUSHIN ...................................................................................................................................39

4. TROUBLESHOOTIN .........................................................................................................................................41

4.1 THE HAMMER DOES NOT START................................................................................................................41

4.2 THE HAMMER OPERATES IRRE ULARLY BUT THE BLOW HAS FULL POWER ......................................42

4.3 THE HAMMER OPERATES IRRE ULARLY AND BLOW HAS NO POWER ................................................42

4.4 IMPACT RATE SLOWS DOWN ......................................................................................................................43

4.5 THE HAMMER DOES NOT STOP OR HAS RUNON ...................................................................................43

4.6 OIL OVERHEATS.............................................................................................................................................44

4.7 RECURRENT TOOL FAILURE........................................................................................................................44

4.8 FURTHER ASSISTANCE..................................................................................................................................45

SPECIFICATIONS.............................................................................................................47

1.HAMMER SPECIFICATIONS.................................................................................................................................48

1.2 MAIN DIMENSIONS .......................................................................................................................................49

2.TOOL SPECIFICATIONS ......................................................................................................................................50