AWS AirBar Operator’s Manual

INTRODUCTION ........................................................................................... 1

FOREWORD...........................................................................................................................1

ITEMS INCLUDED WITH AIRBAR KITS......................................................................................1

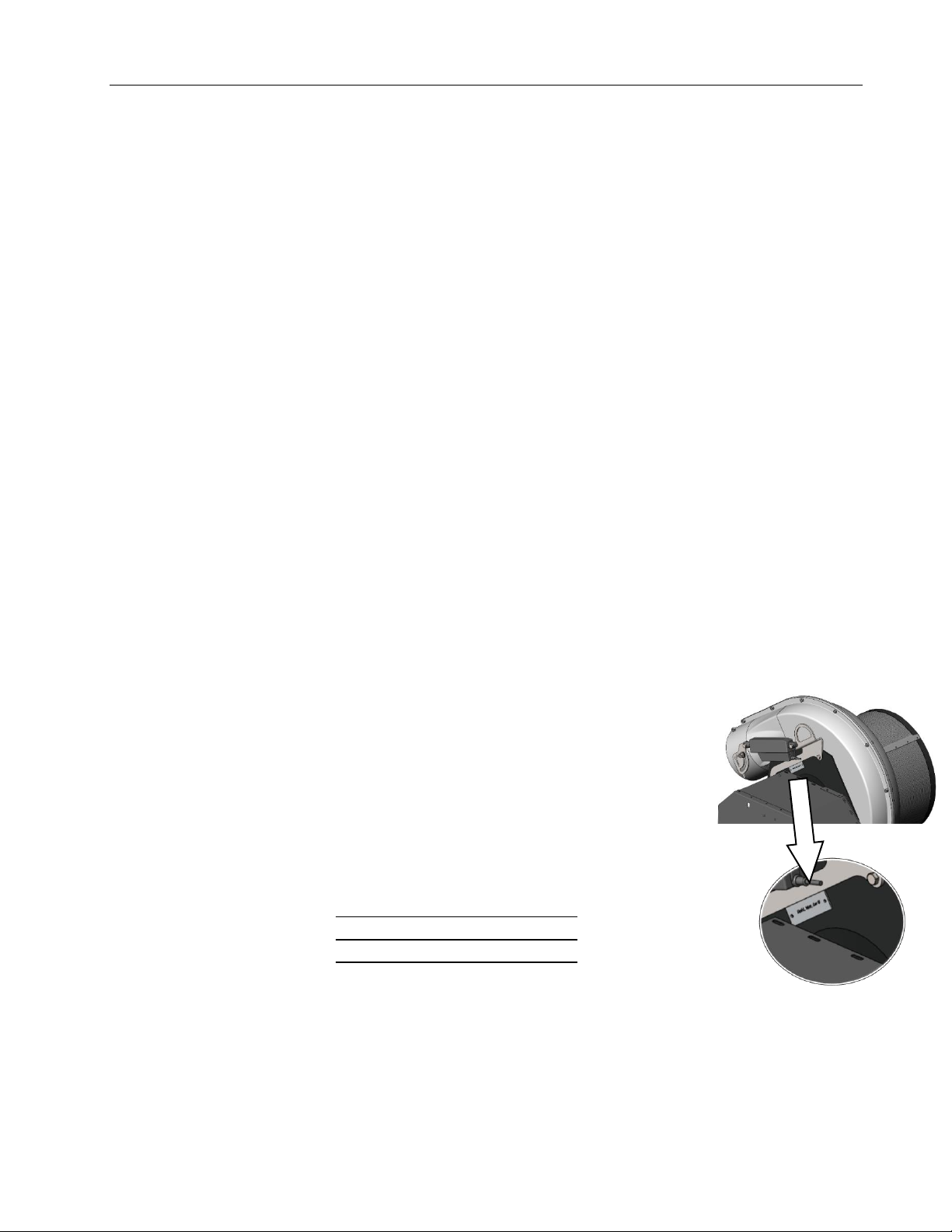

SERIAL NUMBER LOCATION...................................................................................................1

REPLACEMENT PARTS INFORMATION....................................................................................1

UNAUTHORIZED MODIFICAITON ...........................................................................................2

MISUSE OF EQUIPMENT ........................................................................................................2

PRODUCT DESIGN .................................................................................................................2

OFFICIAL LANGUAGE .............................................................................................................2

COMPONENT IDENTIFICATION................................................................... 3

SAFETY ........................................................................................................ 4

SAFETY ALERT SYMBOL..........................................................................................................4

HAZARD SERIOUSNESS LEVEL.................................................................................................4

GENERAL SAFETY PRECAUTIONS............................................................................................4

POWER UNIT SAFETY.............................................................................................................5

OPERATING EQUIPMENT SAFELY ...........................................................................................5

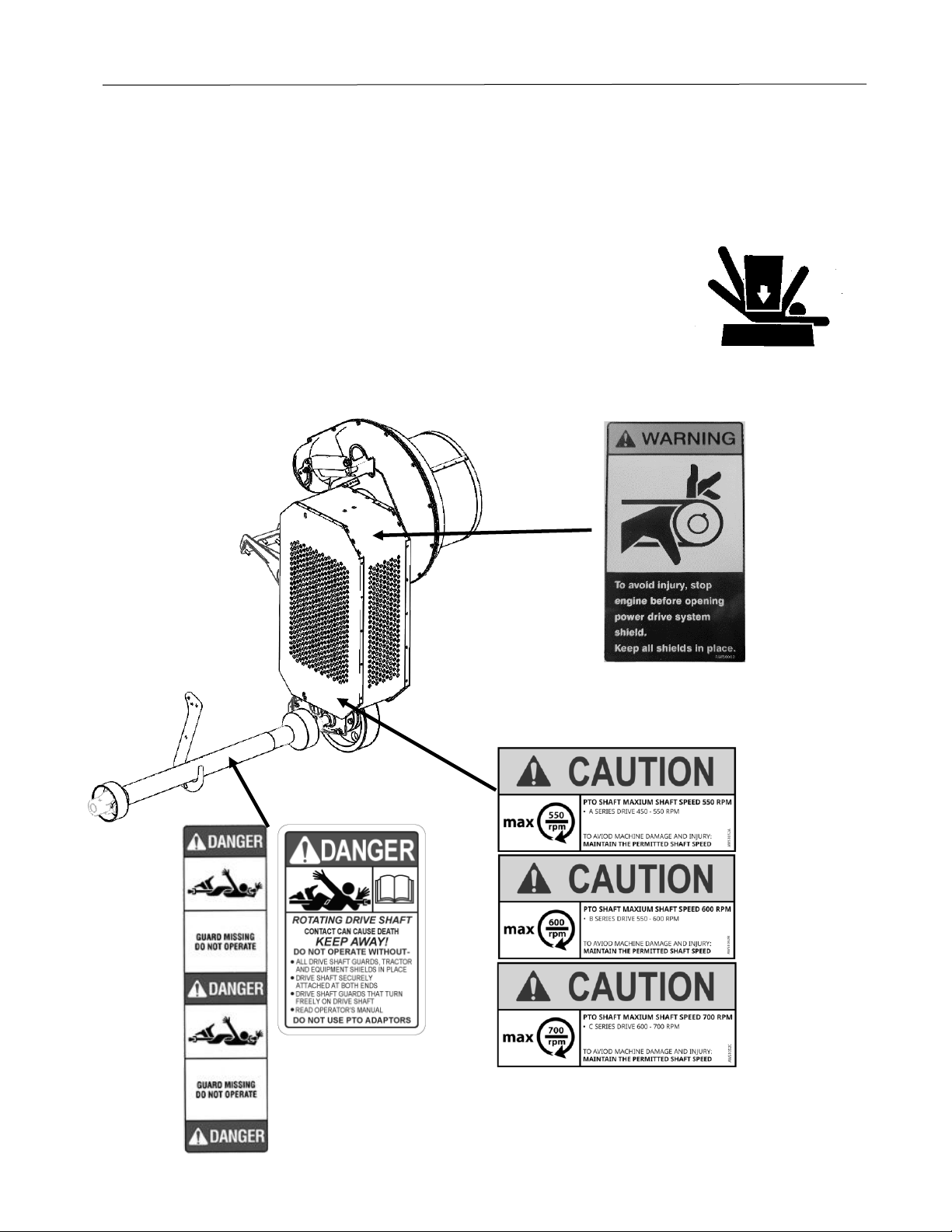

SAFETY DECALS .....................................................................................................................6

SYSTEM SETUP FOR OPERATION .............................................................. 7

WHEN CONNECTING THE HEADER..........................................................................................7

WHEN DISCONNECTING THE HEADER.....................................................................................7

OPERATING THE SYSTEM .......................................................................... 8

DAILY CHECKS .......................................................................................................................8

REEL POSITION......................................................................................................................8

MANIFOLD HEIGHT ADJUSTMENT..........................................................................................8

ELECTRICAL CONTROLS..........................................................................................................8

NOZZLE ROTATION ADJUSTMENT ..........................................................................................9

AIR FLOW ADJUSTMENT......................................................................................................10

MAINTENANCE .......................................................................................... 10

LUBRICATION...................................................................................................................... 11

NOZZLE INSPECTION............................................................................................................ 12

BELT /SHEAVE /IDLER CONDITION ...................................................................................... 13

BELT TENSION ..................................................................................................................... 13

BEARING SERVICE................................................................................................................14

BELT SERVICE ...................................................................................................................... 14

BLOWER INSPECTION .......................................................................................................... 15

ROTARY SCREEN.................................................................................................................. 15

MANIFOLD /AIR DUCTING...................................................................................................15

FASTENER TORQUE .............................................................................................................16