5

Mounting AX-Lightness and

engage Aheadset®-stems

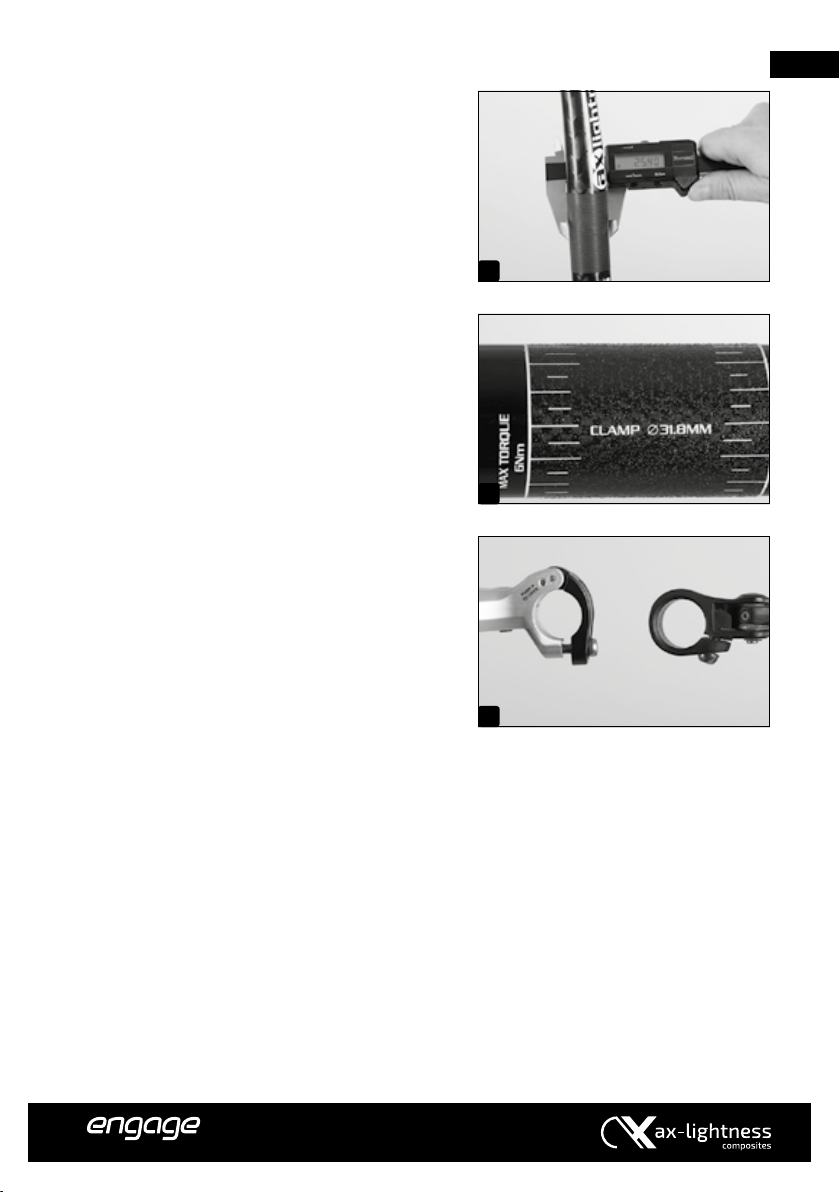

Many AX-Lightness (a) and engage stems can be

mounted in either vertical orientation. These ip-op

models allow handlebars to be positioned at two dif-

ferent heights by simply inverting the stem.

Make sure the AX-Lightness and engage stem and

fork steerer tube always have matching or compati-

ble clamp diameters (b)!

If you t a new AX-Lightness and engage stem on

a fork with carbon steerer tube, check the clamping

area of the fork for notches or abrasion marks. In case

damage is visible, ask your AX-Lightness and engage

dealer whether the fork must be replaced.

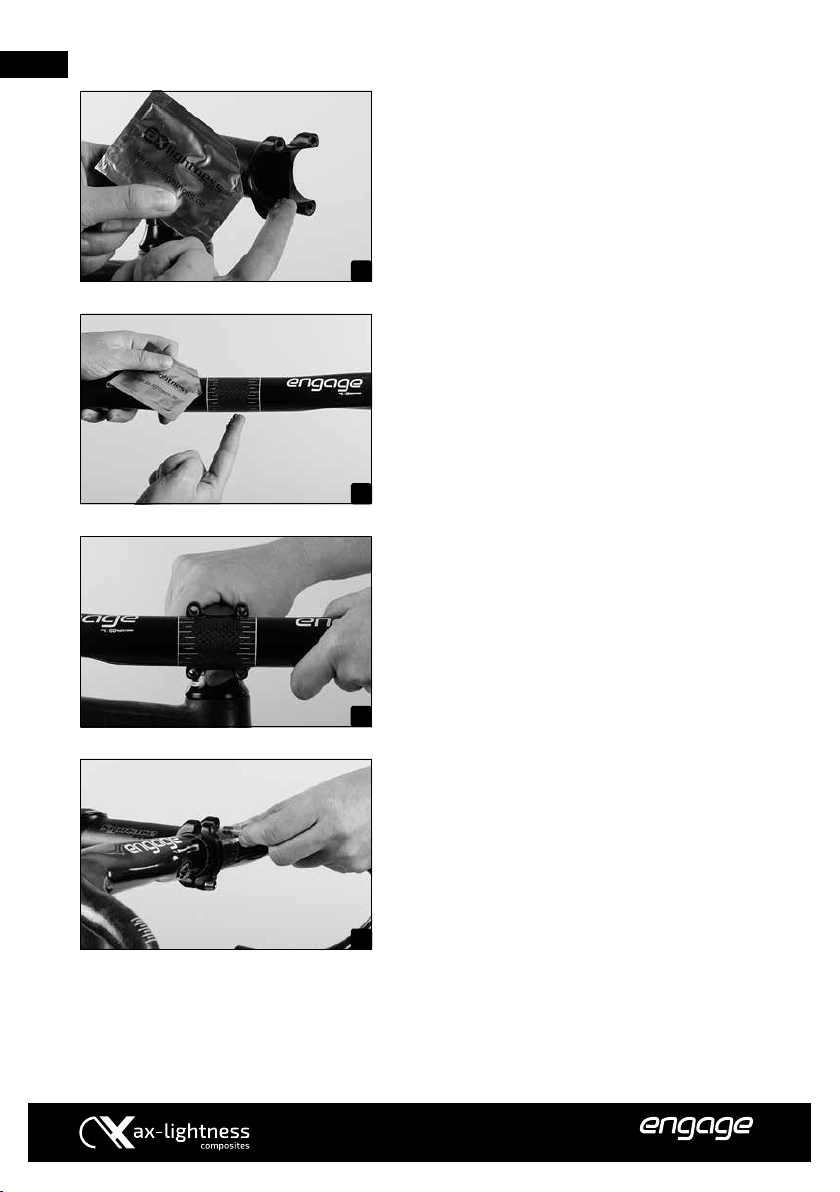

Make sure the clamping areas are absolutely free of

grease, especially when the clamping surfaces are

made of carbon. Use AX-Lightness carbon assembly

paste (c) on the clamping areas to optimize the xing.

Grease the threads and the connecting surfaces/

heads of the steerer clamp bolts (d). Keep lubricants

away from clamping surfaces.

Slide the AX-Lightness and engage stem on the fork

steerer tube (e). It must t snugly on the fork. Do not

t stems which have play on the steerer tube.

Depending on the steerer tube length and the de-

sired stem position, insert spacers (f) on the fork

steerer above the upper cover of the headset, and/

or above the stem. You can stack them up to a maxi-

mum height of 30 mm.

Spacers are available in dierent heights. You have

installed the correct number of spacers, when the

steerer tube ends 2 mm below the top edge of the

stem.

Make sure the stem provides sucient support for

the steerer tube and the steerer tube ends 2 mm at

the most below the top edge of the AX-Lightness and

engage stem. This ensures a reliably clamping when

tightening the clamping bolts of the steerer tube

clamp to the prescribed torque value.

If the preferred height of your AX-Lightness and

engage stem results in a deeper position of the stem

on the steerer tube, the steerer tube projects from the

stem. To check whether you have found the proper

position, slide spacers on the steerer by making sure

that the steerer tube ends 2 mm below the top edge

of the stem. After the test ride the steerer tube of a

carbon fork must be shortened.

For proper load distribution during clamping the

clamp bolts of AX-Lightness and engage stems are

designed to be screwed in in a determined direction

(g). Be sure not to change the screw-in direction.

Tighten the stem bolts only a little, if you intend to

mount the handlebar right afterwards. The headset

has to be adjusted afterwards (h) (see chapter “Ad-

justing the Aheadset®-headset”).

iAX-Lightness and engage stems are ip-

op models, i.e. they allow an upward or

downward oriented mounting.

gThe space between the top of the steerer

tube and the upper edge of the AX-Light-

ness and engage stem should not exceed

a maximum of 2 mm. The space between

the top of the steerer tube and the upper

edge of the AX-Lightness and engage stem

should not exceed a maximum of 2 mm.

gObserve the maximum spacer height of 30

mm and do not insert permanently more

than 5 mm of spacers above the stem, if

your fork steerer tube is made of carbon.

88 89

Handlebars - Stem

a

b

c

d

h

g

f

e

by ax-lightness