GENERAL INSTRUCTIONS FOR 230V MACHINES

5

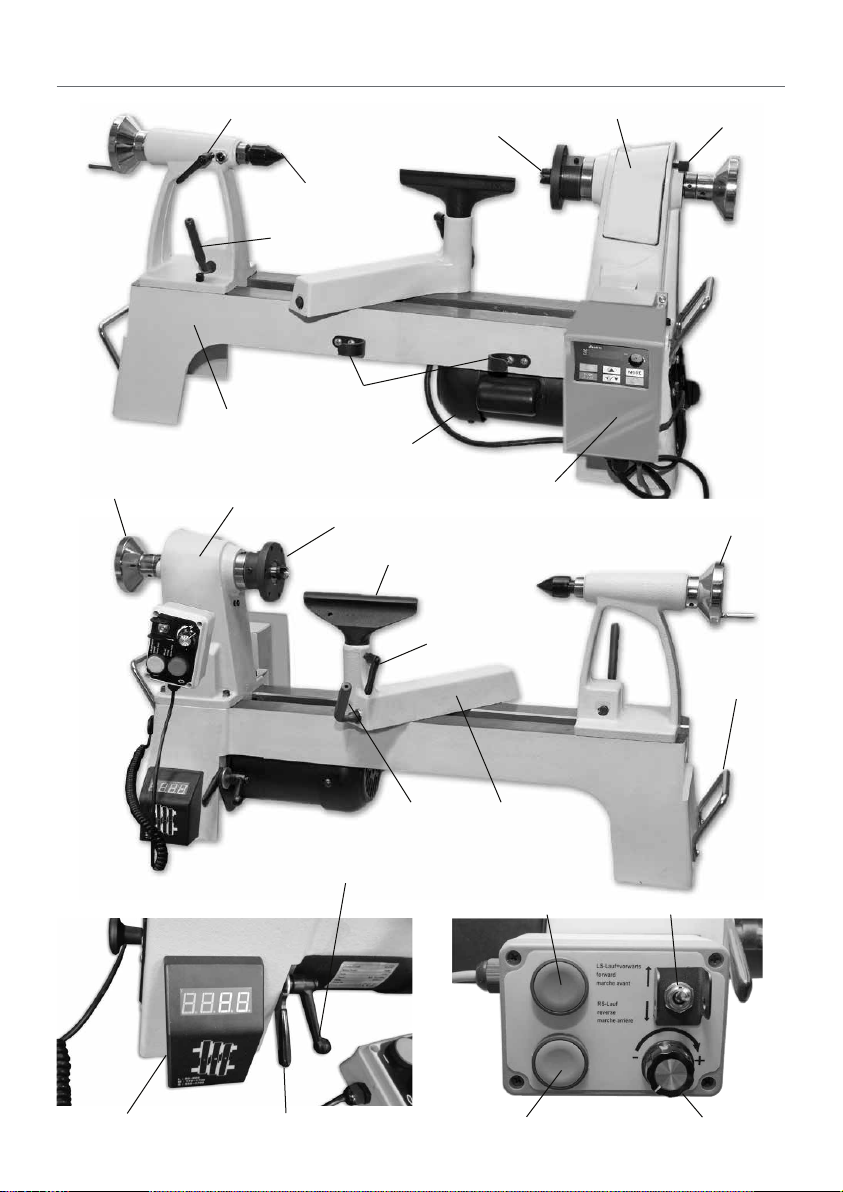

Code 501214

Model AT350WL

Rating Trade

Power 230V 50Hz 750W

Speed L = Low 80-800, M = Medium 170-1700, S = High 350-3,700rpm

Spindle Taper 2 MT

Spindle Thread M33 x 3.5mm (Ref T38)

Taper Tailstock 2 MT

Distance Between Centres 400 mm

Max Diameter over Bed 350 mm

Tool Rest Stem Diameter 25.4 mm

Overall L x W x H 865 x 330 x 415mm (With Extension Bed: 1,465 x 330 x 415 mm)

Weight 41 kg

SPECIFICATION

Make sure you are comfortable before you start work,

balanced,not reaching etc.

If the work you are carrying out is liable to generate

flying grit, dust or chips, wear the appropriate safety

clothing, goggles, gloves, masks etc. If the work

operation appears to be excessively noisy, wear

ear-defenders. If you wear your hair in a long style,

wearing a cap, safety helmet, hairnet, even a

sweatband, will minimise the possibility of your hair

being caught up in the rotating parts of the tool,

likewise, consideration should be given to the

removal of rings and wristwatches, if these are liable

to be a ‘snag’ hazard.Consideration should also be

given to non-slip footwear, etc.

DO NOT work with cutting tools of any description if

you are tired, your attention is wandering or you

are being subjected to distraction. A deep cut, a

lost fingertip or worse; is not worth it! Above all,

OBSERVE…. make sure you know what is happening

around you, and USE YOUR COMMON SENSE.

SPECIFIC SAFETY INSTRUCTIONS

1. Do not use ‘split’ work pieces.

2. Always start at the lowest speed when starting a

new task.

3. Check that the tool rest is at or slightly below the

centre line of the workpiece.

4. Check the work piece is securely mounted in the

lathe before switching on the power.

5. Rotate the work piece by hand, to check that it

is centralised, clear of the tool rest, not‘split’ or has

loose knots.

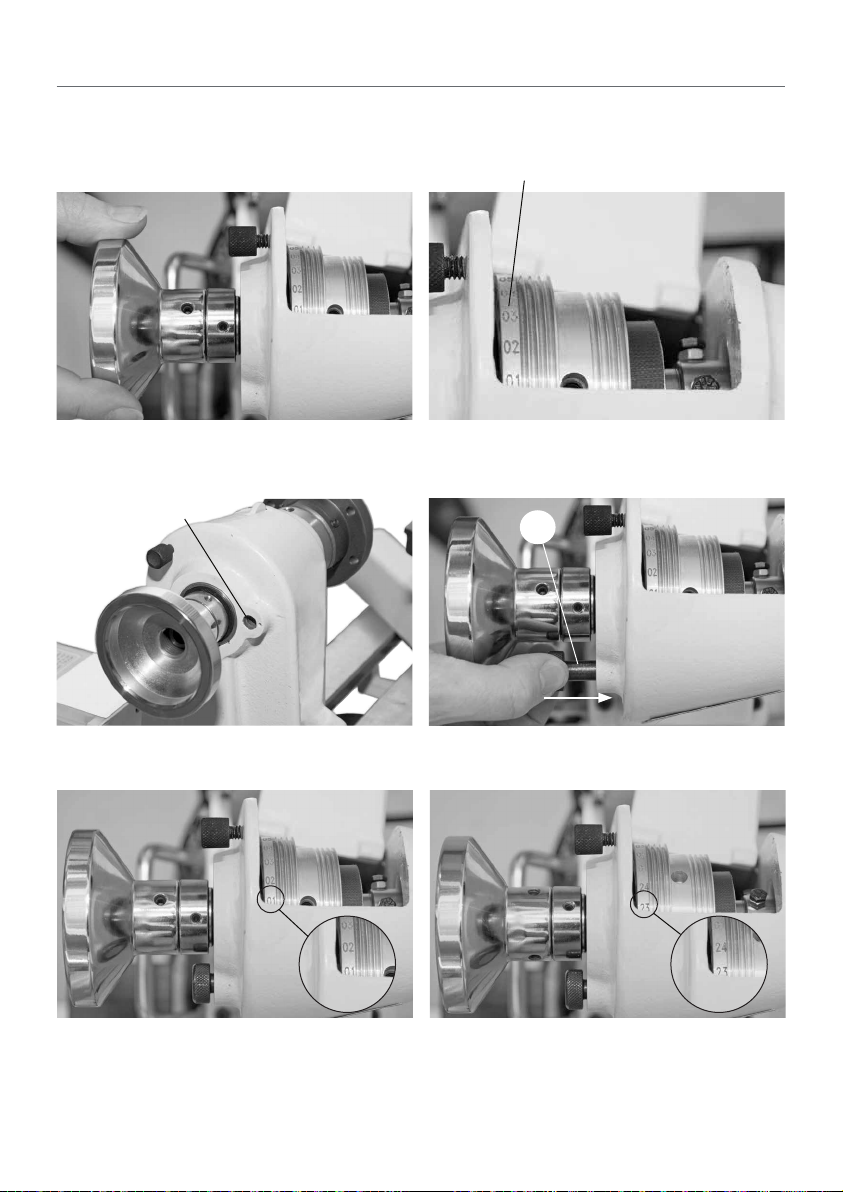

6. Where lathes have the facility to be reversed;

check the machine is rotating in the correct

direction.

7. If your lathe has the facility to run in reverse, you

must ensure that the mounting accessories (chucks,

faceplates etc.,) can be‘locked’ onto the lathe

mandrel, and in the case of chucks have some form of

security device to prevent them‘unwinding’ during

reverse operation.

8. Make sure your tools are stored/racked away from

the turning area of the lathe. Do not reach over a

rotating work piece at any time.

9. Do not ‘dig in’ or try to take too large a cut.

10. Do not leave the lathe running unattended; or

leave the machine until everything is stopped.

11. Some turning tools may have specific sharpening

angles that have been determined by the

manufacturers; when re-sharpening, adhere to these

angles to maximise the finish of your work.