axiomametering.com 5

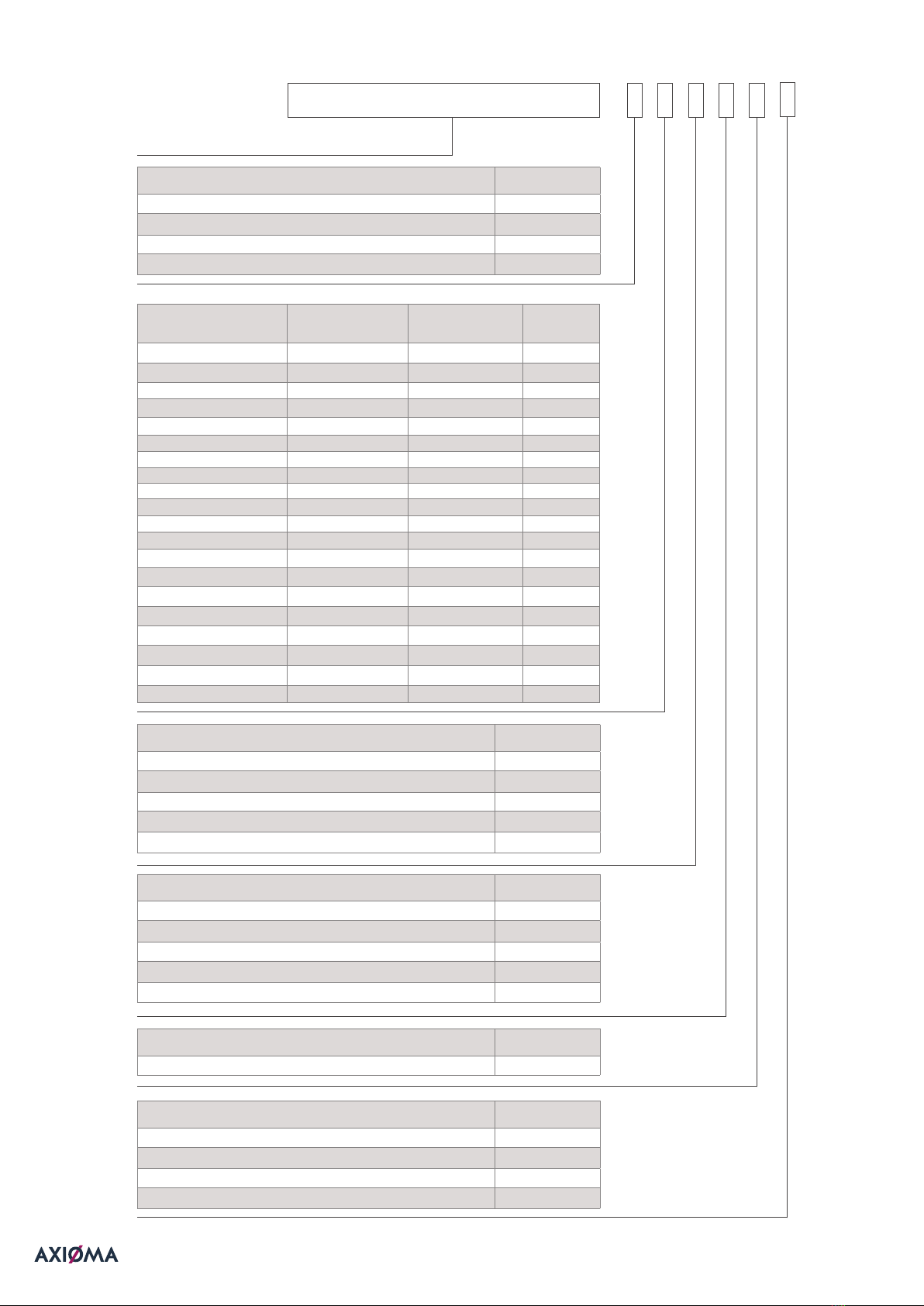

PERMANENT

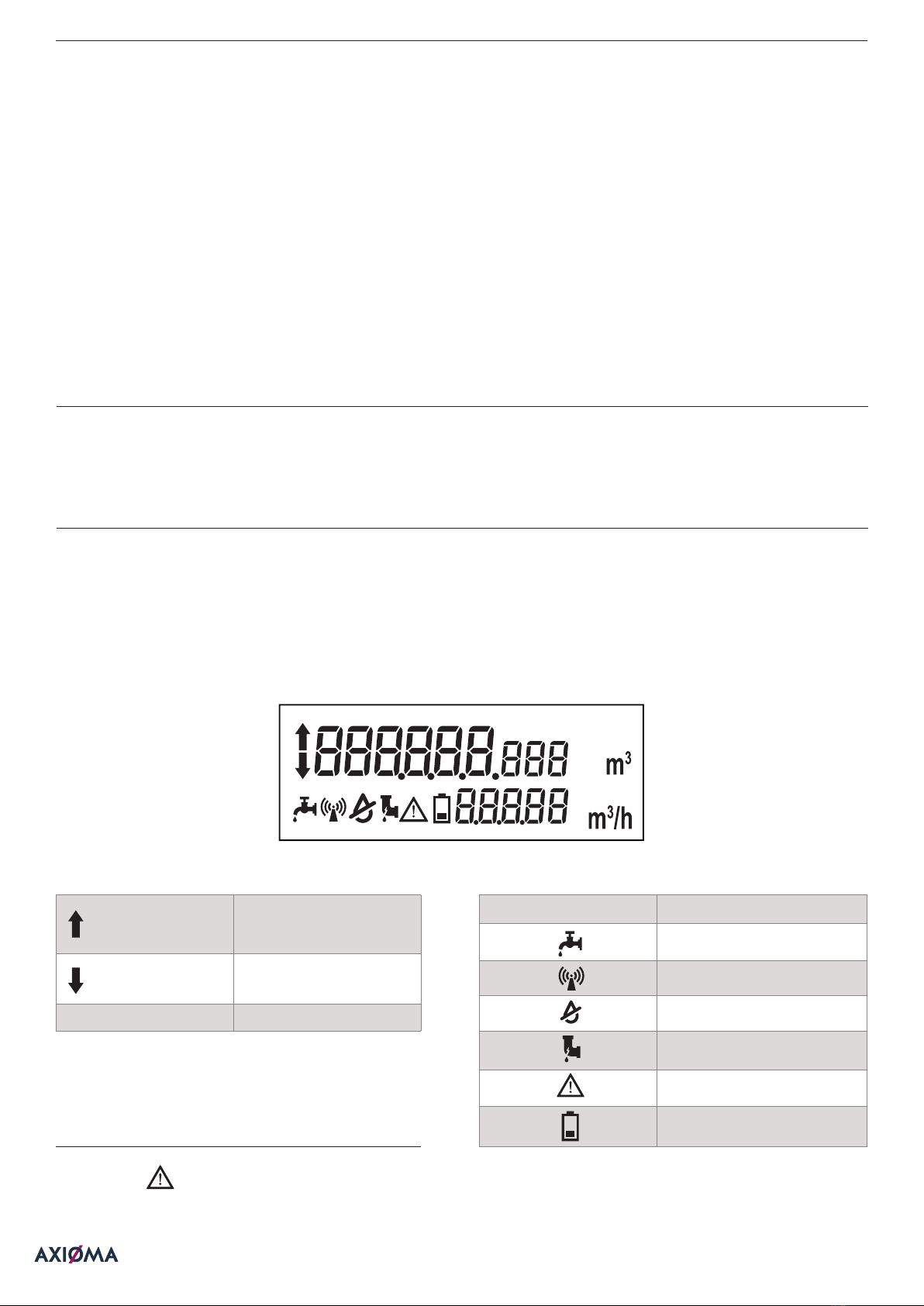

FLOW RATE

Q

3

, M

3

/H

RATIO R

Q3/Q1

OVERLOAD

FLOW RATE

Q

4

, M

3

/H

MINIMUM

FLOW RATE

Q

1

, M

3

/H

TRANSITIONAL

FLOW RATE

Q

2

, M

3

/H

THRESHOLD

VALUE,

M

3

/H

JOINING

TO THE

PIPELINE

(THREAD – G)

OVERALL

LENGTH L,

MM

PRESSURE

LOSS

CLASS ΔP

(BAR X 100)

1,6 250 2 0,0064 0,010 0,001 G ¾ 80 Δp 25

1,6 250 2 0,0064 0,010 0,001 G ¾ 105 Δp 25

1,6 250 2 0,0064 0,010 0,001 G ¾ 110 Δp 25

1,6 250 2 0,0064 0,010 0,001 G ¾ 165 Δp 25

1,6 250 2 0,0064 0,010 0,001 G ¾ 170 Δp25

1,6 315 2 0,005 0,008 0,001 G ¾ 80 Δp25

1,6 315 2 0,005 0,008 0,001 G ¾ 105 Δp25

1,6 315 2 0,005 0,008 0,001 G ¾ 110 Δp25

1,6 315 2 0,005 0,008 0,001 G ¾ 165 Δp25

1,6 315 2 0,005 0,008 0,001 G ¾ 170 Δp25

1,6 400 2 0,004 0,0064 0,001 G ¾ 80 Δp25

1,6 400 2 0,004 0,0064 0,001 G ¾ 105 Δp25

1,6 400 2 0,004 0,0064 0,001 G ¾ 110 Δp25

1,6 400 2 0,004 0,0064 0,001 G ¾ 165 Δp25

1,6 400 2 0,004 0,0064 0,001 G ¾ 170 Δp25

2,5 250 3,125 0,01 0,016 0,001 G ¾ 80 Δp40

2,5 250 3,125 0,01 0,016 0,001 G ¾ 105 Δp40

2,5 250 3,125 0,01 0,016 0,001 G ¾ 110 Δp40

2,5 250 3,125 0,01 0,016 0,001 G ¾ 165 Δp40

2,5 250 3,125 0,01 0,016 0,001 G ¾ 170 Δp40

2,5 400 3,125 0,0062 0,010 0,001 G ¾ 80 Δp40

2,5 400 3,125 0,0062 0,010 0,001 G ¾ 105 Δp40

2,5 400 3,125 0,0062 0,010 0,001 G ¾ 110 Δp40

2,5 400 3,125 0,0062 0,010 0,001 G ¾ 165 Δp40

2,5 400 3,125 0,0062 0,010 0,001 G ¾ 170 Δp40

2,5 800 3,125 0,0031 0,005 0,001 G ¾ 80 Δp40

2,5 800 3,125 0,0031 0,005 0,001 G ¾ 105 Δp40

2,5 800 3,125 0,0031 0,005 0,001 G ¾ 110 Δp40

2,5 800 3,125 0,0031 0,005 0,001 G ¾ 165 Δp40

2,5 800 3,125 0,0031 0,005 0,001 G ¾ 170 Δp40

2,5 250 3,125 0,01 0,016 0,001 G1 105 Δp25

2,5 250 3,125 0,01 0,016 0,001 G1 110 Δp25

2,5 250 3,125 0,01 0,016 0,001 G1 130 Δp25

2,5 250 3,125 0,01 0,016 0,001 G1 165 Δp25

2,5 250 3,125 0,01 0,016 0,001 G1 190 Δp25

2,5 400 3,125 0,0062 0,010 0,001 G1 105 Δp25

2,5 400 3,125 0,0062 0,010 0,001 G1 110 Δp25

2,5 400 3,125 0,0062 0,010 0,001 G1 130 Δp25

2,5 400 3,125 0,0062 0,010 0,001 G1 165 Δp25

2,5 400 3,125 0,0062 0,010 0,001 G1 190 Δp25

4 250 5 0,016 0,025 0,002 G1 105 Δp40

4 250 5 0,016 0,025 0,002 G1 110 Δp40

4 250 5 0,016 0,025 0,002 G1 130 Δp40

4 250 5 0,016 0,025 0,002 G1 165 Δp40

4 250 5 0,016 0,025 0,002 G1 190 Δp40

4 400 5 0,01 0,016 0,002 G1 105 Δp40

4 400 5 0,01 0,016 0,002 G1 110 Δp40

4400 5 0,01 0,016 0,002 G1 130 Δp40

4 400 5 0,01 0,016 0,002 G1 165 Δp40

4 400 5 0,01 0,016 0,002 G1 190 Δp40

4 800 5 0,005 0,008 0,002 G1 105 Δp40

4 800 5 0,005 0,008 0,002 G1 110 Δp40

4 800 5 0,005 0,008 0,002 G1 130 Δp40

4 800 5 0,005 0,008 0,002 G1 165 Δp40

4 800 5 0,005 0,008 0,002 G1 190 Δp40

2 TECHNICAL DATA

Ratio of the permanent flow rate to the lower limit of the flow-rate (selectable by the user):

Q

3

/Q

1

= 250 , Q

3

/Q

1

= 315, Q

3

/Q

1

= 400, Q

3

/Q

1

= 800

The technical data of the meter are provided in Table 1.1.

1.1. Table