AB-7043

3

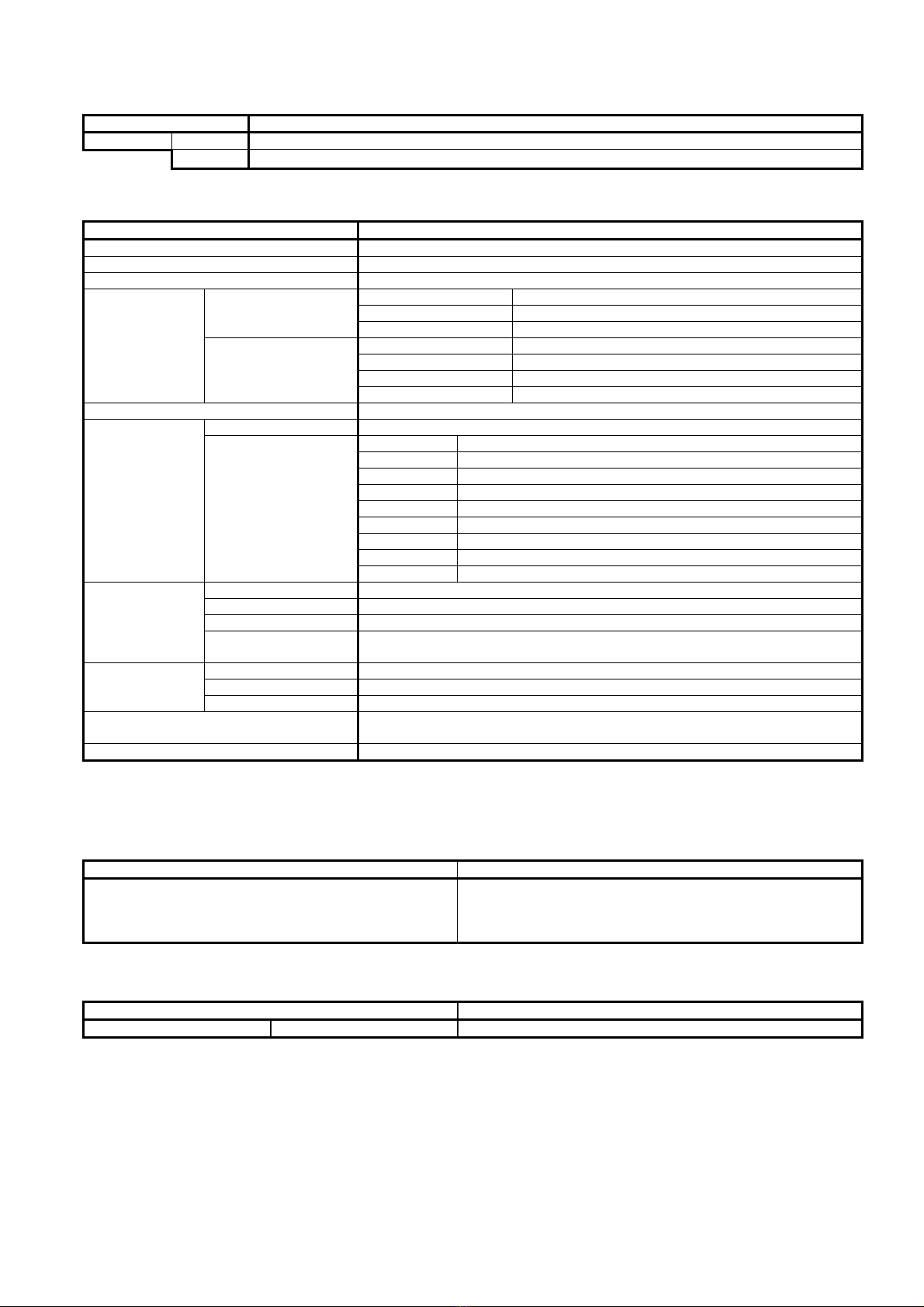

Model Number

Model number Description

QY5010 Base model number of Display Panel for Model FVY513_J/FVY514_J/FVY515_J

S1000 Power supplied from Model FVY513_J/FVY514_J/FVY515_J

Specifications

Item Specification

Power supply 12 V DC 1 V (supplied from Model FVY513_J/FVY514_J/FVY515_J

Power consumption Max. 0.1 VA

Cable JIS VCTF (0.3 mm2 4 cores) cable

Environmental

conditions

Rated operating

condition*1

Ambient temperature 0 C to 50 C

Ambient humidity 10 %RH to 85 %RH (non-condensing)

Vibration 5.9 m/s2 (10 Hz to 150 Hz)

Transport/storage

conditions

Ambient temperature -20 C to 70 C

Ambient humidity 10 %RH to 85 %RH (non-condensing)

Vibration (storage) 5.9 m/s2 (10 Hz to 150 Hz)

Vibration (transport) 9.8 m/s2 (10 Hz to 150 Hz)

Enclosure rating IEC IP40 (dustproof)

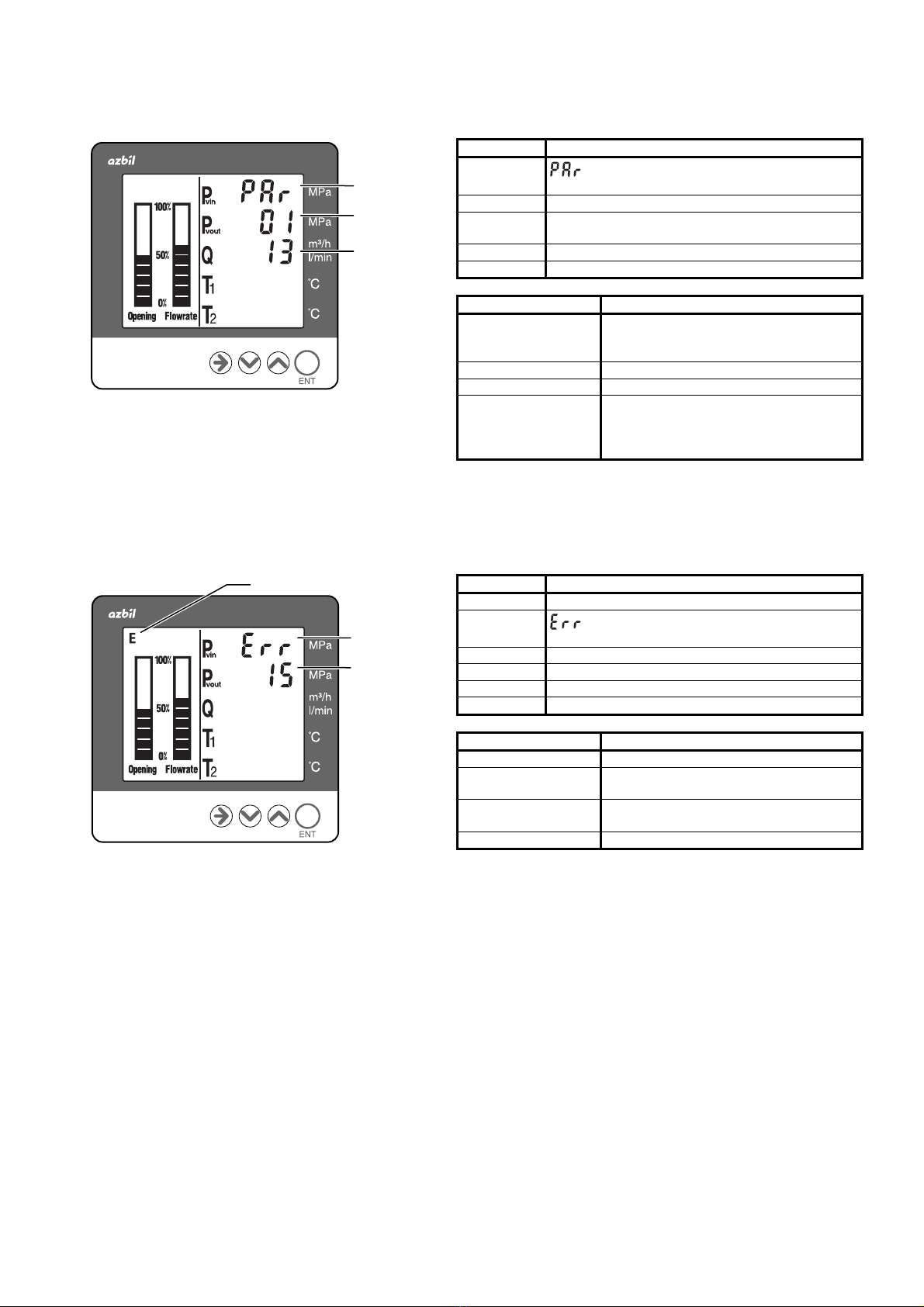

Display*2 Device Liquid Crystal Display (LCD)

Items to display Pvin Valve inlet pressure (MPa or kPa)

Pvout Valve outlet pressure (MPa or kPa)

Q Actual flow (m3/h or l/min)

T1 Coil inlet temperature (C)

T2 Coil outlet temperature (C)

HC Heat/Cool

E Error

Opening Actual valve position (% in bar graph)

Flowrate Actual flow rate (% in bar graph)

Communication Transmission system AP-bus (RS-485 communication)

Transmission speed 4800 bps

Transmission distance Max. 50 m

Number of Display Panel

connectable One per single Model FVY513_J/FVY514_J/FVY515_J

Materials Case Modified polyphenylene ether (PPE)

Base plate Modified polyphenylene ether (PPE)

Face plate Polyester (PET)

Accessory - Two tapping screws (M4) for mounting

- Two 'kPa' unit stickers

Weight 150 g

Notes:

*1 LCD service life may shorten if Display Panel is used in an environment with high temperature and humidity.

*2 For display accuracy, refer to specification data of Model FVY513_J/FVY514_J/FVY515_J.

Recommended Wire Specifications

Cable type Wiring length

Flexible cable (Cabtire cable), 0.3 mm2 × 4-core,

dia. 4.5 mm to dia. 6.0 mm /

JIS*3 VCTF cable , 0.3 mm2 × 4-core , dia. 4.5 mm to dia. 6.0 mm.

(Cable is not supplied with Display Panel.)

50 m

*3 JIS: Japanese Industrial Standards

Option

Item Note

Waterproof box Part No. 83170324-001 Required when Display Panel is installed outdoors.