Copyright 2022, AWE. No part of this document may be reused or duplicated without the express permission of AWE/Secor Ltd. All rights reserved. Rev3.7

NOTE: Always refer to the manufacturer’s service manual for precise torque specifications

on all OEM fasteners.

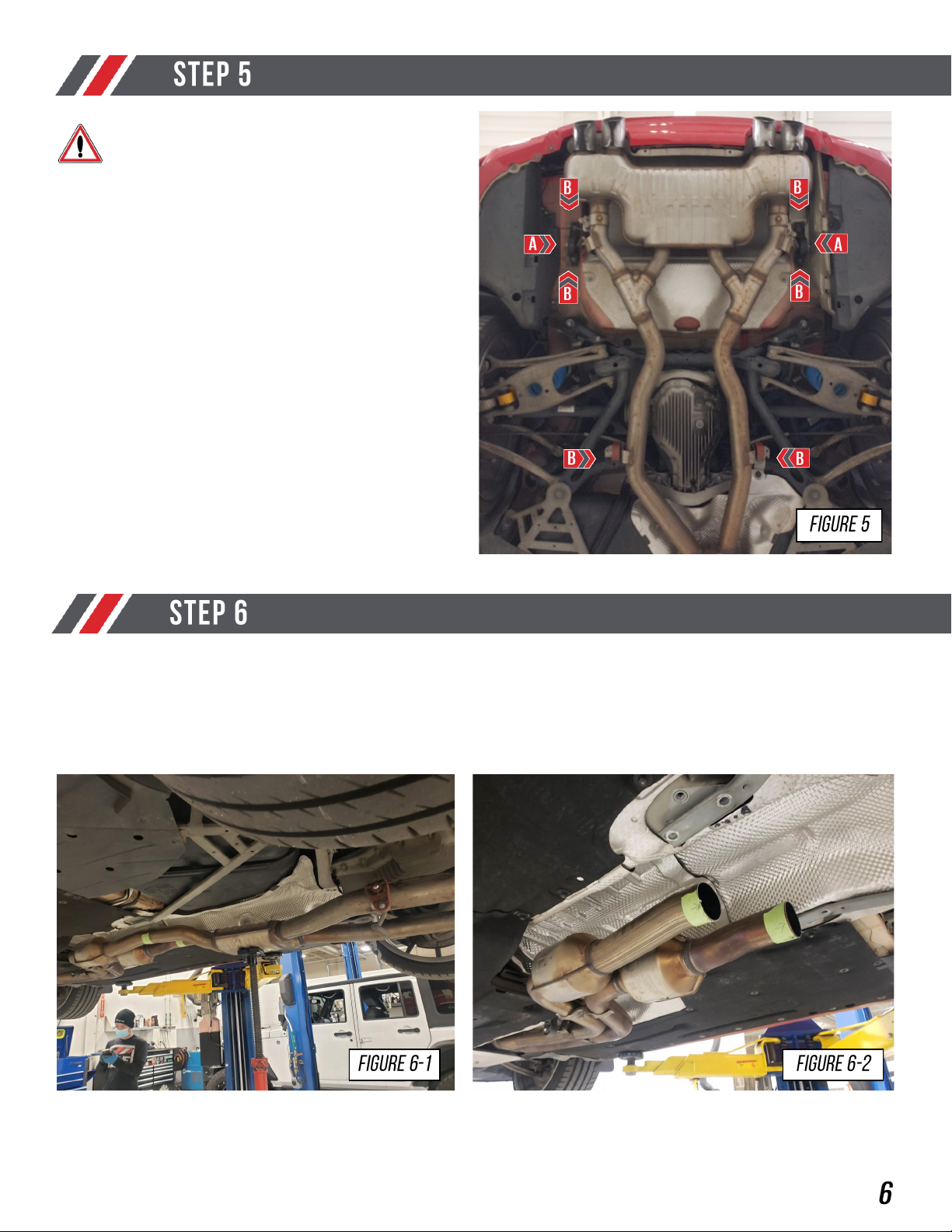

CAUTION: The exhaust may be VERY HOT — allow adequate time for the system to cool

down before disassembly. Severe burns and injury will occur if skin comes into contact with

a hot exhaust system.

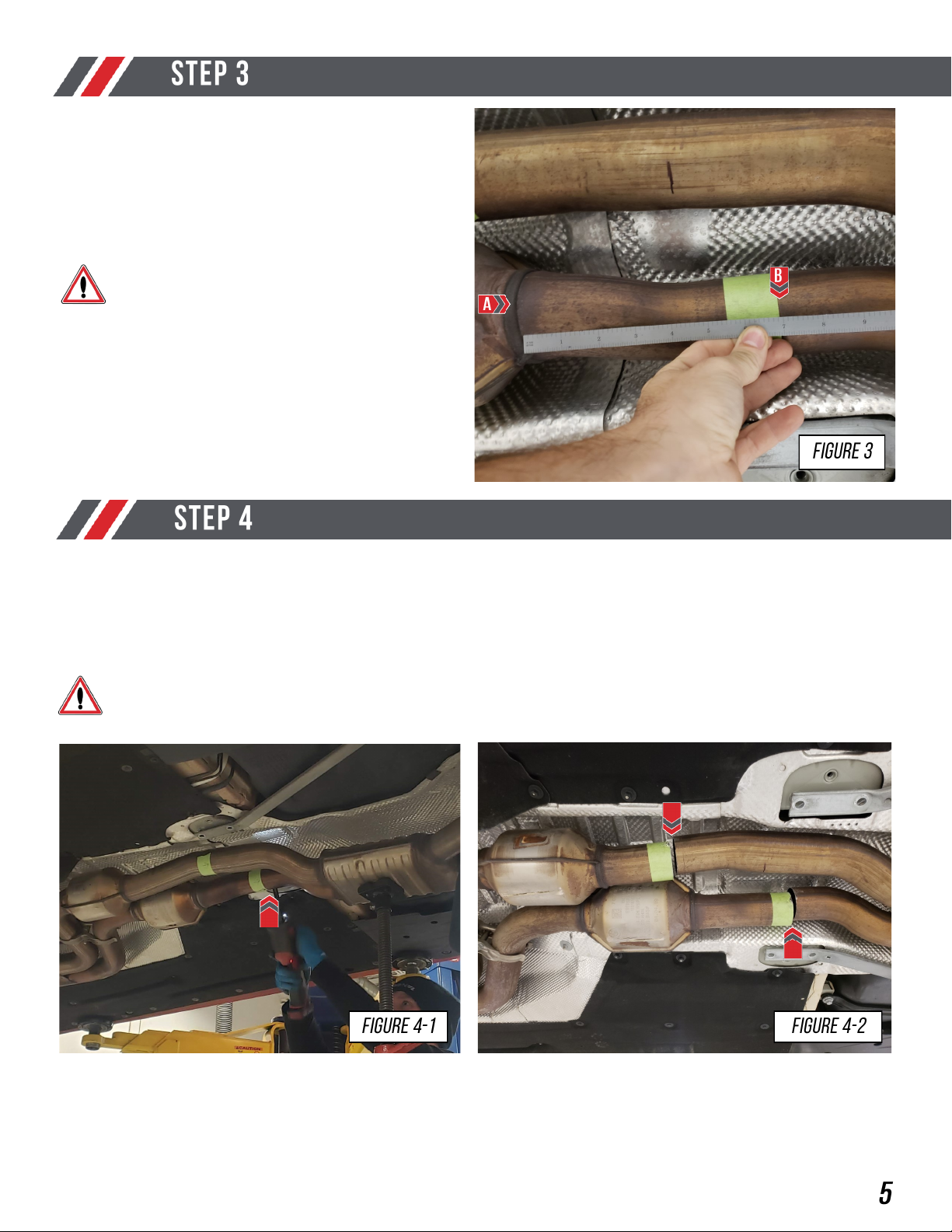

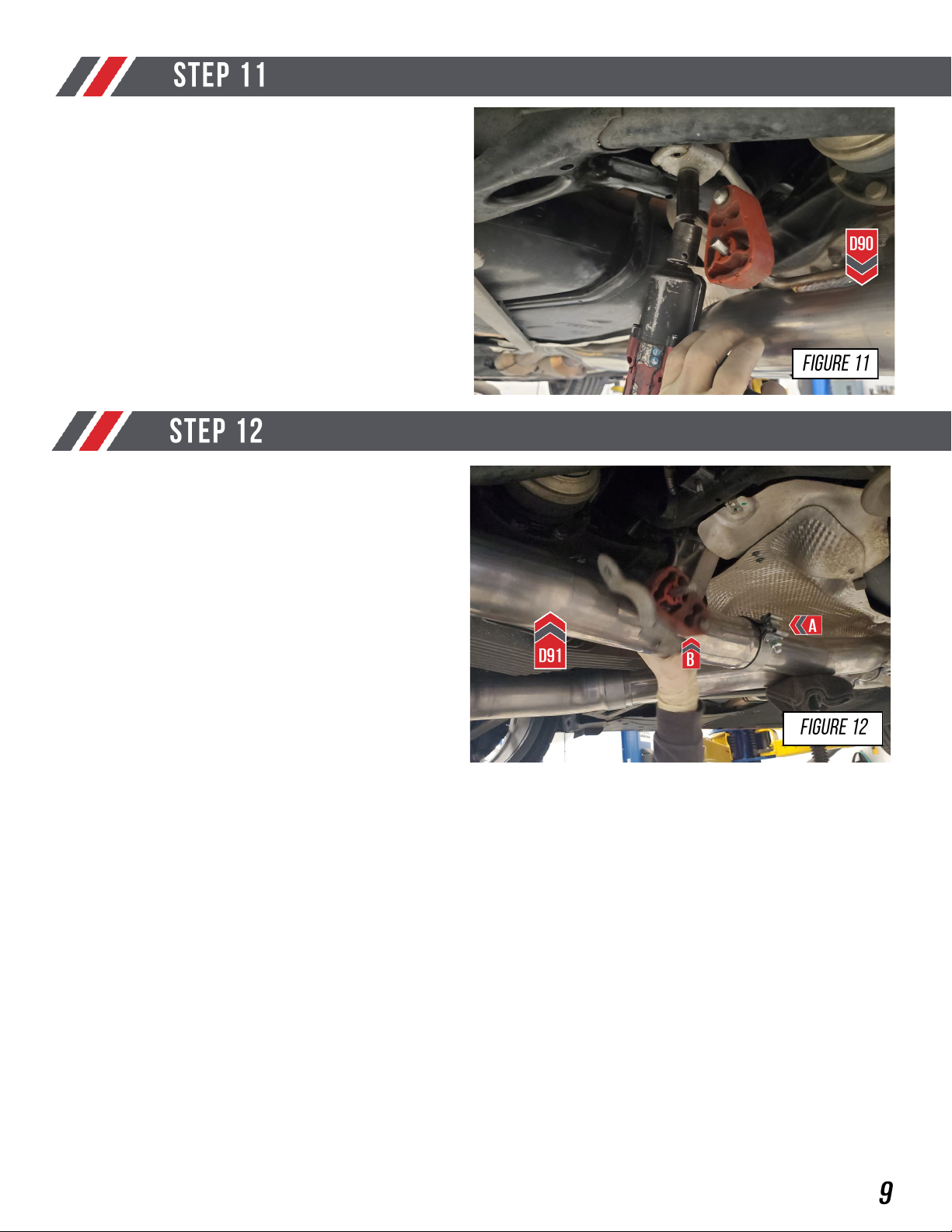

On the driver side catalytic converter measure

4.50” inches from the weld seam (A) towards

the rear of the vehicle.

Mark with tape (B) and an arrow pointing to the

rear of the vehicle, as shown in Figure 2.

It is extremely important that these

measurements are accurate as it will

effect fitment.

Begin by removing the OE bolts mounting the

OE chassis brace to the body, as shown in Fig-

ure 1.

Note: The OE hardware will be reused with the

install of your AWE exhaust.

COMPLETE THIS PROCESS BEFORE MOVING FORWARD

Before starting installation, the factory exhaust valves must be in the open position. Bring the en-

gine up to full operating temperature. With the engine running, press the Engine Dynamics button

to switch into Sport-Plus mode. Blip the throttle to audibly confirm the valves are open. If in doubt

of valve position, peer into the exhaust tips with a flashlight to confirm that they are open. While still

in Sport-Plus mode, shut off engine Disconnect the connectors from both valve electrical motors.

Allow exhaust to cool before proceeding with next install steps. Failure to follow this procedure

will result in the factory valve motors not aligning with the AWE Tuning exhaust valves.