3

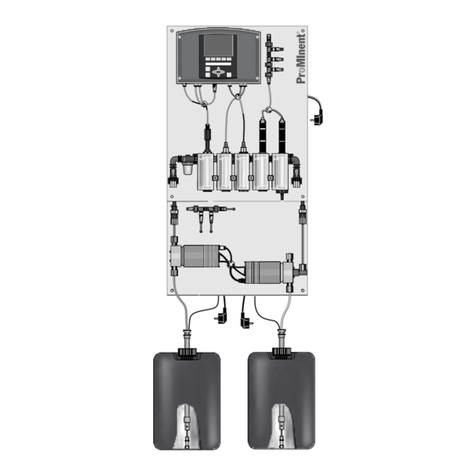

Installation and Start-Up Instructions

A. Uncrate, remove from pallet, and check for damage that may have occurred during shipping. If

damage occurred during shipment, file a claim with the shipping company.

B. If the Weight Scale option was purchased, remove the blocking under the scale that was used

for protection during shipment. NOTE that there is a separate manual for the weight scale.

C. Place the chlorination system in a location near the place of application.

D. Level the system with the supplied leveling bolts. This is important for proper chlorine delivery.

E. Install a pressure regulator on the inlet supply line IF inlet line pressure is greater than 50 psi.

Tank flooding will result if pressure exceeds 50 psi.

F. Float valve is rated to 50 psi. If supply exceeds 50 psi when water system is shut down, a

solenoid valve is required to be installed on the inlet line to prevent chlorination system

flooding. The solenoid valve must be interlocked with your water system pump. Solenoid valve

is not supplied with the P system.

G. Connect Power and Run signal wires (either 110v or dry contact) to the electrical box.

Schematics are shown on pages 6 & 7. A solenoid valve is recommended for municipal water

applications.

H. Connect the inlet flow meter assembly to the solution tank (the parts were shipped loose to

prevent breakage in shipping).

I. Connect the inlet water supply with 1-1/2” PVC pipe or hose. Include an isolation valve at the

main header line. If source water contains debris, include a filter in the line.

J. Connect the chlorine control and check valve assembly to the pump discharge. Close the

chlorine control valve completely. (The parts were shipped loose to prevent breakage in

shipment.)

K. Connect the discharge piping from the chlorine control valve to the chlorine application point

with 1-1/2” PVC pipe or hose. Include an isolation valve at the main header line.

L. Once the water input and output connections are in place, open isolation valves and check for

leaks. Water will begin to flow into the chlorinator and fill the solution tank.

M. Wait until water stops flowing into the solution tank. Open the chlorine control valve about 2-3

full turns, and break loose the upstream union on the flap check valve to prime the pump.

When water flows out, pump should be primed. Tighten union and start the discharge pump.

There is a delay timer for the pump. This is to prevent chattering under low level situations.