AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

4Rev 1.3

1-3: Care and Maintenance

To assure maximum performance and longevity of your Die Mas-

ter, it is very important to perform periodic maintenance. Read

Chapter 5 for more information.

1-4: Safety

The DieMaster is designed to operate at high rates of speed, employing rollers, gears, pulleys, and

other moving parts. Where possible, guards are provided to protect operator from injury. Operators

must keep their hands clear of the machine when it is in operation. Making all operators aware of

potential safety hazards will help minimize any chances of operator injury.

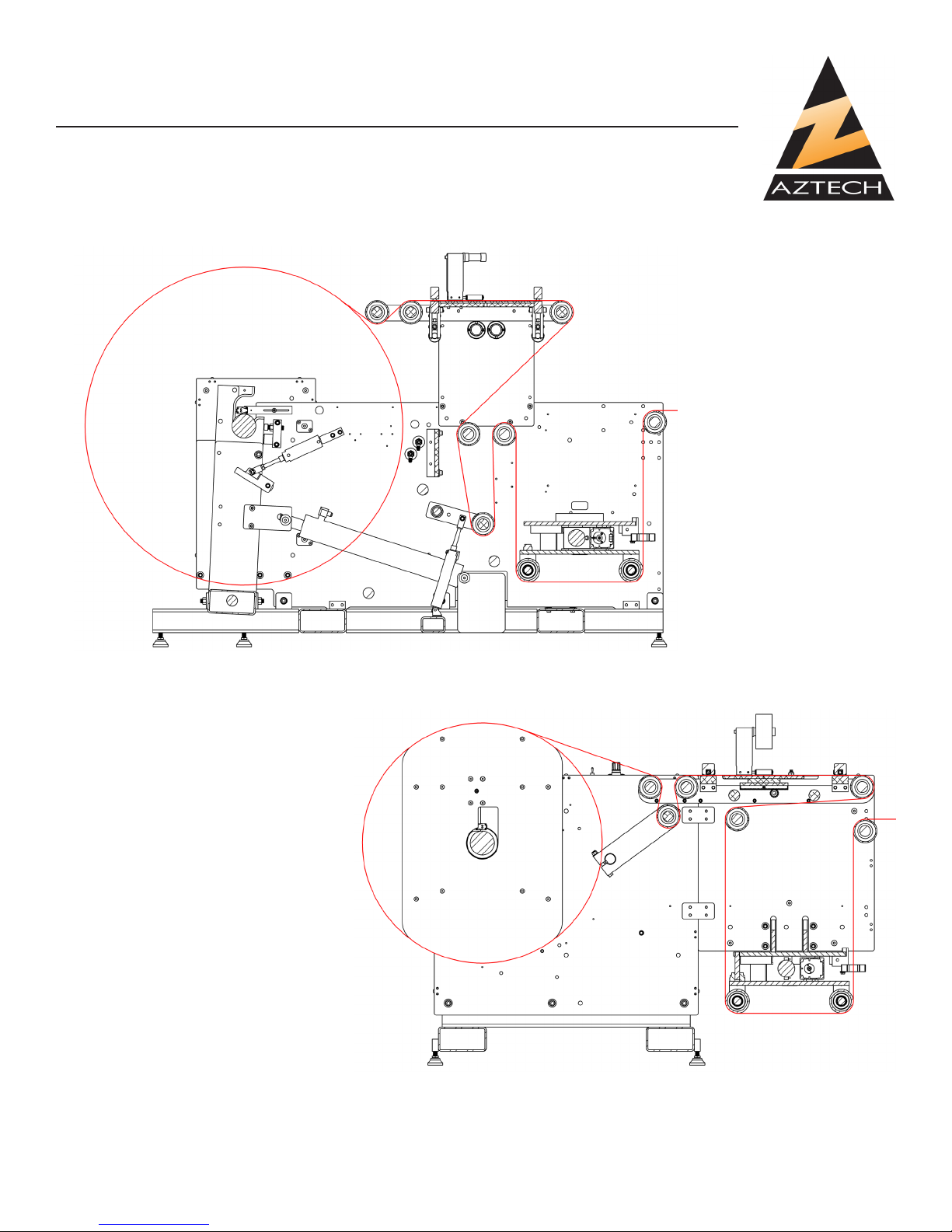

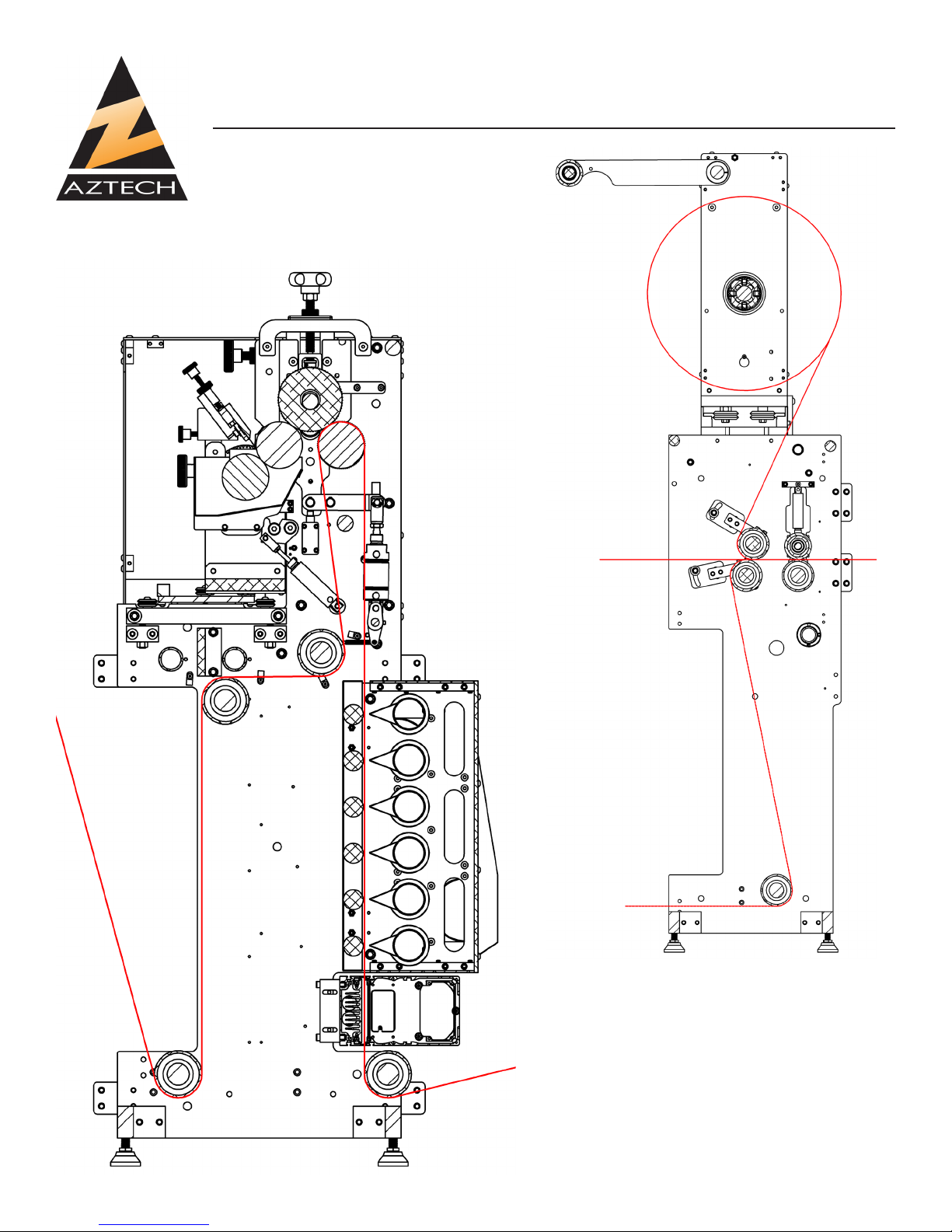

Section 2: Machine Installation

2-1: Preparation

It is important that your DieMaster Rotary Die Cutter be situated on solid and level ground. Make

sure that site allows for access to machine from all 4 sides. If the machine is placed on unstable or

un-level ground, it may tip over risking damage or serious personal injury.

2-2: Un-crating Machine

To avoid damage to your new DieMaster, begin by unfastening the latches on the front panel and

removing the panel to expose the machine. Carefully remove all boxes from inside the crate and

set aside to avoid damage. Remove all 4 lag bolts which hold the machine to the base.

2-3: Removal and Positioning

It is critical that the DieMaster be removed from the crate using a fork lift, making sure that the forks

t directly inside the 2 slots at base of the machine. Lift and remove from crate, and if equipped with

adjustable feet, thread all 4 feet into threaded holes at machine’s base, and lower into desired posi-

tion. Machine may be leveled by turning adjustable feet until level.

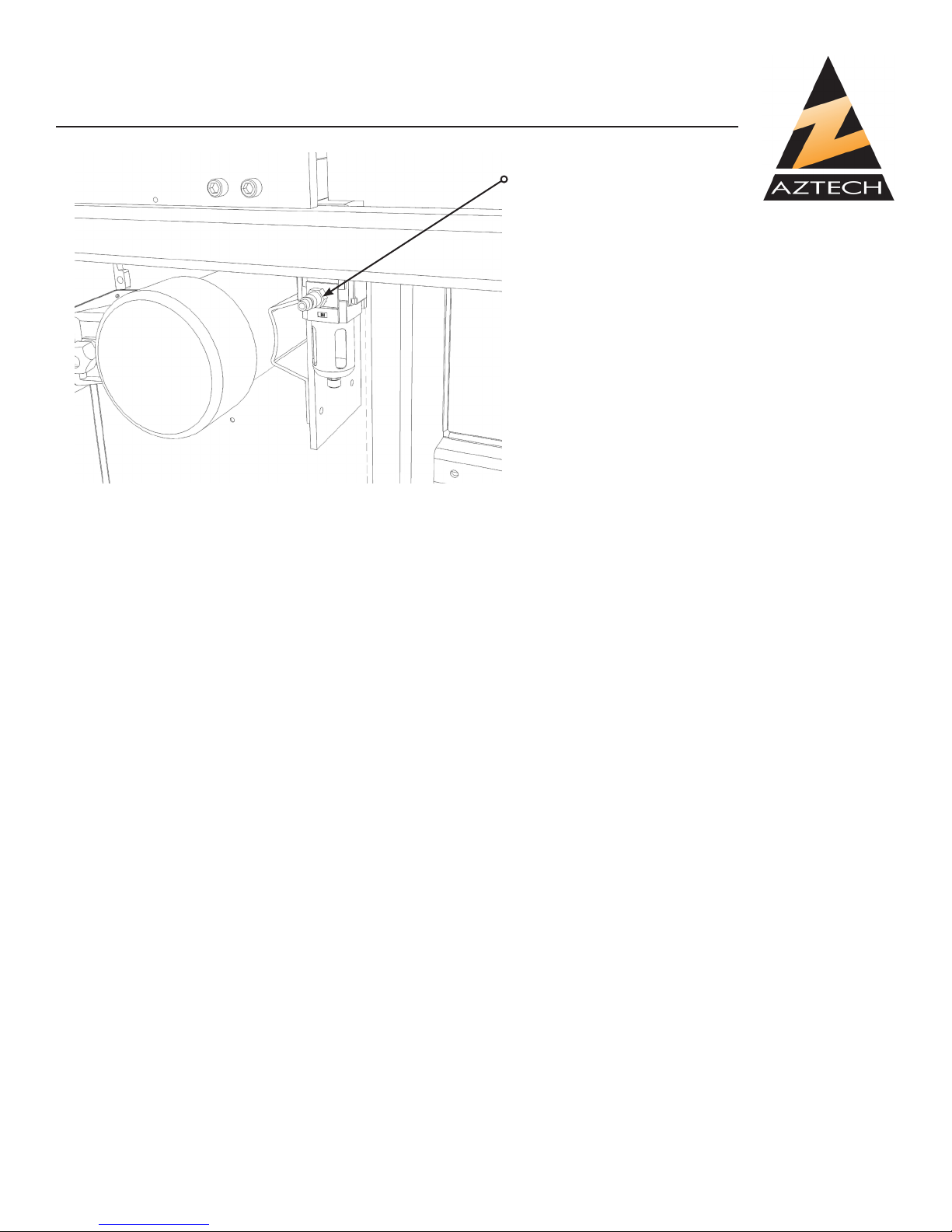

2-4: Electrical and Pneumatic Connections

ELECTRICAL CONNECTIONS: Your DieMaster uses

a power supply of 220 volts, 50 amps AC 3PH. Im-

proper connections or mishandling may cause seri-

ous personal injury. AZTECH highly recommends that

electrical service be performed only by a qualied

electrician.

Electrical connection to the machine is performed

by bringing electrical service to the electrical box at

the back of the machine and making connections as

shown.

50A 220VAC

THREE PHASE

TO DISCONNECT