Service Manual

ALX 720

Release 11/2003 Page 9 Adjustment

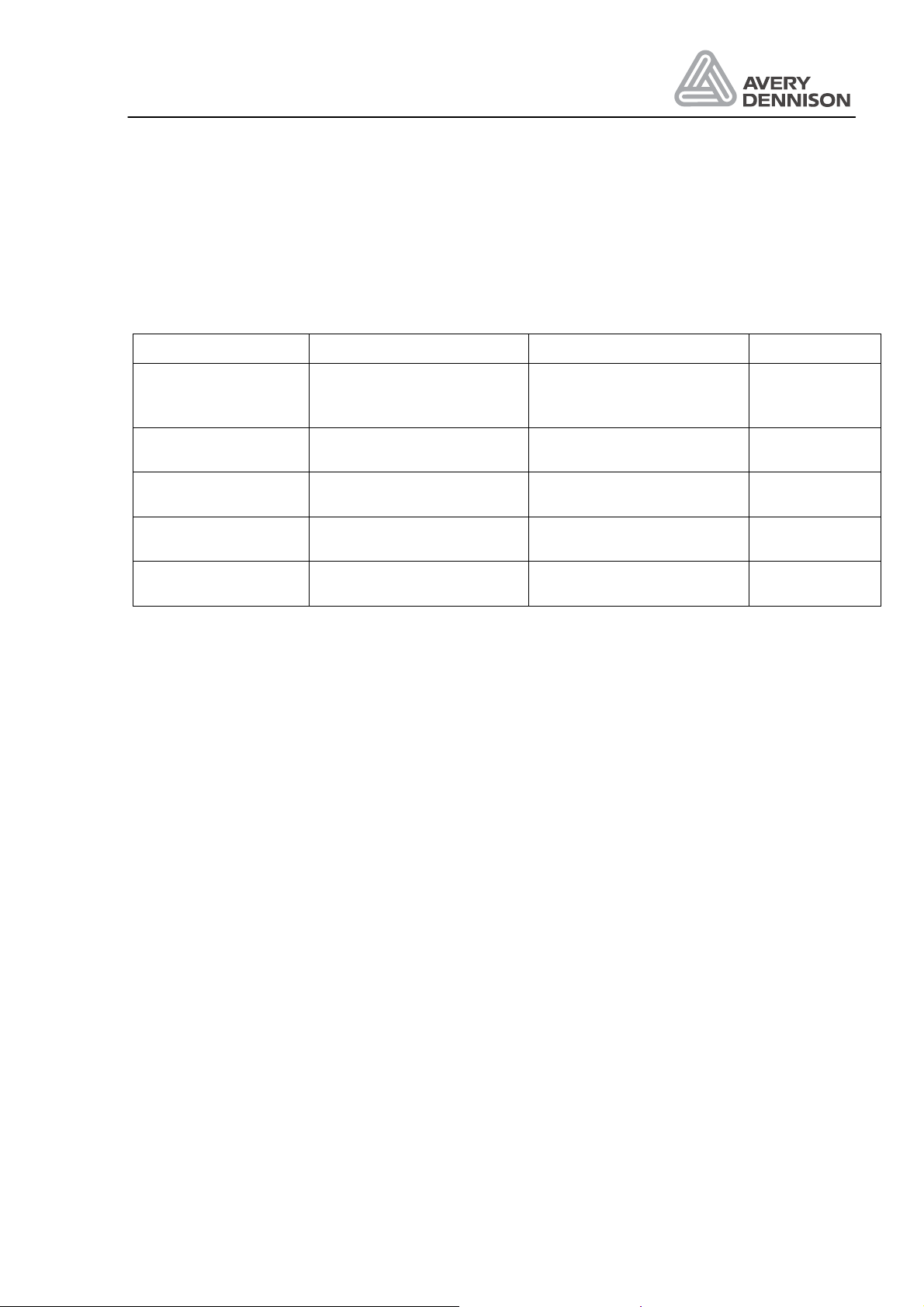

Sensor Connector Adjustment condition Pot Value /

Test point Para

meter Display

value

Label sensor CN15 without material in label

sensor Pot. P7 7 Pxxx 7

(Full size) with material >7

Adjustment Without Material in the label sensor (only backing paper):

For adjustment select the function OTHR/SCHK/Pxxx and turn the po-

tentiometer P7 (I/O-board) to get the display value P7.

With material (label) in the label sensor:

A display value of >P7 should be shown.

3.3 Loop sensor

Function The sensor measure the position of the dancer arm. Is the label loop not

filled, so the dancer arm is not in the home position, the printer starts

printing. If the loop is nearly empty a signal is generated to inhibit the

dispenser.

Location The loop sensor is mounted inside the machine at the dancer arm.

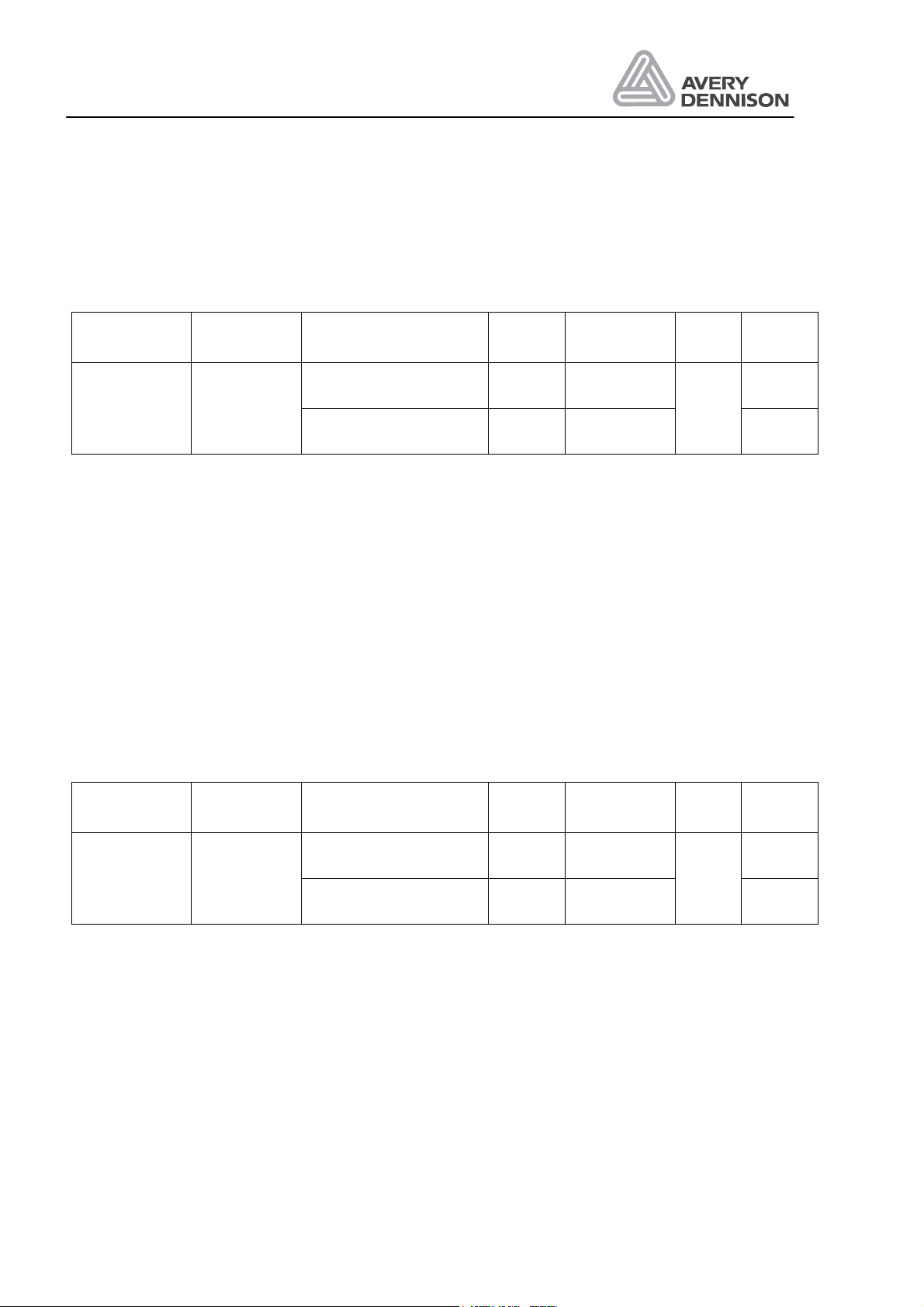

Sensor Connector Adjustment condition Pot Value / Test

point Para

meter Display

value

Loop sensor

CN13 Dancer arm in home posi-

tion Pot. P5 LH: 85

RH: 65 Rxxx LH: 85

RH: 65

Dancer arm at end posi-

tion <240

ca. 150

¯Before starting the adjustment be sure that the white wedge angle is

mechanical correct adjusted. In the home position of the dancer arm the

thick part of the wedge angle should be positioned in the sensor.

Adjustment Loop sensor in home:

For adjustment select the function OTHR/SCHK/Rxxx and turn the Po-

tentiometer P5 (I/O-board) until the value R85 is shown for a left hand

machine or R65 for a right hand machine.

Loop sensor in end position:

The value should so high as possible but not higher than R240.

¯The values itself are not important, but the

difference between the home and the end value should be so high as

possible.

¯The trigger points SW01 (Start of print)

and SW02 (Inhibit signal for dispenser) has to be set in the sub menu

SYSP.