This manual contains important instructions for the proper installation and maintenance of the

Photovoltaic Grid-connected Inverter (Microinverter). To reduce the risk of electrical shock, and

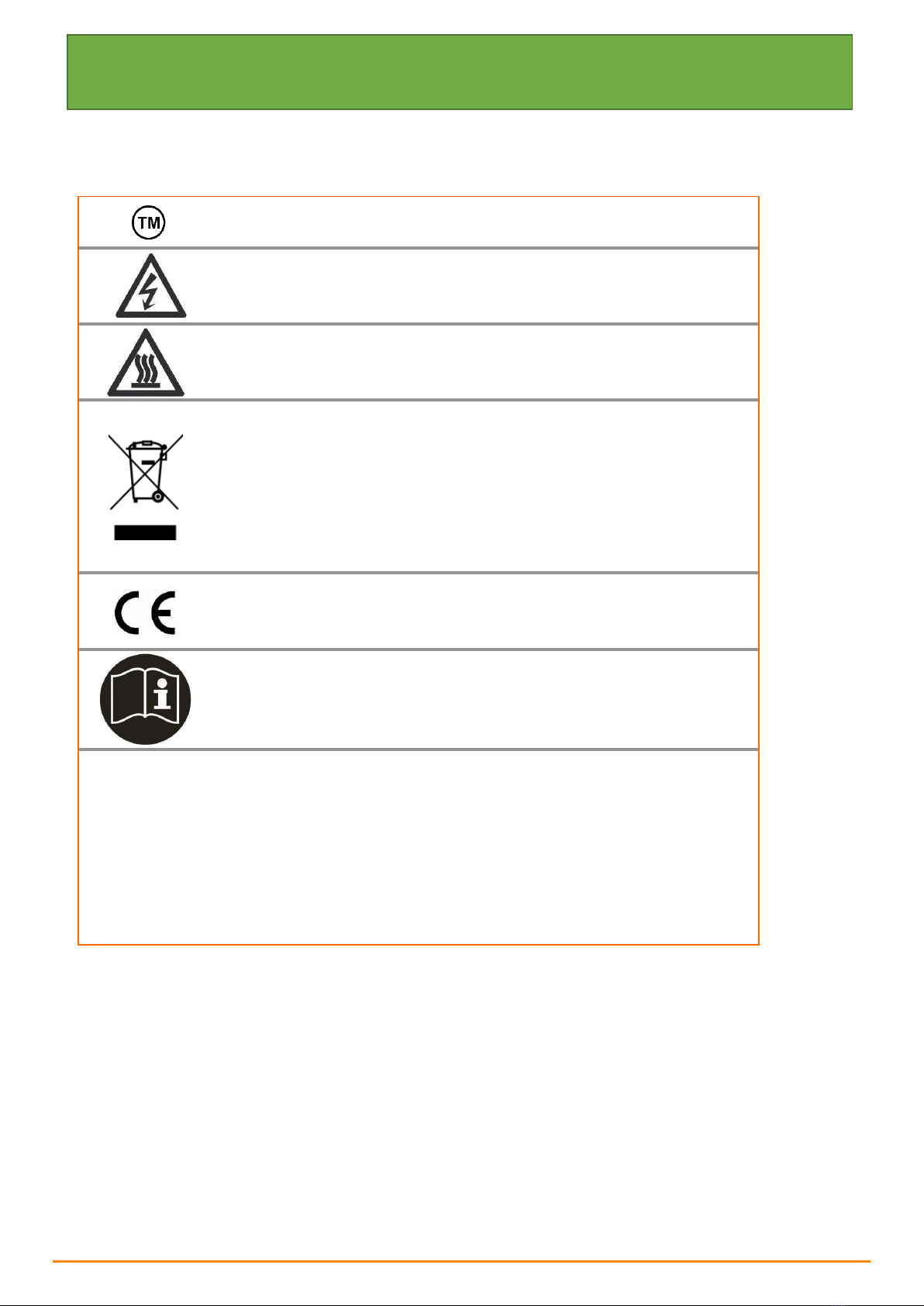

ensure safe installation and operation of the Microinverter, the followingsymbols appear

throughout this document to indicate dangerous conditions and important safety considerations.

Specifications are subject to change without notice - please ensure you are using the most recent update

found at the manufacturer website.

WARNING SYMBOL: Indicates a situation where failure to follow instructions

appropriately may cause a serious hardware failure or personal injury. Use extreme

caution when performing this task.

WARNING

SYMBOL

NOTE SYMBOL: Displays information that is important for optimized microinverter

operation. Follow these instructions closely.

Safety Instructions

Do NOT disconnect the PV module from the Microinverter without

first disconnecting the AC power.

NOTE

SYMBOL

Only qualified professionals should install and/or replace the Microinverters.

Perform all electrical installations in accordance with local electrical codes.

Before installing or using the Microinverter, please read

all instructions and cautionary markings in the technical documents and on the Microinverter

system and the solar-array.

Be aware that the body of the Microinverter is a heat-sink, and can reach temperatures

close to 80°C. To reduce risk of burns, do not touch the body of the Microinverter.

DO NOT attempt to repair the Microinverter. If it fails, contact Customer Support to obtain an

RMA number and start the replacement process. Damaging or opening the Microinverter will

void the warranty.

Caution!

The external protective grounding conductor is connected to the inverter grounding

terminal through AC connector.

For connection: Connect the AC connector first to ensure inverter grounding, then

perform the DC connections.

When disconnecting: First disconnect the AC connector by opening the branch circuit breaker,

with the protective grounding conductor still connected. Disconnect the DC inputs afterwards.

In any circumstance, do not connect DC input when the AC connector is unplugged.

Please install isolation switching devices on the AC side of the inverter.

Important Safety Instructions