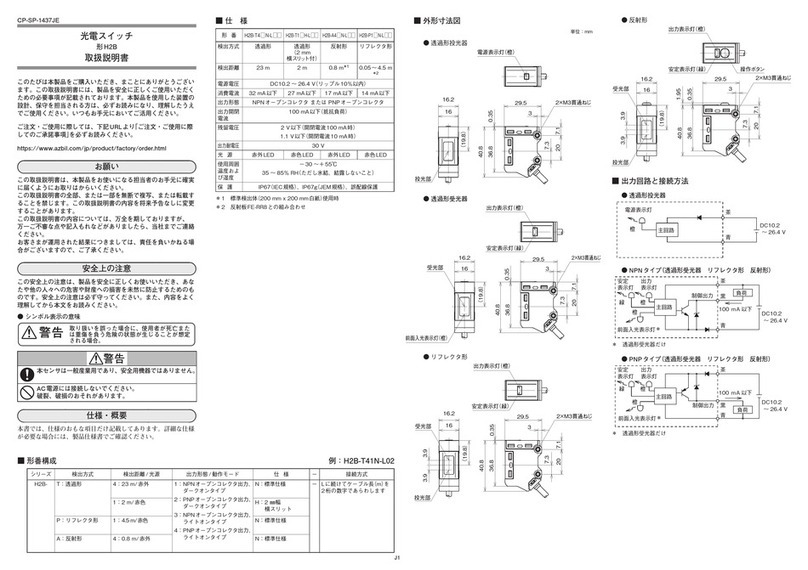

In case of either 100 Vac or 200 Vac, the voltage which is applied

to the load in the ON condition is VL = VS - (output voltage drop

x number of units) (V). Note that the load will not be activated

unless VL is more than the minimum activating voltage of the

load.

When more than 2 units are connected in series and are used in

an AND switching circuit, the maximum number of units is 3.

(Pay attention to the VS value shown in the figure below.)

In principle it is not possible to use more than 2 proximity

switches in parallel as an OR switching circuit. A parallel

connection can be used only if A and B do not operate at the

same time and if it is not necessary to hold the load. However,

consumption current (leakage current) will be multiplied by n (the

number of proximity switches), and recovery failure will occur

more easily.

If A and B operate at the same time and if it is necessary to

retain the load, a parallel connection cannot be used. Under

these conditions, when A is turned ON, the voltage at both ends

of A and B drops to approx. 10V, allowing load current to flow

through A. When a target object approaches B, the switching

element of B cannot be activated because the voltage at both

ends of B is too low. When A is again turned OFF, the voltage

at both ends of A and B increases to the power supply voltage,

and at this point B can be turned ON for the first time.

During this time, since there is a period (approx. 10 ms) when

both A and B are OFF, the load is momentarily reset. In order to

retain the load, use a relay as shown below.

When the proximity switch is connected to a load such as an

electromagnetic switch, lamp or motor that causes inrush current,

use the switch within the rated current, which includes the inrush

current.

After the power is turned ON, it takes at most 80 ms until the

proximity switch is ready for sensing. If the load and the proximity

switch use different power supplies, be sure to turn the proximity

switch ON before turning the load ON.

A minimal current flows as leakage current for operating the

circuits even when the proximity switch is OFF. Keep this in mind

when turning off connected loads.

The minimum bend radius (R) of the cable is 3 times the cable

diameter. Take care not to bend the cable beyond this radius.

Also, do not excessively bend the cable within 30 mm of the cable

lead-in port.

Be sure to connect the proximity switch to the power supply via

the load. If the switch is connected directly to the power supply,

the switch will be damaged. Also, output does not have polarity,

so the load can be connected to either side of the power supply.

However, we recommend connecting the load to the non-

grounded side to prevent short-circuiting of the power supply if a

ground fault caused by damage to the proximity switch occurs.

Load

Load

Load

Load

Load

AC power

supply voltage (Vs)

Cautions for series or parallel connection

Loads that cause inrush current

7.Operation upon power ON

6.Connection to power supply and load

8.Influence of leakage current

9.Minimum cable bend radius (R)

Series connection (AND switching circuit)

Parallel connection (OR switching circuit)

4.1

4.2

Before use, thoroughly read the “Precautions for use” and “Precautions for handling” in the Technical Guide

on pages C-107 to C-113 as well as the instruction manual and product specification for this switch.

7 8