B-FORM Comfort User manual

ITALIA

Via Bassa 36

48123 Mezzano (RA)

Tel. / Fax: 0544 523326

www.bartmedical.com

2

INDEX

• ................................................................................................................. Pag. 3

• ......................................................................................... Pag. 5

• ....................................................................................................... Pag. 7

• ...................................................................................................... Pag. 11

• ...................................................................................................................... Pag. 12

• ............................................................................................................... Pag. 13

• .................................................................................................................. Pag. 15

• ...................................................................................................................... Pag. 16

• .............................................................................................. Pag. 17

• ............................................................................................... Pag. 18

• ........................................................................ Pag. 21

• ................................................................... Pag. 26

• ..................................................................... Pag. 31

• ............................................................................. Pag. 44

• ....................................................................................................................... Pag. 46

• ....................................................................................................................... Pag. 47

• ............................................................................................................................. Pag. 48

ITALIA

Via Bassa 36

48123 Mezzano (RA)

Tel. / Fax: 0544 523326

www.bartmedical.com

3

ank you for purchasing our thermoforming machines and we are pleased to welcome

you into our large family of customers.

Our B-FORM thermoforming machines are of the most recent generation, having a

modern style and a sleek design. ey have been designed to satisfy every need that a

dentist and a dental technician might have in a fast and simple way.

Built with top-quality materials, the B-FORM thermoforming machines have a 3-year

warranty against defects in materials and workmanship.

All the components that make up the outer structure of the B-FORM thermoforming

machines were manufactured using glass-lled nylon and ABS, making it very light and

compact.

e seals were manufactured using silicone and are very resistant to heat and sticky ma-

terials.

ey are equipped with a last generation vacuum pump that is powerful and quiet, and

allows one to perform the thermoforming process in less time and with the utmost pre-

cision.

e equipped well beads make it possible to perform the thermoforming process and

always achieve great professional results even with very high gypsum models, undercuts,

INTRODUCTION

ITALIA

Via Bassa 36

48123 Mezzano (RA)

Tel. / Fax: 0544 523326

www.bartmedical.com

4

sharp edges, and palate or buccal beds (see “ ”).

e locking plate, in which the thermoplastic sheets are inserted, is raised and lowered

by an electric motor in the B-FORM Comfort and Deluxe version, and manually in the

B-FORM Silent version. In addition, the particular design of the plate allows you to use

each type of thermoplastic sheets:

square 13 x 13 cm, round Ø 12 cm, round Ø 12.5 cm.

e heating plate contains quartz modular infrared resistance. e main characteristic of

this resistance is the rapidity of response, and therefore there is no need for preheating.

e heat is emitted by radiation mainly downwards in the direction of the thermoplastic

sheet to be heated, thus it greatly reduces the power consumption during the heating of

the thermoplastic sheet and yields substantial energy savings. Furthermore, the heating

plate containing the resistance does not heat up excessively.

ey have an elegant control keyboard on which the control keys for the functionality of

the thermoforming machine are located.

ey are equipped with an energy saving and security device (automatic standby feature

if the thermoforming machine is not used for approximately 10 minutes).

e B-FORM thermoforming machines have the certication and are provided with a

multilingual user manual and a DVD-R for the use of the thermo-molder.

ITALIA

Via Bassa 36

48123 Mezzano (RA)

Tel. / Fax: 0544 523326

www.bartmedical.com

5

THERMOFORMING TECHNIQUE

To obtain the best results with the thermoforming technique, a good plaster model needs

to be prepared. To do so we recommend that you to keep in mind the following:

• e plaster model can be made with any type of plaster. However, we recommend that

you use a hard plaster because if you use a so plaster, a model completely covered with

powder is obtained, and the powder is transferred to the thermoforming device as well.

• e plaster model must not be very high and therefore it must be thinned as

much as possible. e base of the model must have a smooth, at surface. Remo-

ve the parts of the model (vestibule, buccal oor) that can prevent the molding. Ca-

refully remove the undercut areas and round the sharp edges of the plaster ( ).

You can overcome all of this if you use the well of thermoforming machine, aer

having lled it with beads ( ).

• If you use air-impermeable or lacquered resin models, you run the risk of having an

incomplete mold because the air is unable to escape completely between the model and

the thermoplastic sheet.

• If you remove the hard thermoformed materials from the model, this oen breaks. e

problem is not solved using extra-hard plasters: we recommend the molding with a

duplicate.

ITALIA

Via Bassa 36

48123 Mezzano (RA)

Tel. / Fax: 0544 523326

www.bartmedical.com

6

• During the thermoforming there is always a thinning of the material with respect to

the original thickness. In general, our long experience has taught us that for every cen-

timeter of height of the plaster model, there is a loss of thickness of approximately 20%.

For this reason, it is necessary to lower the plaster model height as much as possible

or insert the plaster model into the well of the thermoforming machine and cover it with

beads, leaving only the area that you want to mold uncovered.

• With the B-FORM thermoforming machines there is a molding in an axial direction, in

which the suitably heated sheet descends vertically on the model, surrounding it

completely. is creates a uniform thickness over the entire surface of the plaster mo-

del.

ITALIA

Via Bassa 36

48123 Mezzano (RA)

Tel. / Fax: 0544 523326

www.bartmedical.com

7

Please read and take the following precautions before using the equipment.

Positioning

1. e thermoforming machine must always be placed on a at and open surface:

Under no circumstances must the thermoforming machine be operated when it is

located inside a cabinet.

2. During operation, do not put the thermoforming machine too close to the walls, cabi-

nets or any other equipment due to the heat emitted from the resistance located in

heating plate.

3. Do not place the thermoforming machine near ammable liquids, such as alcohol

or solvents.

In case the internal electrical components come into contact with ammable liquids,

re or electric shocks might occur. Should one of these liquids penetrate in the appa-

ratus, disconnect the power supply cable immediately and contact your local dealer.

4. Do not put the equipment in the following places (re or electric shocks may occur).

- Areas with high humidity.

- Areas subject to direct sunlight.

SAFETY PRECAUTIONS

ITALIA

Via Bassa 36

48123 Mezzano (RA)

Tel. / Fax: 0544 523326

www.bartmedical.com

8

- Areas with high temperatures.

- Areas near ame sources.

5. Do not place the thermoforming machine on uneven supports, unstable surfaces or

surfaces that are subject to frequent vibrations. If the equipment falls, it can cause

injury.

6. Do not put heavy objects on the device. e objects may fall and cause injury.

Power supply

1. Do not damage, cut or modify the power supply cable. Do not put heavy objects on

the power supply cable, and do not pull and bend it excessively. Damaged wires may

cause a re or electric shocks.

2. Do not insert or remove the plug of the power supply cable with wet hands. Electric

shocks may occur.

3. Do not connect an excessive number of plugs to a single electrical socket. Fire or

electric shocks may occur.

4. Always make sure that the power supply cable is inserted properly into the wall socket.

If it is not fully inserted, it can cause a re or electric shocks.

5. Do not use power supply cables other than the one supplied. Fire or electric shocks

may occur. If you use a power supply cable that was not supplied by the dealer, make

ITALIA

Via Bassa 36

48123 Mezzano (RA)

Tel. / Fax: 0544 523326

www.bartmedical.com

9

sure it conforms to the standards in force in your country. If the power supply cable

is defective, please contact the manufacturer or your authorized supplier for a repla-

cement.

6. As a rule, please do not use extension cords. Fire or electric shocks may occur. In the

event that the use of an extension cord is inevitable, do not use one that is longer than

5 meters. Make sure that the cord is not twisted and that the power supply cable is

connected properly to the extension. Do not use multiple extension cords.

7. Do not use extension cord in corridors or in other areas that are used frequently whe-

re they can be stepped on or tripped over. is may damage the cables and it can cau-

se a re or electric shocks.

8. Do not connect the device into a power socket with an electrical voltage that is die-

rent than the one specied. is may cause re or electric shocks.

9. When removing the power supply cable from the wall socket, always pull it out from

the body of the plug. If the pull it using the power supply cable, the metal wires may

be damaged and cause a re or electric shock.

General precautions for use

1. Do not disassemble or modify the device. is may cause a re or electric shocks from

the improper use of its components.

2. In case you hear unusual sounds, see smoke, experience any excessive heat, or smell

ITALIA

Via Bassa 36

48123 Mezzano (RA)

Tel. / Fax: 0544 523326

www.bartmedical.com

10

an unusual smell disconnect power supply cable and contact your local dealer. Pro-

longed use may cause a re or electric shocks.

3. If you do not use the device for long periods, such as for example over the weekend,

be sure to disconnect the power supply cable as a precaution.

4. Be very careful when transporting the equipment. If you let it fall down, it may cause

an injury.

5. Wait until the device has cooled down before you put a cover over it. Otherwise, a re

may occur.

6. When you switch on the resistance for the rst time, you may notice some smoke co-

ming out of it. Do not worry because this is due to dust that was deposited on the re-

sistance.

7. When you’re nished working with the thermo-molder, remember to turn o the vol-

tage switch located on the rear of the device. ( ).

8. 8. Do not throw away the cardboard box and the packaging materials. ey are ideal

for transporting the equipment.

ITALIA

Via Bassa 36

48123 Mezzano (RA)

Tel. / Fax: 0544 523326

www.bartmedical.com

11

ank you for purchasing the B-FORM thermoforming machine. Verify that the

package contains all of the following items. If part of the material is missing or damaged,

please contact your local dealer. ( ).

• ermoforming machine.

• Schuko power supply cable.

• Perforated plate.

• Stainless steel balls per well.

• Interactive user manual on DVD-R.

MATERIALS PROVIDED

ITALIA

Via Bassa 36

48123 Mezzano (RA)

Tel. / Fax: 0544 523326

www.bartmedical.com

12

Do not use ammable sprays near the device. In addition, do not pour water, liquids, or

ammable liquids on the device. If these liquids get in this device and come in contact

with the electrical parts, this may cause a re or electric shocks. If something gets into the

device, disconnect the power supply cable immediately and contact your local dealer.

Always remove the power supply cable from the wall socket when cleaning the device.

Otherwise, a re or electric shocks may occur.

When you clean the equipment, use a well-wrung cloth dampened with water. Do not

use ammable liquids, such as alcohol, benzene or solvents. In case in a ammable liquid

penetrates in the electrical parts inside, it can cause a re or electric shocks.

CLEANING

ITALIA

Via Bassa 36

48123 Mezzano (RA)

Tel. / Fax: 0544 523326

www.bartmedical.com

13

1. e stopper with a hole in it, located at the bottom of the well, must always be free of

any debris that may form during the operation of the thermoforming machine. e

refore, you must periodically remove the beads from the well and thoroughly inspect

this area and check the lter located inside it ( ).

2. Check periodically to see if the power supply cable is worn and check to make sure

that the connection plugs are inserted correctly.

3. Replacing the fuse : In the electrical outlet, located in the rear part of the ther-

moforming machine, there are two incorporated fuses to protect the various electri-

cal components of the device. Should the fuse malfunction for some reason, you must

replace it. For the replacement of the fuse proceed as follows:

• First unplug the power supply cable both from the wall socket and also from the socket

of the device.

• Open the ap of the fuse container gently with a screwdriver ( ) and repla-

ce the old fuse with a new one. It is very important have spare fuses of the same type

(delayed 3.15 AT for 220 volts version and delayed AT 6.30 for the 115 volts version)

to be able to replace them should the need arise. Dierent types of fuses may cause

damage to the device and thus void the warranty.

MAINTENANCE

ITALIA

Via Bassa 36

48123 Mezzano (RA)

Tel. / Fax: 0544 523326

www.bartmedical.com

14

4. In the construction of the thermoforming machine, high quality materials were used.

However, aer some years of use the resistance, the seals and some other part may

wear down and you may need to replace them.

ITALIA

Via Bassa 36

48123 Mezzano (RA)

Tel. / Fax: 0544 523326

www.bartmedical.com

15

e thermoforming machine is supplied ready for use. A few simple steps are required

for the installation and operation.

1. Take the thermoforming machine out of the packaging and place it on a at surface.

2. Connect the female part of the power supply cable to the power socket of the thermo-

forming machine, located at the rear, and the male part of the power supply cable to

the mains power supply outlet. Never put the power supply cable near any heat sour-

ce. Turn on the switch located on the rear, and the thermoforming machine is ready

for operation ( ). A light will turn on the control panel that will illuminate the

logo “B-FORM” to conrm that electric voltage is arriving in the machine.

ATTENTION: Before operating your thermoforming machine, check the voltage of

the main electricity supply.

INSTALLATION

ITALIA

Via Bassa 36

48123 Mezzano (RA)

Tel. / Fax: 0544 523326

www.bartmedical.com

16

e B-FORM thermoforming machine is guaranteed for 3 years from the date of purcha-

se, for defects recognized in material or manufacture.

If during the warranty period a defect is observed, the thermoforming machine will be

repaired or replaced for free only if:

1. e thermoforming machine has not been used for purposes other than normal use.

2. No unauthorized modications or repair have been made.

NOTE: e following are excluded from the warranty: the seals, the fuses, the stain-

less steels balls, the ower supply cable.

e conditions of warranty may vary according to the country of purchase of the ther-

moforming machine.

WARRANTY

ITALIA

Via Bassa 36

48123 Mezzano (RA)

Tel. / Fax: 0544 523326

www.bartmedical.com

17

For any type of repair, please send the B-FORM thermoforming machine to your dealer

or directly to our service center.

For repairs, we recommend that you follow the following instructions:

1. Always send the thermo-molder with a transport document. It should also be accom-

panied by a precise and detailed description of the problem.

2. e thermoforming machine must be shipped to our address always as carriage paid

and undamaged. Otherwise, the item will not be accepted.

3. e return of the item, from our head oce to your home, will be executed as carriage

paid and undamaged with charges for the cost of shipping on the invoice.

4. All of our repairs will be sent to you in the following manner: cash on delivery or pre-

payment.

5. When you send the thermo-molder, please make sure to pack it with great care using

the original packaging. In any case, you should never use polystyrene as packing ma-

terial because it may deposit within the resistance and may cause res.

ATTENTION: Never include the stainless steel balls in the package.

INSTRUCTIONS FOR REPAIRS

ITALIA

Via Bassa 36

48123 Mezzano (RA)

Tel. / Fax: 0544 523326

www.bartmedical.com

18

Check the following before requesting technical assistance:

• Insucient details - is is oen caused by an incorrect heating or vacuum time of

the plastic sheet. If your overlay does not have sucient details, you must prolong the

heating and/or vacuum time of the plastic sheet.

• Creased or torn material - is is due to an excessive heating of the plastic sheet.

Simply reducing the heating time solves this problem.

• Material glued to the model - e problem is solved by spraying the plaster model

with a silicone lubricant prior to the implementation of the overlay.

• Material glued to the seals - Replace the seals.

• Material glued in the holes in the vacuum plate - is happens when the plastic

sheet is heated excessively and is sucked inside the plate holes. Let the plastic material

cool down completely and then try to pull it out gently from the holes in the plate.

• e resistance does not work / e vacuum pump does not work / e clamping

plate does not move up and cannot be lowered - Check to see if the power supply

cable is properly inserted both in the thermo-molding socket of the thermo-molding

and the wall outlet. Check the fuse. Remove and replace it if it is blown.

TROUBLESHOOTING GUIDE

ITALIA

Via Bassa 36

48123 Mezzano (RA)

Tel. / Fax: 0544 523326

www.bartmedical.com

19

ATTENTION: If the problems persist please consult maintenance personnel. Do not

try to carry out the maintenance alone since opening the structure of the device may

expose the user to the danger of electrical shocks or other hazards. Please contact

qualied technical personnel.

ITALIA

Via Bassa 36

48123 Mezzano (RA)

Tel. / Fax: 0544 523326

www.bartmedical.com

20

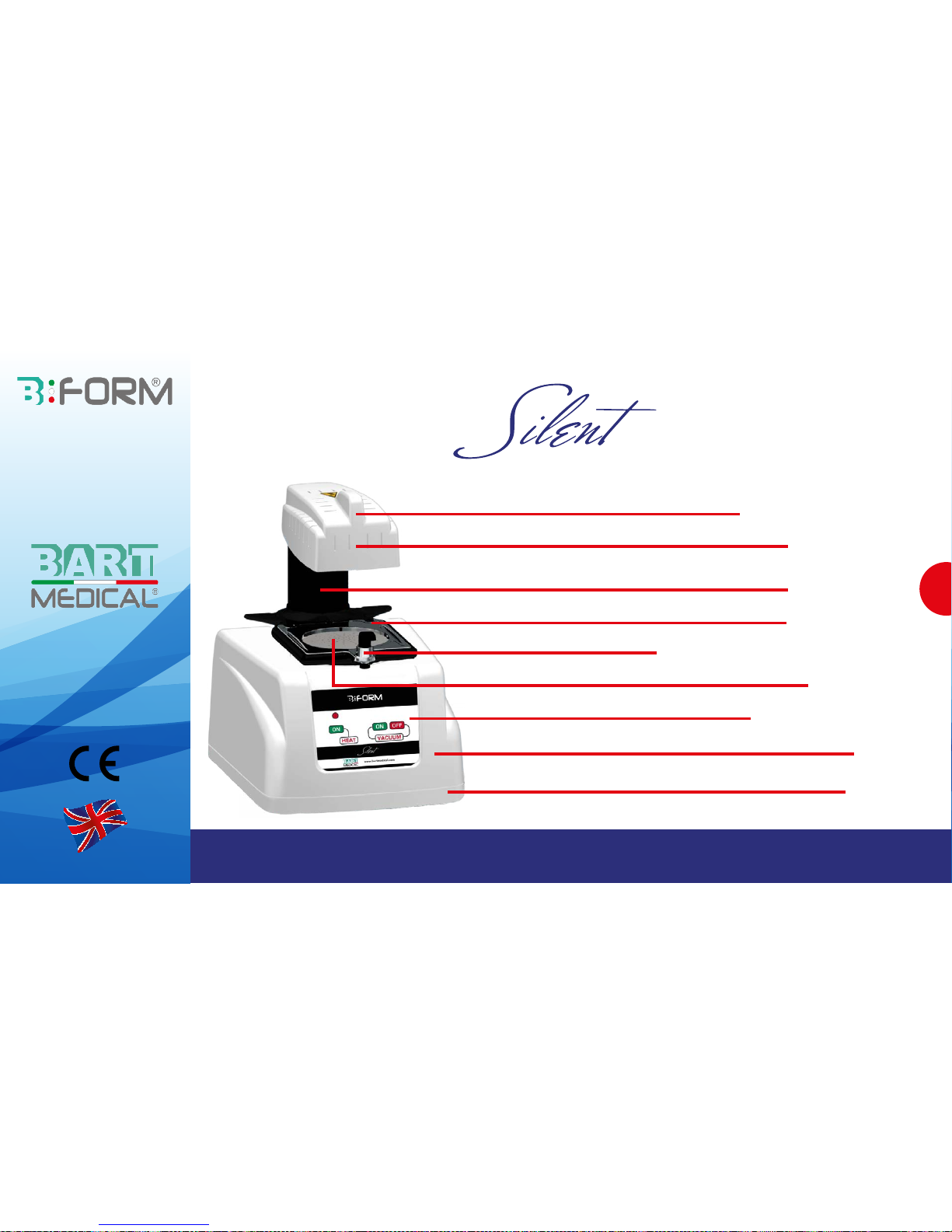

Cover

Heating plate Knob

Heating plate

Sliding sleeve

Manopola piastra di serraggio

Locking plate

Well beads

Control Keyboard

Base

This manual suits for next models

2

Table of contents

Popular Dental Equipment manuals by other brands

Dentsply Sirona

Dentsply Sirona CEREC Zirconia meso Processing instructions

Durr Dental

Durr Dental Hygopac View Installation and operating instructions

Sirona

Sirona DAC UNIVERSAL user guide

DentalEZ

DentalEZ Star Aeras 500 Elite quick start guide

Durr Dental

Durr Dental VistaCam iX Installation and operating instructions

NSK

NSK Presto II Operation manual

Miele professional

Miele professional A 814 operating instructions

Cattani

Cattani Mono-Jet Series Operator's handbook

DENTSPLY

DENTSPLY Cavitron Plus Ultrasonic Scaler Directions for use

Olsen

Olsen Flex Quality Operation guide

DENTSPLY

DENTSPLY ORTHORALIX 9200 manual

Woodpecker

Woodpecker Endo Radar Pro instruction manual