MVR-SC™ Refrigerant Leak Monitor

1100-2184 Rev 1 3

Table of Contents

SECTION 1. INTRODUCTION 4

1.1 About this Manual............................................................................................................................................................................... 4

1.2 Iconography........................................................................................................................................................................................ 4

1.3 General Safety Statements................................................................................................................................................................. 4

SECTION 2. PRODUCT DESCRIPTION 5

2.1 Product Overview ............................................................................................................................................................................... 5

2.2 Design Features ................................................................................................................................................................................. 5

2.3 Bill of Materials ................................................................................................................................................................................... 5

2.4 Specifications ..................................................................................................................................................................................... 6

2.4.1 Hardware Specification.............................................................................................................................................................. 6

2.4.2 Network Specifications .............................................................................................................................................................. 6

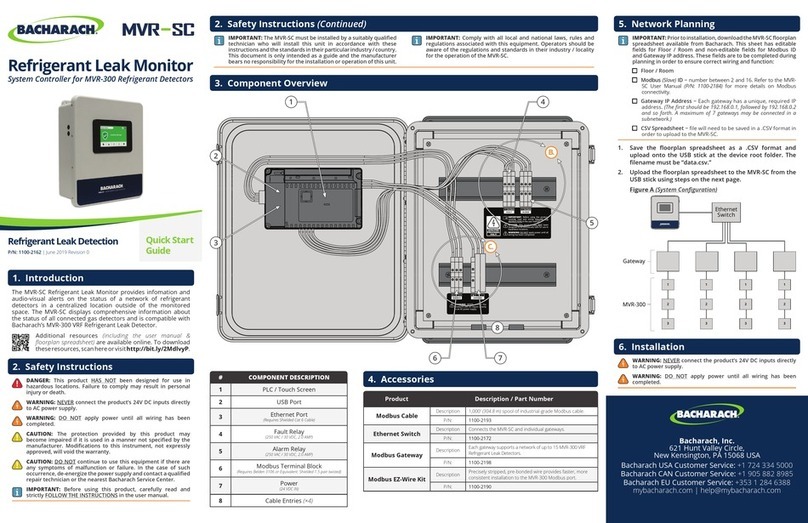

2.5 Components ....................................................................................................................................................................................... 7

2.5.1 Network Components................................................................................................................................................................ 8

SECTION 3. NETWORK OVERVIEW 9

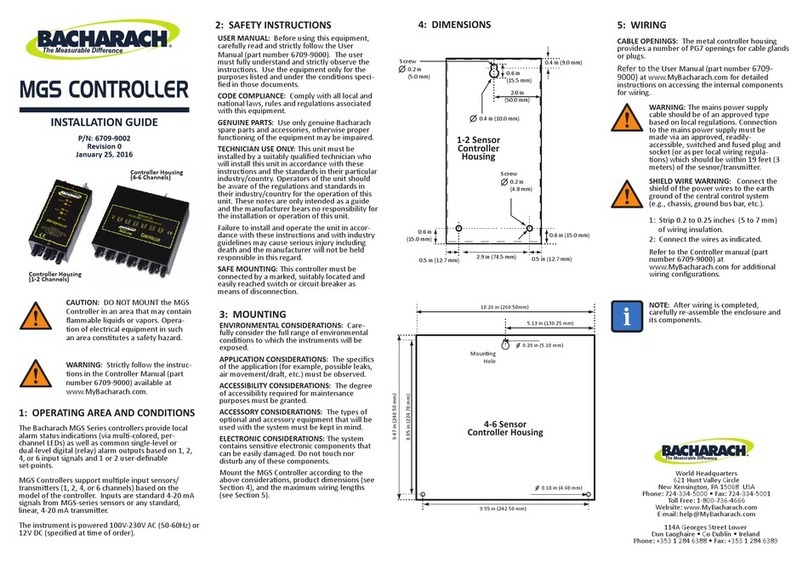

SECTION 4. INSTALLATION 10

4.1 Warnings & Cautions........................................................................................................................................................................ 10

4.2 Preliminary Inspection ...................................................................................................................................................................... 10

4.3 Suitable / Appropriate Locations....................................................................................................................................................... 10

4.4 Mounting Instructions........................................................................................................................................................................ 11

4.5 Electrical and Communications Wiring.............................................................................................................................................. 12

4.6 Relay Wiring ..................................................................................................................................................................................... 13

4.7 Connecting Modbus Gateways (1100-2198, MOXA MGate MB3170) .............................................................................................. 13

4.8 Connecting Ethernet Network Switches (1100-2172, MOXA EDS-208A) ......................................................................................... 14

4.9 Connecting MVR-300’s..................................................................................................................................................................... 15

SECTION 5. COMMISSIONING 16

5.1 System Overview.............................................................................................................................................................................. 16

5.2 Commissioning MVR-SC .................................................................................................................................................................. 19

5.2.1 Floorplan Spreadsheet ............................................................................................................................................................ 19

5.2.2 Floorplan Spreadsheet Setup.................................................................................................................................................. 20

5.2.3 Upload Floorplan ..................................................................................................................................................................... 20

5.2.4 System Time and Date ............................................................................................................................................................ 21

5.3 Commissioning MVR-300’s .............................................................................................................................................................. 22

5.3.1 MVR-300 Firmware Version .................................................................................................................................................... 22

5.3.2 MVR-300 Factory Reset.......................................................................................................................................................... 22

5.3.3 Method 1: Modbus ID Auto-Assign .......................................................................................................................................... 23

5.3.4 Method 2: Set Modbus ID Manually......................................................................................................................................... 24

5.4 Commissioning Gateways ................................................................................................................................................................ 24

5.4.1 Change Gateway IP Address .................................................................................................................................................. 25

SECTION 6. OPERATION 26

SECTION 7. TROUBLESHOOTING 26

SECTION 8. ADDITIONAL INFORMATION 27

8.1 Disposing of the Instrument .............................................................................................................................................................. 27

8.2 Service Center Locations.................................................................................................................................................................. 27