11

Due to the above described circumstances it is important to control the difference in

temperature between the supplied air and the existing air at the level of the operating

table and nowhere else.

When Opragon was developed and tested we discovered that it takes a difference in

temperature (ΔT-value) between -1.5 to -2°C to ensure an air speed at the level of the

operating table of 0.25 m/s. This difference is between the supplied clean and filtered air

and the surrounding air at the level of the operating table. Our system constantly monitors

and controls that the supplied air has an under temperature of 1.5-2°C regardless of the

temperature of the surrounding air.

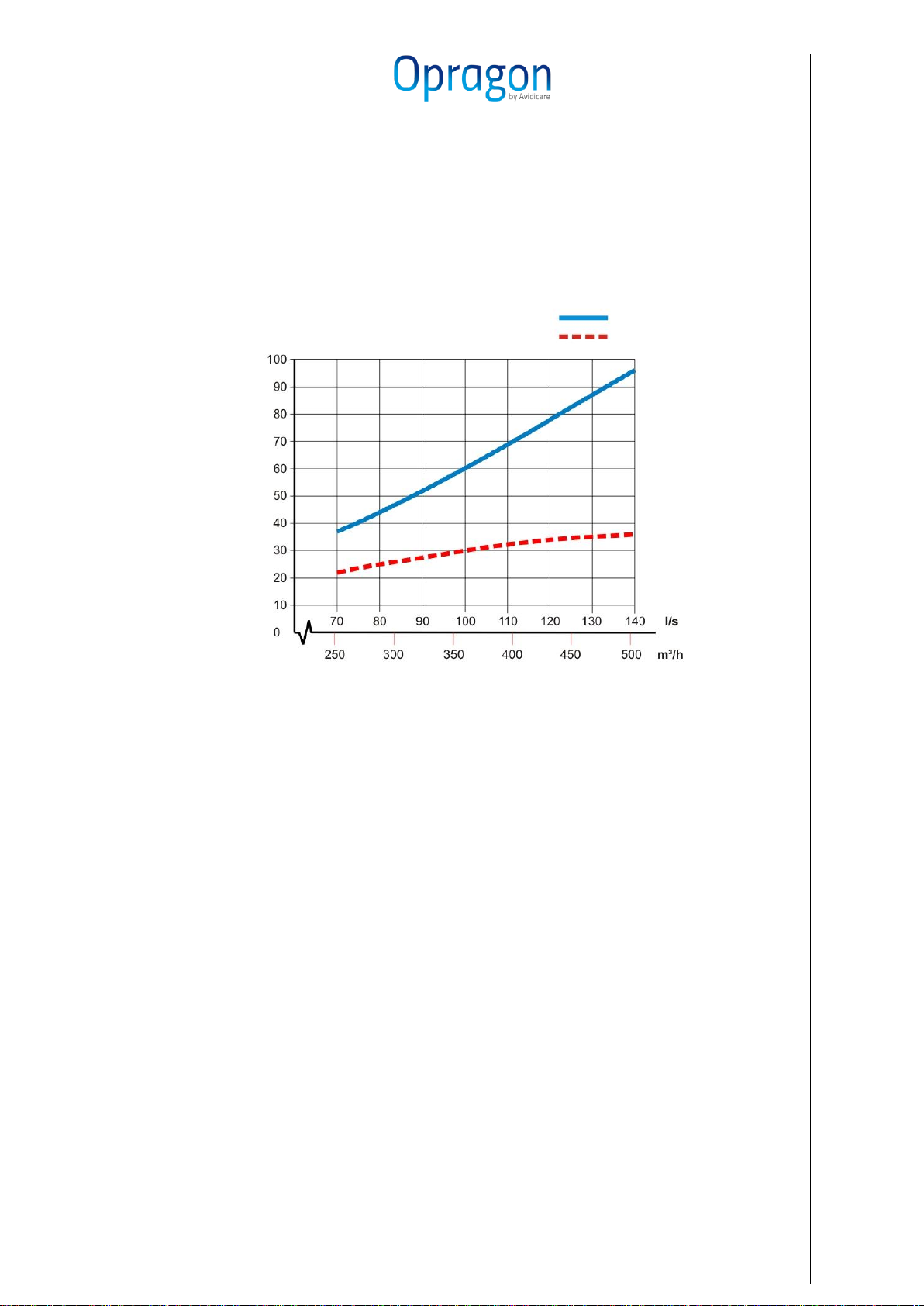

The speed at the outer edge of a free-flowing downwards air flow with a limited cross-

sectional area can either be increased or reduced depending on the temperature difference

to the surrounding stationary air. Cold air has greater density than warm air and vice versa.

A vertical, free-flowing temperature-controlled air flow that is colder than the surrounding

air will sink towards the floor as long as the difference in temperature persists. Thus, it is

impossible to achieve such an air flow if the surrounding air has the same temperature or is

colder than the air supplied.

When air is supplied through an LAF ceiling, it will seek out a layer of air with the same

temperature and air movement will cease there. In unfavourable circumstances, the

temperature of the supplied air will be higher or equal to the temperature in the layer just

below the operating theatre ceiling. Air movement will then cease as soon as the kinetic

energy from the fan in the LAF ceiling dissipates and the clean air is disseminated

horizontally under the ceiling instead of protecting the surgical site. More advanced LAF

systems regulate the temperature of the supplied air so that it maintains the value set by

staff depending on comfort and type of surgical procedure. These systems are intended to

regulate the temperature for staff working under the LAF ceiling. They do not take into

consideration thermal loads that exist in the area. These are from heat from lamps,

electrical equipment, staff and, where applicable, solar radiation. They do not utilise gravity

as a propelling force to control the speed of the downward-flowing air flow either. They do

not control the difference in temperature between the supplied air and the surrounding

stationary air in the rest of the operating theatre. The temperature difference will

consequently vary depending on variations in thermal loads during surgery and the speed

of the air flow will fluctuate during and between surgeries.

The solution to the problem described above is to measure room temperature at the level

of the operating table and control the temperature of the air flow in relation to this value.

This way, air speed in the working area is controlled, which is desirable. The effect of this is

a well controlled air flow at the surgical site and control of the thermal loads in the

operating theatre. In addition, staff can choose a suitable room temperature in which to

work without jeopardising the protection against infection that the clean air flow is

intended to provide.

In order for this to work, a corresponding method is needed to control room temperature

that does not conflict with the temperature-controlled air flow above the operating table.

An effective solution to the problem is to control room temperature by supplying heated or

cooled air through air showers placed in the ceiling outside of the surgical environment. We

then obtain downward-flowing air flows with different speeds in the entire room. This also

enables adjustment of room temperature to the level that staff prefers or the procedure

requires without a change in the air speed at the surgical site.

Thus, instead of controlling one of two parameters that affect the temperature difference

between the supplied air at the surgical site and room temperature, TAF technique and the