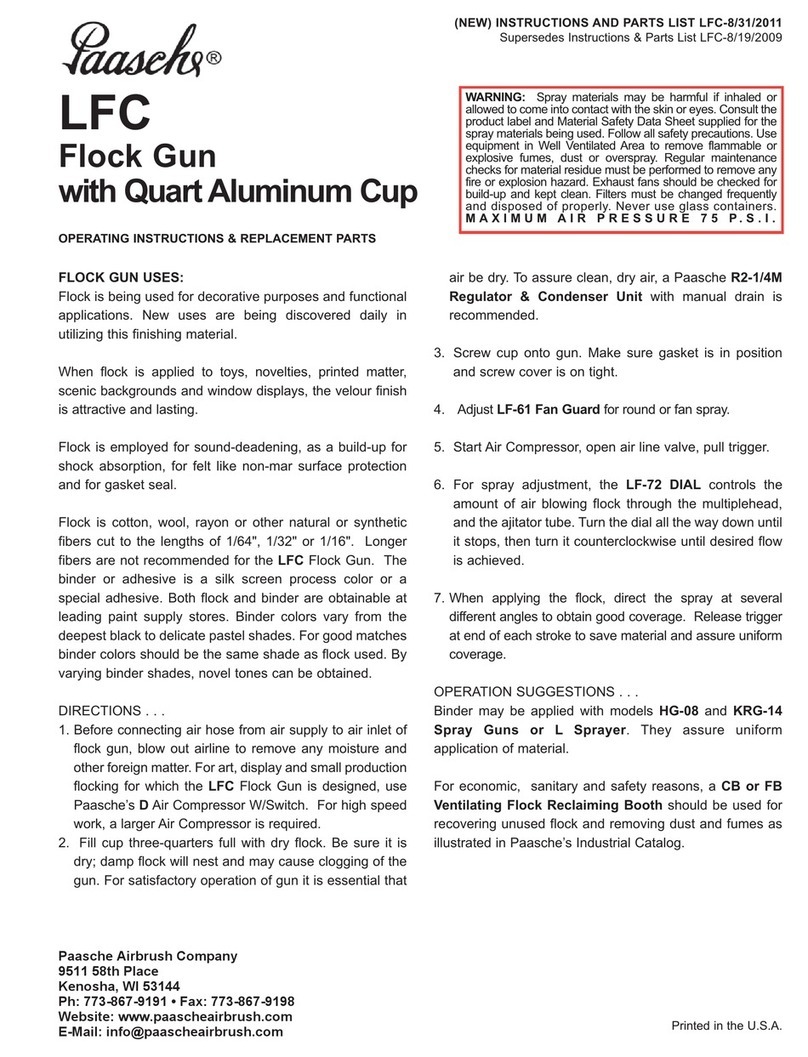

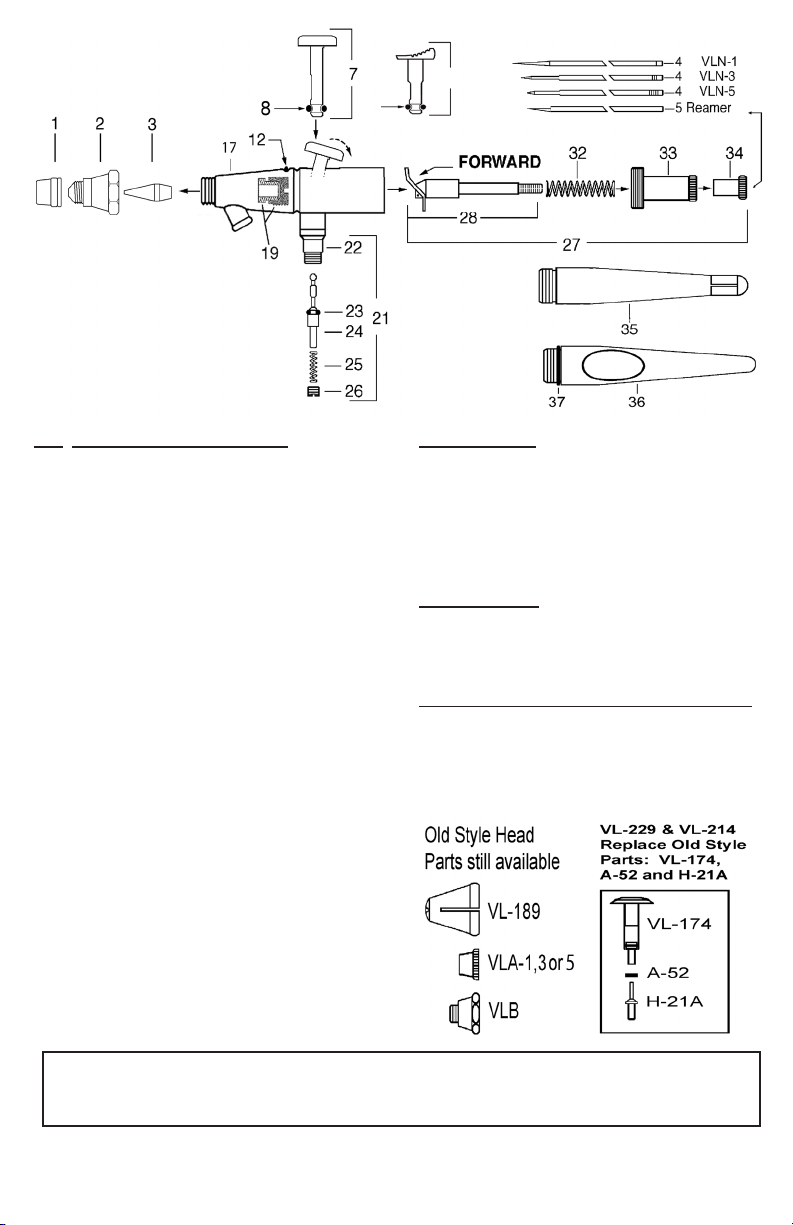

INSTRUCTIONS AND PARTS LIST VL-4/20/2023

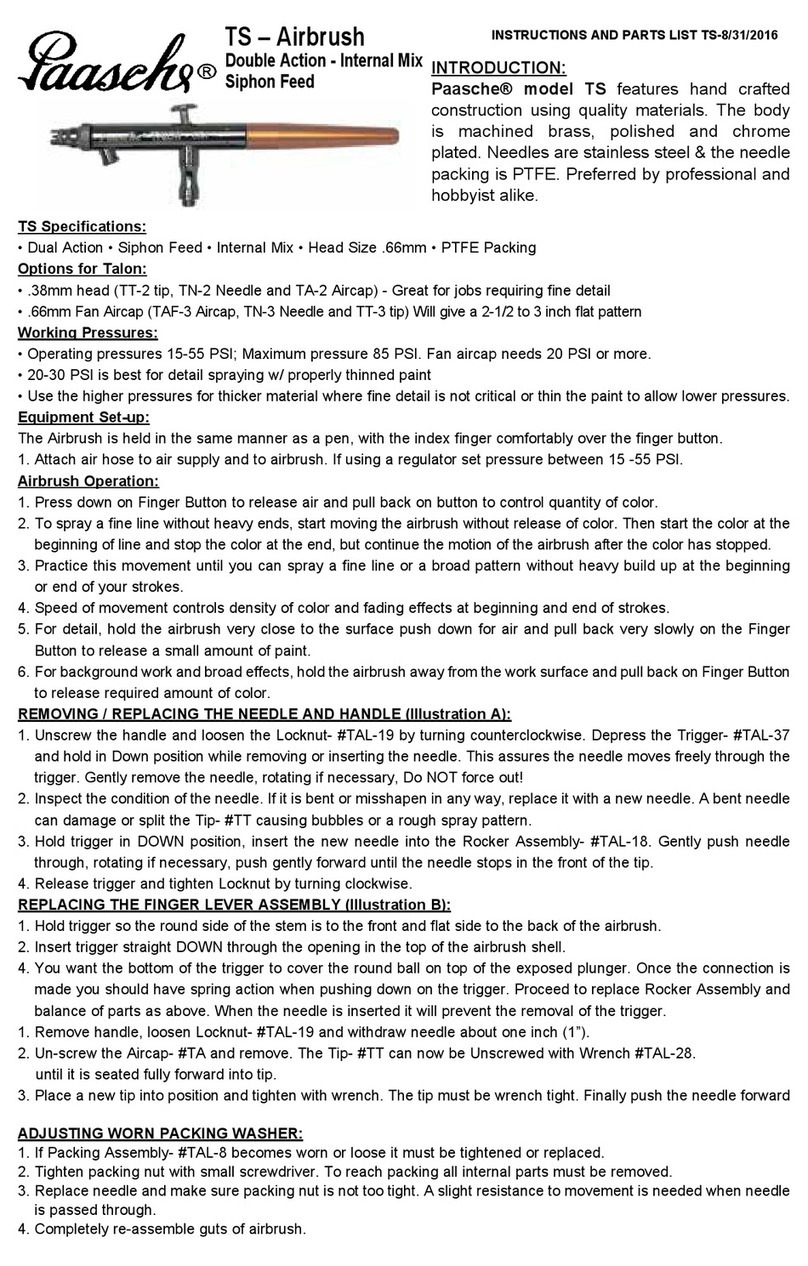

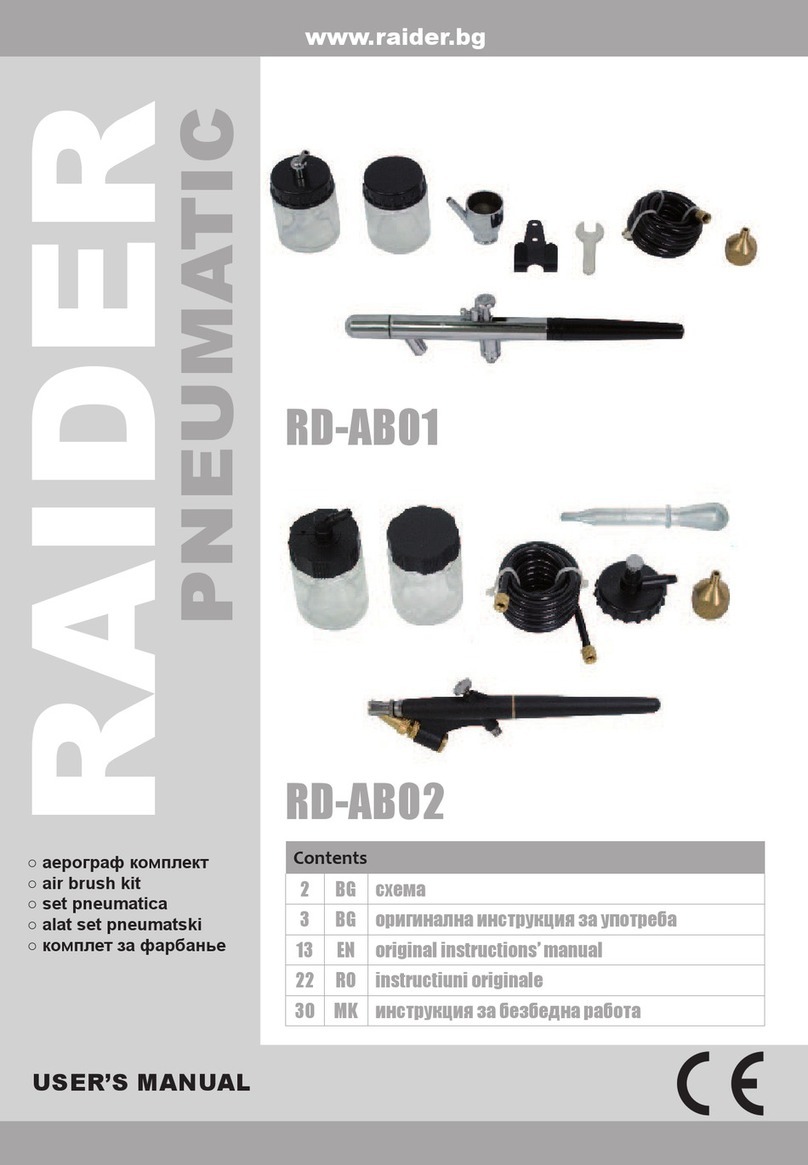

VL – Airbrush

Double Action - Internal

Mix - Siphon Feed

INTRODUCTlON:

Paasche® model VL features hand crafted

construction using quality materials. The

body is machined brass, polished and

chrome plated. Fluid tips are nickel silver,

needles are stainless steel & the needle

packing is PTFE. Preferred by professional

and hobbyist alike.

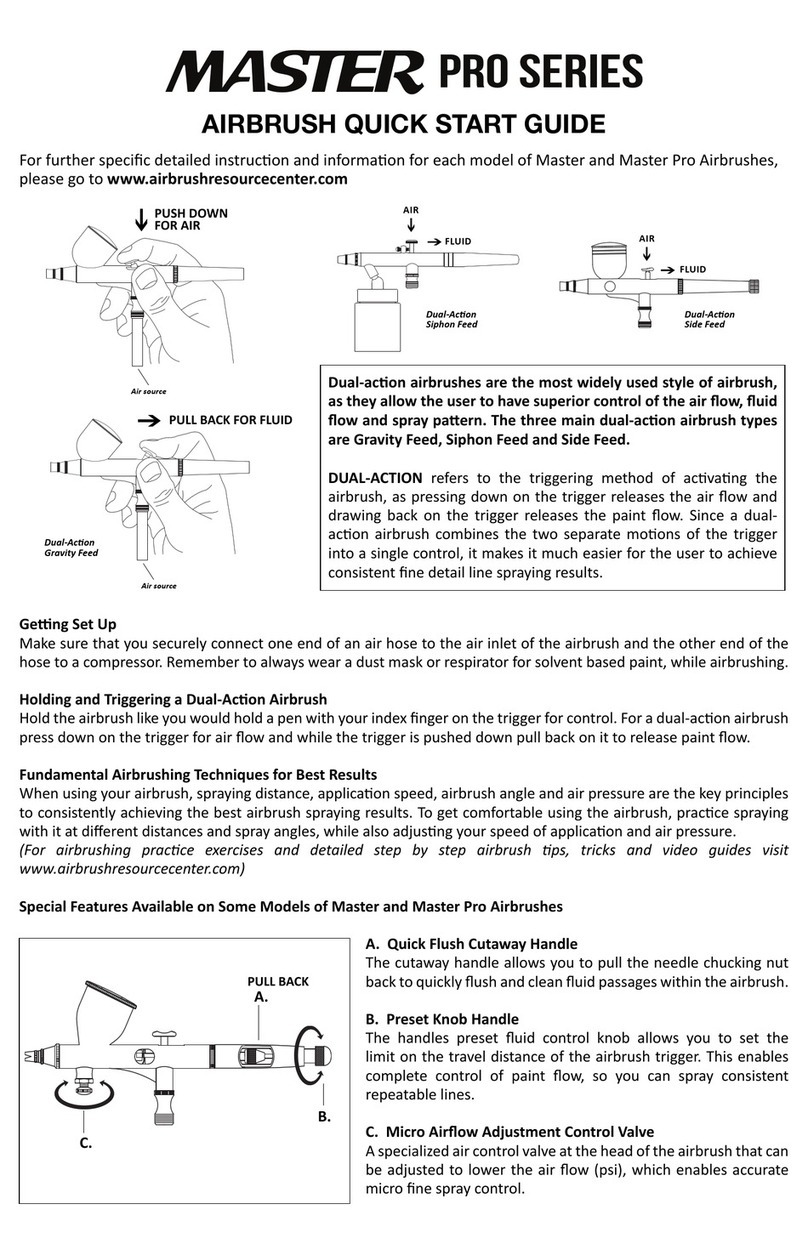

Airbrush Operation:

1. Press down on Trigger to release air and pull back on Trigger to control quantity of color.

2. To spray a ne line without heavy ends, start moving the airbrush without release of color. Then start

the color at the beginning of line and stop the color at the end, but continue the motion of the airbrush

after the color has stopped.

3. Practice until you can spray a ne line or a broad pattern without heavy build up at the beginning or

end of your strokes.

4. Speed of movement controls density of color and fading eects at beginning and end of strokes.

5. For detail, hold the airbrush very close to the surface and then push down for air and pull back very

slowly on the Trigger to release a small amount of paint.

6. For background work and broad eects, hold the airbrush away from the work surface and pull back

on Trigger to release required amount of color.

Head Sizes - Patterns - Fluid Thickness

Size 1 - Tip size .55mm Size 3 -Tip size .73mm Size 5 -Tip Size 1.06mm

- Pencil Line to 1’’ patterns -1/32’’ to 1-1/2’’ patterns -1/16’’ to 1-1/2’’ patterns

-Paint thinned further than 3 & 5 -Thicker paint than size 1 -Thicker paint than size 3

Working Pressures:

• Operating pressures 20-55 PSI; Maximum pressure 75 PSI

• 20-30 PSI is best for detail spraying w/ properly thinned paint

• Use the higher pressures for thicker material where ne detail is not critical or thin the paint to allow

lower pressures.

Equipment Set-up:

The Airbrush is held in the same manner as a pen, with the index nger comfortably over the Trigger.

1. Attach airhose to air supply and to airbrush. If using a regulator, set pressure between 20 -30 PSI.

2. Attach the color cup or bottle assembly to color socket.

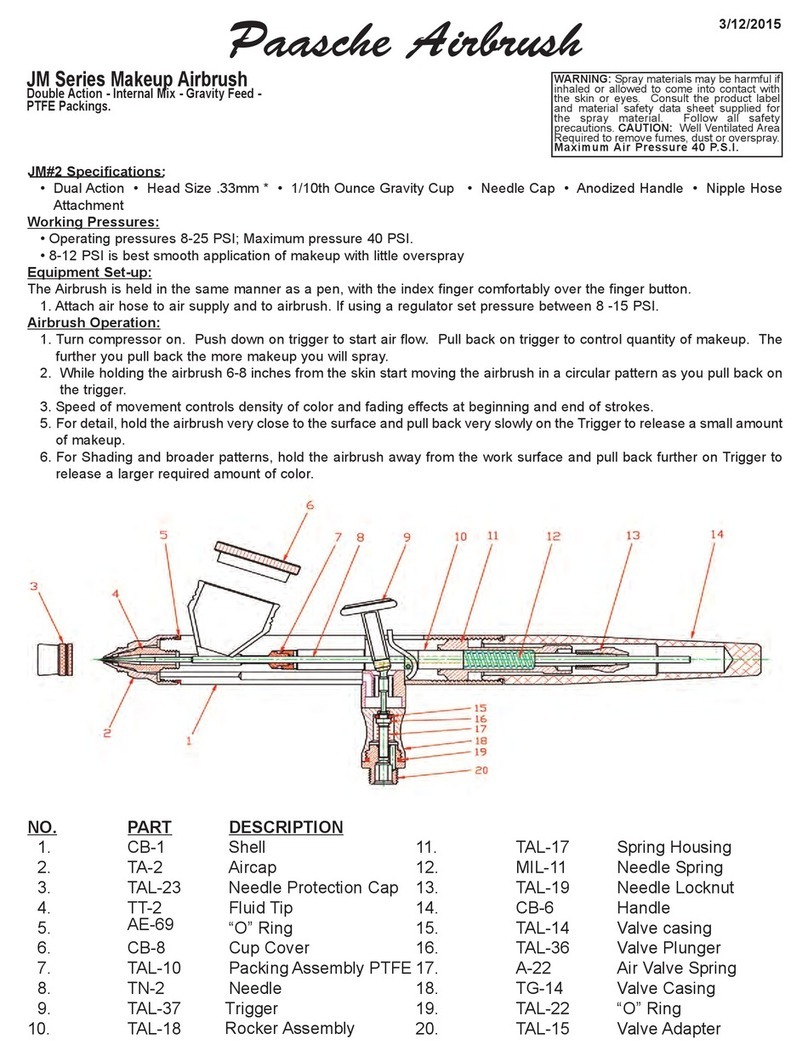

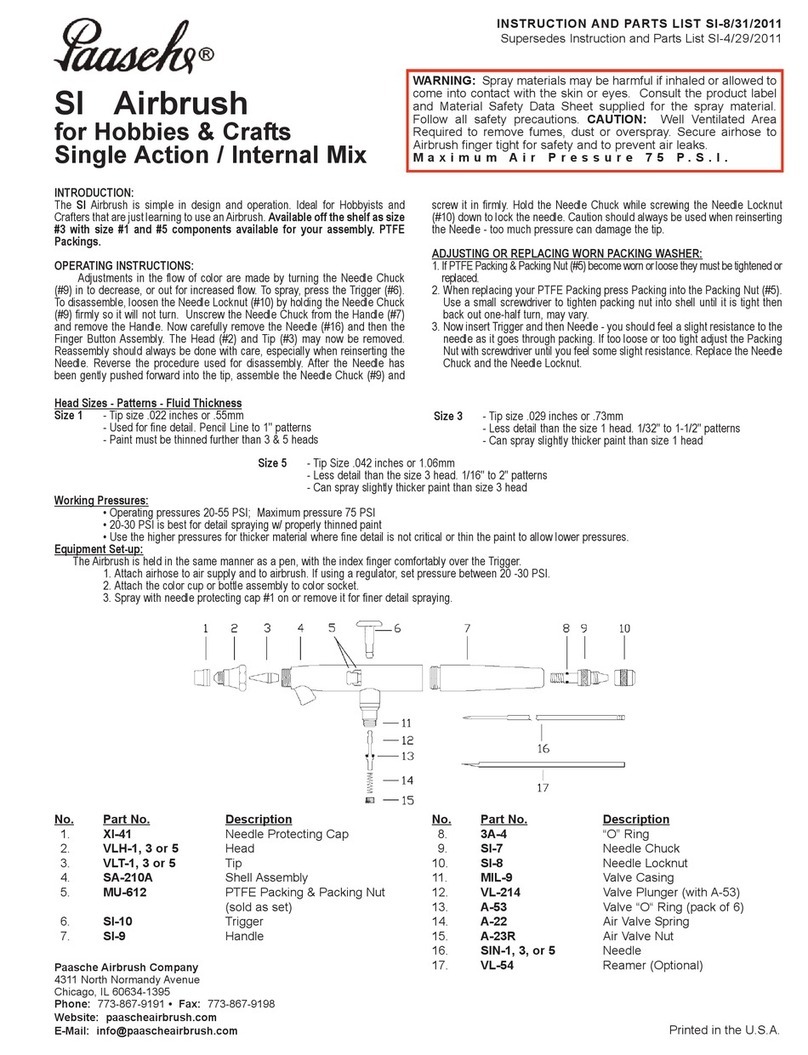

REMOVING/REPLAClNG THE NEEDLE AND HANDLE:

1. Unscrew the handle and loosen the Locknut #34 by turning counterclockwise. Depress the Trigger

#7 and hold in Down position while removing or inserting the needle. This assures the needle moves

freely through the trigger. Gently remove the needle, rotating if necessary, Do NOT force out!

2. Inspect the condition of the needle. If it is bent or misshapen in any way, replace it with a new needle.

A bent needle can damage or split the Tip #3 causing bubbles or a rough spray pattern.

3. Hold trigger in DOWN position, insert the new needle into the Rocker Assembly #28. Gently push

needle through, rotating if necessary. until the needle stops in the front of the tip.

4. Release trigger and tighten locknut by turning clockwise.

REPLACING THE TRIGGER:

( If the Trigger #7 is removed, it must be replaced inside the airbrush shell, before the Rocker Assembly #28

and needle are re-inserted. )

1. Hold the trigger so the opening in the lever is in-line with the opening in the end of the airbrush shell

and the at side of the trigger stem is to the rear.

2. Insert trigger so the bottom of the stem covers the round top of the valve plunger.

REPLACING THE TIP:

1. Remove handle, loosen Locknut #34 and withdraw needle about one inch (1”).

2. Un-screw the Head #2 and remove. The Tip #3 can now be easily removed by hand. If stuck in shell tap

lightly with wrench.

3. Place a new tip into position and tighten head to shell with a wrench. Push needle forward until it

seats fully forward in tip and tighten locknut.

1

Paasche

Airbrush

Co

951

1

58th

Place,

Kenosha,

WI

53144

Ph:

773-867-9191

E-mail:

[email protected]