Digitrax SDH164K1C User manual

©2010 Digitrax, Inc. www.digitrax.com 1

Complete Train Control

un Your Trains, Not Your Track!

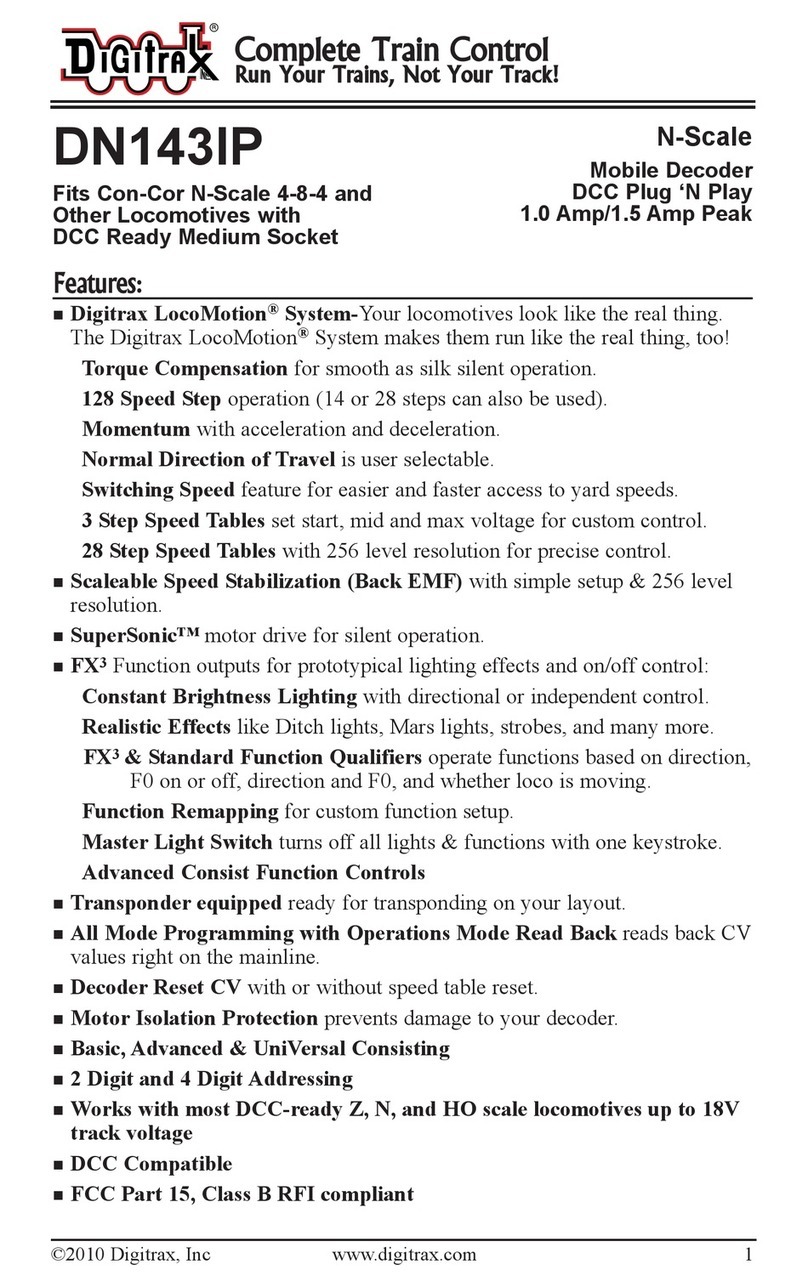

DH164K1C

Plug ‘N Play for Kato F40PH HO

Locomotives. Light Board replacement

decoder for motor, lights and sound.

Preloaded with F40PH ound cheme

(Does Not include or use FN04

Function/Light Decoder)

HO cale

DH164K1C: Drop in

Mobile Decoder with

oundFXTM

Includes 28mm 32 Ohm

peaker & 330uF Capacitor

1.0 Amp/1.3 Amps Peak

Features:

nDigitrax SoundFX™ Sound System -Your locomotives will sound in scale

like the real thing with SoundFX™

Customizable 8 Bit Sound

3 simultaneous voices

Downloadable Sound with Digitrax PR2/3 and SoundLoader software

4 Megabit Onboard Sound Memory

1 Watt Sound Output

4 CV-selectable Horn choices in factory preloaded scheme

Cam input-synchronized steam-chuff option for steam loco use

nDrop in Light board replacement for easy install.

nFactory 28mm round 32 ohm speaker

nSmart Power Management-no more booster or programmer shutdowns! No

extra equipment needed to program or run

nSoundFX™ does not require an external rate sensor to vary workload.

nDigitrax LocoMotion®System-Your locomotives look like the real thing.

The Digitrax LocoMotion®System makes them run like the real thing, too!

nSuperSonic motor drive for silent operation.

nDigitrax FX3Functions-Control lights and functions for prototypical light-

ing effects and on/off control:

nTransponder D Equipped ready for transponding on your Layout

nProgram CV’s using any Digitrax Compatible Control system without

having to buy any extra equipment

nDirect mode programming

nOperations Mode Programming

nDecoder Reset CV with or without speed table reset.

nMotor solation Protection helps prevent damage to your decoder.

nBasic, Advanced & UniVersal Consisting

n2 Digit and 4 Digit Addressing

nDCC Compatible

nDigitrax “no worries” warranty

nFCC Part 15, Class B RF compliant

©2010 Digitrax, Inc. www.digitrax.com 2

Parts List

1 SDH164 1C Mobile with Sound FXTM 1 Instruction sheet

1 Speaker harness with 28mm 32 Ohm speaker and 330 uF capacitor/clip

Installation Information

See the Digitrax Decoder Manual for complete decoder test procedures, instal-

lation instructions, programming and technical information. Digitrax manuals

and instructions are updated periodically. Please visit www.digitrax.com for the

latest versions, technical updates and additional locomotive-specific installation

instructions.

Installation Instructions

1) Carefully remove the F40PH couplers, shell, and platform/walkway as indi-

cated on manufacturer’s model assembly diagram.

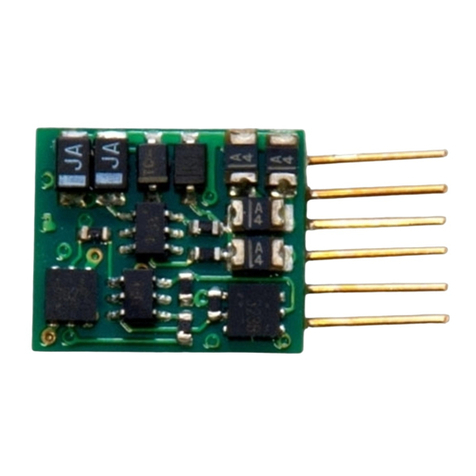

2) Disconnect 2 track power clips on the light board. Unscrew and remove

Complete Train Control

un Your Trains, Not Your Track!

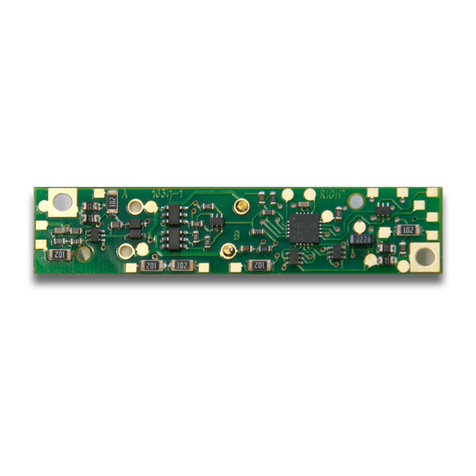

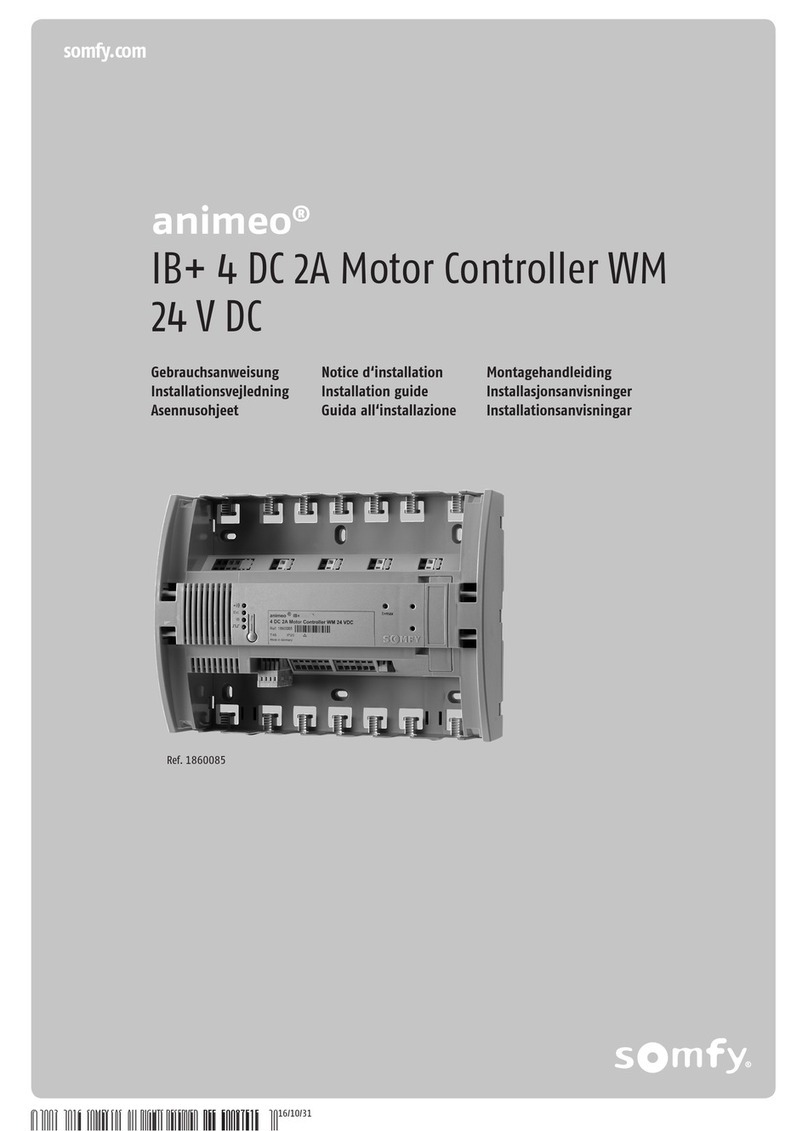

Figure 2: Installation Diagram

Warning:

To prevent decoder

damage, be sure the

motor and track power

contacts are properly

connected before

applying power.

Motor contact holes

Speaker

Capacitor

Track contact clip

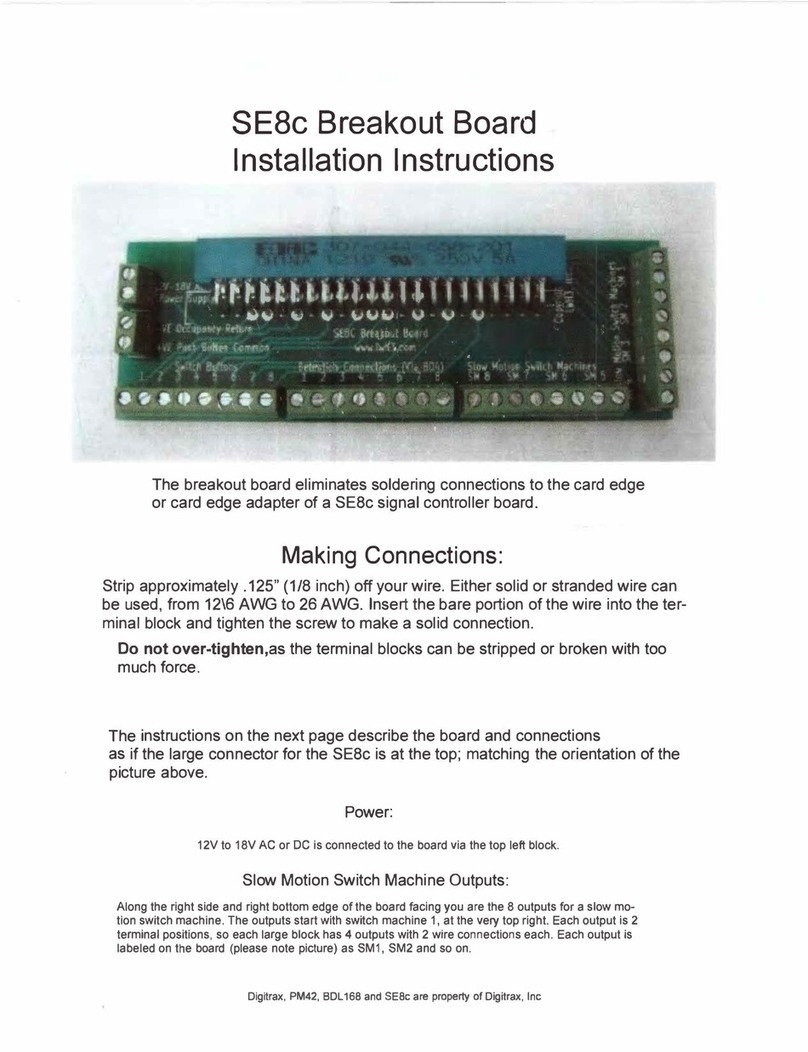

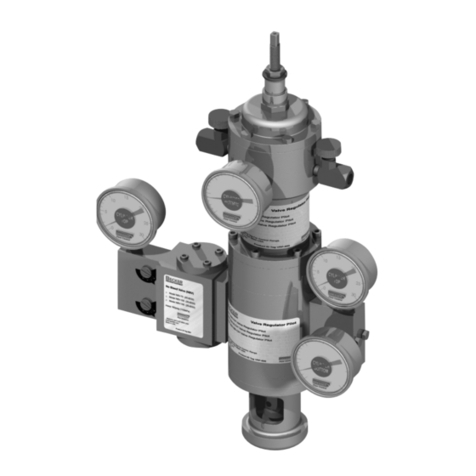

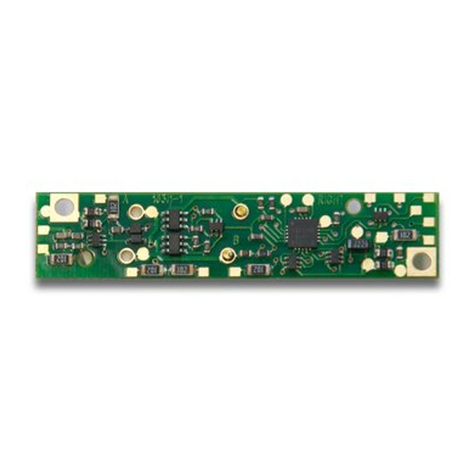

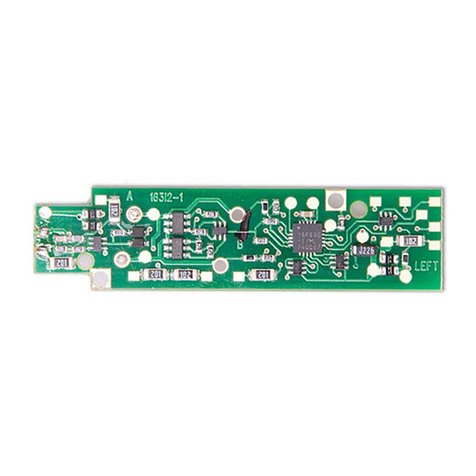

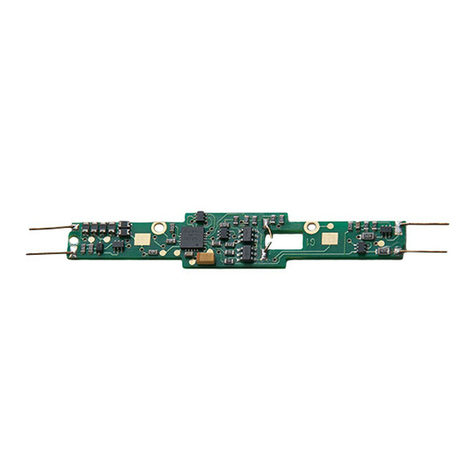

Figure 1: DH164K1C Decoder

Light board (removed)

Motor Contact holes Track contact pads

Mount screws

©2010 Digitrax, Inc. www.digitrax.com 3

light board. Retain the two screws.

3) Place SDH164 1C decoder in position shown in Figure 2 and use small pli-

ers to press in 2 motor contacts into the motor contact holes. Using 2 light

board screws removed earlier, secure the decoder in position.

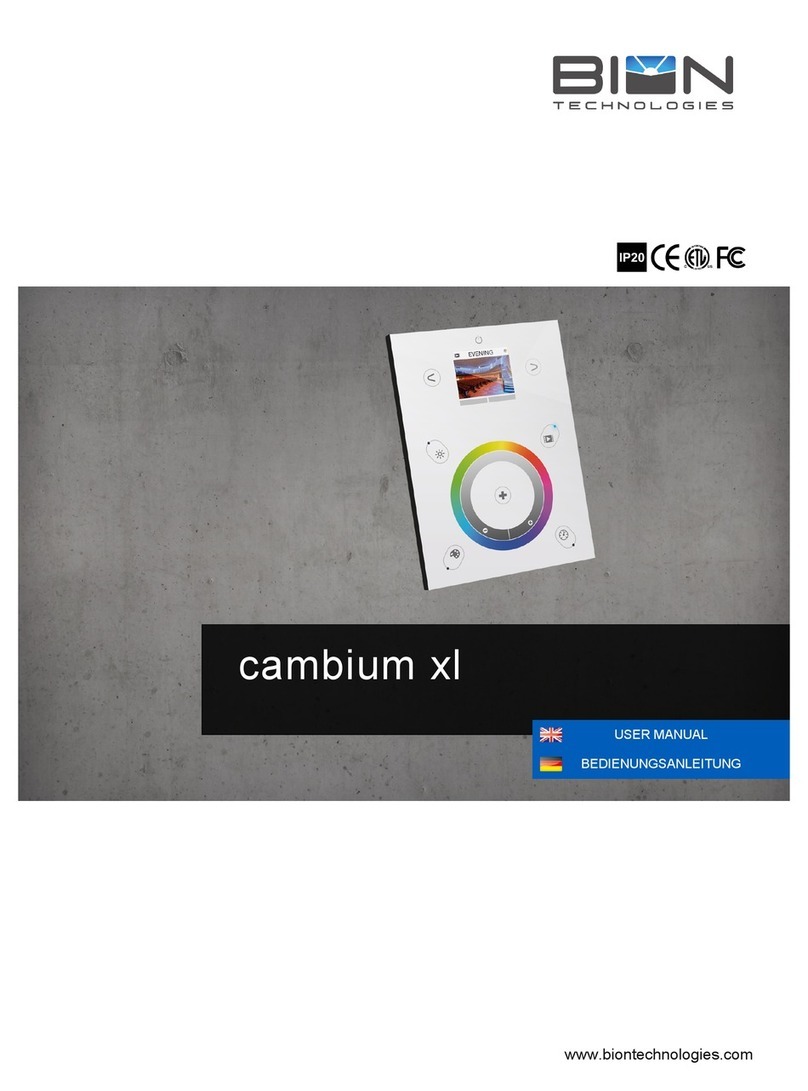

4) Install the 28mm round speaker in the upper rear of the F40PH shell as

shown in Figure 3. . Ensure the speaker leads are routed out through the two

slots provided in the speaker housing edge.

5) Replace platform/walkway and couplers.

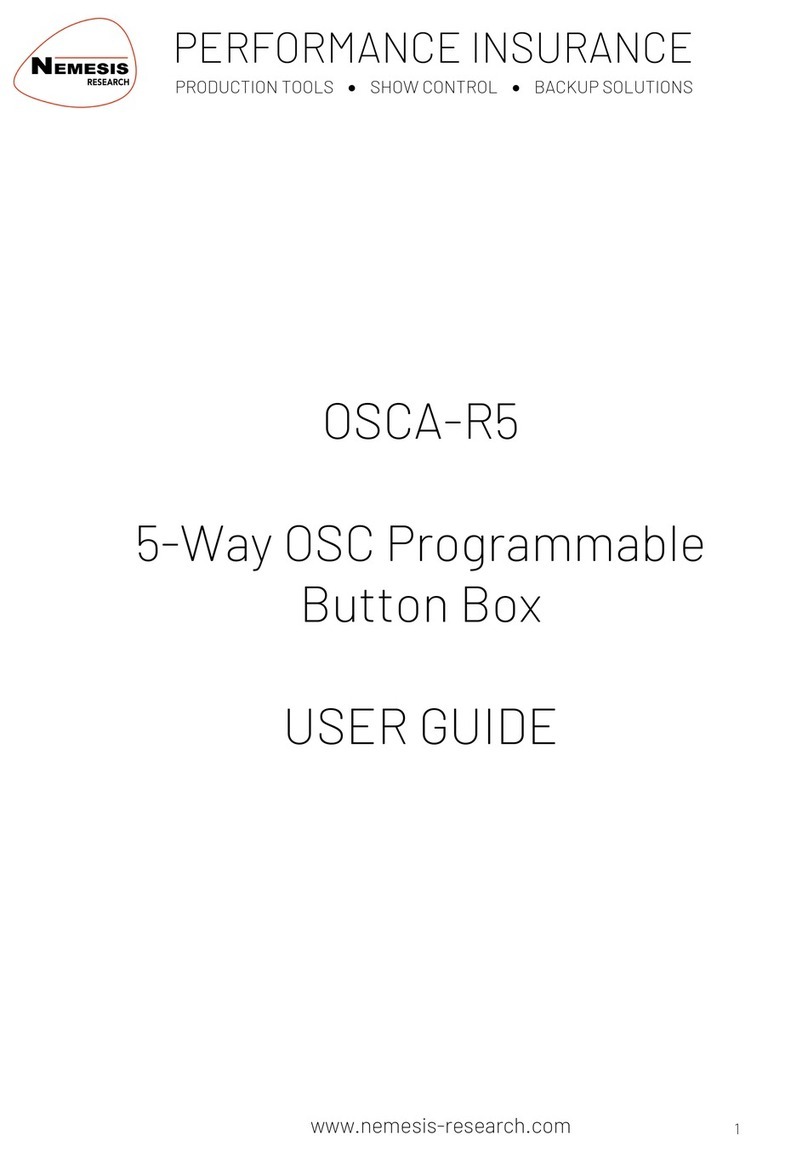

6) Reattach the two press-fit brass track power clips to the track power pads on

the decoder.

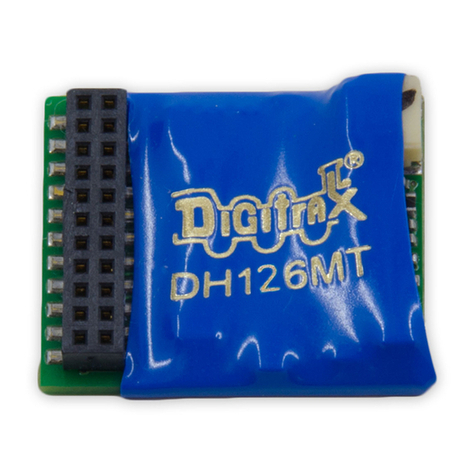

7) Install the capacitor attached to the wire harness at the rear of the casting

using the plastic clip provided. Be sure no wires short to the casting. Trim

back and secure any unused wires so they do not short to the decoder or

frame or bind the drive shafts.

8) Inspect and test the installation before replacing the shell.

2443 Transmitter D T850-872-9890

Panama City, FL 32404 F850-872-9557

www.digitrax.com

Speaker Installed Inside

Speaker Enclosure

Figure 3: Speaker Installation Diagram

©2010 Digitrax, Inc. www.digitrax.com 4

Customizing Your Decoder

Your Digitrax decoder is ready to run and will operate using address 03 with no

additional programming. On your Digitrax system, simply select the locomo-

tive’s address and the sound will start. On some DCC systems, it is necessary

to select the locomotive address AND send a command to start the sound.

For a more prototypical railroading experience, your decoder can be cus-

tomized for your specific locomotive by programming some of the

Configuration Variables, or CVs, available. Digitrax SD decoders can be pro-

grammed using either the direct method on a programming track or with the

operations mode using the main line. See the Digitrax Decoder Manual or the

Digitrax web site for more information.

nitial Test and Programming: This decoder is preprogrammed and tested

with an F40PH sound scheme, and is ready to operate on factory default

address 03. Before customizing the decoder it is useful to run it on the fac-

tory default address 03 to check the installation. The following sections

show how to change the locomotive address and customize the decoder

For more information on decoder installation and programming techniques and

examples visit the www.digitrax.com

Changing the Decoder Address

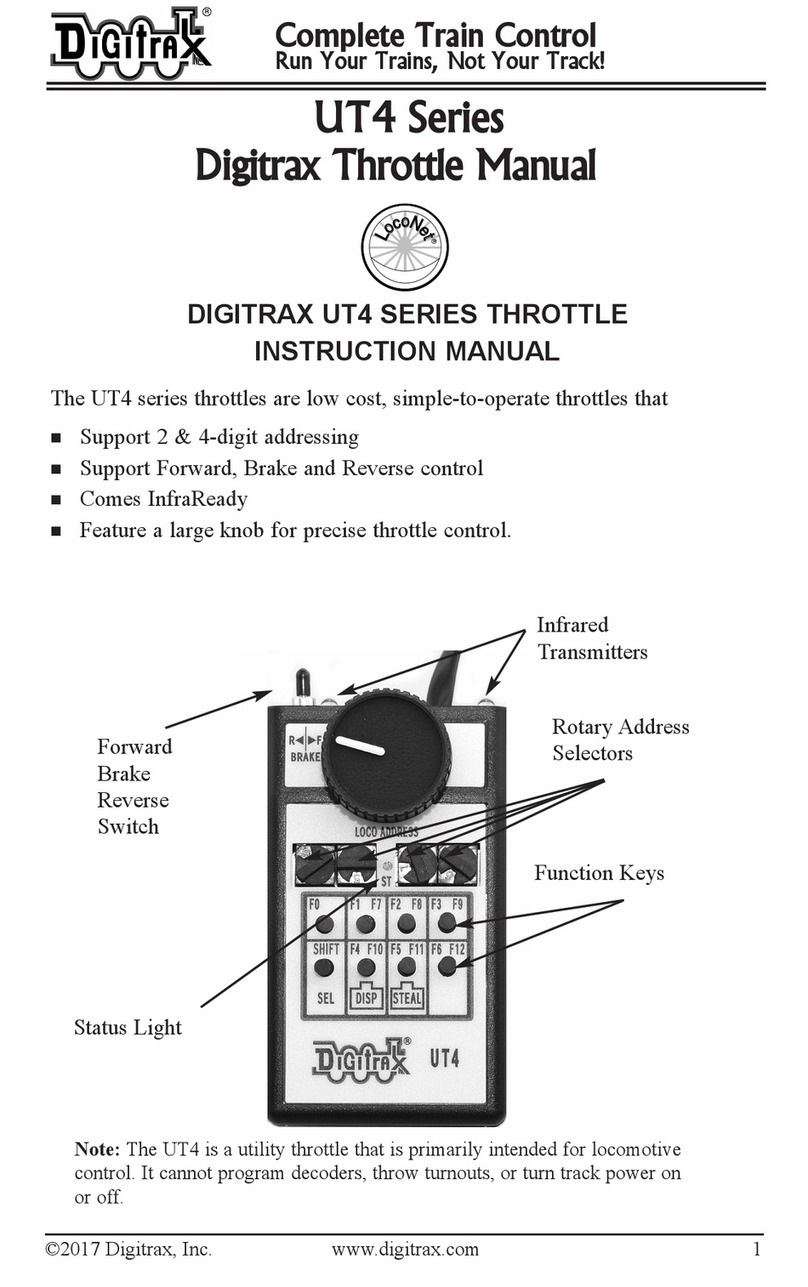

The first CV most people change is the decoder address. This allows you to

independently control each loco with a unique address. Digitrax decoders are

Complete Train Control

un Your Trains, Not Your Track!

Track Power Clips

Capacitor with

Clip nstalled

Figure 4: Installation Diagram

©2010 Digitrax, Inc. www.digitrax.com 5

shipped with CV01 (AD2), the two digit address, set to 03. Following is a brief

description of how to change the decoder address with a Digitrax DT series

throttle. See your Starter Set Manual for complete programming instructions.

1. Place the loco on the programming track. Go into Program Mode on your system.

On DT400/DT402 press PROG. On DT300, DT100 & DT200 press RUN/ TOP &

FN/F0.

2. Choose AD2 for 2 digit addressing or AD4 for 4 digit addressing (DT400/DT402

and DT300). (Ad for DT100 & DT200, see set manual for 4 digit instructions).

3. Choose the address you want to set up for the decoder.

4. Complete address programming. On DT400/DT402 press ENTER. On DT300,

DT100 & DT200 press EL.

Note: CV29 must also be programmed to enable 4 digit addressing, this is

done automatically by the DT400/DT402 & DT300 but not on earlier throttles.

Using this decoder in other locomotives

The sound project loaded into this decoder is for an F40PH diesel locomotive.

If you want to install it in a different locomotive, you can simply load a dif-

ferent sound project for that type of locomotive. The cam input is available

for steam installations where you want to synchronize chuffing.

Digitrax LocoMotion

®

System

Your locomotives look like the real thing, now you can make them run like the

real thing, too. Digitrax decoders incorporate torque compensation for smooth

as silk operation. You can also program CVs that control momentum, 3 step

and 128 step speed tables, switching speed, normal direction of travel,

scaleable speed stabilization and more to take full advantage of the Digitrax

LocoMotion System.

Momentum-CV03 & CV04

Momentum is part of the LocoMotion System. Acceleration is controlled by

CV03 and deceleration by CV04. Both come from the factory set to 000. A

range of 000 to 031 is available for both accel and decel. We recommend that

you try CV03:003 and CV04:000 as a starting point for experimenting with

momentum.

Speed Tables-How the Loco esponds to the Throttle

With Digitrax LocoMotion, there are two types of speed tables: 3 Step Tables

and High Resolution 28 Step Tables. Please see your Digitrax Decoder Manual

for a discussion of the 28 Step Tables. The 3 Step Tables are set up by program-

ming 3 CVs: Start Voltage (CV02), Mid point Voltage (CV06) and Max Voltage

(CV05). These values are set at 000 at the factory. All have a range of values

from 000 to 255. We recommend the following CV values as a starting point for

2443 Transmitter D T850-872-9890

Panama City, FL 32404 F850-872-9557

www.digitrax.com

©2010 Digitrax, Inc. www.digitrax.com 6

experimenting with speed tables.

Other LocoMotion

®

Features: Switching Speed, Normal Direction of

Travel & Scaleable Speed Stabilization (Back EMF) Features

Switching speed is controlled by CV54. The factory setting is 000 for OFF. To

turn on the switching speed feature, program CV54 to a value of 001. When

this feature is on, use F6 to activate and deactivate switching speed. When

switching speed is ON and F6 is ON, the switching speed feature is on. With

the feature on the throttle’s target speed is effectively reduced by about 50%

and the effects of accel and decel programmed into the decoder are reduced by

1/4. This is useful for yard switching operations.

Normal Direction of Travel is controlled by CV29. See your decoder manual

for additional information on the settings for CV29.

Scaleable Speed Stabilization (Back EMF) intensity, or droop, is controlled

by CV57. The factory setting for this feature is 006 which is suitable for most

locos. You can adjust this value in the range of 000 for OFF to 015 for the

maximum effect. Consult your Digitrax Decoder Manual for info about CVs 55

& 56 and their effects on scaleable speed stabilization. The factory setting for

both CV55 & CV56 is 000.

SuperSonic Silent Operation and Torque Compensation

The factory settings in the decoder provide silent, smooth operation of your

locomotive under most conditions. For more information about these settings,

please see the Digitrax Decoder Manual or our website.

Digitrax Transponding CV61

Digitrax Transponding is controlled by CV61. The initial factory set value is

000 for OFF. To turn on transponding, program CV61 to a value of 002. This

allows you to use Digitrax transponding to keep track of your rolling stock.

When transponding is enabled, the front light of the locomotive may flicker

slightly to indicate transponding signal is being communicated. For optimal

transponding operation, we recommend that you hook up the forward and rear

Complete Train Control

un Your Trains, Not Your Track!

Loco Type V tart V Mid V Max

CV02 CV06 CV05

Switcher

Concentrated low speed. Limited top 002 038 064

speed

Road Switcher

Prototypical top speed w/evenly 002 048 098

distributed curve from 0 to top speed

Mainline Loco

Quick increase to cruising speed then 002 128 154

levels off to prototypical top speed.

©2010 Digitrax, Inc. www.digitrax.com 7

lights as shown above.

Decoder eset CV08

Decoder reset lets you reset all CV values to the initial factory settings. To

reset all CV values, program CV08 to a value of 008. You also have the option

of resetting all values except the 28 speed step tables. To do this,

program CV08 to a value of 009.

Digitrax SoundFXTM System

Digitrax SoundFXTM lets you make your locos sound like the real thing!

The SoundFX™ sound CVs in the range of CV140 to CV256 let you cus-

tomize your decoder without having to reprogram or change the installed

sound scheme.

Standard decoder CVs in the range of CV01 to CV120 operate the same as for

a non-sound FX3Digitrax decoders (they control motor and light functions

etc.) CV58 is used as Master Volume, and CV60 is used to select an alter-

nate scheme, if provided in the sound project.

Sound CV155 is provided to select Diesel engine “notching” modes. The

default of CV155= 00 provides “automatic notching” that changes the

diesel RPM settings at 8 distinct throttle speeds that are controlled by Sound

CV132.

Sound CV155=01 selects “semi-automatic notching” mode that allows F6 ON

to increase the notch from the current throttle setting and F7 ON to decrease

back towards the lowest current throttle notch setting.

Sound CV155=02 selects “manual notching” mode that allows F6 ON to

increase the notch setting and F7 ON to decrease the notch setting irrespec-

tive of the throttle setting, which controls just the motor speed.

The decoder’s sound scheme can be reloaded using a Digitrax PR2 program-

mer and a sound project file (for example SD38_2.spj) from the Digitrax

Sound Depot web site. Typical sound downloads take between 50 and 100

seconds depending on the project complexity and file size.

The following tables show the CVs used in this decoder version and how it is

set up at the factory to operate various sounds using your throttle.

2443 Transmitter D T850-872-9890

Panama City, FL 32404 F850-872-9557

www.digitrax.com

©2010 Digitrax, Inc. www.digitrax.com 8

Complete Train Control

un Your Trains, Not Your Track!

CV# Used For Range

[default val]

01 2 Digit Address [03]

11 Sound Time Out, 06 = Sound ends when loco address is

de-selected, 00=Sound stays on after loco is de-selected

[06]

29 Configuration [06]

49 Forward Light (FOF) -Headlight - FX configuration [0]

50 Reverse Light (FOR) -Rev Light - FX configuration [0]

51 Function 1 - FX configuration [0]

52 Function 2 - FX configuration [0]

58 Master Volume (F8 ON used for Muting) 0-15 [9]

60 Factory Scheme Select: 0=F40PH [0]

132 Notch Rate [127]

135 Mute Volume [0]

140 Prime Mover Volume 0-64 [60]

141 Bell Volume (Min=0, Max=64) [25]

142 Horn Volume (Min=0, Max=64) [60]

143 Time-Scattered Air Effects Volume 0-64 [30]

145 Misc Vols 0-64 [40]

146 Bell Ring Rate (1=24 milliseconds) 1-100 [07]

147 Air Drier Rate (1-about 2 seconds) 1-64 [02]

148 Compressor Run Rate [30]

149 Air Compressor On Time [20]

150 Horn Setup. Default=0, Alternate Horns= 1, 2, 3

Playable Horn versions =128, 129, 130, 131

[0]

151 Auto Coupler Sequence Threshold Value-Peak speed to

allow auto coupler/brake when direction change occurs

and F3 is ON

0-64 [48]

152 Project Author D, Digitrax=221 [221]

153 Project D, F40PH scheme [4]

155 Notching/Slip Mode: 00=Automatic,

01=Semi-Automatic, 02=Manual

[00]

©2010 Digitrax, Inc. www.digitrax.com 9

Function emapping

Function remapping allows you to program the function outputs of your decoder

to be controlled by selected function keys on your throttle. Please consult the

Digitrax Decoder Manual or website for information on function remapping.

Master Light Switch

Each of the four function outputs can be programmed to turn on and off with

the F0 ON/OFF key on your throttle, creating a Master Light Switch. The CV

values for creating this effect are listed in the Digitrax Decoder Manual in the

2443 Transmitter D T850-872-9890

Panama City, FL 32404 F850-872-9557

www.digitrax.com

Function # Used For Notes

F0 Lights

F1 Bell

F2 Horn/Whistle CV150 selects horn

F3 Coupler crash Auto coupler/brake set by

CV151 max speed

F4 Air feature disable F4 off enables pop-off,

drier and starts compres-

sor

F5 Diesel = Dynamic brake

Fans

F6 Diesel = Notch Up Notch UP if CV155=01 or

02

F7 Crossing Gate Airhorn

or;

Diesel = Notch DOWN

Notch DOWN, if

CV155 = 01 or 02

(Crossing Gate Horn active

if CV155=0)

F8 Mute Control F8 ON is muted

F9 Brake squeal

F10 Crossing Gate

Airhorn Sequence

F11 Handbrake

F12

©2010 Digitrax, Inc. www.digitrax.com 10

section: Setting up FX & FX3Effects On Function Outputs.plugs into the

decoder. This 9 pin connector has been adopted by other companies in the DCC

industry, too.

SoundFX™DC Operation Mode

Digitrax SoundFX™ decoders will operate on smooth DC power. The sound

will not start until approximately 5 volts is applied to the track and there will

be no “start up sound.”

SoundFX™Troubleshooting

f the sound does not start in the decoder

1. Make sure you have selected the locomotive address on a throttle. The

sound will not run unless the locomotive is addressed in the system. Make sure

F8 is OFF.

2. Check your installation to make sure the decoder is installed properly.

f the sound output sounds distorted

1. Check the speaker cone for magnetic debris that may have collected there.

Debris on the speaker will cause a loss of sound quality and must be removed.

2. Be sure that the CV58 volume is not set at a level that is too high for the

speaker being used. For impedances below 32ohms (e.g. 8 to 30 ohms) set this

volume setting lower to ensure the 1 watt output rating is not exceeded.

f the sound in your decoder shuts down after you stop it and you are not

using a Digitrax system for control. On some DCC systems decoders are not

addressed by DCC packets after the locomotive is set to 0 speed. In this case

after the CV11 timeout elapses (6 second default), sound will “shutdown.”. To

defeat this feature, set CV11=00 to remove the timeout and shutdown. To make

sounds, the decoder must ha e a command addressed to it at least once.

f you have trouble reading back CV’s on the programming track, this may

be due to insufficient current draw on the SDH164 1C motor or function

leads, particularly if it is not installed in a loco. Of course you can always just

re-program the CV value into a CV to get the desired results, even though read-

ing CV’s might not work.

OPS mode is recommended for writing to (programming) all CVs except

CV01, CV17 & CV18 (2 digit and 4 digit addresses). If a second DCC

decoder is present that is not SoundFX™ compatible then correct read back of

CV data is not possible,since the NMRA CV read back was not designed for

multiple decoder read back.

have loaded a new scheme but the CV’s and Functions are not what

expected. Load the sound project you programmed and then select the

“view>project description” menu and then read the text file on the screen that

defines how that project in particular uses CV’s and Functions for sound

generation and configuration. Even without a programmer you can get

Complete Train Control

un Your Trains, Not Your Track!

©2010 Digitrax, Inc. www.digitrax.com 11

SoundLoader and the sound projects from the Digitrax web site and review the

descriptions on your compatible PC.

My speaker does not have a polarity mark.

Speaker Polarity is simply used to ensure when more than one speaker is being

used that they can be wired or “phased” so the input causes the diaphragm to

move in the same direction. It can be ignored in a single speaker case.

When using my LT1 and test kit when blow the Horn the decoder resets .

Using the LT1 test kit and protection resistor is good to check the decoder is

safely connected, but when a loud sound like a horn is activated the protection

resistor limits the available track input power too much, so the decoder resets.

Simply test full volume sounds on normal track power after connections check

O .

When blow the Horn while on normal powered track the decoder slows

down or resets .

1. If high volume overloads the decoder and the loco slows down, set CV57=0

to turn off BEMF.

2. Alternatively if you are using a speaker with too low an impedance, try a

new speaker with the factory recommended 32 ohm impedance. It is safe to

use a 4 or 8ohm speaker, as long as the volume is not set too high which may

overload beyond the designed power level.

Warranty & epair

Digitrax gives a one year “No Worries" Warranty against manufacturing

defects and accidental customer damage on all Digitrax products.

That's it! A simple, straightforward warranty with no tricky language!

Visit www.digitrax.com for complete warranty details and instructions for

returning items for repair.

Digitrax, Inc. is not responsible for unintentional

errors or omissions in this document.

2443 Transmitter D T850-872-9890

Panama City, FL 32404 F850-872-9557

www.digitrax.com

Made in U.S.A.

307-SDH164K1C

DH164K1C

Plug ‘N Play ound/Mobile Decoder

for Kato HO F40PH

2443 Transmitter oad

Panama City, FL 32404

www.digitrax.com

T850-872-9890

F850-872-9557

Table of contents

Other Digitrax Controllers manuals

Digitrax

Digitrax DN166I1C User manual

Digitrax

Digitrax DN143IP User manual

Digitrax

Digitrax DN166I2 User manual

Digitrax

Digitrax UT6 Series User manual

Digitrax

Digitrax UT4 Series User manual

Digitrax

Digitrax DZ126IN User manual

Digitrax

Digitrax SoundFX SDXH186MT User manual

Digitrax

Digitrax DN166PS User manual

Digitrax

Digitrax DH126MT User manual

Digitrax

Digitrax DZ123MK0 User manual

Popular Controllers manuals by other brands

Mitsubishi Electric

Mitsubishi Electric MR-J5W-G Series user manual

CKD

CKD ABSODEX MINI AX6000M Series manual

Insight Control

Insight Control ZONE-IT installation manual

Arthur Grillo

Arthur Grillo DPC200 manual

Fastech

Fastech Ezi-servo plus-R user manual

Hubbell

Hubbell CHANCE Installation, operation and maintenance manual