For any questions regarding this product, please contact your local agency,

or inquire from the following website.

http://www.4oakton.com/

CODE:M003857-3200839729-GZ0000590175

December, 2019

Oakton Instruments

Phone number: (1)888-462-5866

625 E. Bunker Ct. Vernon Hills, IL. 60061, USA

Gel-filled pH Electrode (35660-54 / 35660-56)

Instruction Manual

This manual describes the operation of the gel-filled pH

electrode, 35660-54/35660-56. Be sure to read this manual

carefully, before using the electrode.

Conformable standards

Authorised representative in EU

Cole-Parmer UK

9 Orion Court, Ambuscade Road

Colmworth Business Park

St Neots

Cambridgeshire

PE19 8YX, United Kingdom

Phone: +44-(0)1480-272279

Fax: +44-(0)1480-212111

Caution on use

Safety precautions

Points of concern

Do not give an excessive shock to the electrode.

Cracked or chapped electrode can not be used.Replace

such electrode with a new one.

Do not wet the connector with water or sample and do

not touch the connector with wet fingers. If it is wet

measured value might be erroneous.

If the dirt on the responsive glass membrane or liquid

junction can not be removed by pure water, clean them

with the other way referring to the Maintenance.(Refer to

“ Maintenance ” (page 2).)

Avoid continuous measurement soaking in the strong

acidic or alkaline solution concentrated more than 0.01

mol/L. These solution may reduce the performance and

the lifetime of the electrode.

Do not to use the electrode in a solution in which

hydrofluoric acid (HF) is contained. Glassware will

corrode in the HF solution.

Avoid sudden temperature change over 50 °C on the

electrode. The body of the electrode might be deformed

or the glassware might be cracked.

Solid particles of silver chloride might be observed

floating in the inner solution of the responsive glass

membrane. This is not a problem and this will not affect

performances of the electrode.

Do not use the electrode in any place where operation

temperature is out of the specified range.

Do not swing the electrode like a pendulum, and do not

pull up the electrode by the lead wire. Also, avoid

This equipment conforms to the following standards:

RoHS: EN50581

9. Monitoring and control instruments

Chemical solution

If the internal material comes in contact with the hands or skin,

wash immediately with water.

Glass fragments

Glass fragments can cause injury.

The tip of the electrode are made of glass.

Be careful not to break them.

hanging the electrode or the pH meter by the lead wire.

It may be a cause of breaking wires.

When disposing of the product, follow the related laws

and/or regulations of your country for disposal of the

product.

Packaged contents

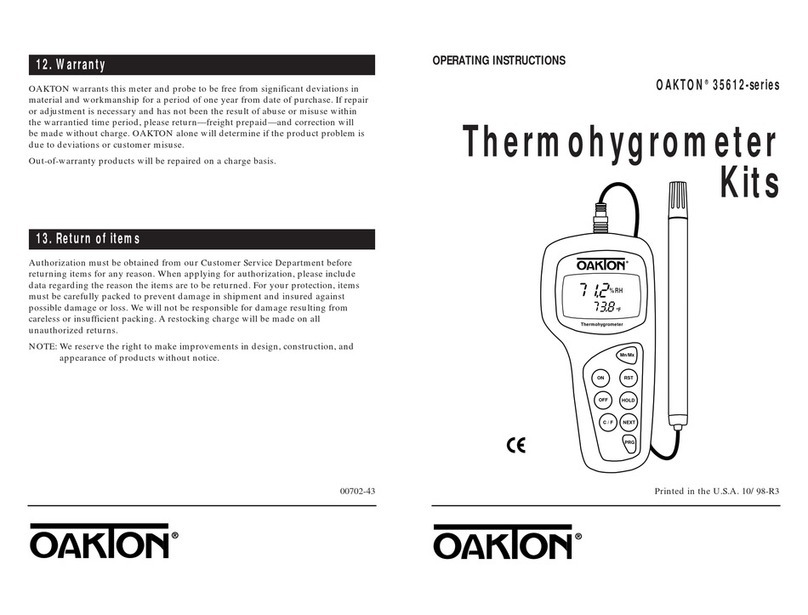

Specifications and parts description

Part name

Specifications

Body material is plastic. Do not use organic solvents (such as

acetone or toluene).

Name Q’ty

Electrode 1 pc

Instruction manual (this book) 1 booklet

Electrode model 35660-54, 35660-56

Measurement range pH 0 to 14

Operation temperature range 0°C to 80°C

Storage temperature range 0°C to 50°C

Internal electrode Silver/silver chloride

Reference electrode system Double junction

Reference electrode internal

electrolyte Polymer-gel, 3.3 mol/L KCl

Liquid junction material Porous sintered polyethylene

Wetted material Glass, butyl rubber, polycarbonate,

polyethylene

Electrode length 150 mm

Ext. diam. of wetted part 16 mm

Liquid junction height Approximately 15 mm

(from the tip of electrode)

Cable length 10D: 1 m 20D: 2 m

Connector BNC/Mini plug

Temperature probe NTC

Maximum dipping depth 1 m

Zero point pH7.0

Responsive glass

membrane

Liquid junction

Protective cap

Body

Cap Lead

Connector cover

Electrode connector

Temperature connector

Guard tube