4

Preface

Please take time to read this Instruction Manual before unpacking your Volvere Turntable.

This product is meticulously engineered and whilst damage is unlikely with careful handling, the sheer mass of some of

the parts could damage the less robust parts within its design. Please keep in mind that certain parts have been

deliberately excluded from the warranty, so it is essential to handle and operate the turntable with care and attention.

Introduction

The Volvere is an audio turntable manufactured to extreme limits of precision, design and detail. There are many unique

and novel features in this product and its design allows you to install the pick-up arm and cartridge of your choice.

With correct ancillary equipment it will take your listening pleasure to new levels of excellence.

Whilst it shares some features found in other turntables, it has been designed without compromise not trying to emulate

or improve existing designs but redefine the whole thinking behind turntable design.

We hope that you enjoy this product for many years!

Warnings

1. To prevent fire or electric shocks do not expose either the power supply or motor to rain or moisture

2. The Main Bearing contains a Sapphire Cup Jewel and can be damaged if proper care is not taken, such as moving

the turntable or dropping the platter when fitting and this part is excluded from warranty

3. The threaded spindle is made from brass for sonic reasons and is a much softer than the stainless steel clamp.

If cross threaded whilst fitting the thread will eventually wear out. Some owners have never had occasion to

replace this part after decades of use and others damage it quickly. For this reason it is excluded from warranty.

4. The platter surface (mat) is a specially cork/rubber composite, optimised to reduce vibration within the record and

is bonded to the platter. You should not try to remove it, or fit another mat over the top as this will stop the

clamp/bearing for working effectively.

5. The Power Supply contains voltages which can cause serious injury. There are no user serviceable parts inside and

no reason to open it. In situations of failure, return to your dealer or contact AVID directly. There are calibrated

components inside and altering any settings will reduce performance and void the warranty.

6. The motor is a precision mechanism and must under no circumstances be opened or adjusted. If you experience

what you believe to be a problem, consult your dealer or AVID directly.

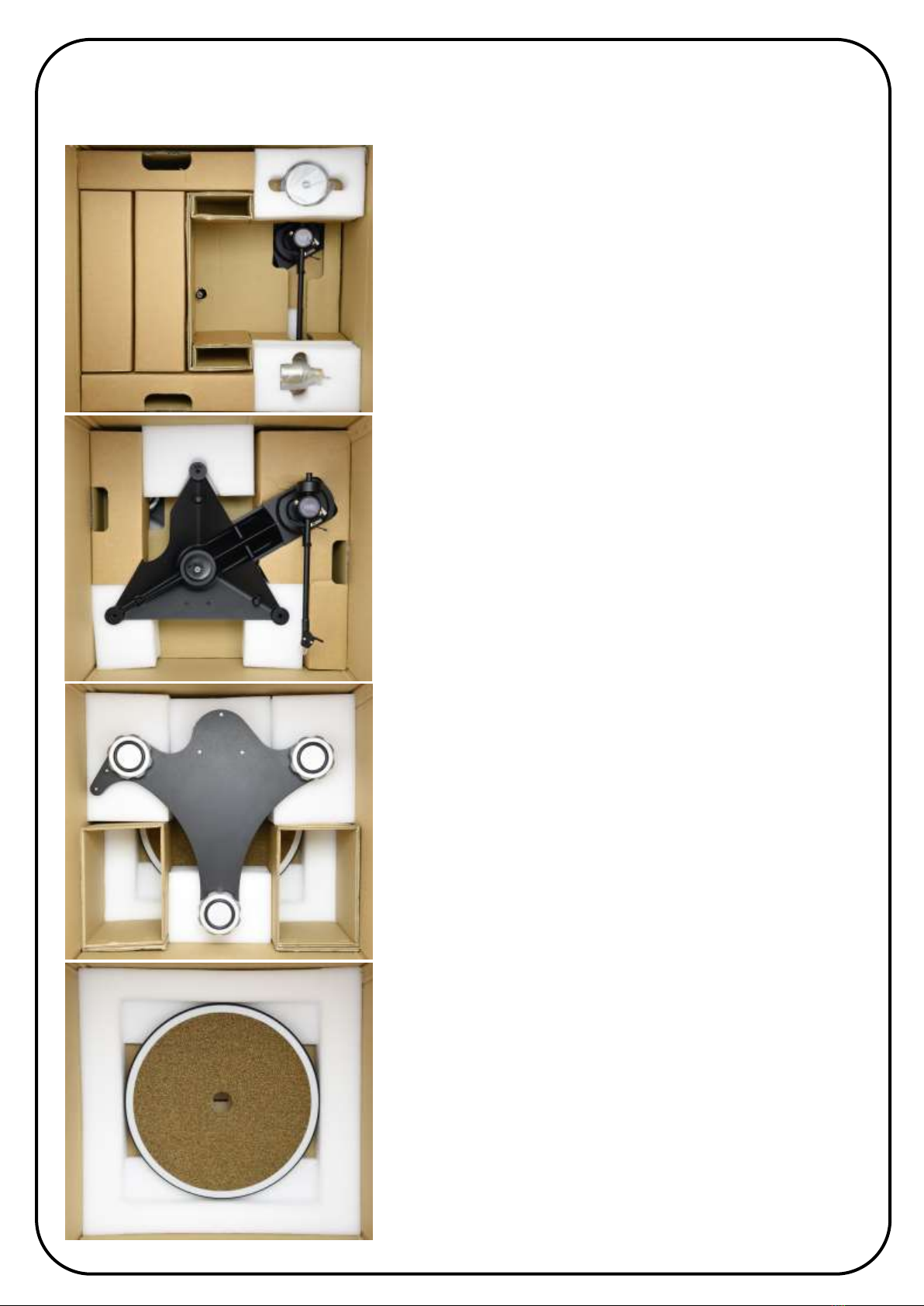

Packaging

The packaging is very expensive to replace, so save all the packing in a dry place away from fire hazard.

The AVID Turntable is a precision instrument and the packaging has been especially designed so that all component parts

are safe during transportation. If you should need to return your unit for upgrade, service or repair, you will be required

to use its original packaging to keep it from damage. In the event of the packing being lost or damaged further packing

can be provided at cost.

Do not transport the turntable assembled. This will cause damage and void the warranty.

Parts Check List

The packing is designed to eliminate parts being missed, however if something is found amiss please contact your dealer.

Instruction Manual 1Drive Belt 2Suspension Lateral O-Ring 3

Platter 1Main Bearing 1Wrench Key Size 3mm A/F 1

Sub-Chassis 1Belt Pin 14mm Tungsten Carbide Ball 1

Clamp 1Power Supply 1Power Cord 1

Main Chassis 1Tonearm (if supplied) 1Cartridge (if supplied) 1