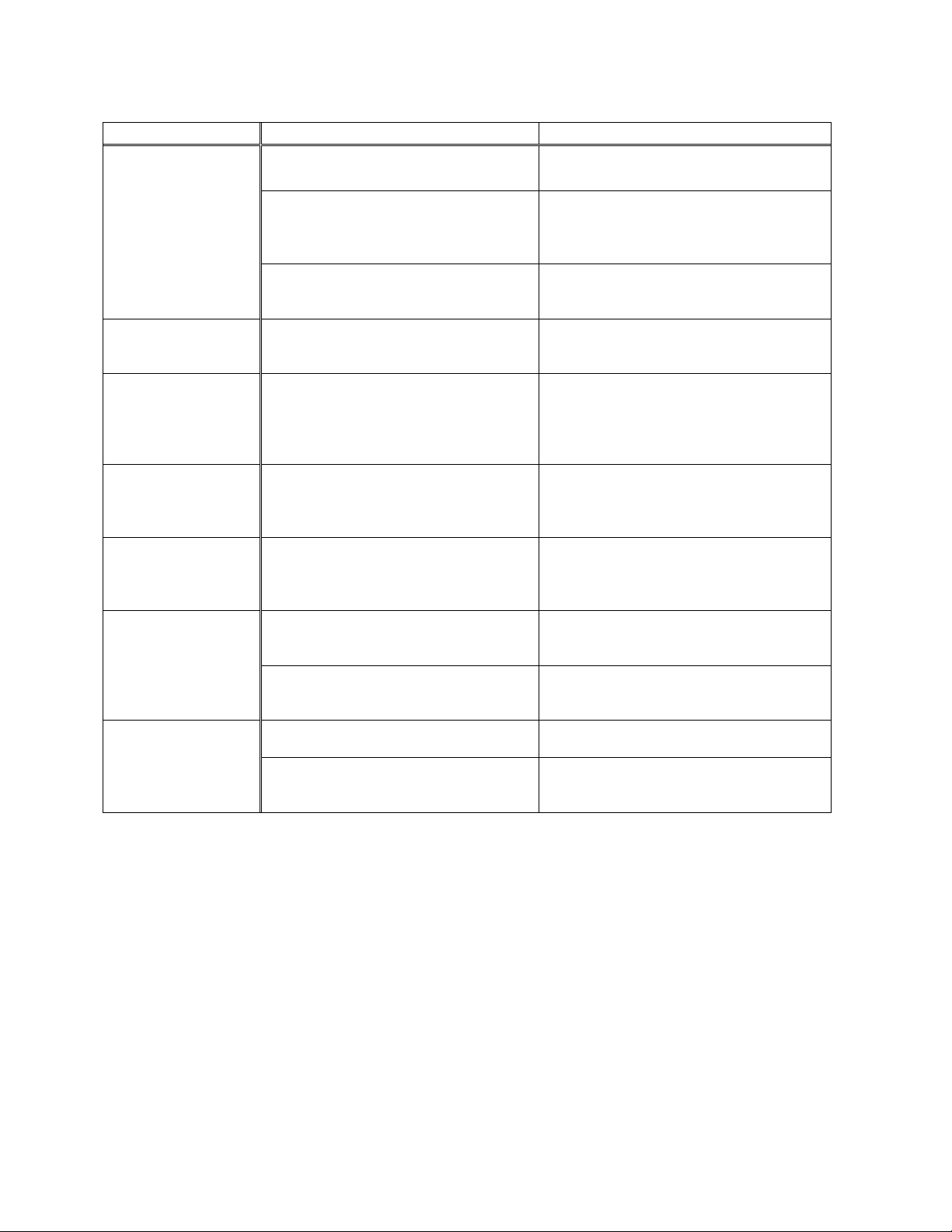

10.2 EW-45 English Wheel – Parts List

Index No. Part No. Description Size Qty

1 ............... EW45-01 .................. Frame ................................................................... ................................... 1

1-1 ............ EW45-01-1 ............... Post Clamp ........................................................... ................................... 2

1-2 ............ EW45-01-2 ............... Frame Support Stand ........................................... ................................... 1

2 ............... WH45-2 .................... Collar .................................................................... ................................... 1

3 ............... WH45-3 .................... Adjusting Lock Knob ............................................ ................................... 1

4 ............... WH45-4 .................... Washer ................................................................. ................................... 1

5 ............... WH45-5 .................... Upper Wheel Shaft ............................................... ................................... 1

6 ............... WH45-6 .................... Short Pin .............................................................. ................................... 1

7 ............... WH45-7 .................... Position Block ....................................................... ................................... 1

8 ............... EW45-08 .................. Upper Wheel Housing .......................................... ................................... 1

9 ............... WH45-9 .................... Inner Tube Adjusting Post .................................... ................................... 1

9-2 ............ WH45-9-2 ................. Collar .................................................................... ................................... 1

10 ............. EW45-10 .................. Outer Post ............................................................ ................................... 1

11 ............. WH45-11 .................. Flange Bushing .................................................... ................................... 1

12 ............. WH45-12 .................. Lead Screw .......................................................... ................................... 1

13 ............. WH45-13 .................. Lifting Lever .......................................................... ................................... 1

13-1 .......... WH45-13-1 ............... Cam ...................................................................... ................................... 2

13-2 .......... WH45-13-2 ............... Spacer .................................................................. ................................... 2

13-3 .......... WH45-13-3 ............... Lifting Lever Handle ............................................. ................................... 1

15 ............. WH45-15 .................. Lower Wheel Shaft ............................................... ................................. 10

16 ............. EW45-16 .................. Lower Wheel Storage Bracket ............................. ................................. 10

17 ............. EW45-17 .................. Upper Wheel Storage Bracket ............................. ................................... 3

18A ........... WH45-18A ............... Lower Wheel 1 Assembly (Index #18, 15, 31) ..... 1/8” Edge .................... 1

18 ............. WH45-18 .................. Lower Wheel 1 ..................................................... ................................... 1

19A ........... WH45-19A ............... Lower Wheel 9 Assembly (Index #19, 15, 31) ..... 1/2" Ridged ................. 1

19 ............. WH45-19 .................. Lower Wheel 9 ..................................................... ................................... 1

20A ........... WH45-20A ............... Lower Wheel 7 Assembly (Index #20, 15, 31) ..... 1/8" Ridged ................. 1

20 ............. WH45-20 .................. Lower Wheel 7 ..................................................... ................................... 1

21A ........... WH45-21A ............... Lower Wheel 6 Assembly (Index #21, 15, 31) ..... 1/4" ............................. 1

21 ............. WH45-21 .................. Lower Wheel 6 ..................................................... ................................... 1

22A ........... WH45-22A ............... Lower Wheel 8 Assembly (Index #22, 15, 31) ..... 3/4" ............................. 1

22 ............. WH45-22 .................. Lower Wheel 8 ..................................................... ................................... 1

23A ........... WH45-23A ............... Lower Wheel 4 Assembly (Index #23, 15, 31) ..... 2-1/4” .......................... 1

23 ............. WH45-23 .................. Lower Wheel 4 ..................................................... ................................... 1

24A ........... WH45-24A ............... Lower Wheel 3 Assembly (Index #24, 15, 31) ..... 3/4" ............................. 1

24 ............. WH45-24 .................. Lower Wheel 3 ..................................................... ................................... 1

25A ........... WH45-25A ............... Lower Wheel 2 Assembly (Index #25, 15, 31) ..... 1-29/64” ...................... 1

25 ............. WH45-25 .................. Lower Wheel 2 ..................................................... ................................... 1

26A ........... WH45-26A ............... Lower Wheel 5 Assembly (Index #26, 15, 31) ..... 2-5/8" .......................... 1

26 ............. WH45-26 .................. Lower Wheel 5 ..................................................... ................................... 1

27A ........... WH45-27A ............... Upper Wheel 10 Assembly (Index #27, 31) ......... 3/4" ............................. 1

27 ............. WH45-27 .................. Upper Wheel 10 ................................................... ................................... 1

28A ........... WH45-28A ............... Upper Wheel 11 Assembly (Index #28, 31) ......... 1-29/64” ...................... 1

28 ............. WH45-28 .................. Upper Wheel 11 ................................................... ................................... 1

29A ........... WH45-29A ............... Upper Wheel 12 Assembly (Index #29, 31) ......... 1/8” Edge .................... 1

29 ............. WH45-29 .................. Upper Wheel 12 ................................................... ................................... 1

30 ............. WH45-30 .................. Lower Wheel Housing .......................................... ................................... 1

31 ............. BB-6204ZZ ............... Ball Bearing .......................................................... 6204ZZ ..................... 28

32 ............. EW45-32 .................. Adjusting Wheel ................................................... ................................... 1

33 ............. TS-1551041 ............. Lock Washer ........................................................ M6 ............................ 35

34 ............. TS-1503061 ............. Socket Head Cap Screw ...................................... M6x25 ....................... 30

35 ............. TS-1503111 ............. Socket Head Cap Screw ...................................... M6x50 ......................... 4

36 ............. TS-1503091 ............. Socket Head Cap Screw ...................................... M6x40 ......................... 1

37 ............. TS-1522031 ............. Socket Set Screw ................................................. M5x10 ......................... 2

38 ............. TS-1522041 ............. Socket Set Screw ................................................. M5x12 ......................... 2

39 ............. TS-152706 ............... Hex Wrench ......................................................... 5mm ........................... 1

40 ............. EW45-40 .................. Wheel Handle ....................................................... ................................... 6