Table of Contents

INTRODUCTION.............................................................................................................1

GENERAL NOTES..........................................................................................................1

SAFETY INSTRUCTIONS ..............................................................................................2

SAFETY PRECAUTIONS ...............................................................................................5

Dear Valued Customer:................................................................................................... 5

TECHNICAL INFORMATION AND SUPPORT...............................................................7

Read This Manual .......................................................................................................7

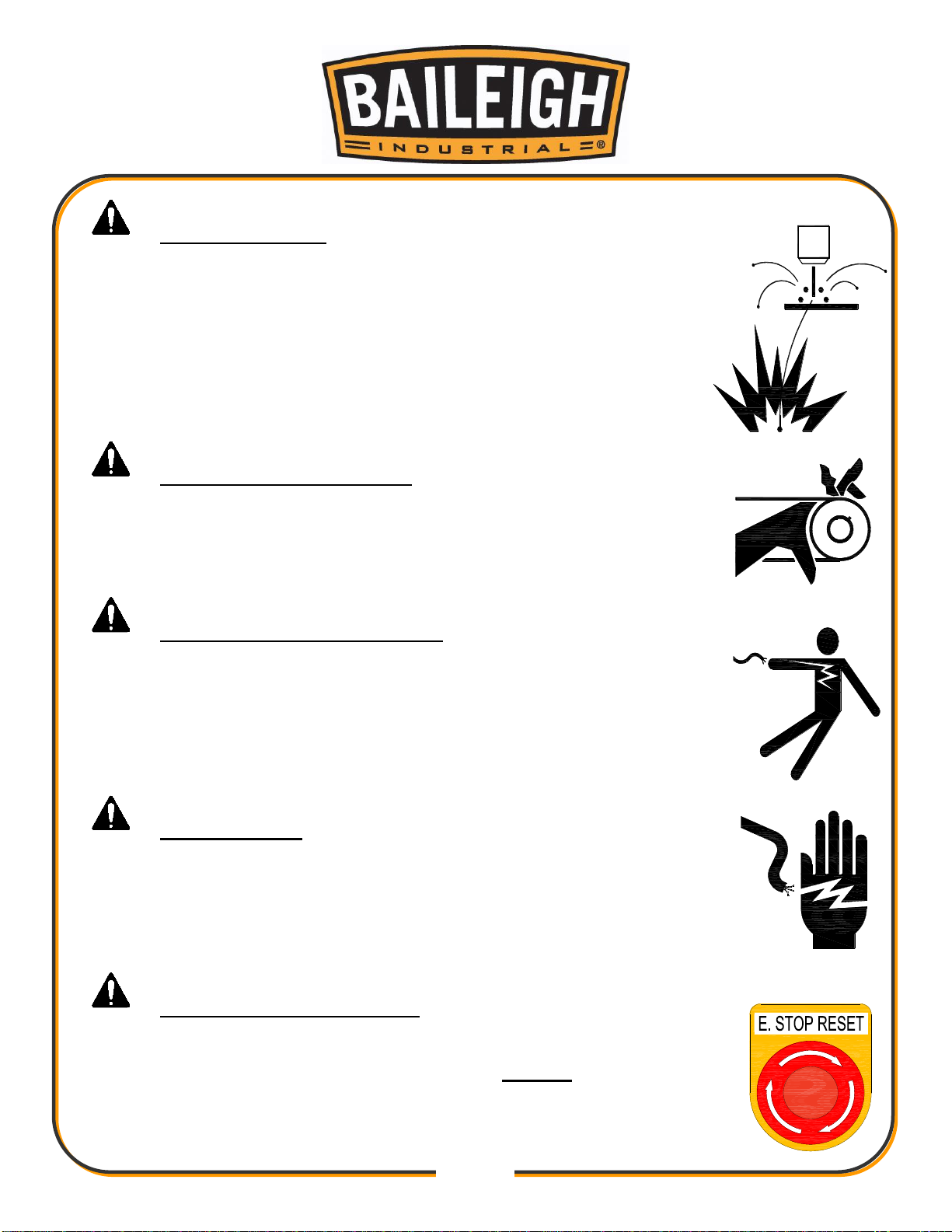

Work Condition............................................................................................................7

Maintenance................................................................................................................7

High Voltages..............................................................................................................7

TECHNICAL SUPPORT ................................................................................................. 8

Cleaning ...................................................................................................................... 8

INTRODUCTION.............................................................................................................9

System Characteristics................................................................................................9

Technical Standard.................................................................................................... 10

System Interface........................................................................................................ 10

SYSTEM BOARD AND MAIN INTERFACE.................................................................. 11

Operating Board Introduction..................................................................................... 11

Power On Process And Main Interface...................................................................... 12

CUTTING FUNCTION................................................................................................... 14

Speed Control and Adjustment.................................................................................. 15

Forward ..................................................................................................................... 15

Backward................................................................................................................... 16

Edge Cutting / Offset Cutting / Return....................................................................... 17

Back to Reference Function ...................................................................................... 17

Perforation Point Selection........................................................................................ 18

Cutting Exit................................................................................................................ 18

Frame Function ......................................................................................................... 19

PART OPTIONS ........................................................................................................... 20

[F1] Mirror.................................................................................................................. 20

Angle Adjustment ...................................................................................................... 21

Array.......................................................................................................................... 22

Zoom in/out................................................................................................................ 26

Select row/number..................................................................................................... 26

Operation after select row/number ............................................................................ 27

Revert........................................................................................................................ 27

MANUAL FUNCTION.................................................................................................... 28

Fixed Moving Function .............................................................................................. 28

Continuous Moving Function..................................................................................... 29

Fixed distance moving............................................................................................... 29

Breakpoint Recovery................................................................................................. 29

FILE OPERATION ........................................................................................................ 30