3

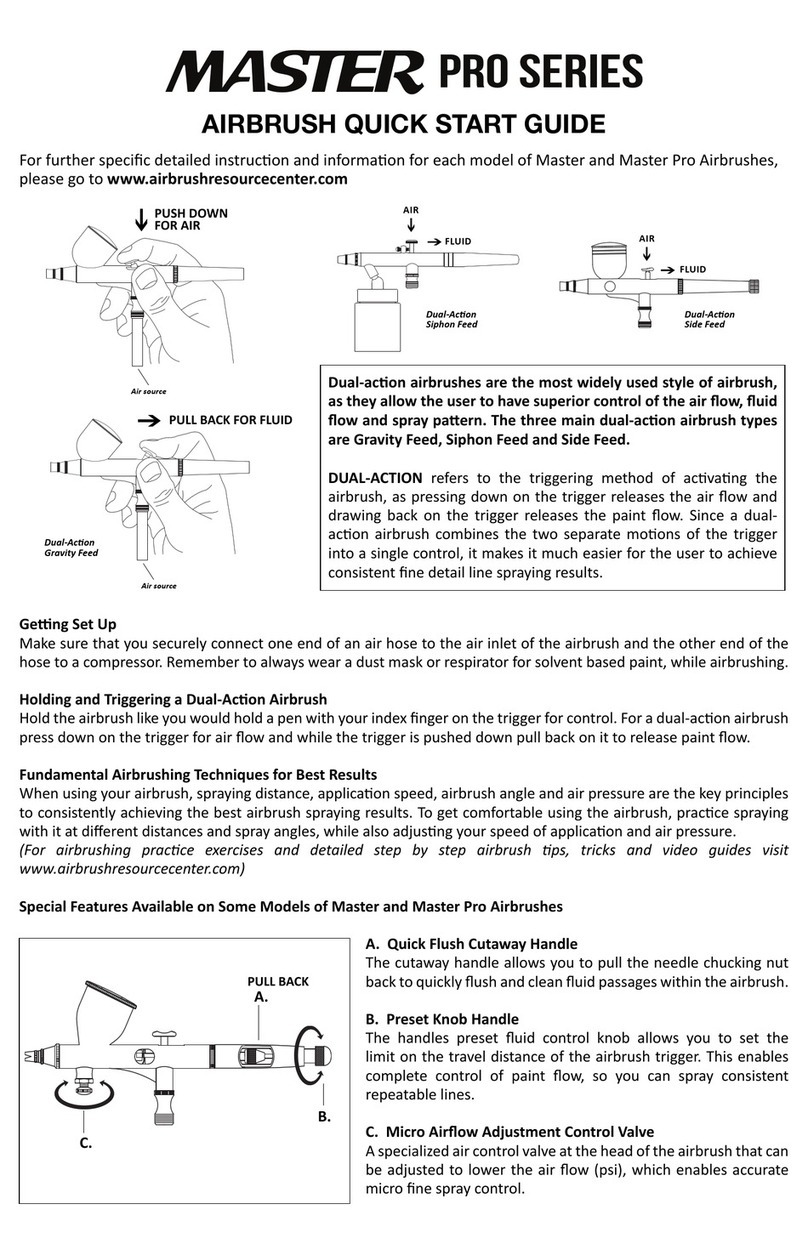

SURFACE

START PRESS PULL KEEP STEADY MOVE RELEASE FOLLOW

MOTION TRIGGER TRIGGER MOTION TRIGGER TRIGGER THRU

HERE DOWN BACK AND SPRAY FORWARD MOTION

DON’T ARC

If airbrush motion in uneven,

paint finish will be uneven.

SURFACE

BUILD-UP

ARCING MOTION

THE MOST

COMMON

PROBLEM

Runs and sags

are caused by

one or more of

the following

errors.

1. “Freezing” or forgetting to release trigger at the

end of the stroke.

2. Holding airbrush still or moving too slowly.

3. Holding airbrush too close to surface.

LEARN TO TRIGGER

Best results are achieved by a good constant motion. Start motion before pressing trigger, follow through

motion after releasing trigger. Do not hesitate while spraying or you will create what is called the Barbell

Effect. See Figure 3 pg. 9.

Careful cleaning and maintenance of your airbrush

is essential if it is to continue to work effectively.

The small passages inside the airbrush can become

blocked easily by dried paint if the airbrush is not

cleaned after each use. If there is still a useable

amount of color in the color cup or reservoir when

you have finished spraying, pour the remainder

back into the original paint bottle. Operate the air-

brush, spraying on a scrap piece of paper until the

color is gone and only air is sprayed. Take a clean

color cup or jar full of appropriate cleaner. Insert it

into the airbrush, spray some cleaner through the

airbrush at broad and small patterns until it comes

out colorless. After removing color cup or jar, turn

brush upside down and press trigger. This will

remove any material still in the brush. Always clean

the airbrush every time you finish spraying as some

types of paint can dry remarkably fast, and may

cause your airbrush to clog if not cleaned properly.

Another method of cleaning the airbrush is back

flushing using a closed container such as a jar

assembly. Take a soft cloth and cover the spray reg-

ulator–depress and pull back on the trigger (6). This

will cause back pressure which induces a bubble

action inside the airbrush and in the container

which helps to clean the fluid passages. Never use

an open color cup for this procedure as color will

blow out. Take away the cloth and spray and repeat

this procedure several times. After this is done you

should remove the needle for cleaning.

If the paint is allowed to dry inside the airbrush you

may not be able to dissolve it with clean water.

Cleaning with solvent is the next step. If cleaning

MAINTENANCE AND CLEANING OF YOUR AIRBRUSH

with solvent does not dissolve the blockage, you

will have to disassemble the airbrush, by first

removing the needle and then the head. Soak the tip

in warm soapy water or appropriate solvent for ten

minutes. Then take a tooth pick and gently remove

the dried paint from inside the fluid tip. This

procedure may have to be repeated. Be careful

during disassembly not to lose any small parts.

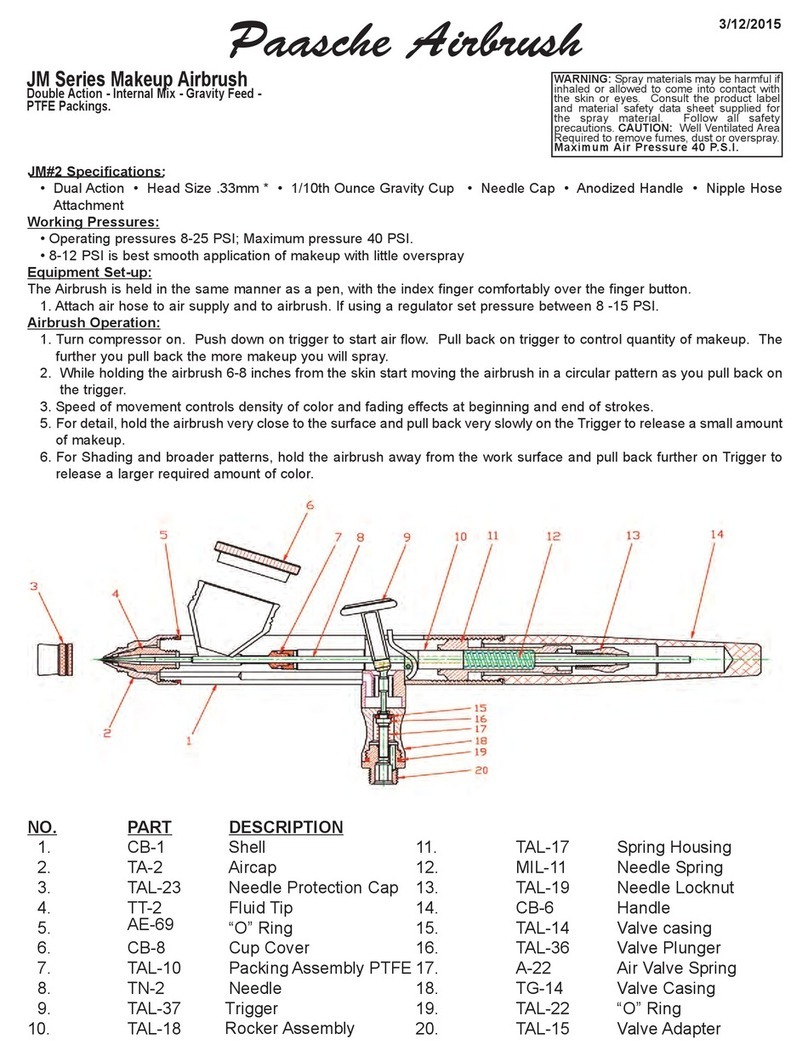

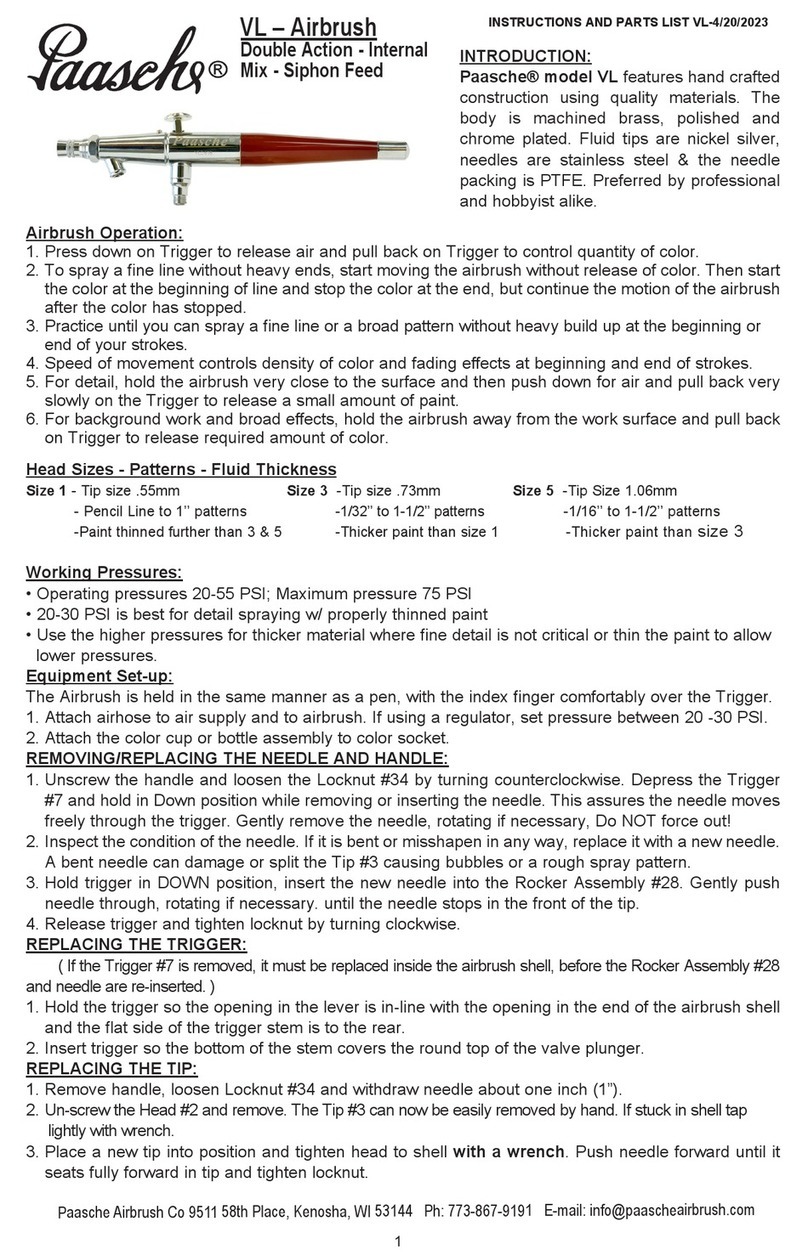

Replacing the Tip

1) Remove Handle (10) by unsnapping the quick

disconnect handle, (See figure 1). Loosen Needle

Chuck (15) and withdraw Needle (16) about one

inch. If the needle is stuck–see “Removing the

Needle,” step 7. If the Needle Chuck (15) is too

tight and the Tube Shank Assembly turns,

unscrew the Handle Adaptor (9). Hold the Tube

Shank (12) between your fingers and loosen the

Needle Chuck counterclockwise.

2) Unscrew the Spray Regulator (2) Unscrew Head

(3). See Manufacturer’s Note Below.

3) Remove tip (4) from body. If tip is lodged in the

head (3), place the tip in angled hole at end of

handle (9) and gently press the tip out of the

head. See figure 2.

MANUFACTURER’S NOTE: Although the nozzle and

needle assemblies of this airbrush are manufactured

to easier maintenance “finger tight” tolerances, the

initial removal of some components may require the

use of a small pliers. If a pliers is necessary for

initial component disassembly, just finger tighten it

when reassembling and the pliers should not be

required for assembly/disassembly thereafter.