B meters HYDROCAL-M4 Assembly instructions

Other B meters Measuring Instrument manuals

B meters

B meters Hydrocal-M3 User manual

B meters

B meters HYDROCLIMA 2 User manual

B meters

B meters LORA-PULSE LORAWAN pulse User manual

B meters

B meters HYDRODIGIT-S1 User manual

B meters

B meters HYDRODIGIT-S1 User manual

B meters

B meters GMDM-I User manual

B meters

B meters MAG User manual

B meters

B meters HYDROCLIMA 2 User manual

B meters

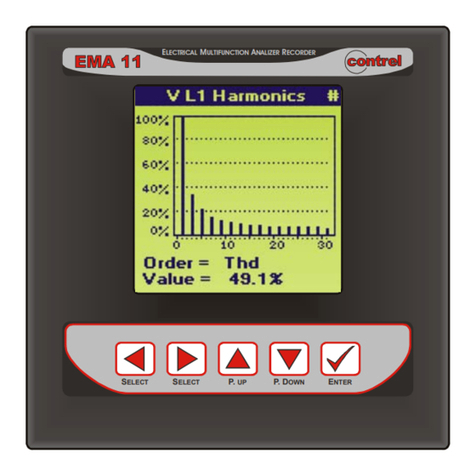

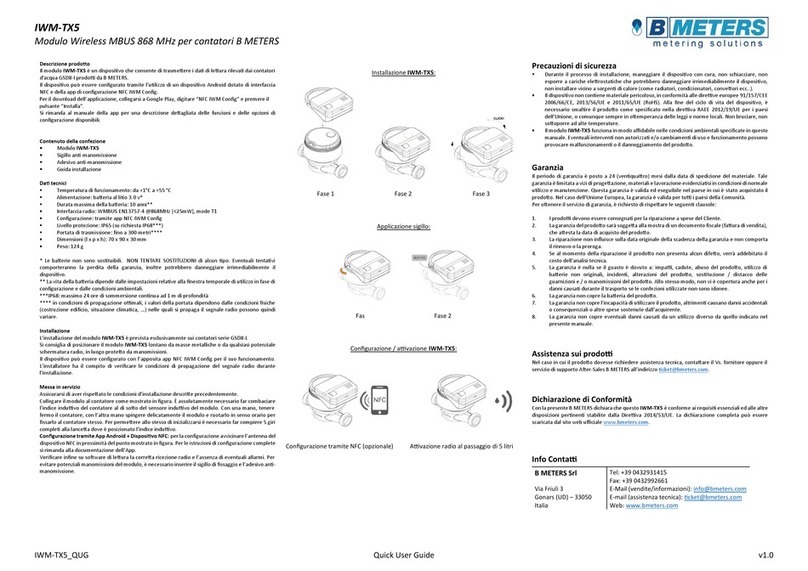

B meters IWM-TX5 User manual

B meters

B meters Hydrosplit-M3 User manual

B meters

B meters HYDRODIGIT User manual

B meters

B meters HYDROSONIS-UP User manual

B meters

B meters IWM-LR3 User manual

B meters

B meters HYDROCAL-M4 User manual

B meters

B meters HYDROSONIC-M1 User manual

B meters

B meters HYDROSPLIT R 21 User manual

B meters

B meters GSD534AF Operating manual

B meters

B meters HYDROCAL-M4 Assembly instructions

B meters

B meters HYDROCAL-M4 User manual

B meters

B meters H7-BM1 User manual

Popular Measuring Instrument manuals by other brands

GE

GE AquaTrans AT600 user manual

LaserLiner

LaserLiner MultiFinder Pro manual

Pfeiffer Vacuum

Pfeiffer Vacuum TPG 362 operating instructions

GretagMacbeth

GretagMacbeth Spectroeye operating manual

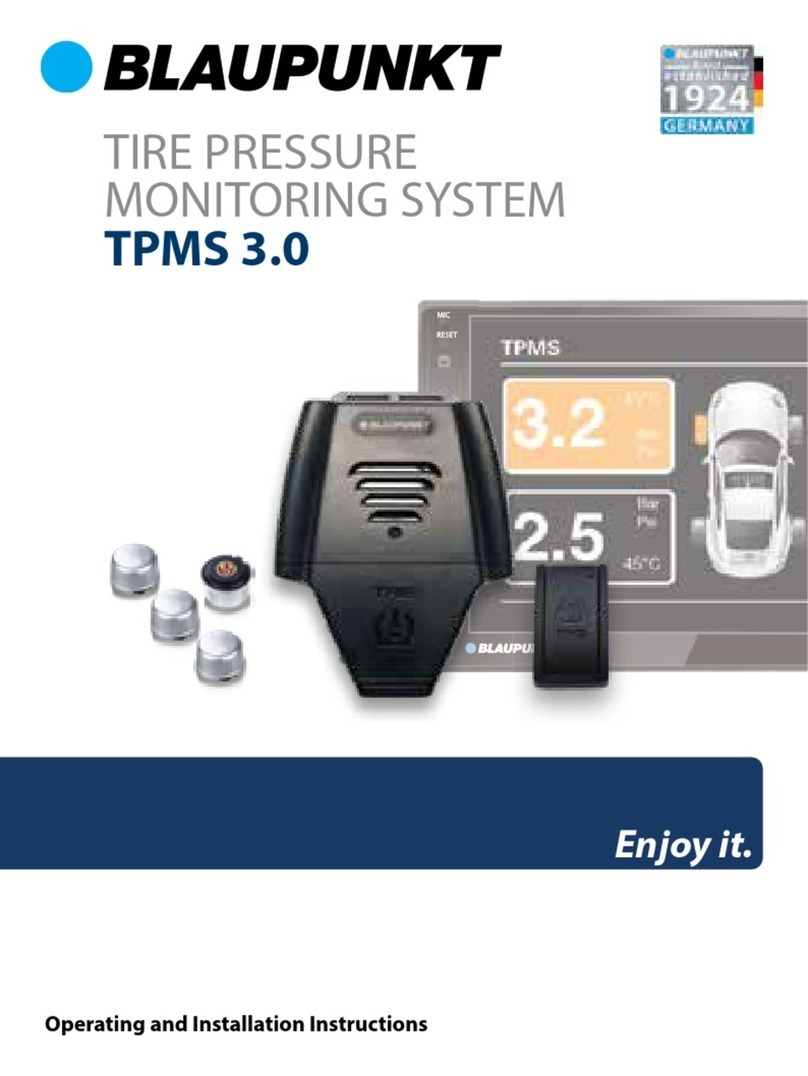

Blaupunkt

Blaupunkt TPMS 3.0 Operating and installation instructions

Brookfield

Brookfield KF40 operating instructions

AR

AR DC7210A Operating and service manual

Union Instruments

Union Instruments INCA6004 Translation of the original operating instructions

VOLTCRAFT

VOLTCRAFT PL-130 AN manual

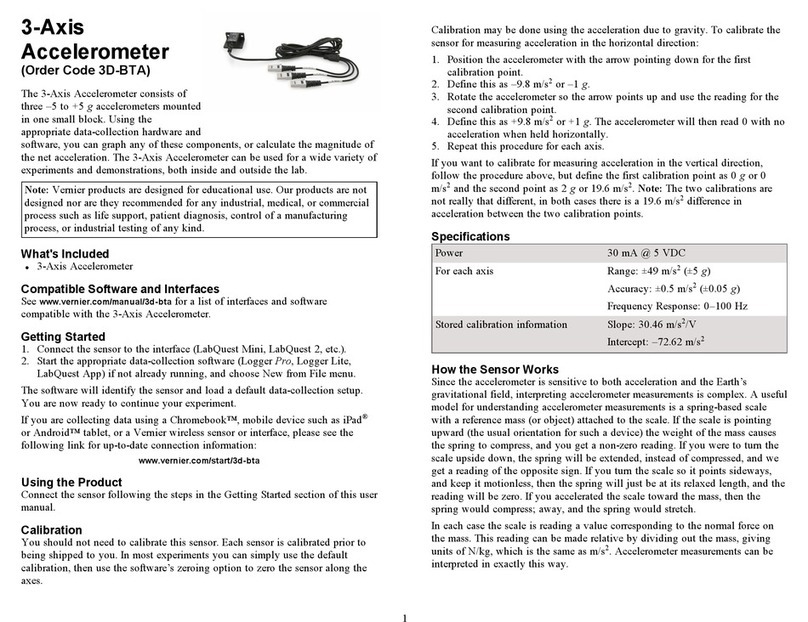

Vernier

Vernier 3D-BTA quick start guide

IFM

IFM efector300 SA3000 operating instructions

Ametek

Ametek BARBEN ANALYTICAL OXY visor Installation, operation and maintenance manual