1

GuilloMax

GuilloMaxGuilloMax

GuilloMax

User Manual

The Guillomax has distinct features such as its unique structure and ease of cutting. It combines symmetry with

functionality with the necessary maintenance tools stored in a convenient built in tool box, as well as arallel handles for

its a er clam and blade handle that are close to each other for easy two handed o eration even by just one user. The

heavy duty construction is sim le yet efficient with minimal moving arts for easy maintenance. The cutting blade is

extremely shar , so several safety features are included with the machine, such as a blade handle lock, blade guard

and a unique blade holder that enables the user to handle the blade without actually touching it directly.

Cutting Preparation

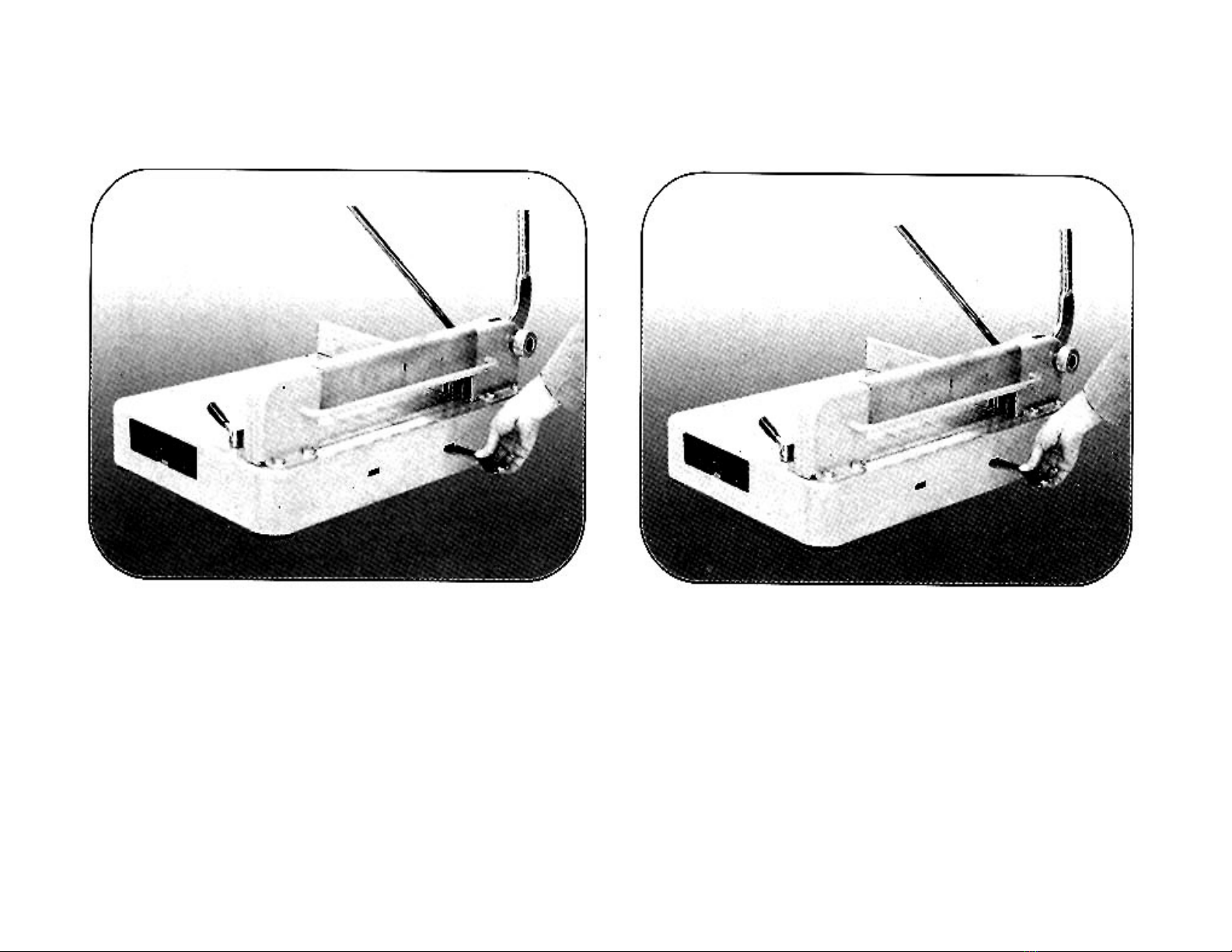

Place the handles for both the blade and the clam all the way u . Doing this with the blade handle locks it in lace.

The blade handle lock can be released by holding down the lock release on the base of cutter while bringing down the

handle.

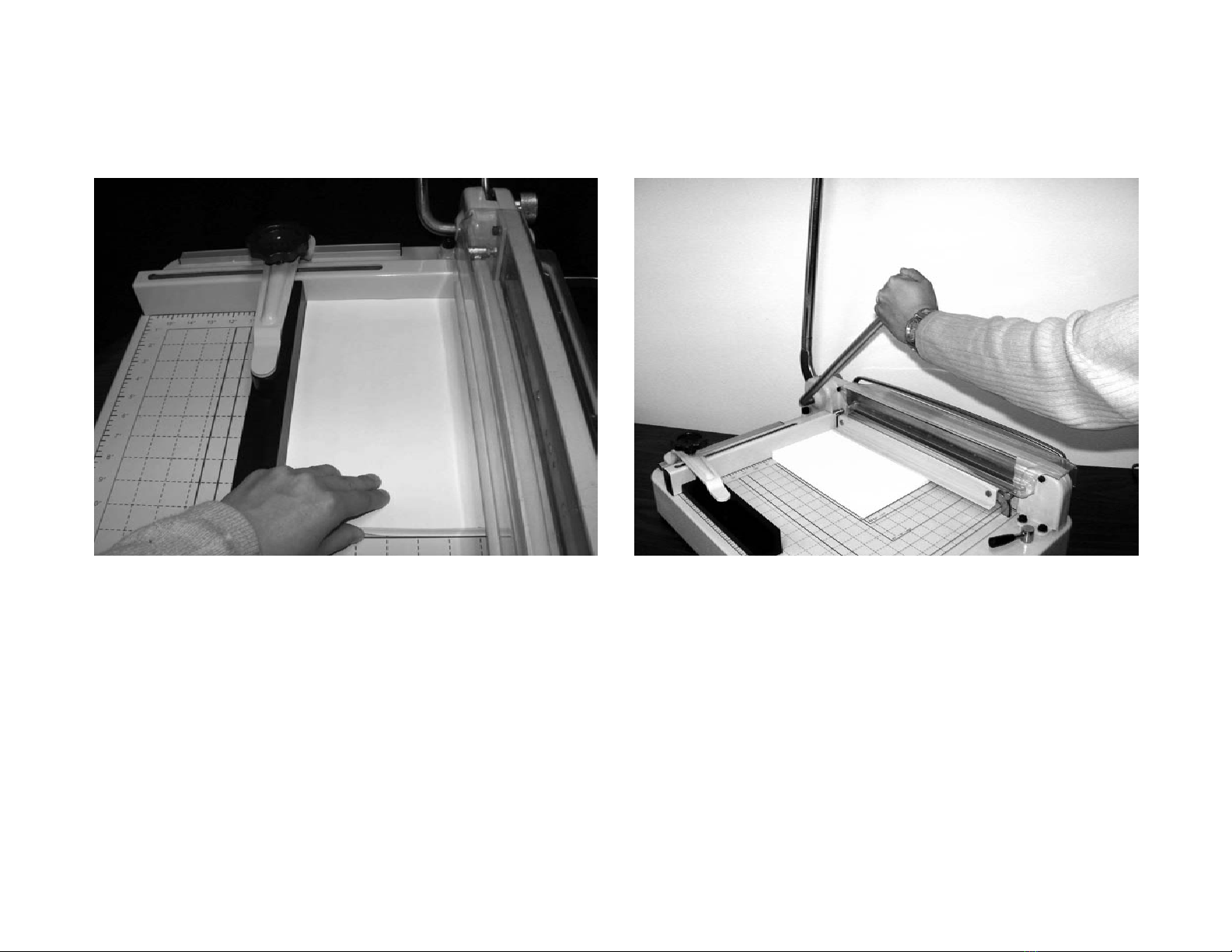

With the blade handle in the locked osition, set the a er stack against the alignment guides for the to and side of the

stack. As soon as the a er stack is set under the cutting blade based on the desired osition, ull the clam handle

down on the stack and secure it by ressing down on the handle to lock the stack in lace. Unlock the blade handle and

ull down to start cutting.

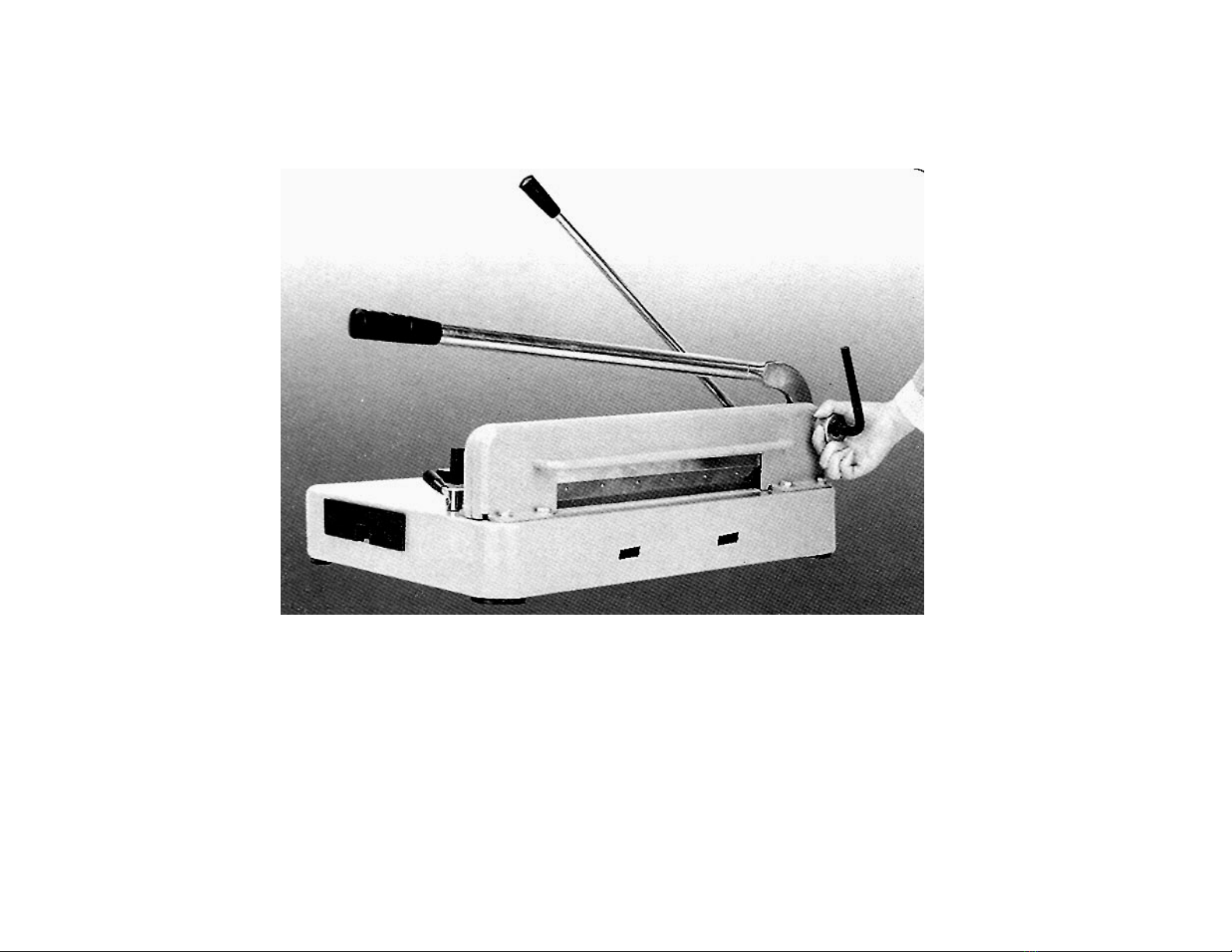

Remember to ush the handle all the way u and lock it to secure the blade in a safe osition when the cutter is not

being used.

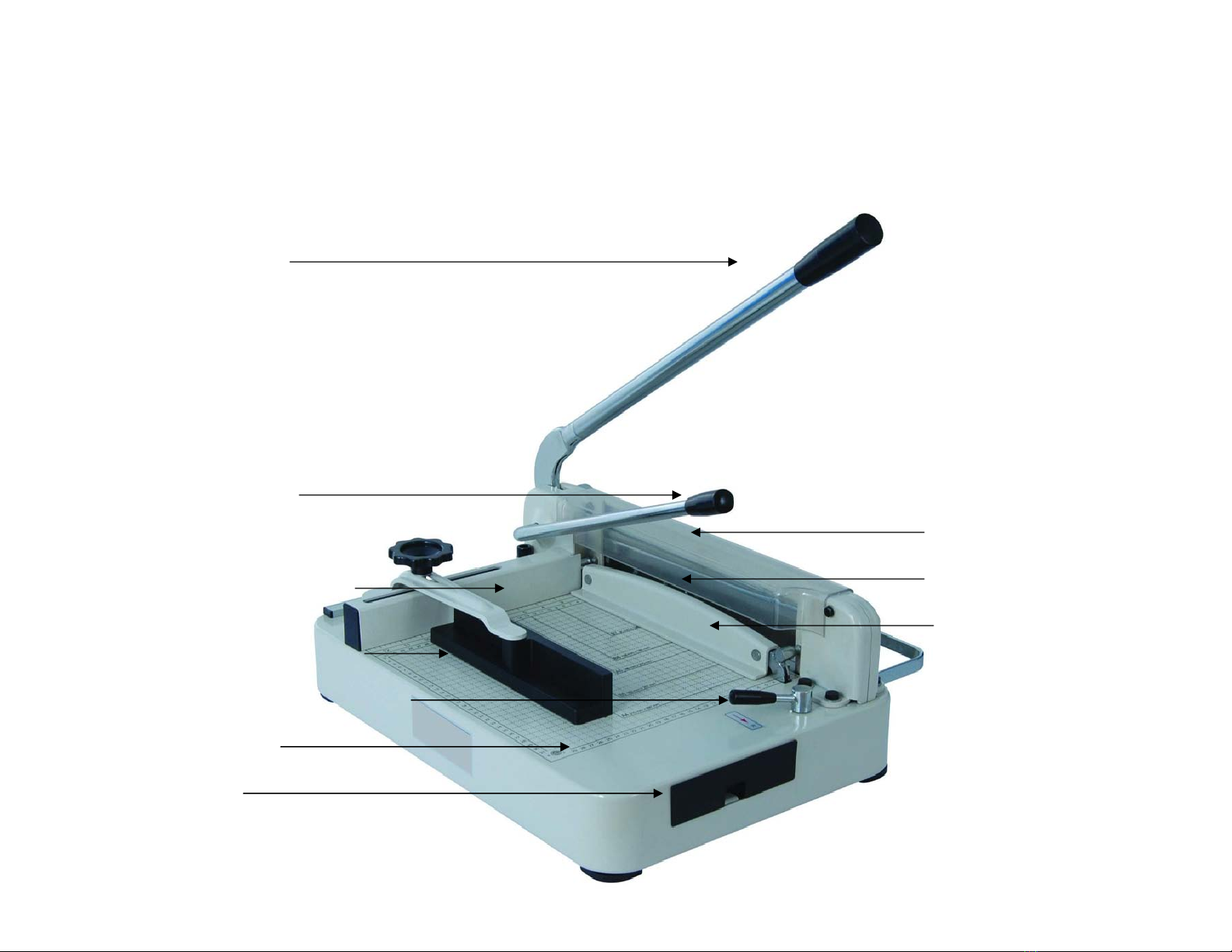

Parts: Tools Included:

1. Blade handle 1. Blade holder

2. Clam handle 2. S are cutting bar

3. To alignment guide 3. Blade guard

4. Side alignment guide 4. ½” allen wrench

5. Cutting blade 5. Phili s screw driver

6. Pa er clam 6. S are screws

7. Tool box

8. Blade handle lock release

9. Cutting base

10. Blade cradle