v

Detailed Table of Contents

Chapter 1 - Configuration and Structure of the Measuring

Systems ........................................................................... 1 - 1

Outline of this chapter ....................................................... 1 - 1

1.1 System Configuration ....................................................... 1 - 2

Measuring System ............................................................ 1 - 2

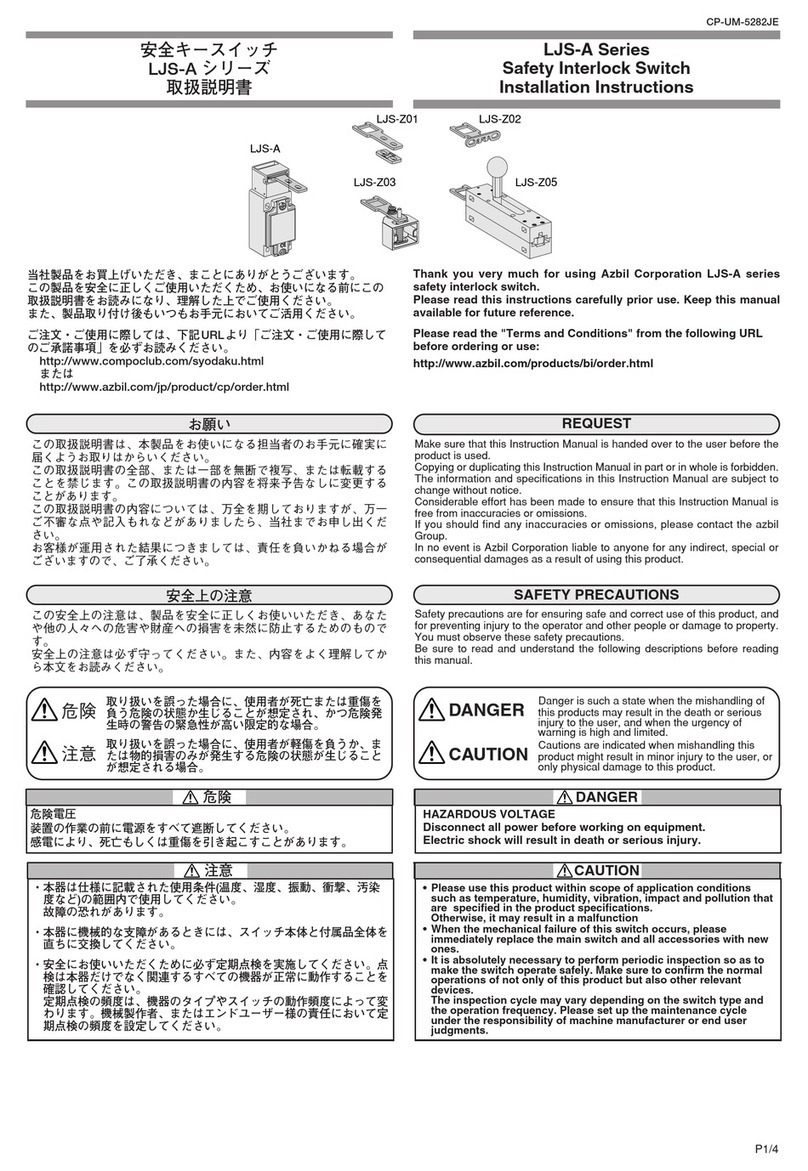

1.2 Structure of this Unit and Functions of Parts .................... 1 - 4

Structure of the Device ..................................................... 1 - 4

Chapter 2 - Installing the Device ....................................................... 2 - 1

Outline of this chapter ....................................................... 2 - 1

2.1 Before Installation ............................................................. 2 - 2

Selecting the Installation Site (1) ...................................... 2 - 2

2.2 Installation Method ........................................................... 2 - 3

Installing the Converter ..................................................... 2 - 3

Electrical Wiring (1)........................................................... 2 - 5

Electrical Wiring (2)........................................................... 2 - 7

Electrical Wiring (3)........................................................... 2 - 10

Electrical Wiring (4)........................................................... 2 - 11

Chapter 3 - Operating and Stopping of the Measuring System ..... 3 - 1

Outline of this chapter ....................................................... 3 - 1

3.1 Start-up ............................................................................. 3 - 2

3.2 Preparations before Measurement ................................... 3 - 3

Zero Adjustment (1) .......................................................... 3 - 3

Method Using the Data Setting Device ............................. 3 - 4

3.3 Stopping ........................................................................... 3 - 6

3.4 Setting Write Protection .................................................... 3 - 7

Chapter 4 - Operation Using the Data Setting Device ..................... 4 - 1

Outline of this chapter ....................................................... 4 - 1

4.1 Functions of the Data Setting Device ............................... 4 - 2

Data Setting Device .......................................................... 4 - 2

Operating the Display/Data Setting Device ...................... 4 - 5

Screen Organization ......................................................... 4 - 7

Measuring Mode ............................................................... 4 - 9

How to Skillfully Operate the Touch Key Switches ........... 4 - 10

How to Enter the Operator's Mode ................................... 4 - 11

Operating in Operator’s Mode .......................................... 4 - 12

Resetting the Damping Time Constant ............................. 4 - 13

Zero Adjustment ............................................................... 4 - 14

Setting/Changing the Flow Rate Indication ...................... 4 - 16

Selecting Modes ............................................................... 4 - 17

Engineering Mode............................................................. 4 - 19

Setting the ID .................................................................... 4 - 20

Detector Data Setup ......................................................... 4 - 21

Setting the Range ............................................................. 4 - 23

Setting the Specific Gravity............................................... 4 - 24

Setting alarm contact 1 ..................................................... 4 - 25

Setting alarm contact 2 ..................................................... 4 - 26

Setting alarm hysteresis ................................................... 4 - 27