5

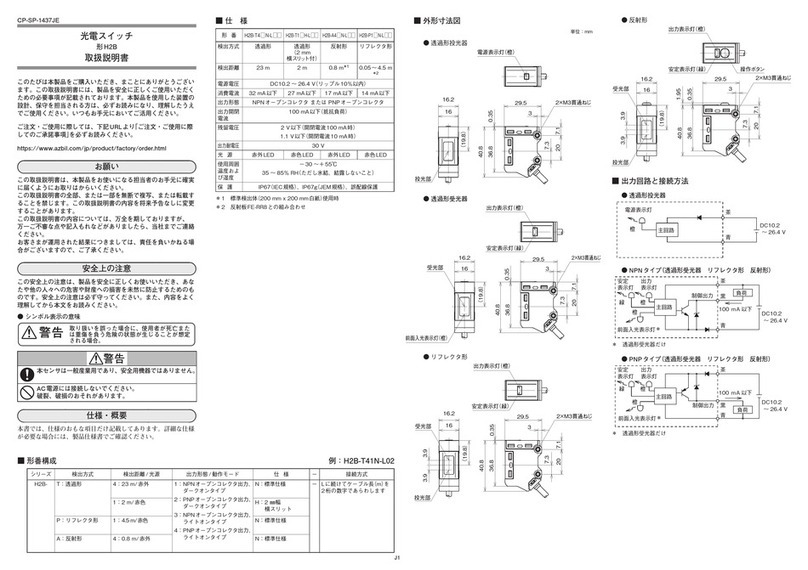

Catalog

listing

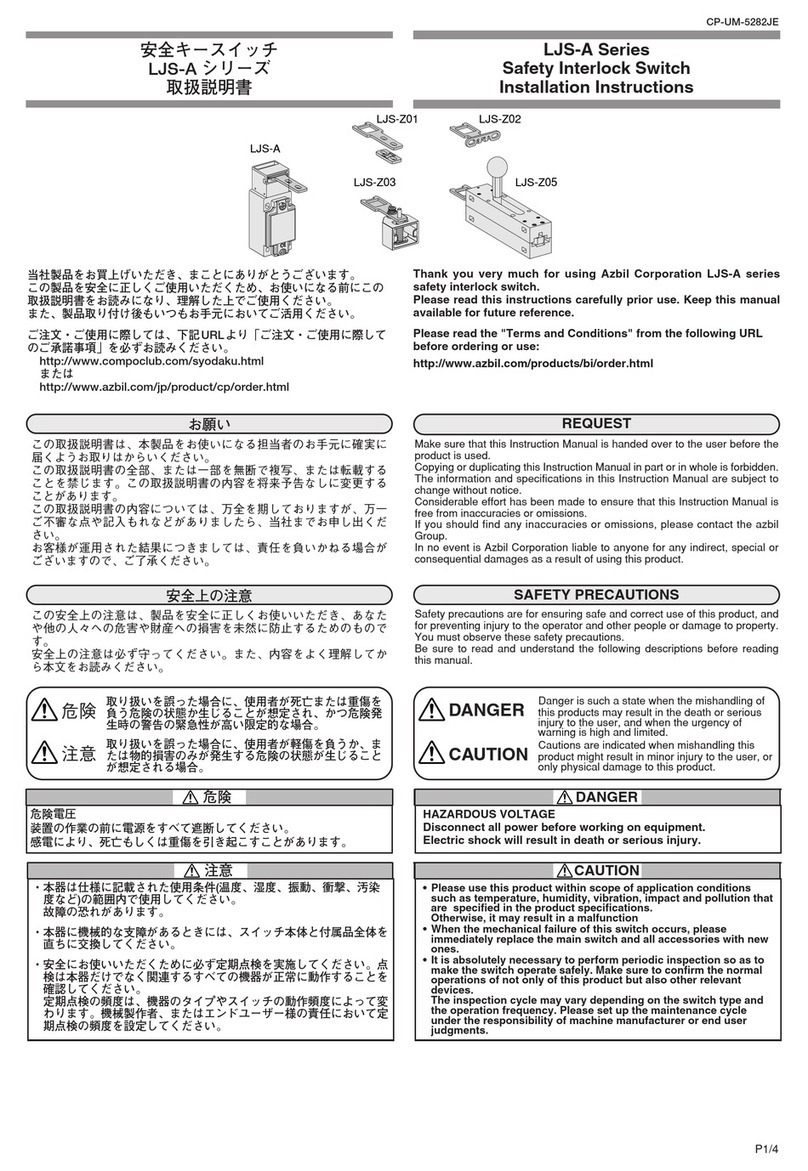

NPN HP7-P11 HP7-T51 HP7-T11 (Red)

HP7-T21 (Infrared)

HP7-T41 HP7-A13 HP7-A43 HP7-D23 HP7-D63 HP7-C11S

PNP HP7-P12 HP7-T52

HP7-P51

HP7-P52 HP7-T12 (Red)

HP7-T22 (Infrared)

HP7-T42 HP7-A14 HP7-A44 HP7-D24 HP7-D64 HP7-C12S

Detection

method

Retroreflective*2 Thru-scan Diffuse-scan Retroreflective transparent

object detection

Power supply

10.2 to 26.4 Vdc (Ripple 10% max.)

Power

consumption

− −−

14 mA max.

22 mA max.

25 mA max. (Red)

30 mA max. (Infrared)

32 mA max. 14 mA max. 17 mA max.

17 mA max. 15 mA max.

Scanning

distance

5 m (with

FE-RR8

reflector)

4 m 15 m 30 m 0.5 m 1 m 100 mm 50 mm

0.05 to 0.5 m

(when combined with

FE-RR17C reflector)

Target object

Opaque object 80 mm

dia. min(with

FE-RR8

reflector)

Opaque object 12 mm dia. min. Standard target object: 200 × 200 mm

paper, 90 % reflectivity

10% light blockage or more,

50 × 50 mm or more

(when combined with

FE-RR17C reflector)

Differential travel

20% max. (at rated scanning distance)

Operation mode

Light-operate / Dark-operate selectable by operation button

Output mode*1

NPN open collector / PNP open collector

Control output

Switching current: preleaded. Preleaded connector type 100 mA (Resistance load)

M8 connector type and low-temperature cable type 50 mA (Resistance load)

Output withstand voltage: 30 V

Residual voltage: 2 V or lower (at switching current of 100 mA/50 mA),

1.1 V or less (at switching current below 10 mA)

Switching current: 50 mA or

lower (Resistive load)

Output withstand voltage: 30 V

Residual voltage: 1 V or less

Response time*3

1 msec

1 msec (Different frequency model: 3 ms)

1 msec 1 msec

Light source

Red, 4 elements

(Wavelength approx.

645 nm)

Red, 4

elements

(Wavel-

ength

approx.

645 nm)

Red, 4 elements

(Wavelength

approx. 645 nm)

Infrared

(Wavelength

approx. 860 nm)

Infrared

(Wavel-

ength

approx.

860 nm)

Red, 4

elements

(Wavel-

ength

approx.

645 nm)

Infrared

(Wavelength approx. 860 nm)

Red, 4 elements

(Wavelength approx.

645 nm)

Scanning angle

0.5 to 10°

3 m (with

FE-RR8

reflector)

2 to 20° Switch: 0.5° to 10°

Indicator

Output ON: orange indicator ON. At stable light and stable dark: green indicator

Thru-scan emitter: power indicator, 30 m thru-scan receiver: light-operated indicator on front

Ambient light

immunity

Incandescent lamp: 10,000 lux max. Sunlight: 40,000 lux max. HP7-T_, HP7-P_, HP7-C_: Minimum angle of incidence of surrounding light = 5°

HP7-A_: Minimum angle of incidence of surrounding light = 15° HP7-D_:Figures apply to indirect illumination.

Operating

temperature

-30 to + 55˚C (without freezing or condensation)

*6

-10 to + 55˚C (without freezing

or condensation)

*6

Storage temperature

-40 to + 70˚C (without freezing or condensation)

Operating humidity

35 to 85% RH (without freezing or condensation)

Insulation resistance

20M min. (at 500Vdc)

Dielectric strength

1,000Vac 50/60Hz for one minute between electrically live metal and case

Vibration resistance

10 to 55Hz, 1.5 mm peak-to-peak amplitude, 2 hours each in X, Y, and Z directions

Shock resistance

500 m/s 10 times each in X, Y and Z directions

Sensitivity adjustment

Operation button

Protective structure

IP67 (IEC standard)

Wiring method

HP7-_ _: preleaded 2 m, HP7-_-L050: preleaded 5 m, HP7-_-C003: M12 preleaded connector 30 cm, HP7-_-T: M8 connector

Circuit

protection

Error prevention circuit at power on (max. 60 ms)

Full wiring error protection

Error prevention circuit at

power on (max. 80 ms)

Power supply reverse polarity

protection, output

short-circuit protection

Interference

suppression*5

Diffuse-scan, retroreflective, retroreflective transparent object detection models up to 2 units.

Thru-scan models with different frequencies, up to 2 units. Thru-scan models with mutual interference prevention filter*4

(for red), up to 2 units.

Different frequency models + mutual interference prevention filters (for red), up to 4 units.

*1. An FET is used for output

*2. Retroreflective switches feature polarizing filters; however, performance may be affected by highly reflective objects and objects that interfere with polarization.

*3. Response time may be longer if affected by light from other switches.

*4. Mutual interference protection filters are for red light source.

*5. Avoid operating diffuse-scan switches head-on when using gang mounting.

*6. In a low-temperature environment (0° or below), the standard cable will harden. Low temperature cables are available. Contact our branch or sales office to order.

(Not available for HP7-C1_S.)

Thru-scan emitter (NPN output type)

Polarized retroreflector model,

Thru-scan receiver, Diffuse-scan mode

(PNP output type)

Polarized retroreflector model,

Thru-scan receiver, Diffuse-scan model

Main

circuit

Control output

Brown

Load

100 mA max.

10.2 to

26.4

Vdc

Black

Blue

1

4

3

Main

circuit

Brown

10.2 to

26.4

Vdc

Blue

1

3

Main

circuit

Control output

Brown

Load

100 mA max. 10.2 to

26.4

Vdc

Black

Blue

1

4

3

OUTPUT CIRCUIT DIAGRAM (Note that a FET is used for output)

−