4

Chapter 3.

INSTALLATION AND ADJUSTMENT

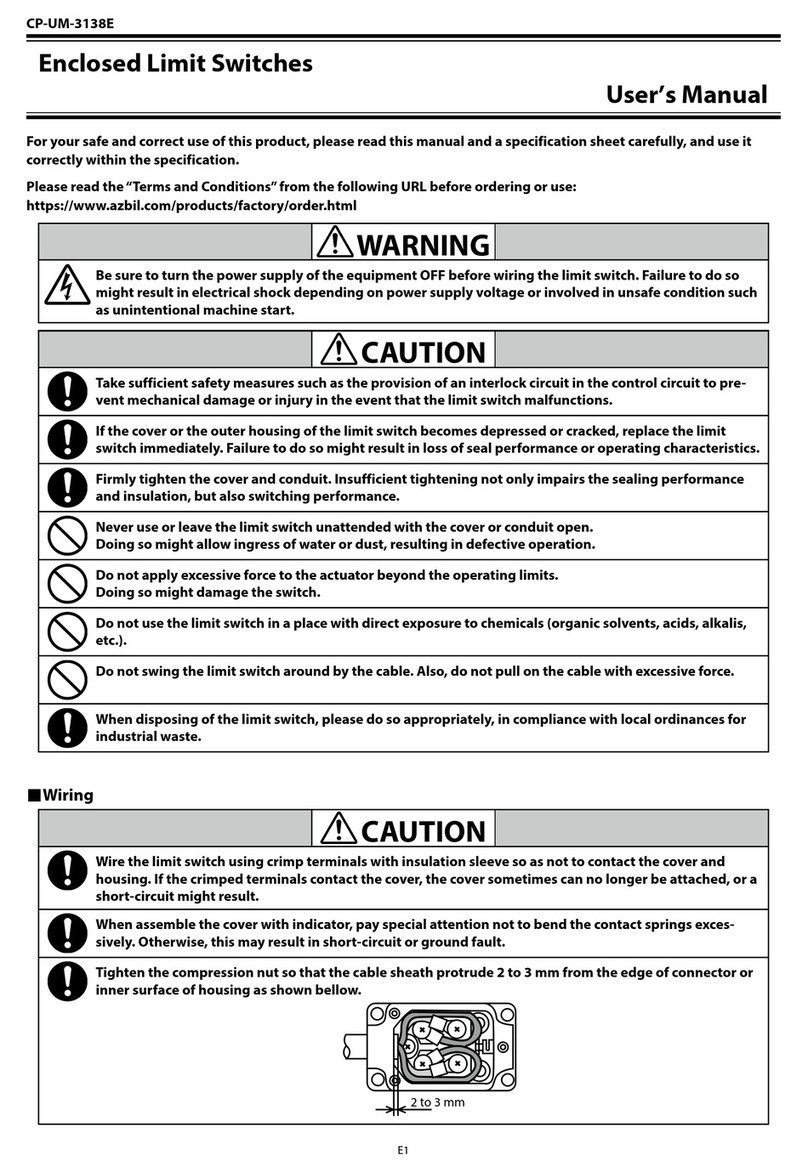

This section describes how to install the limit switch.

WARNING

Never leave or use the limit switch when the cover is off. Doing so may cause an explosion resulting in

serious harm.

CAUTION

Do not remove the cover or the plug from the limit switch until you are ready to do the wiring. If dust

or liquid enters the switch, poor operation, poor electrical contact, or insulation failure may result.

After wiring is complete, do not leave the limit switch with its cover off. If dust or liquid enters the

switch, poor operation, poor electrical contact, or insulation failure may result.

Before using for the first time, keep the whole limit switch protected with a dustproof and waterproof

sheet. Substances like cement or paint stuck to the switch may cause the lever to malfunction.

Do not leave the limit switch in an atmosphere containing gases that can adversely affect the contacts

and/or other materials (H2S, SOx, etc.). Exposure to such gases can cause contact failure.

Do not allow the limit switch seal to come into contact with solvents (benzene, kerosene, alcohol, etc.)

that may adversely affect them. Contact may lead to poor functioning or insulation failure.

Do not stand on the limit switch, place heavy objects on it, or strike it. Never apply a force 5 times

greater than the operating force (O.F.) to the switch lever. Failure to observe these precautions may re-

sult in faulty operation.

Before using a sealing agent, locking agent, etc., on the conduit joint, make sure that it will not gener-

ate fumes that will damage the contacts.

Make use of heat insulating material, a shielding plate, etc., in mounting the limit switch so that its tem-

perature will not exceed the working temperature range as a result of radiant heat or heat conduction.

Take appropriate protective countermeasures if the limit switch is installed in a location subject to con-

tinuous vibration or impact.