© 2010 Axxiom Manufacturing, Inc.

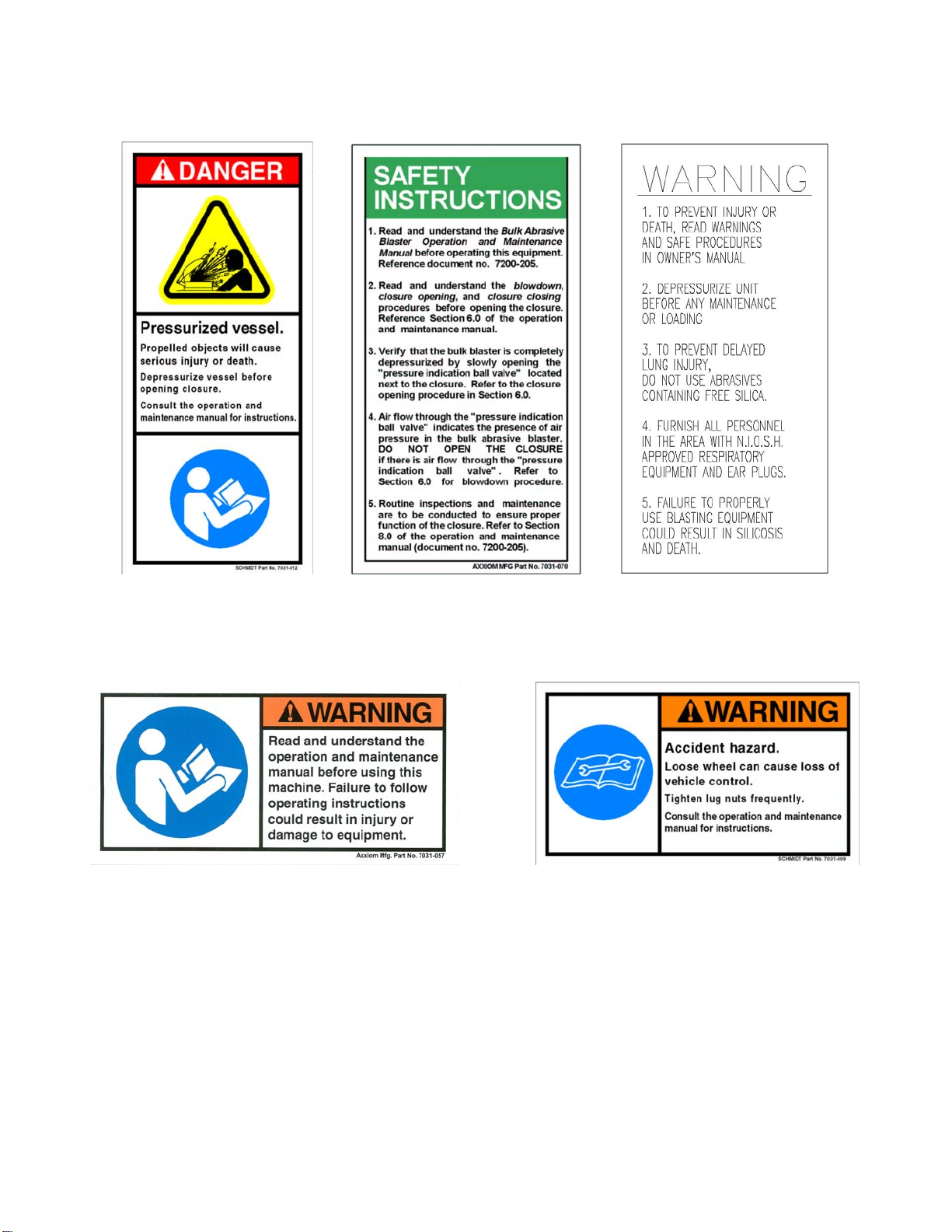

WARNING

1. Any person intending to operate this equipment or any person intending to be in the vicinity

during its operation must receive proper training from his/her supervisor, employer and/or

supplier. If this equipment is to be leased or rented, the supplier must assure that the lessee or

renter has received proper training before the lessee or renter takes possession of the

equipment. Consult Axxiom Manufacturing, Inc.

2. Any person authorized to operate this equipment or any person intending to be in the vicinity

during its operation and who is not capable of reading and understanding this manual must

be fully trained regarding the Rules for Safer Operation and all operating procedures, and

must be made aware of all the Dangers, Warnings, and Cautions identified herein. Consult

Axxiom Manufacturing, Inc.

3. Do Not operate any abrasive blaster or blast equipment before reading and completely

understanding all the warnings, operating procedures and instructions, and the Rules for

Safer Operation contained in this manual.

4. Do Not operate any abrasive blaster or blast equipment without following the Rules for Safer

Operation and all the operating procedures and instructions. Failure to properly use blast

equipment could result in serious injury or death.

5. Do Not perform any maintenance on any abrasive blaster or blast equipment while it is

pressurized. Always depressurize the abrasive blaster vessel before loading abrasive or

performing any maintenance.

6. Do Not use abrasives containing free silica. Silica can cause silicosis or other related

respiratory damage. All operators must wear personal protective equipment for all abrasive

blasting operations. Observe all applicable local, state and federal safety regulations in

conjunction with airline filters and respiratory protection. Reference OSHA 29 CFR

1910.134.

7. Do Not enter areas during abrasive blasting operations without breathing protection. All

personnel in the vicinity of abrasive blasting operations should wear NIOSH approved air fed

respirators, hoods or helmets.

8. Do Not modify or alter any abrasive blaster, blast equipment or controls thereof without

written consent from Axxiom Manufacturing, Inc.

9. Do Not use bleeder type deadman valves on any Schmidt® abrasive blaster. The use of A-

BEC, Clemco or a similar bleeder type deadman valve can cause unintentional start-up

without warning, which can result in serious personal injury.

10. Do Not sell, rent, or operate abrasive blasters without remote controls. OSHA regulations

require remote controls on all blast machines. Failure to use remote controls can cause

serious injury or death to the operator(s) or other personnel in the blasting area. Reference

OSHA 29 CFR 1910.244(b).

11. Do Not repair or replace any portion of Schmidt® equipment using components that are not

Schmidt® original factory replacement parts. Use of replacement components that are not

Schmidt® original factory replacement parts may result in equipment failure which can

result in serious personal injury and in addition will void all warranties.

12. Do Not transport trailer mounted bulk blasters on public roadways with abrasive loaded in

pressure vessel.

13. Do Not tow trailer mounted bulk blasters at speeds exceeding 65 mph.